Dual-planetary wheel mixing machine

A mixer and planetary mechanism technology, applied in mixers, mixer accessories, dissolution and other directions, can solve the problems of acetone solvent characteristics, low quality of lithium iron phosphate batteries, temperature sensitivity, etc., to achieve corrosion resistance and reduce waste. , to avoid abnormal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] An embodiment of the present invention provides a double planetary mixer for efficiently and stably preparing a lithium iron phosphate battery using acetone as a solvent.

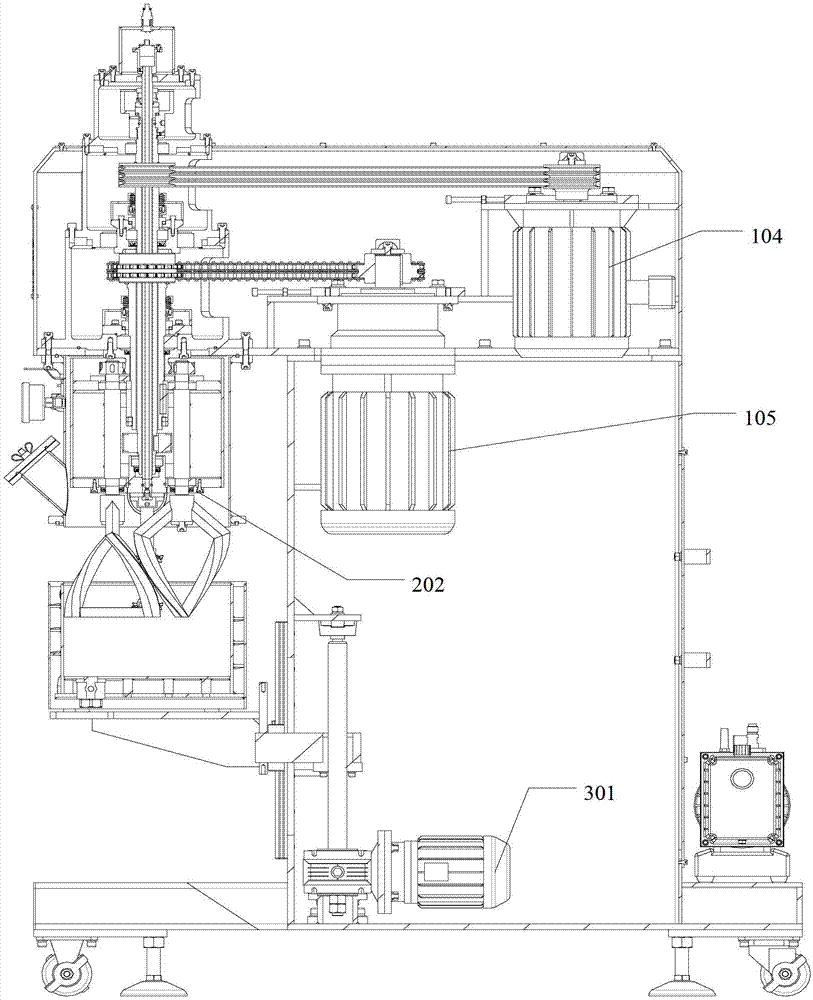

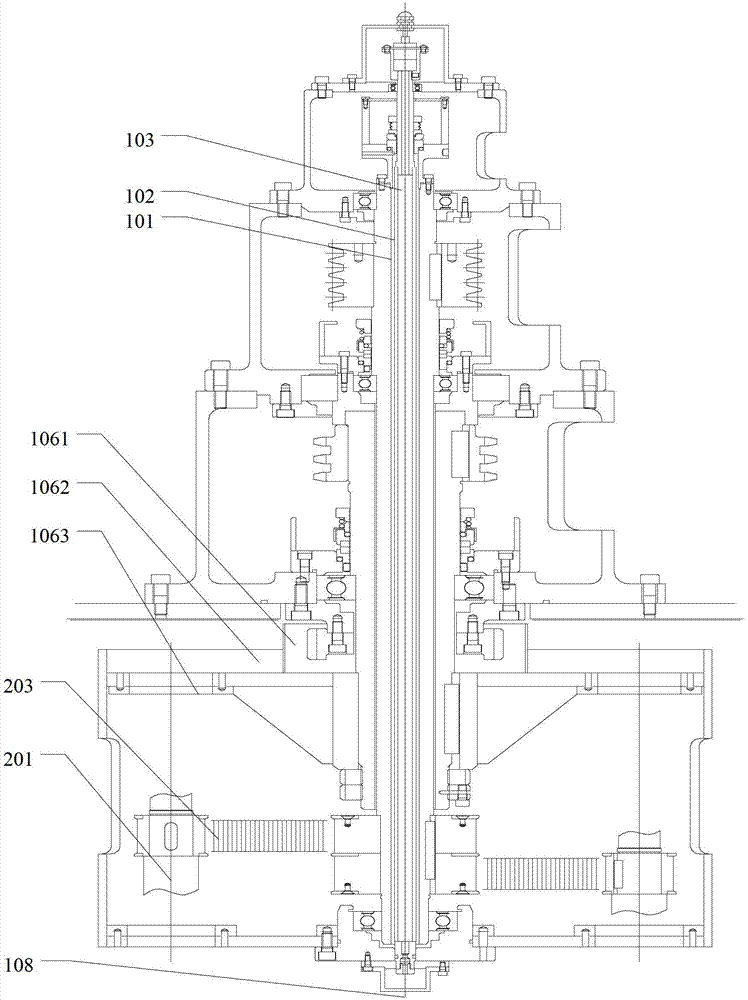

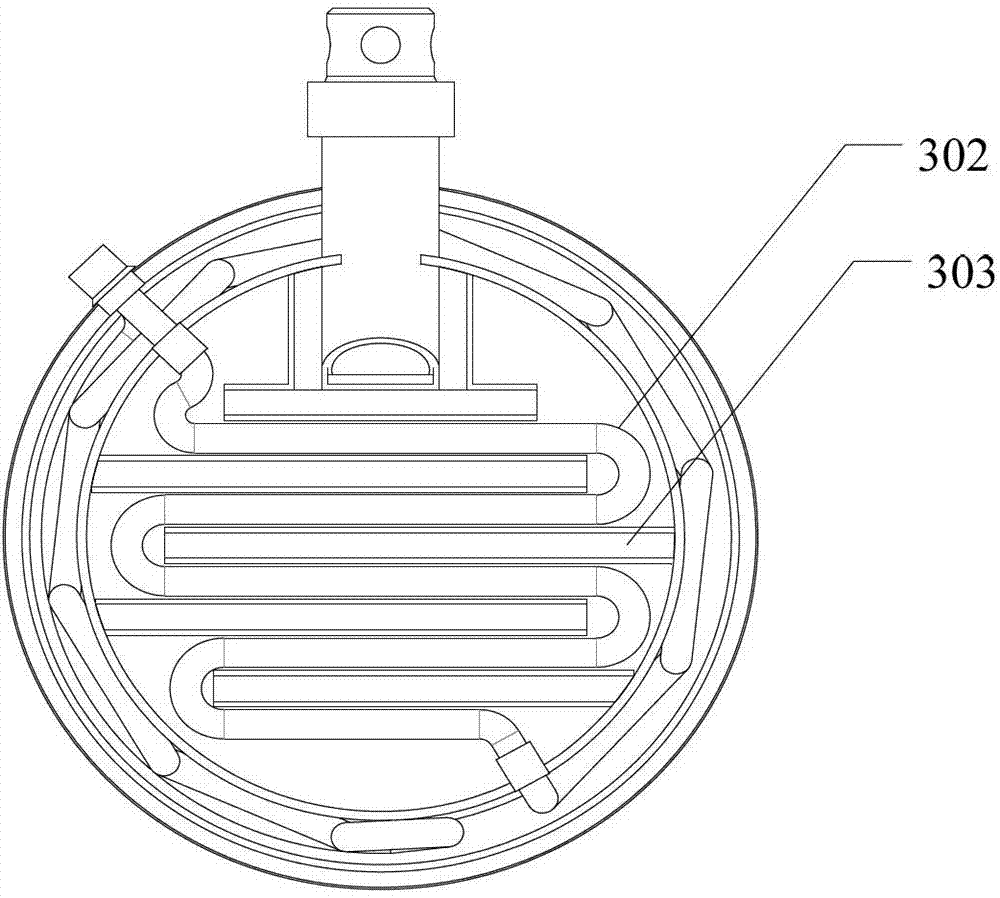

[0035] figure 1 It is the structural representation of the double planetary mixer of the present invention, figure 2 It is a structural schematic diagram of the power mixing structure of the double planetary mixer of the present invention.

[0036] see figure 1 , The double planetary dynamic mixer is equipped with a material cylinder container 3, a dynamic mixing structure 1 and a high-speed dispersion structure 2.

[0037] In this embodiment, the power mixing structure 1 is provided with three transmission systems: a mixing main shaft 101 , a dispersion main shaft 102 and a temperature measuring rod shaft 103 . Wherein, the mixing main shaft 101, the dispersing main shaft 102 and the temperature measuring rod shaft 103 are vacuum structures, both ends are fixed on the mixer, the temperature meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com