Patents

Literature

129results about How to "Effective engagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

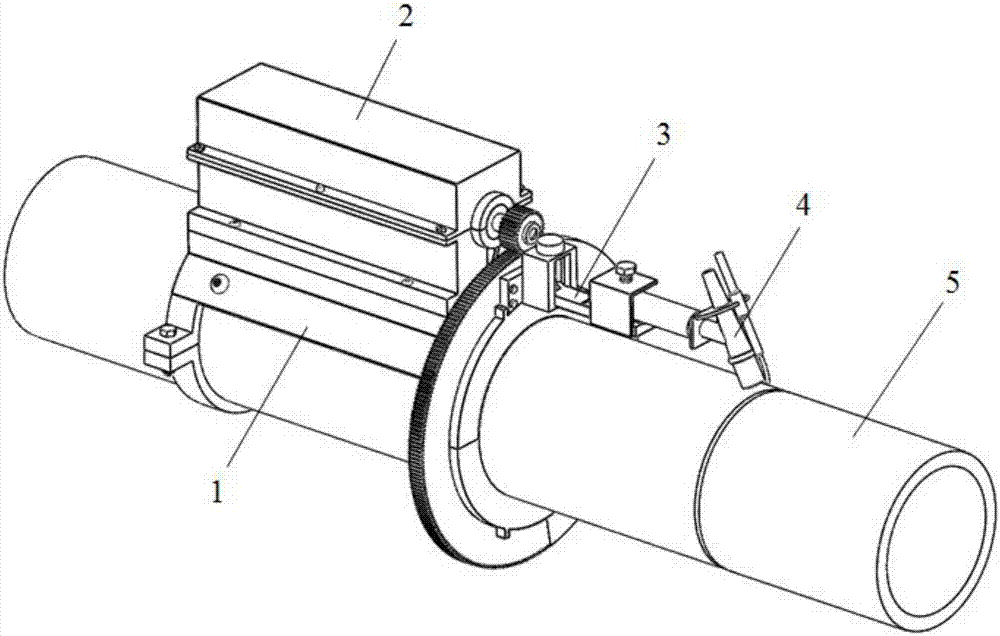

