Chemical tank gyro wheel axle stirring device

A technology of a stirring device and chemical tank, which is applied in the directions of mixer accessories, transportation and packaging, chemical instruments and methods, etc., can solve the problems of single fixing of the stirring method, prolong the stirring time, reduce the stirring efficiency, etc., and achieve good stirring effect. Stirring time, the effect of improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

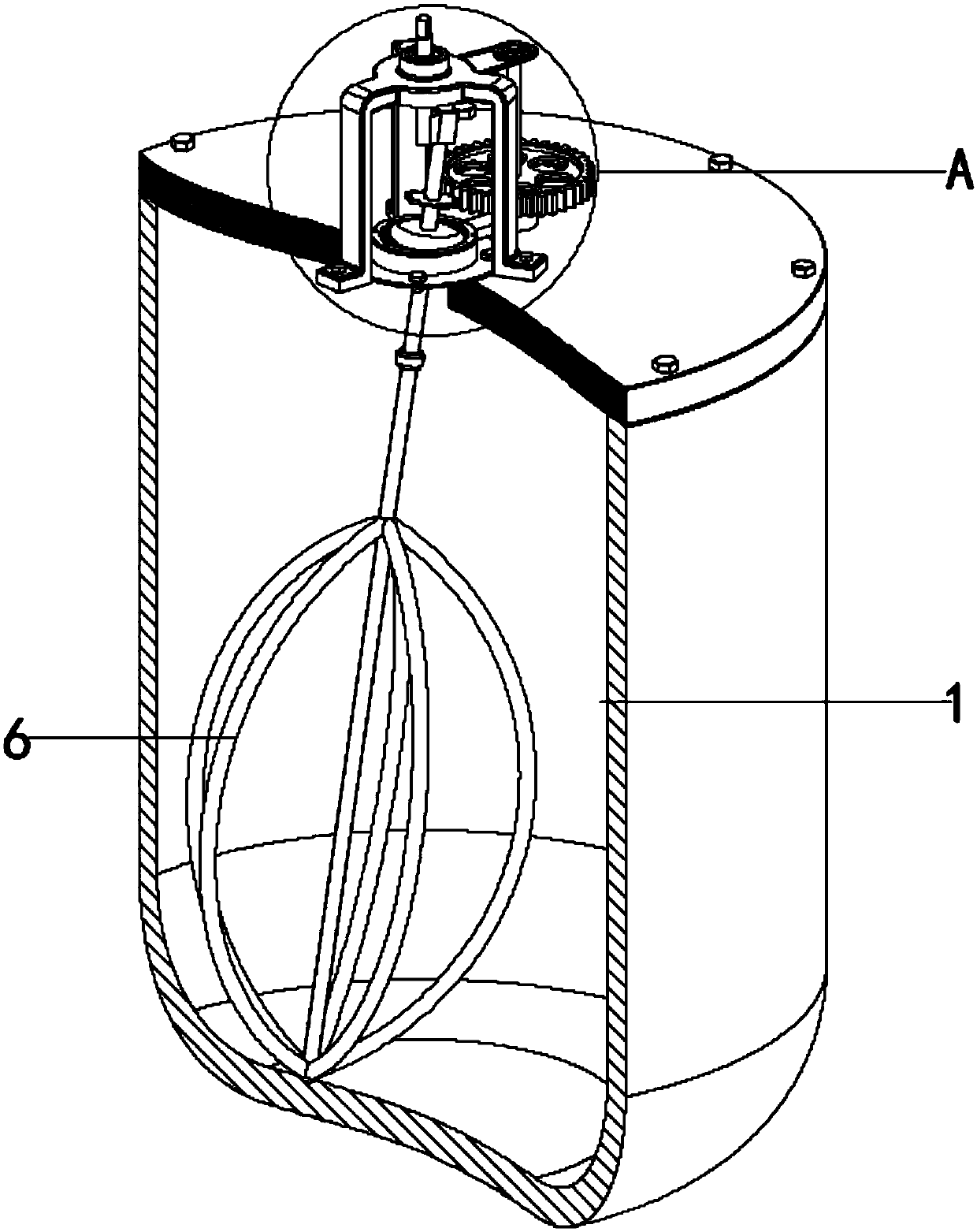

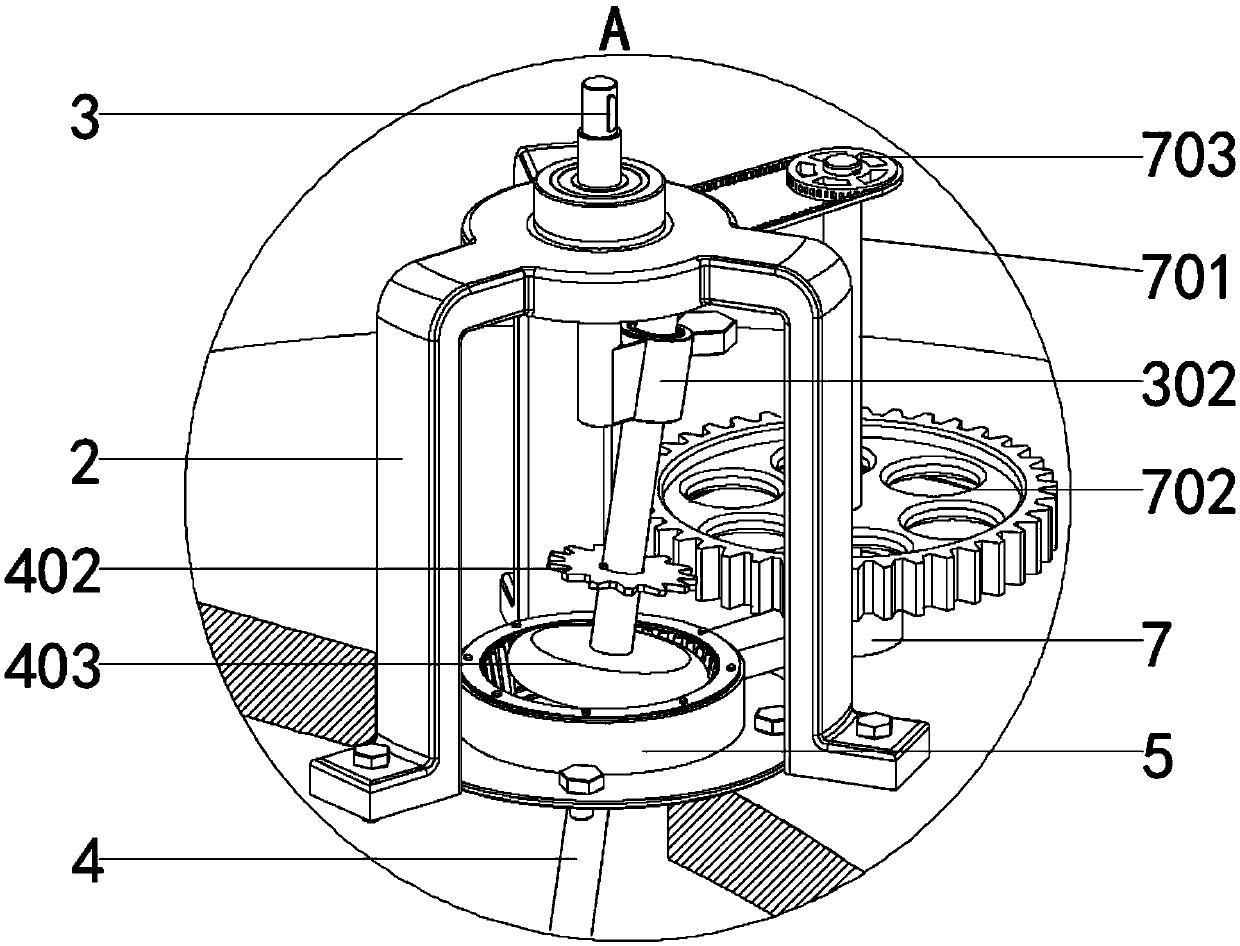

