Milk foaming machine

A foaming machine and milk technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of smaller driving magnetic force, affecting the high-speed rotation and stirring of the stirrer, inaccurate positioning, etc., to enhance the ability to resist the wear of the convex part , Improve product quality and practicability, solve product quality problems and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

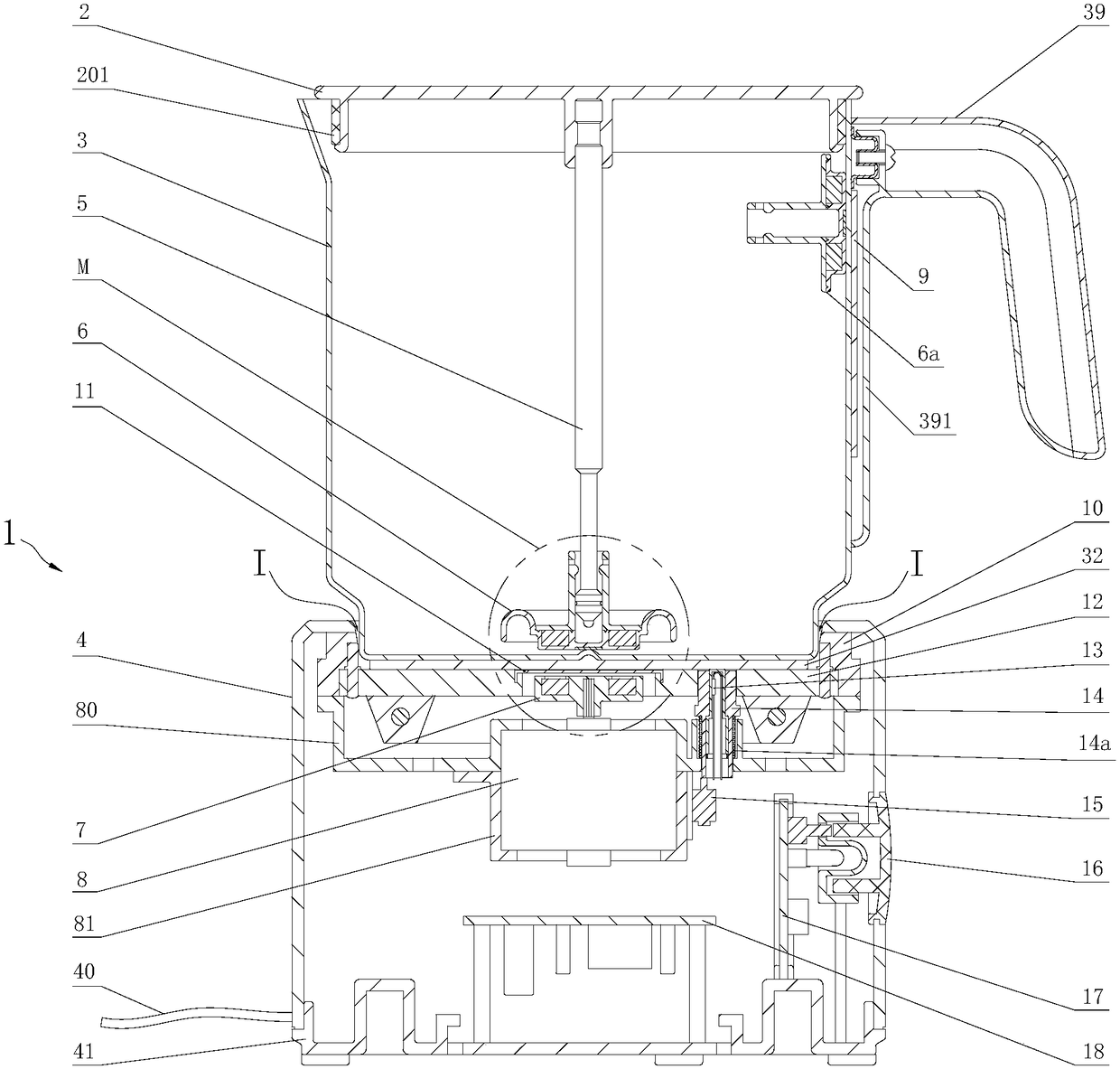

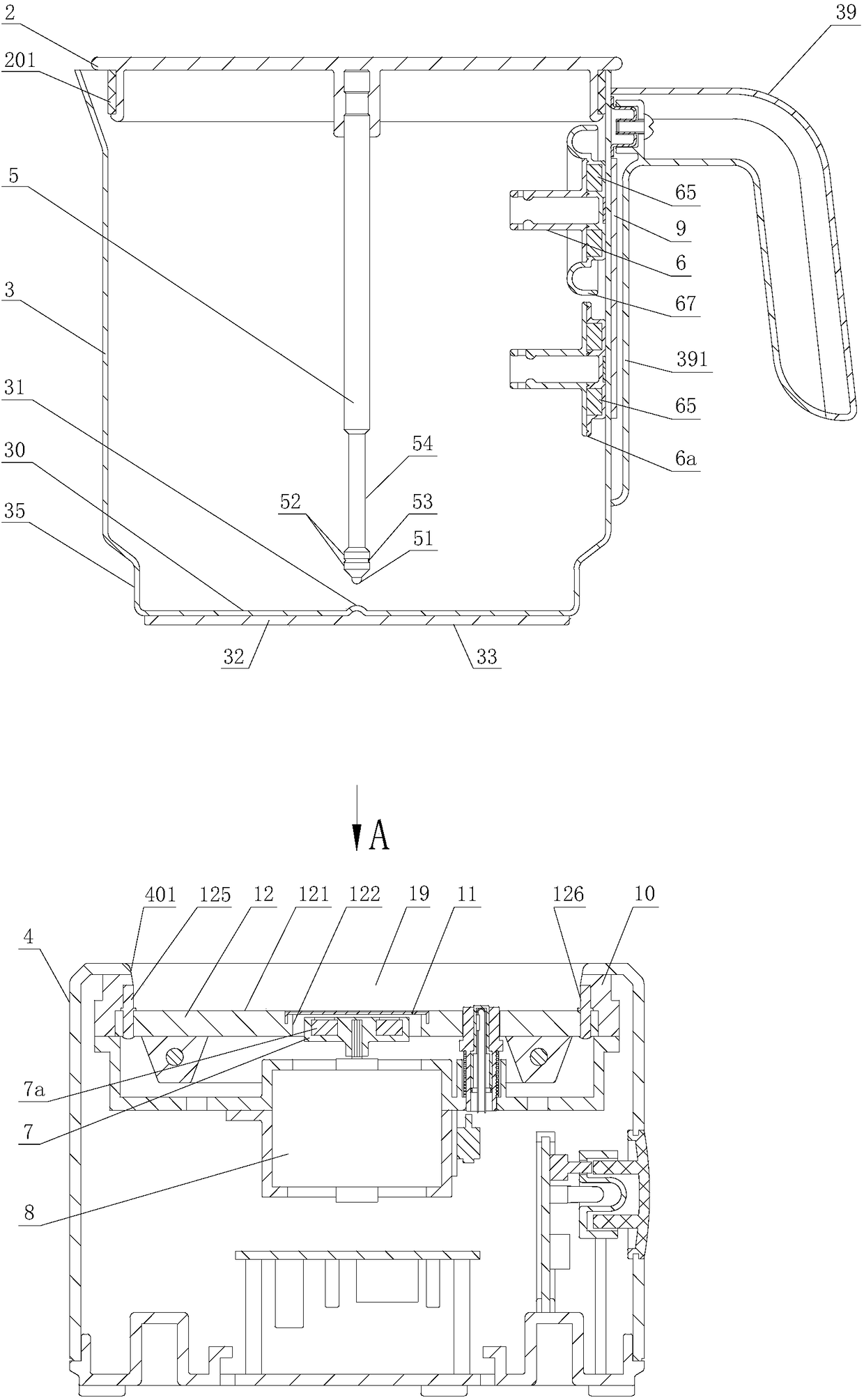

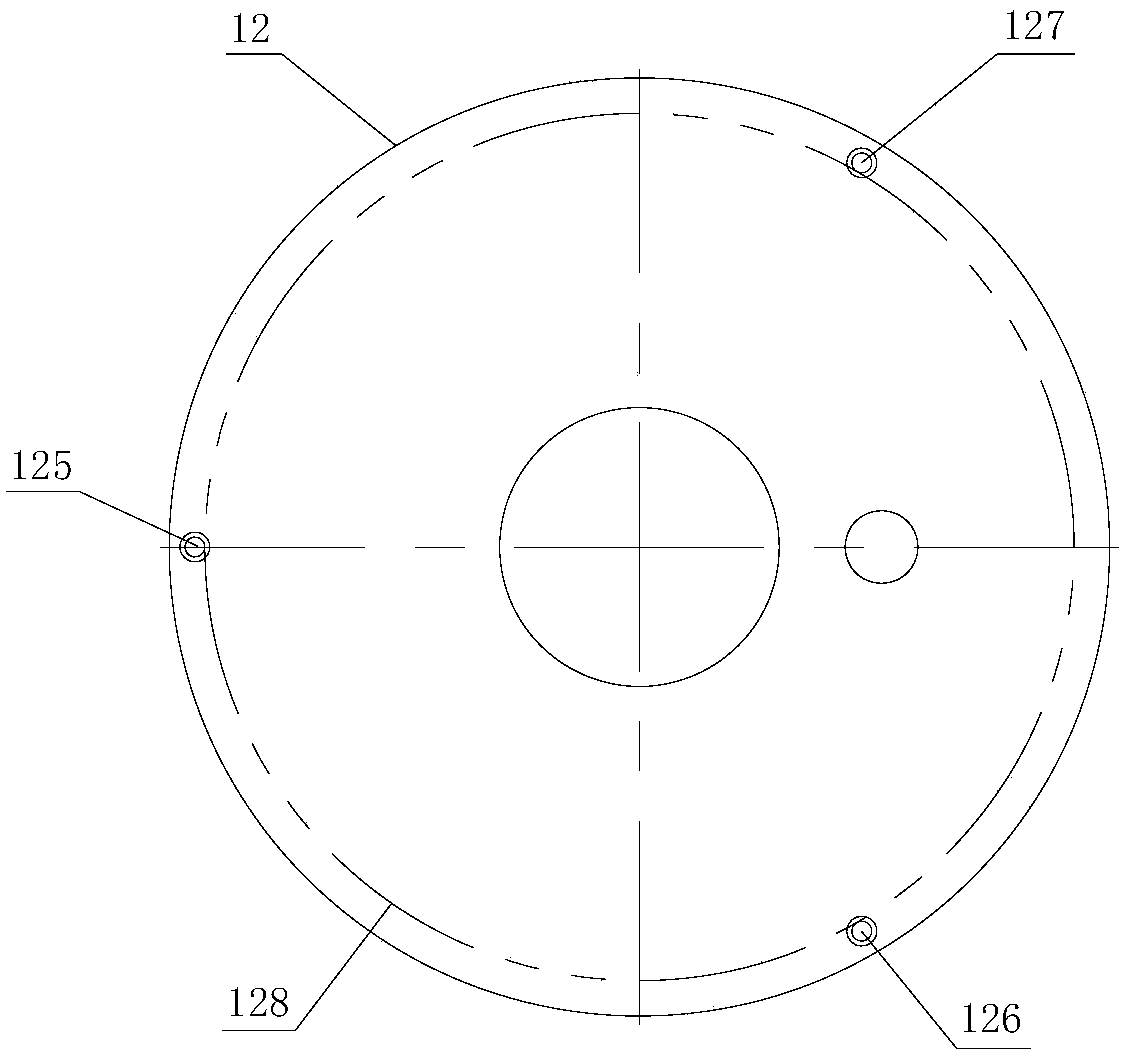

[0079] Such as figure 1 As shown, a kind of milk foaming machine 1 of the present invention adopts the principle of magnetic stirring and foaming, and the magnet 7a in the driving magnet disc 7 on the motor shaft of the driving device 8 is non-contact magnetically driven to the magnet 65 of the stirrer 6 Rotate and stir, the heating surface 121 of the heating plate 12 heats the outer bottom surface 33 of the container cup 3, the container cup 3 is detachable from the heating surface 121, and the driving magnet disk 7 on the motor shaft of the driving device 8 and the agitator 6 are aligned coaxially in the center. The container cup 3 of the present embodiment is a stainless steel cup.