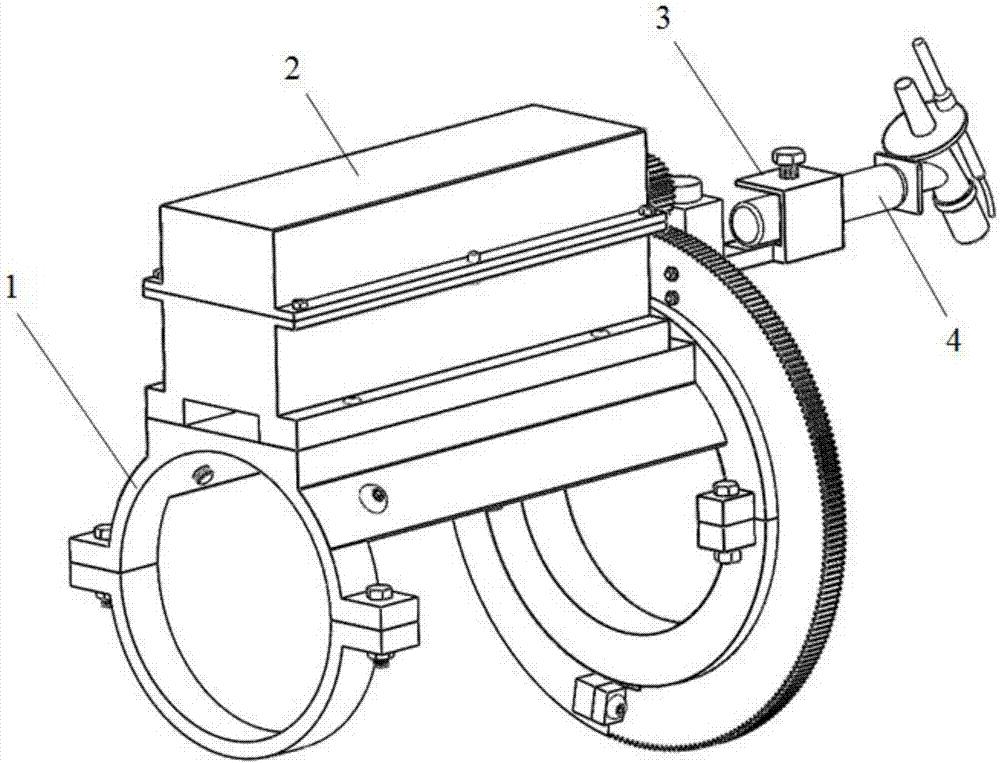

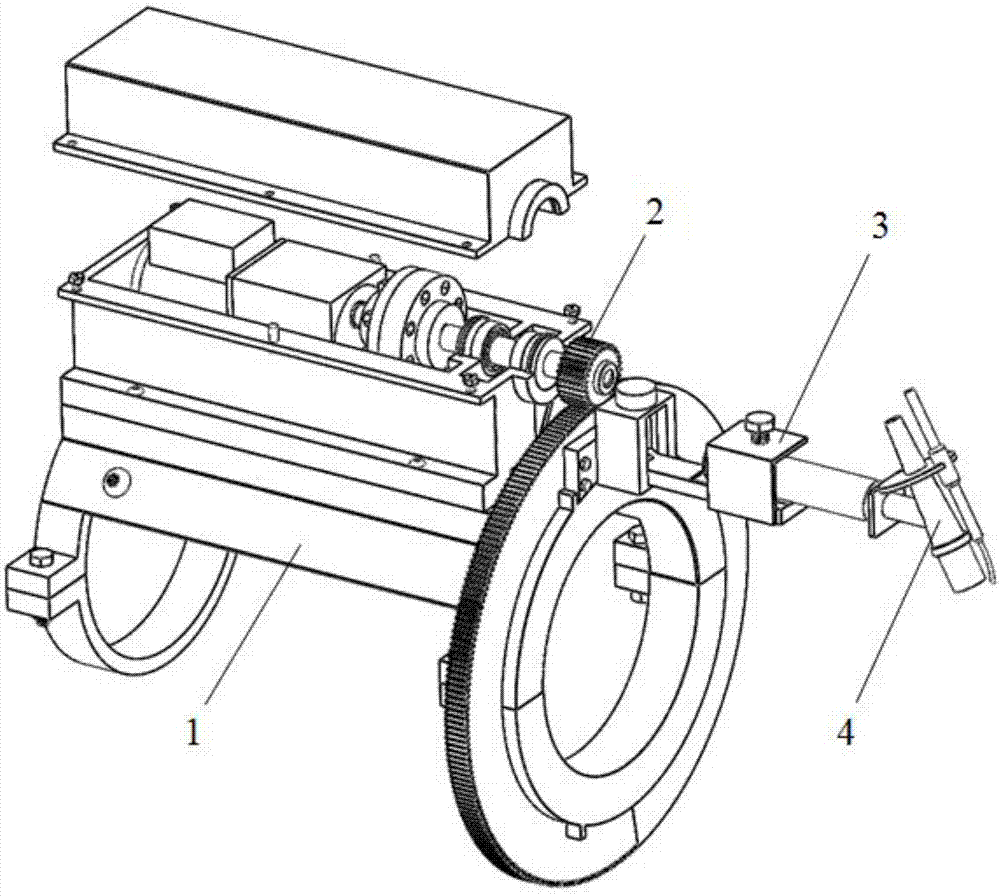

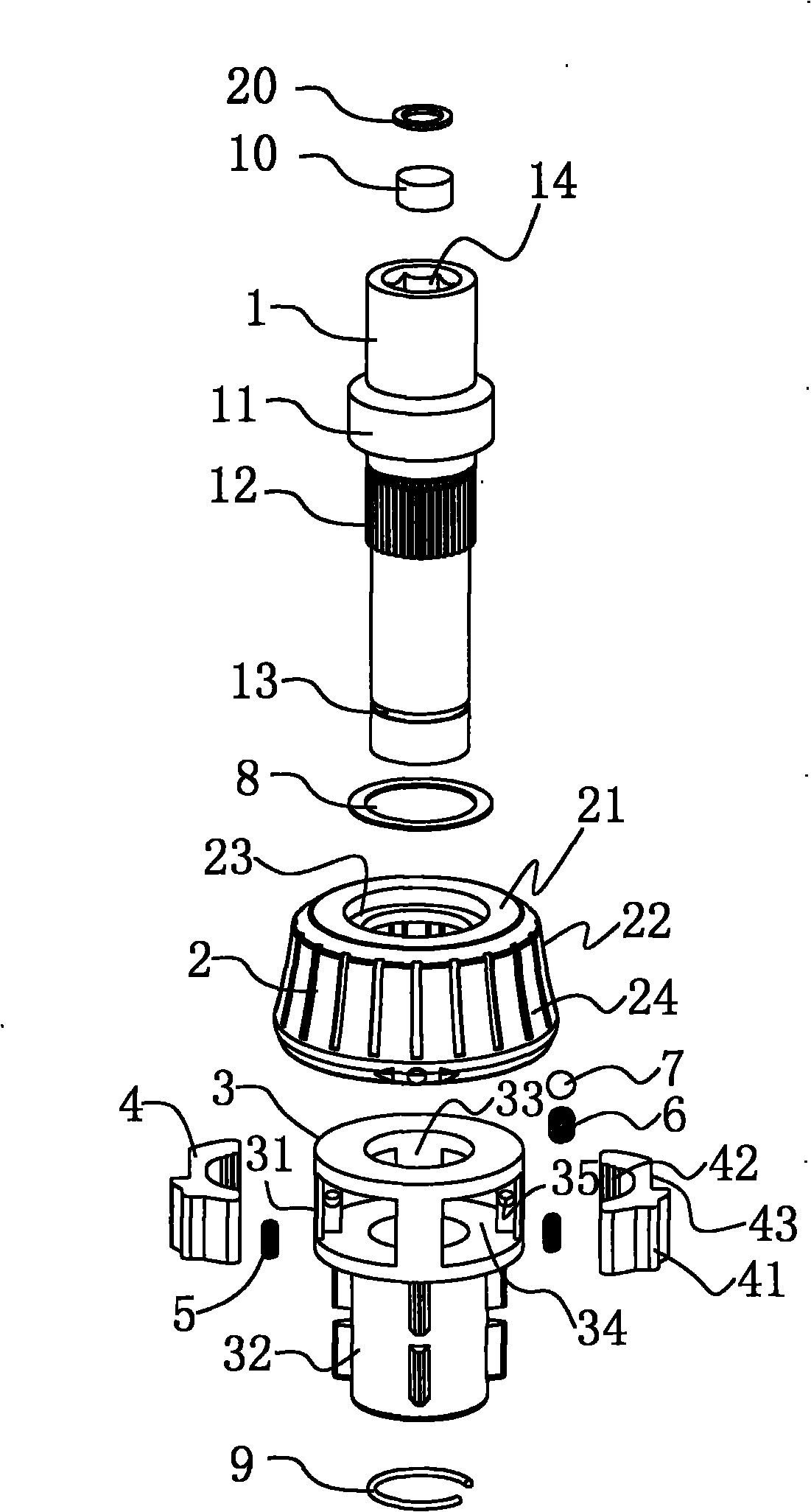

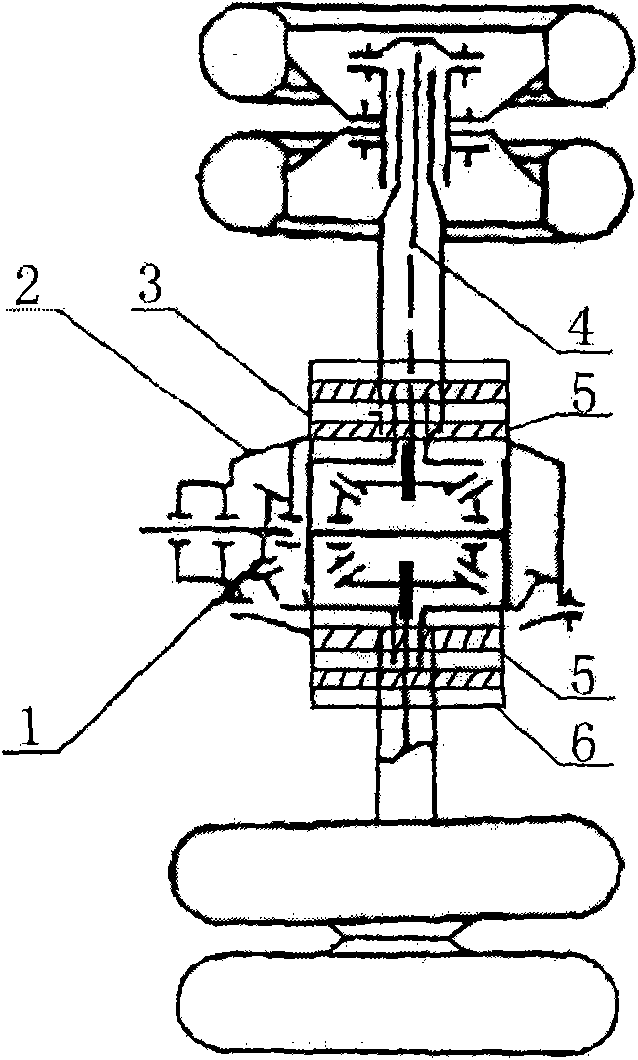