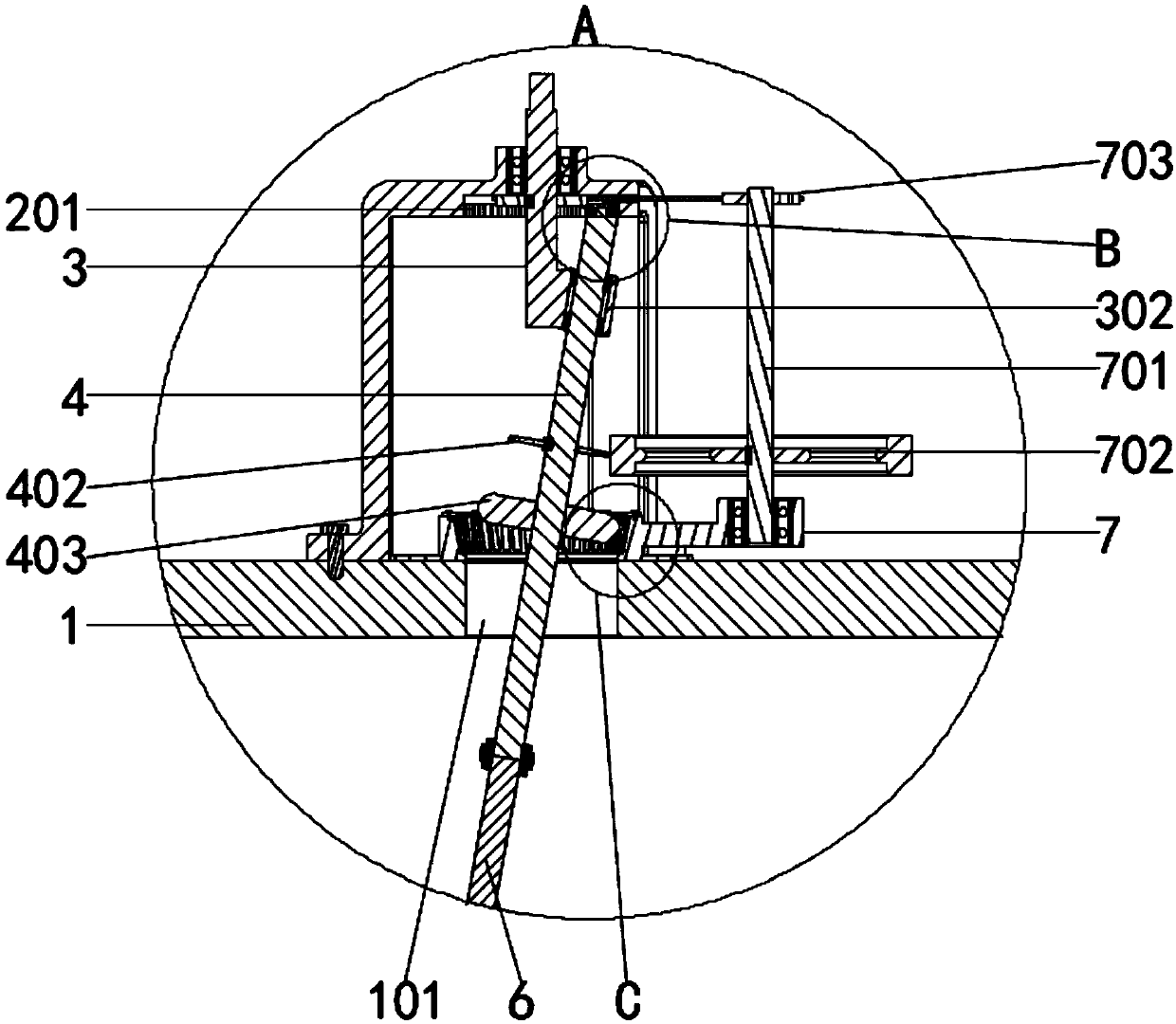

[0041] A chemical tank gyro shaft stirring device, comprising: a tank body 1, a through hole 101, a mounting frame 2, an inner gear ring 201, a mounting seat 202, a protrusion 203, a bearing inlay hole 204, a fitting groove 205, a power shaft 3, Main synchronous pulley 301, eccentric sleeve 302, wheel shaft 4, planetary gear 401, pinion gear 402, gyro wheel 403, rotating shaft 404, gyro wheel seat 5, upper cover 501, roller groove 502, roller wheel 503, mounting flange 504, through hole 505, agitator 6, connecting seat 7, transmission rod 701, main gear 702, auxiliary synchronous pulley 703; the tank body 1 is hollow cylindrical, and the bottom of the tank body 1 is a semicircular transition, and the tank body 1 A circular through-hole 101 is provided in the middle of the top of the body 1; a cylindrical gyro wheel seat 5 is provided directly above the through hole 101, and the bottom of the gyro wheel seat 5 is provided with an integral structure mounting flange 504, and Gyro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com