Sliding rail type mechanical stirrer

A stirrer, mechanical technology, applied in the direction of mixer accessories, mixers with rotating stirring devices, chemical/physical/physicochemical stationary reactors, etc., can solve shaft vibration, noise, deflection, inconvenient motor adjustment, Long stirring time and other problems, to achieve the effect of reducing the amount of vibration, the number of parts used, and sufficient stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

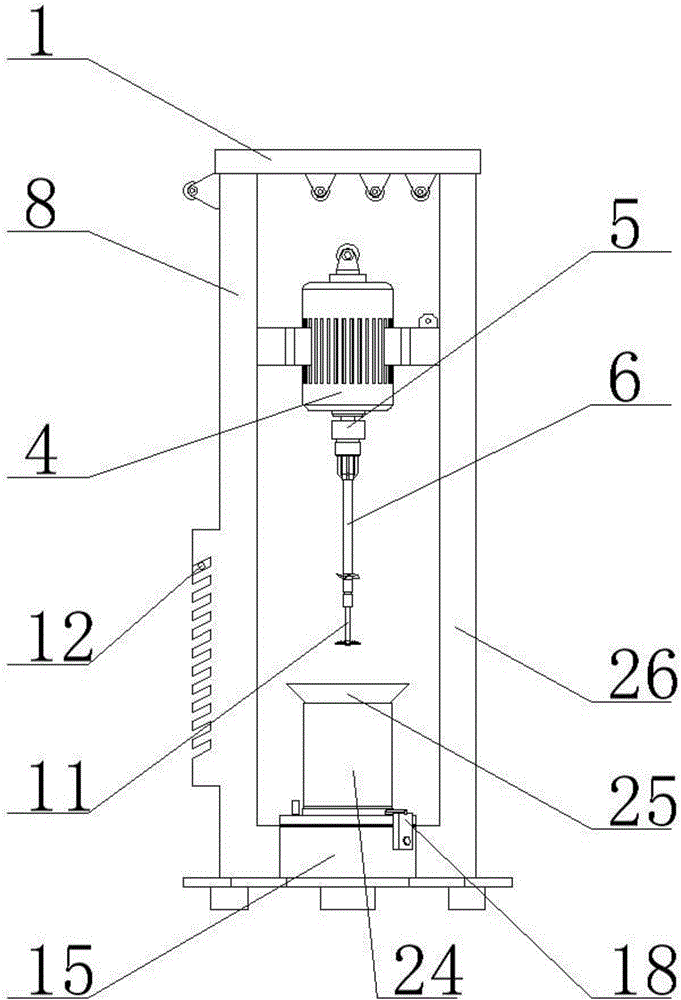

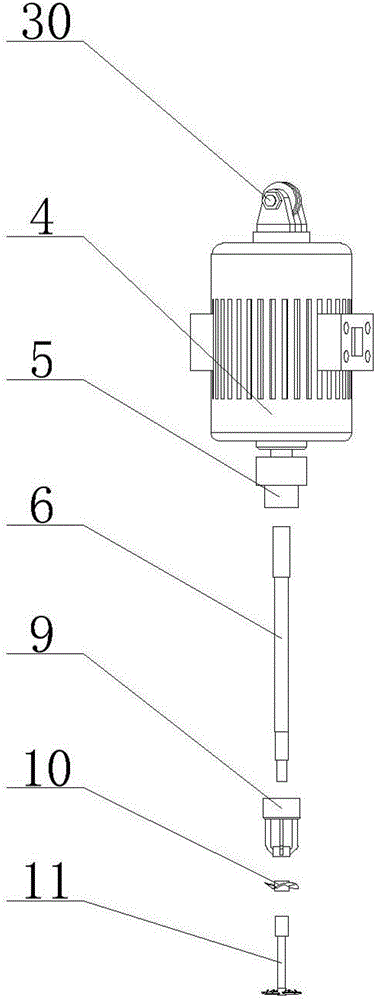

[0035] refer to figure 1 , a slide rail type mechanical stirrer, the stirrer includes a motor adjustment part, a stirring part, a base part and a stirring container part, wherein the motor adjusting part is fixed at both ends of the base part; the stirring container part Adsorbed on the base part; the upper end of the motor adjustment part is connected with the stirring part through a steel wire rope, and the two ends are closely matched with the stirring part.

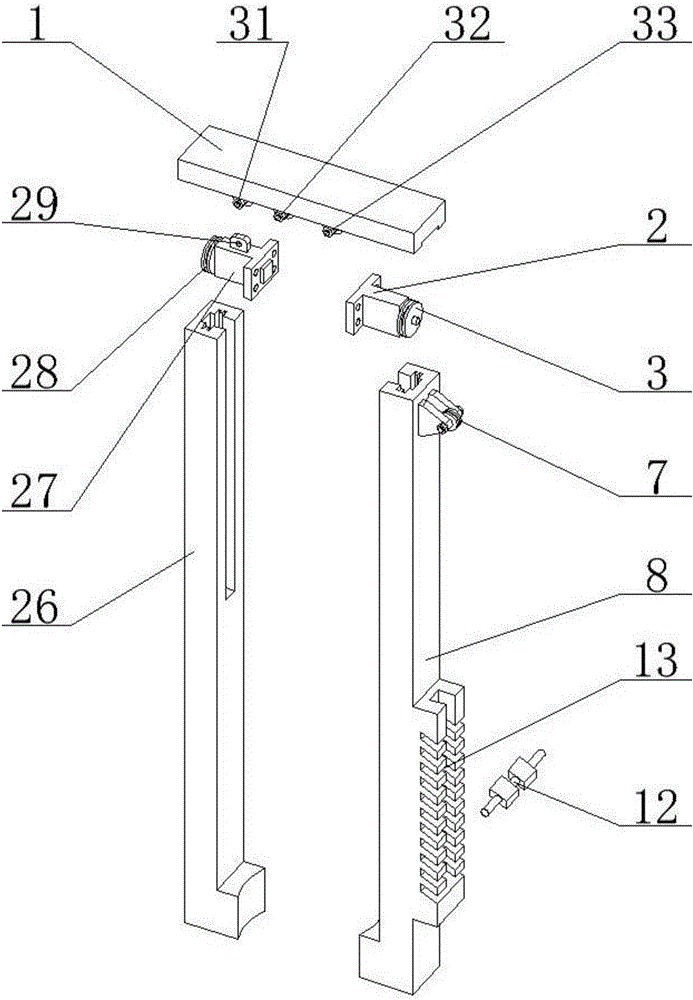

[0036] refer to figure 2 , Figure 7 , Figure 8 , Figure 11 , the motor adjustment part includes pillar cover 1, slider a2, pulley a3, runner block d7, slide rail a8, snap rod 12, snap slot 13, slide rail b26, slider b27, pulley b28, pass Hole 29, wheel block c31, wheel block b32 and wheel block a33;

[0037] The slider b27 and the slider a2 are in the shape of "T", the lower end of the "T" of the slider b27 is installed with a pulley b28 stuck in the inner track of the slide rail a8, and the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com