Photocatalytic hydrogen production system and hydrogen production method

A hydrogen production system and photocatalysis technology, applied in the field of photocatalytic reaction, can solve the problems of high maintenance cost, complex system, complicated maintenance, etc., and achieve the effects of reduced operation difficulty, simple detection method and improved maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

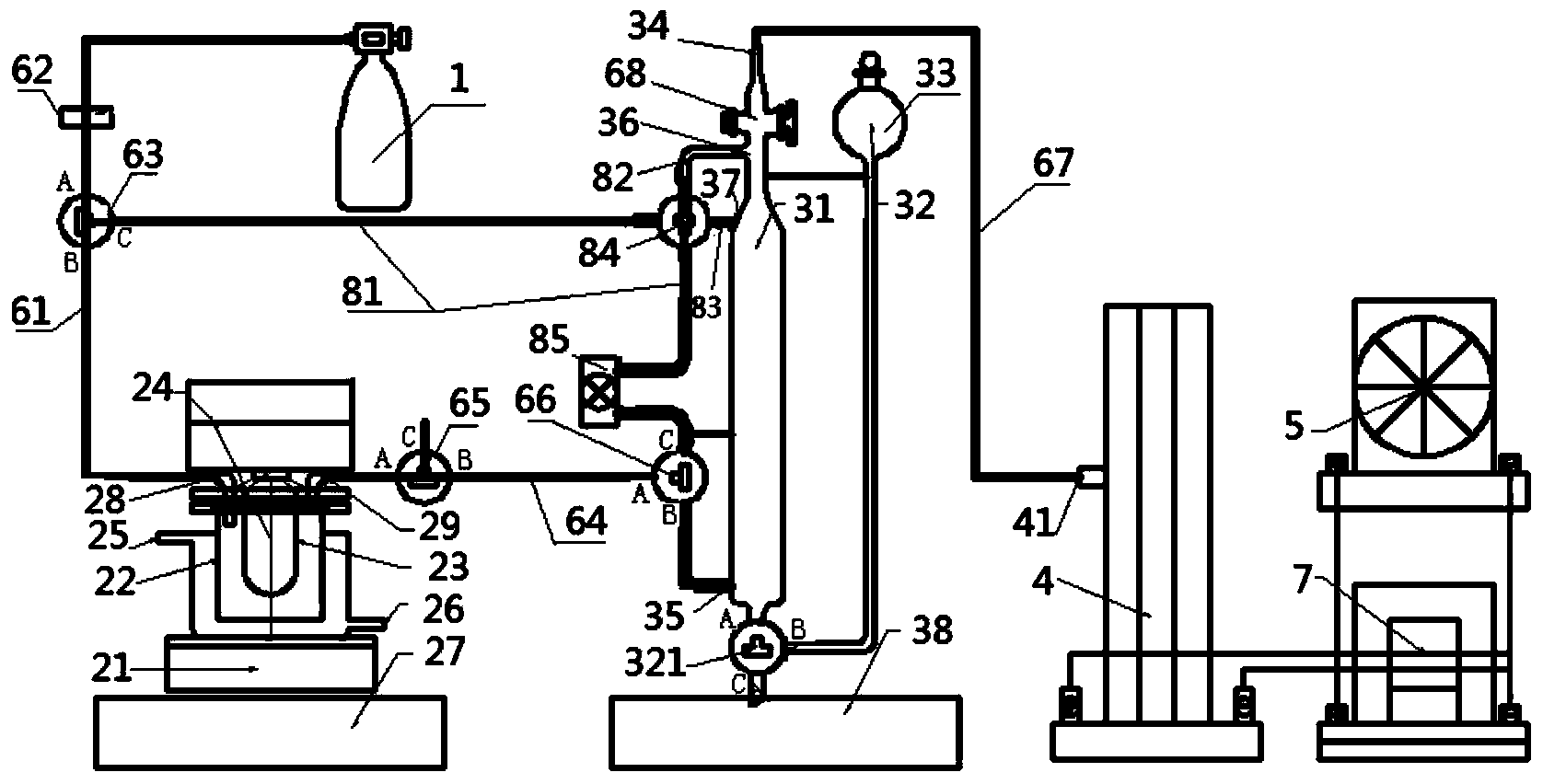

[0040] Such as figure 2 As shown, another embodiment of the present invention is: the circulation pipeline 8 also includes a first circulation pipeline 81, a second circulation pipeline 82, a third circulation pipeline 83, a four-way valve 84 and a circulation pump 85,

[0041] The first circulation line 81 is connected to the third port of the first three-way valve 63, and the other end is connected to the third port of the third three-way valve 66; the four-way valve 84 passes through two ports Connected to the first circulation pipeline 81; the circulation pump 85 is connected to the first circulation pipeline 81 between the four-way valve 84 and the third three-way valve 66; the second circulation pipeline One end of 82 is connected to the third port of the four-way valve, and the other end is connected to the upper side exhaust port 36 of the gas collection and discharge metering device 3; one end of the third circulation pipeline 83 is connected to the four-way valve 84...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com