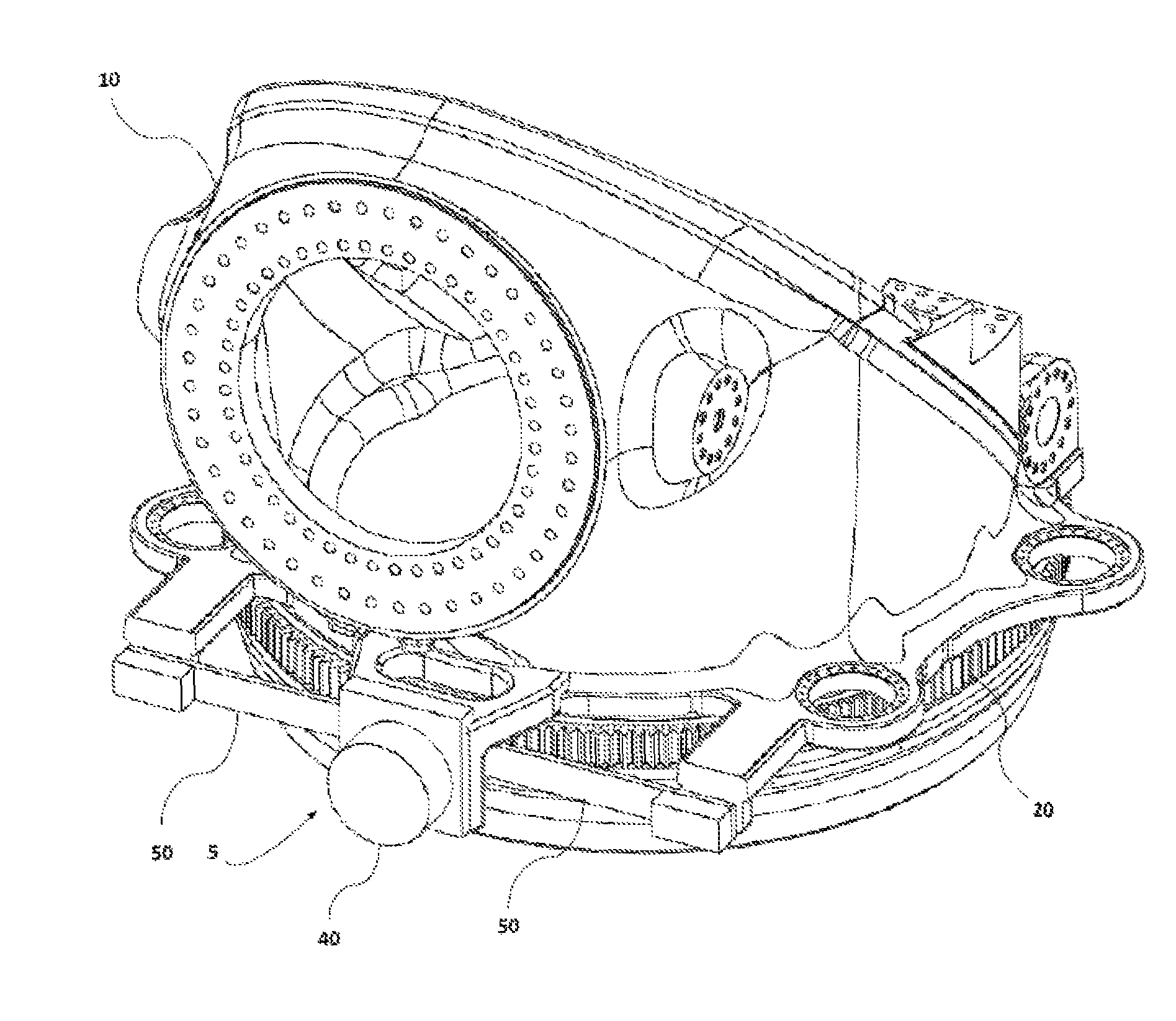

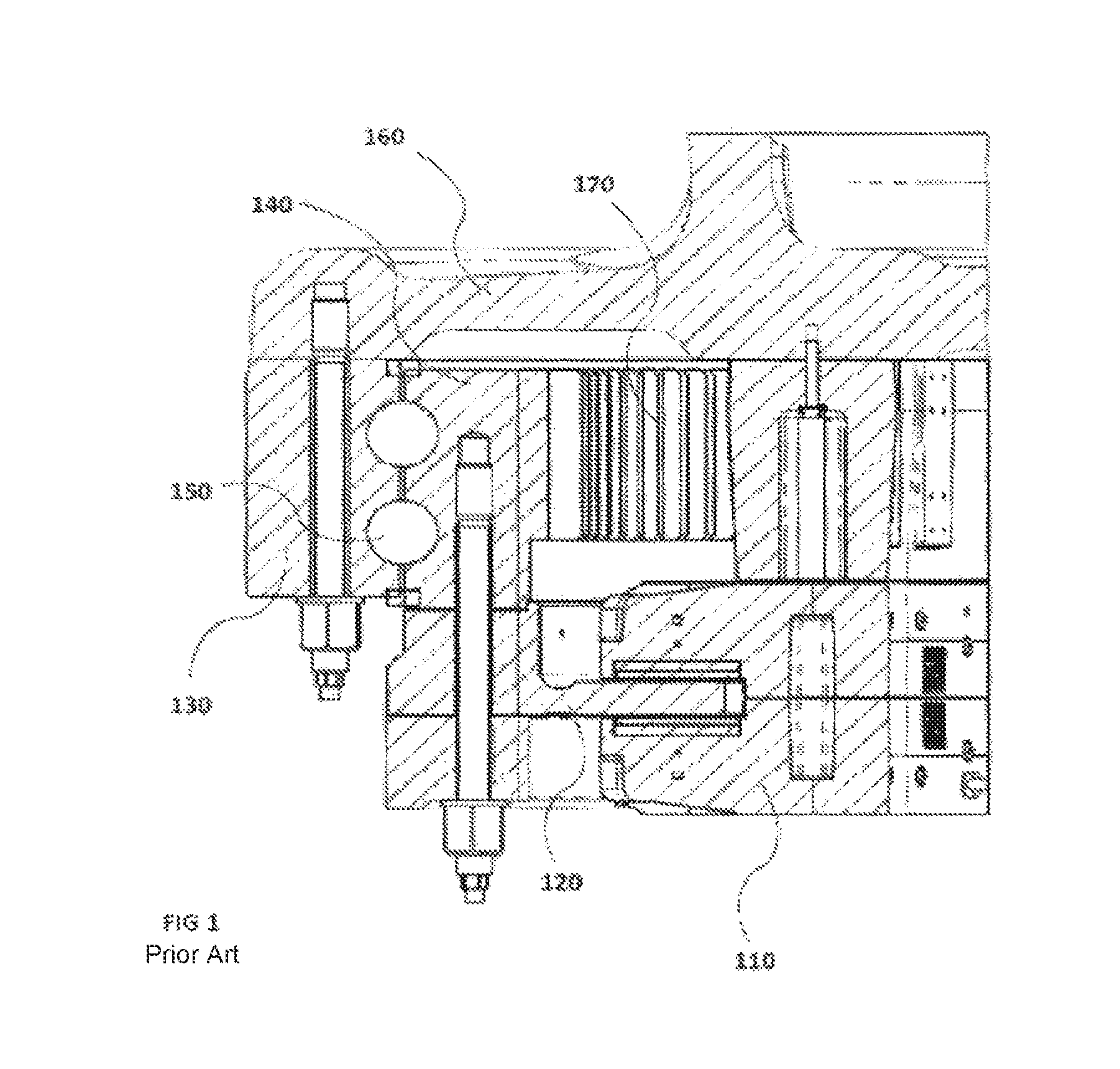

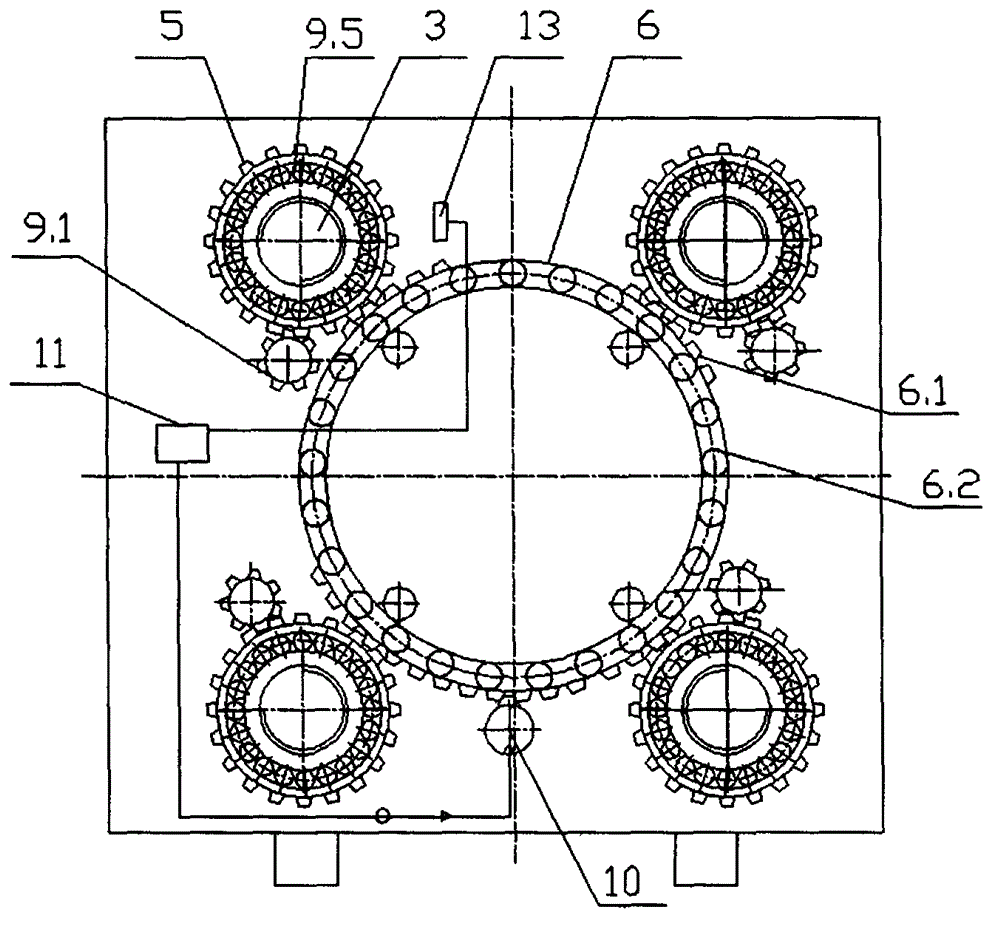

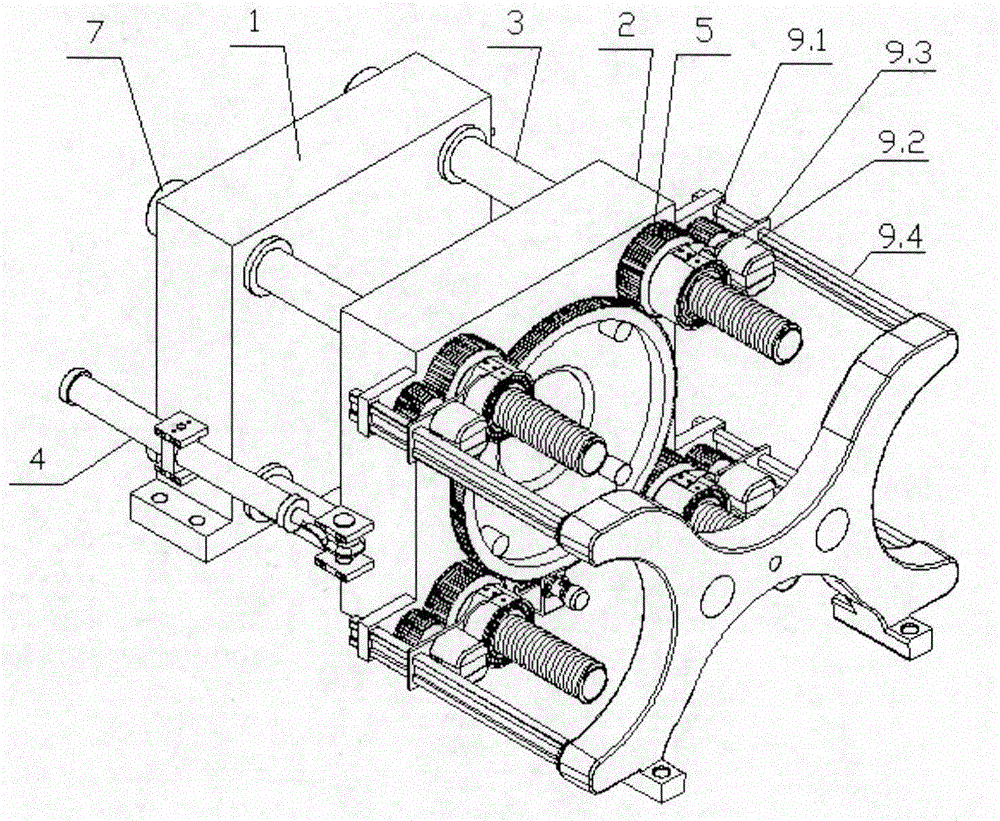

Automatic petroleum pipeline circular seam welding device

ActiveCN107414367ACompact structureReduce volumeWelding/cutting auxillary devicesAuxillary welding devicesControl systemContact type