[0080] Drive device 8 is made up of motor and the driving magnet disk 7 that is fixed on the motor shaft.

[0081] The seat body 4 is provided with: a heating plate 12, a heat-resistant ring 10, a motor of the driving device 8 and a driving magnet plate 7 installed on the motor shaft, circuit ...

Embodiment 2

[0117] Such as Figure 10 to Figure 12 As shown, the principle of the second embodiment is the same as that of the first embodiment above, and the structure is similar. The difference is that the connection between the lower end of the central shaft 500 and the agitator 600 is different, and the lower circumference of the agitator 600 is provided with an agitating spring 606 and a binding ring. 607: The container cup 3 is separable from the heating plate 12, and the container cup 3 in this embodiment is a stainless steel cup.

[0118] The stirrer 600 and the stirrer 600a are magnetically stored in the area corresponding to the storage connector 9 inside the container cup 3 .

[0119] Stirrer 600 is used for high-speed stirring to froth milk; stirrer 600a is used for low-speed stirring to avoid

[0120] Milk paste pot and make milk temperature even.

[0121] The connection mode between the agitator 600 and the agitator 600a and the lower end of the central shaft 500 and the a...

Embodiment 3

[0143] Such as Figure 13 shown, combined with figure 1 , the principle of the third embodiment is the same as that of the second embodiment above, and the structure is similar, the difference is: the container of this embodiment is a glass cup 300, and the storage connector 91 is arranged on the container cover 2; the glass cup 300 and the heating plate 12 can be separate.

[0144] The bottom of the glass cup 300 is an open structure, and the glass cup 300 has a handle 309 .

[0145] The bottom of the glass cup 300 is fixed with a stainless steel bottom plate 310 . The stainless steel bottom plate 310 is provided with a convex portion 31 .

[0146] In this embodiment, the bottom of the glass cup 300 and the stainless steel bottom plate 310 are bonded and fixed by food-grade high-temperature-resistant high-strength glue, and other methods can also be used for fixing.

[0147] The upper end of the storage connector 91 is fixed on the container cover, the lower end of the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com