Novel stirring kettle

A stirring tank, a new type of technology, applied to mixers with rotating stirring devices, dissolving, mixing machines, etc., can solve the problems of foaming, energy consumption, and the limitation of stirring area, so as to prevent excessive foaming and improve the stirring effect Good, well-designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

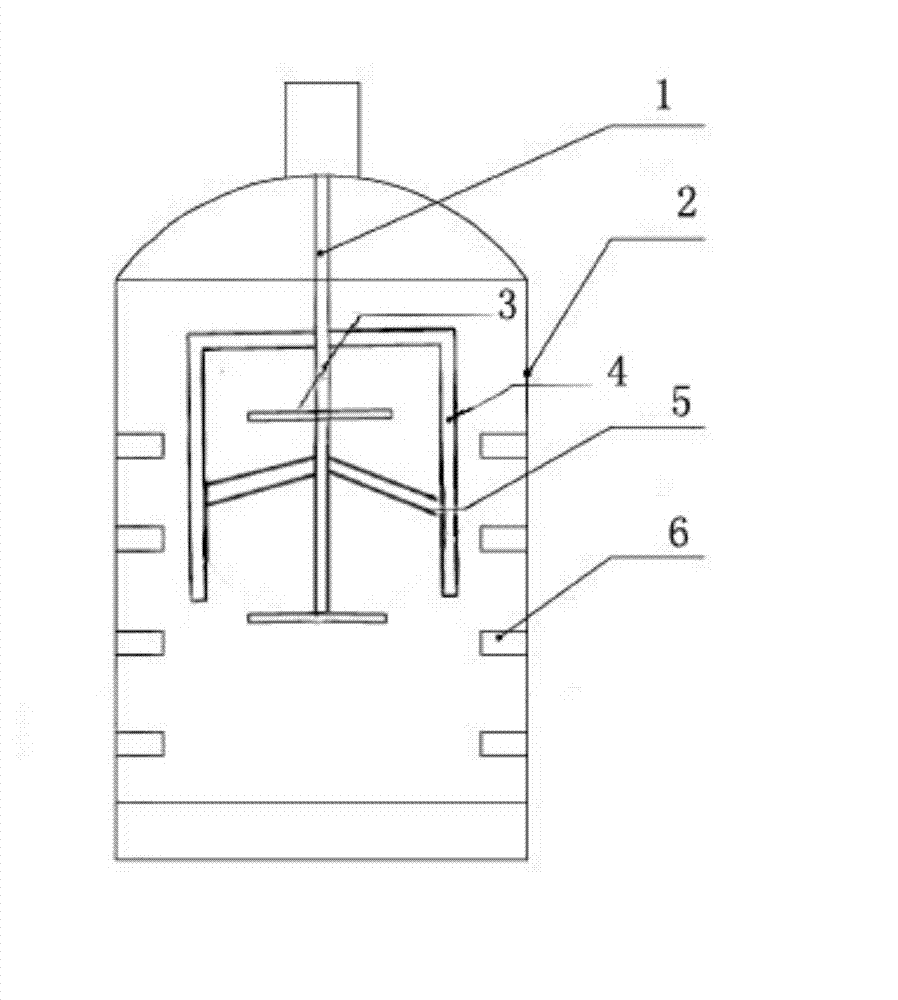

[0010] Such as figure 1 Shown is a new type of stirred tank, comprising a kettle body 2, a stirring shaft 1 is arranged inside the kettle body 2, a foaming rod 3 is left in the middle of the stirring shaft 1, and a paddle is left at the bottom of the stirring shaft 1. An outer frame 4 is arranged on the stirring shaft 1, and the crossbeam of the outer frame 4 is welded and fixed to the stirring shaft 1, and two supports 5 are fixed on the stirring shaft 1 at an angle of 45° with the horizontal line clip and the outer frame 4, and the kettle body 1 The side wall is provided with protrusions 6.

[0011] The shape of the outer frame 4 can be strip shape, sector shape, square shape and so on.

[0012] The number of protrusions 6 in each column is at least three, and they are evenly arranged.

[0013] The design is reasonable, the stirring is stable, and the outer frame rotates at the same time while stirring, the outer frame 4 is stable due to the action of the bracket 5, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com