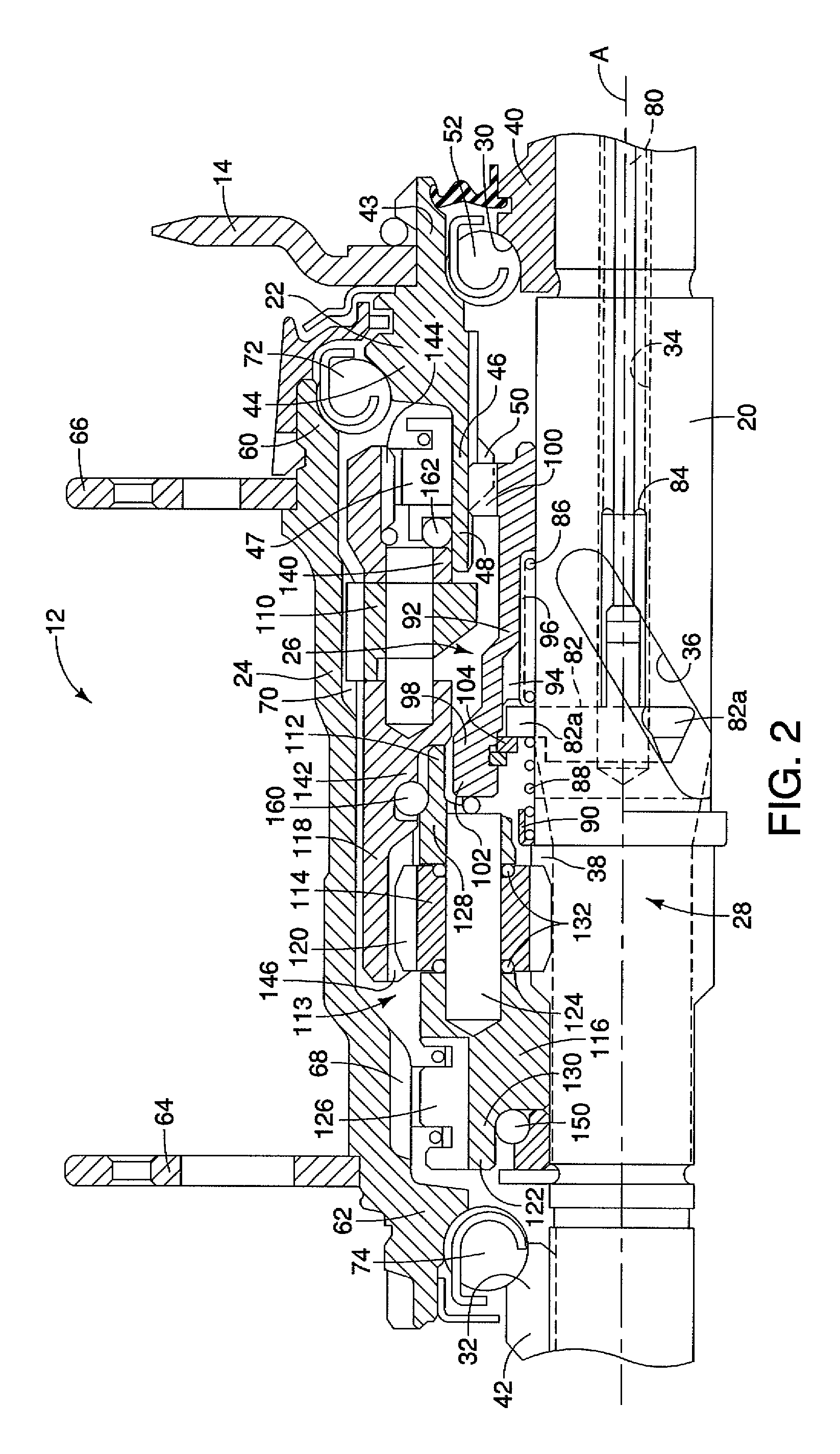

The invention relates to a welding device, in particular to an automatic petroleum pipeline circular seam welding device. The automatic petroleum pipeline circular seam welding device comprises a pipeline clamping system, a power and control system, a welding gun clamping system and a welding gun. The pipeline clamping system is installed on a petroleum pipeline, the power and control system is installed on the pipeline clamping system, the welding gun clamping system is installed on the power and control system, and the welding gun is installed on the welding gun clamping system. The automatic petroleum pipeline circular seam welding device is directly installed on the petroleum pipeline in need of welding, the welding gun is driven to act through gear transmission so as to complete the circular seam welding process. The automatic petroleum pipeline circular seam welding device has the advantages of being simple and compact in structure, small in size, low in cost and high in automated degree. Welding can be stopped automatically through a contact type travel switch when a half circle is welded, the welding process is divided into two steps and completed through welding of the two half circles, and thus welding quality is improved. Spiral transmission is adopted for the welding gun clamping system to adjust the position of the welding gun, the distance between the welding gun and the petroleum pipeline can be adjusted precisely, and the welding quality of a circular seam is further improved.

Owner:XUZHOU XINLONG PIPE IND CO LTD

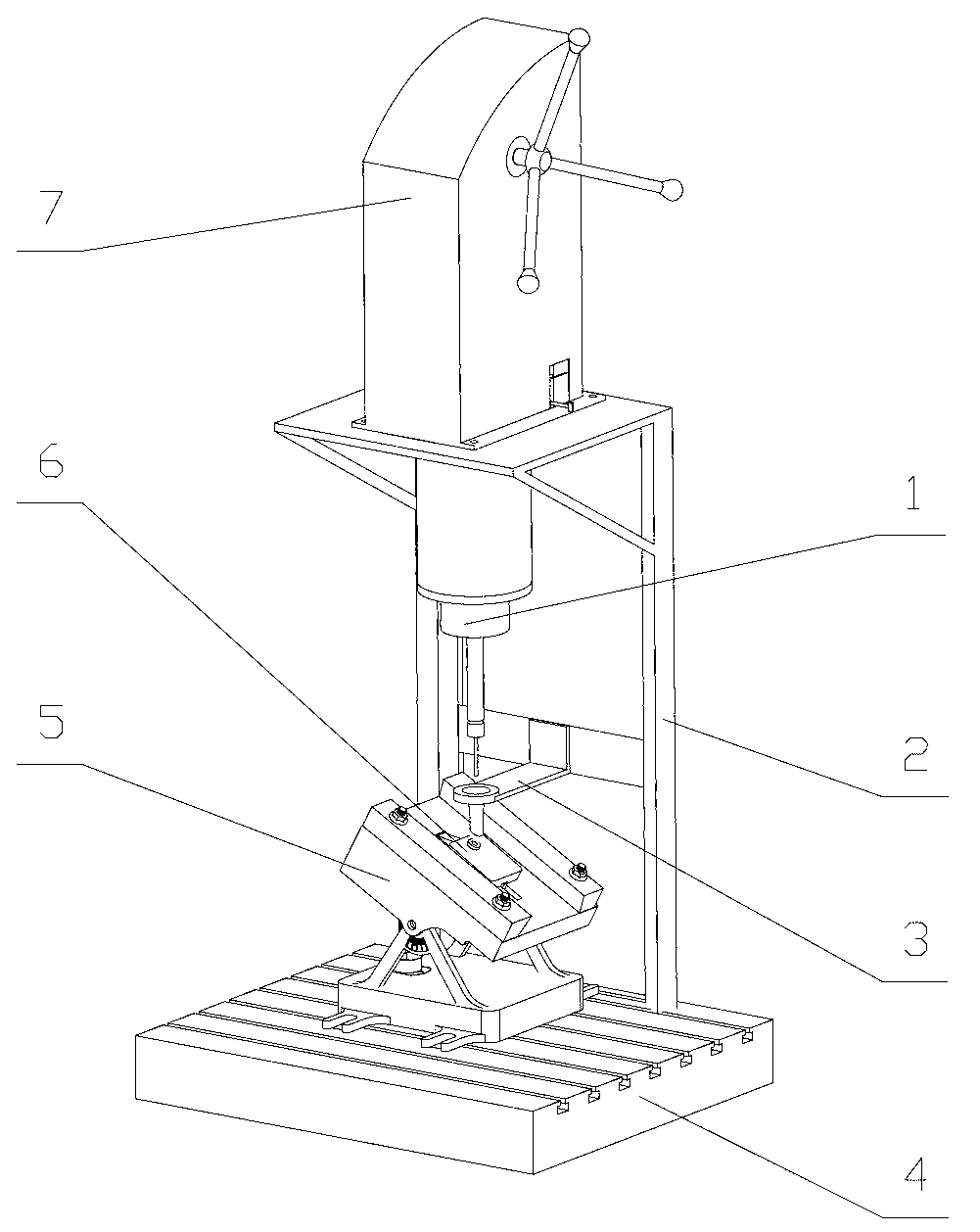

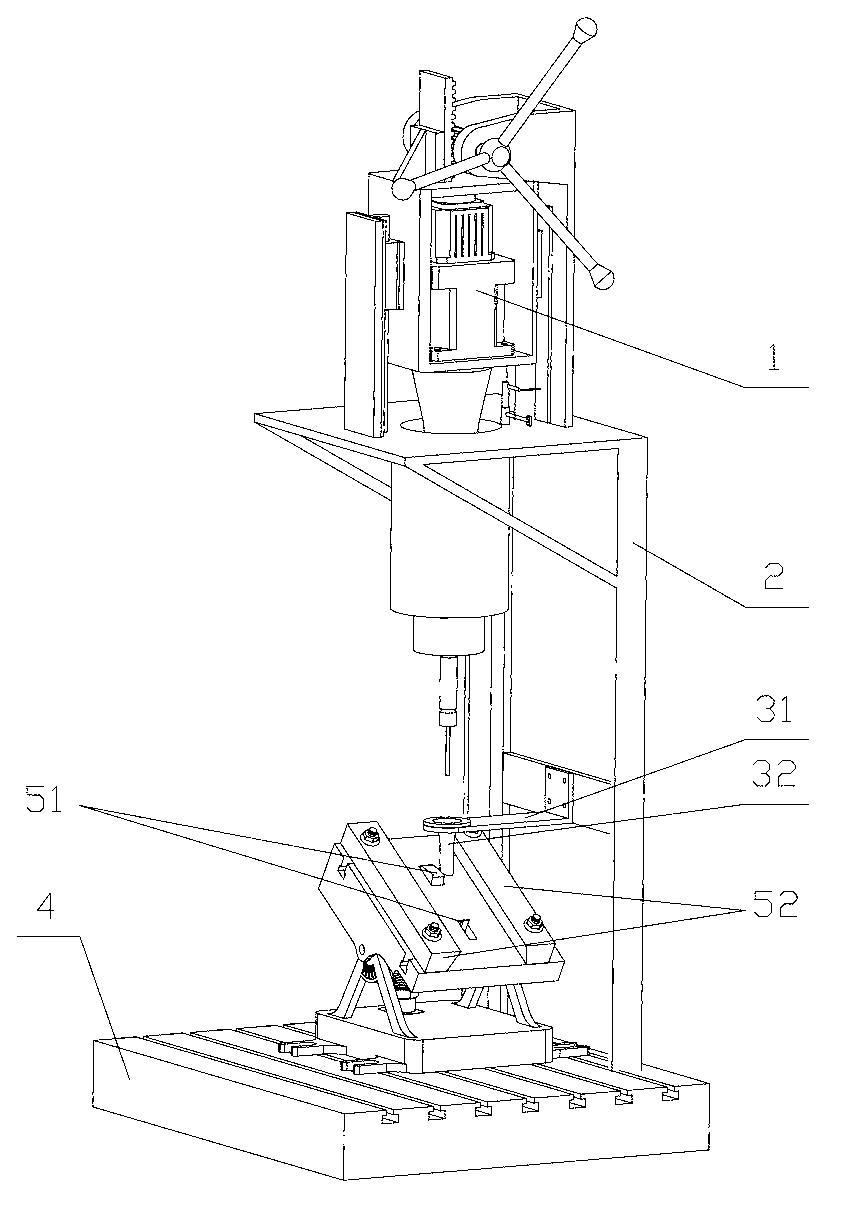

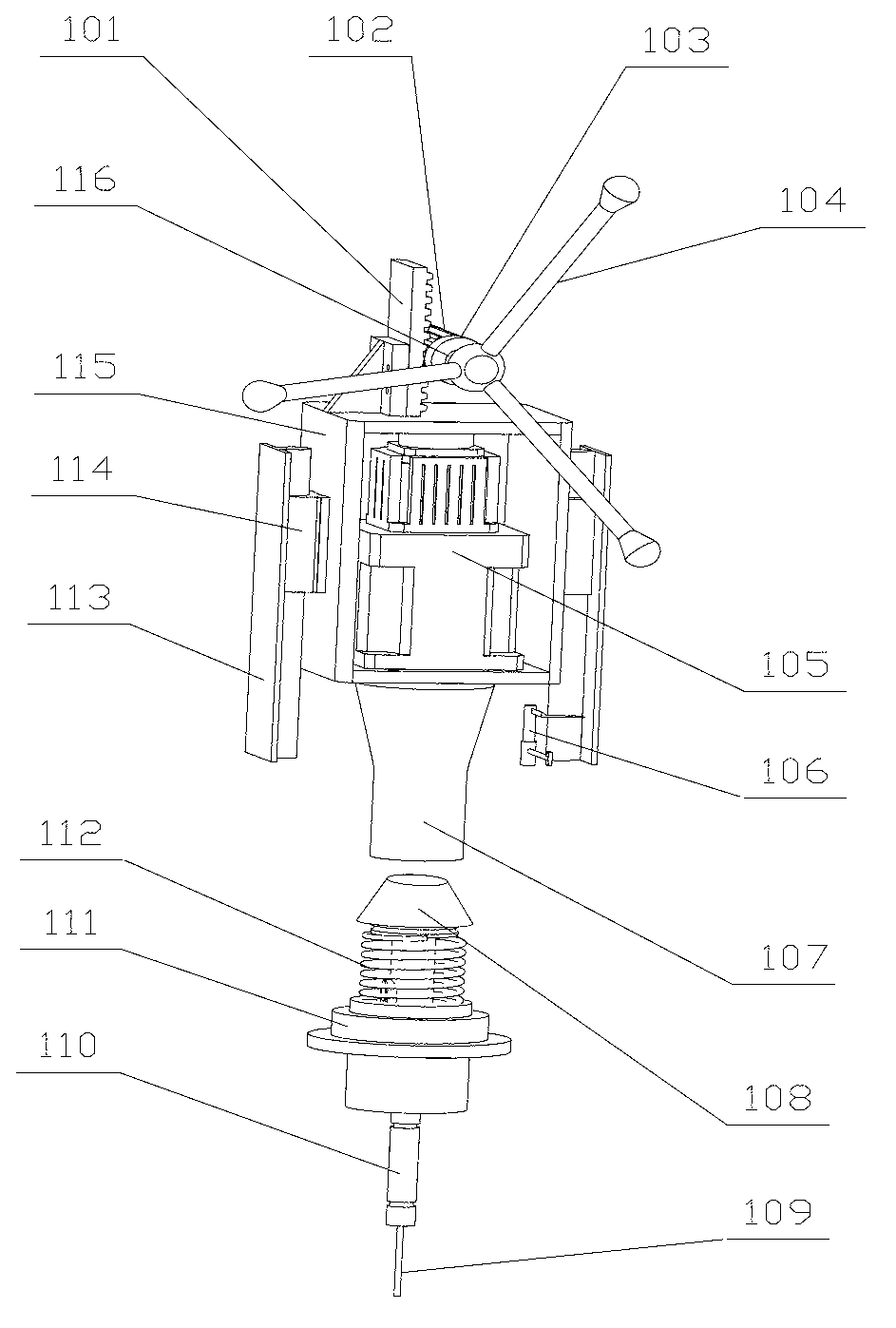

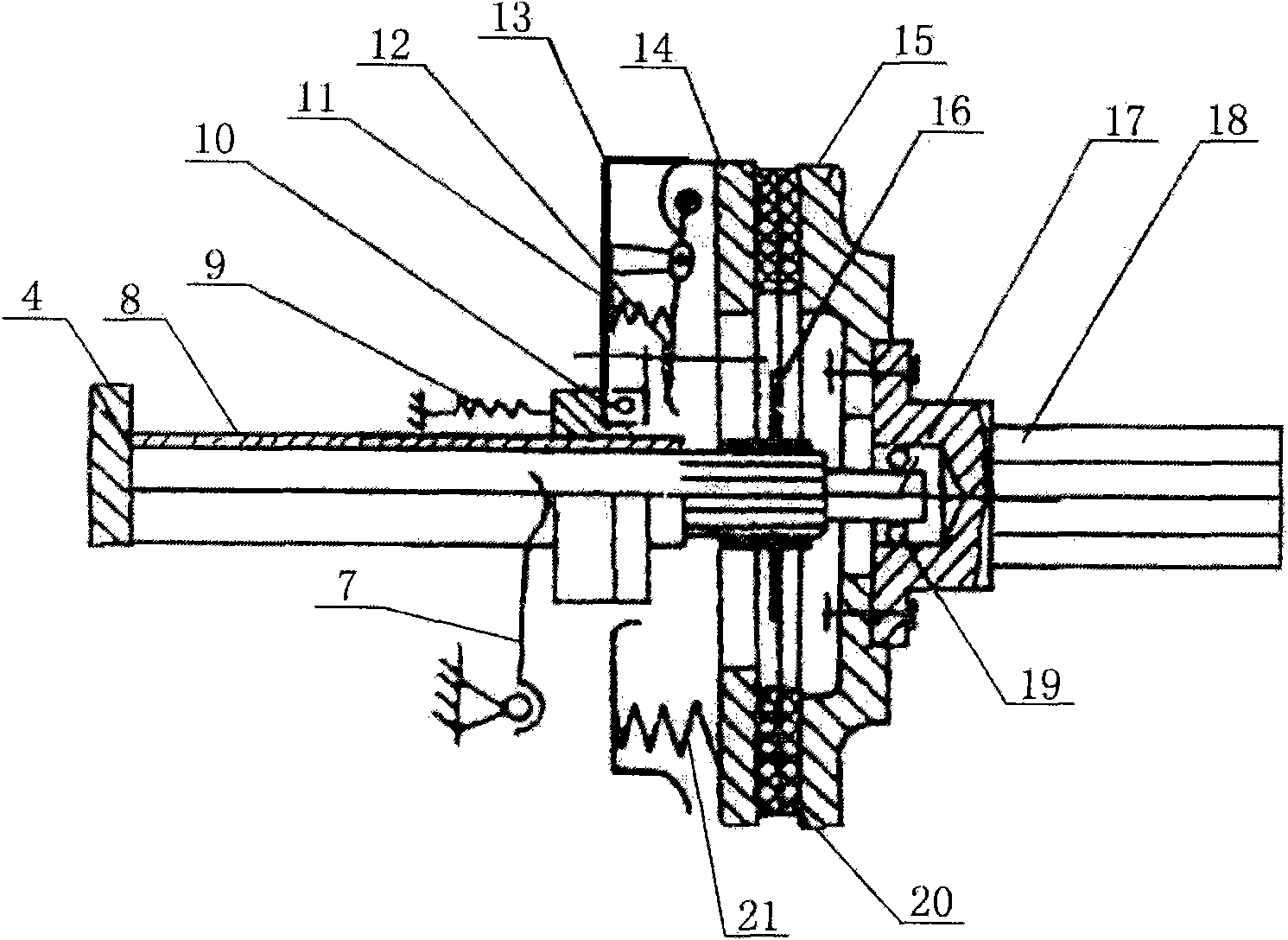

Semi-automatic set screw assembling machine

ActiveCN103252640AReduce scrap rateIncrease productivityMetal working apparatusSemi automationSet screw

A semi-automatic set screw assembling machine comprises a screwing-in device, a support, a screw guiding device, a base plate and a working platform, wherein the support is fixed on one side of the base plate, the working platform is arranged on the upper surface of the base plate, the screw guiding device and the screwing-in device are vertically arranged above the working platform in sequence and respectively connected with the support, the screw guiding device comprises a supporting plate and a guiding sleeve, the upper end of the guiding sleeve is in a cone shape, one end of the supporting plate is fixed on the support through bolts, a cone-shaped hole is formed in the other end of the supporting plate, the guiding sleeve penetrates through the cone-shaped hole and is fixed on the supporting plate, a screwing tool of the screwing-in device, the guiding sleeve and a threaded hole of a piece to be fixed are coaxial, movable inclined plane blocks are arranged on two sides of the working platform, a first limiting wedge and a second limiting wedge are installed between the inclined plane blocks, and the first limiting wedge and the second limiting wedge are in linkage. The semi-automatic set screw assembling machine has certain flexibility, the phenomenon of destroying a screw hole or a screw by screwing is avoided, clamping and uninstalling are synchronous, a screwing length of threads can be adjusted, operation is easy and convenient, production efficiency is high, and an application range is wide.

Owner:GUANGXI UNIV

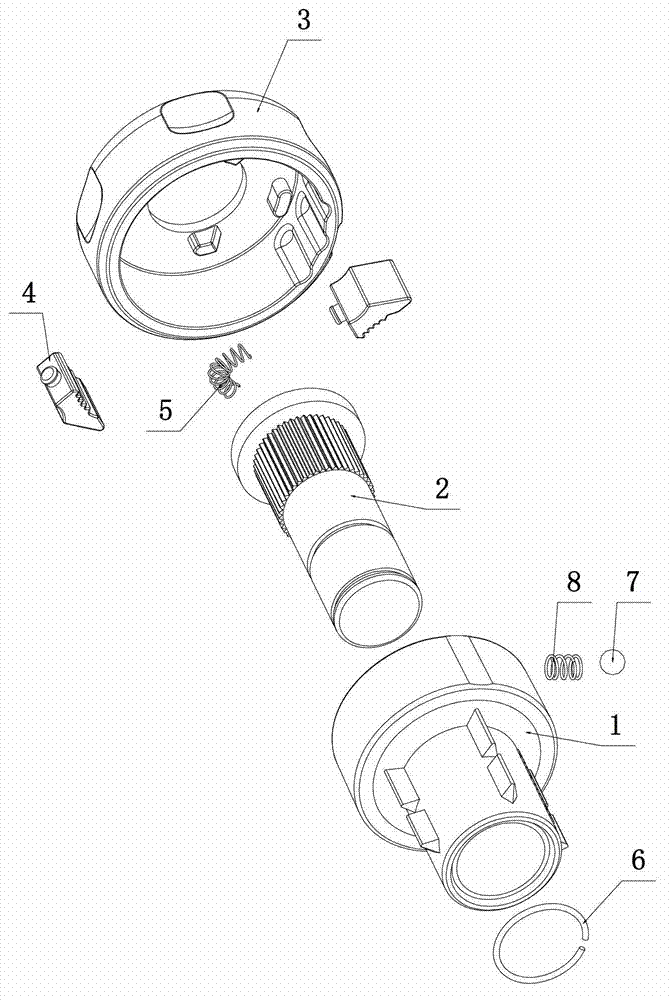

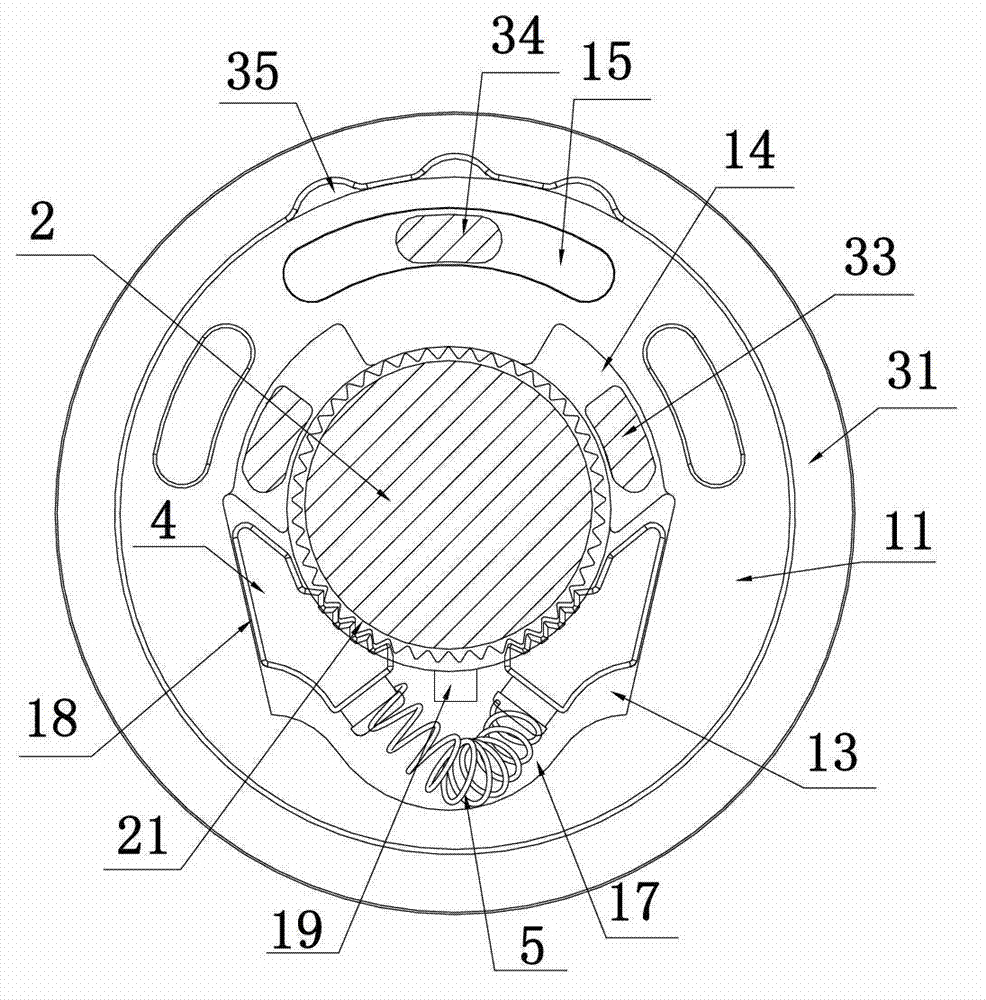

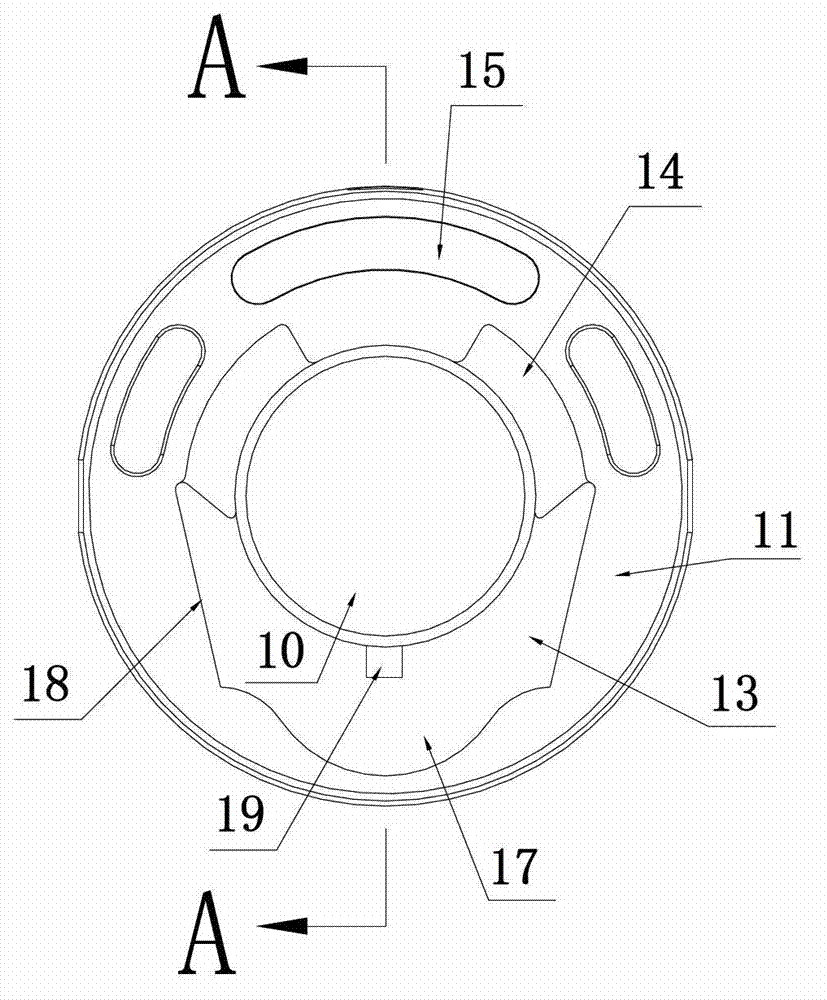

Ratchet gear of screw driver and screw driver using ratchet gear

The invention relates to a structure of a screw driver with a ratchet gear, in particular to the ratchet gear of the screw driver and the screw driver using the ratchet gear. The ratchet gear of the screw driver comprises a pawl seat, a ratchet shaft, an outer clamping ring and two pawls. When the ratchet gear is located at a locking state normally, and the outer clamping ring is rotated in a clockwise direction, a toggling protrusion pushes the left pawl to move outwards along the first inclined surface so as to enable the ratches on the left pawl and a strip tooth to demesh; when the ratchet gear is located in an anticlockwise rotation state, and the outer clamping ring is rotated in an anticlockwise direction, the toggling protrusion pushes the right pawl to move outwards along the first inclined surface so as to enable the ratches on the right pawl and the strip tooth to demesh; and the ratchet gear is located at a clockwise rotation state. The invention has the characteristics that the structure of the ratchet gear is simplified, the production cost is reduced, and the service life is long.

Owner:ZHEJIANG SANDING TOOLS

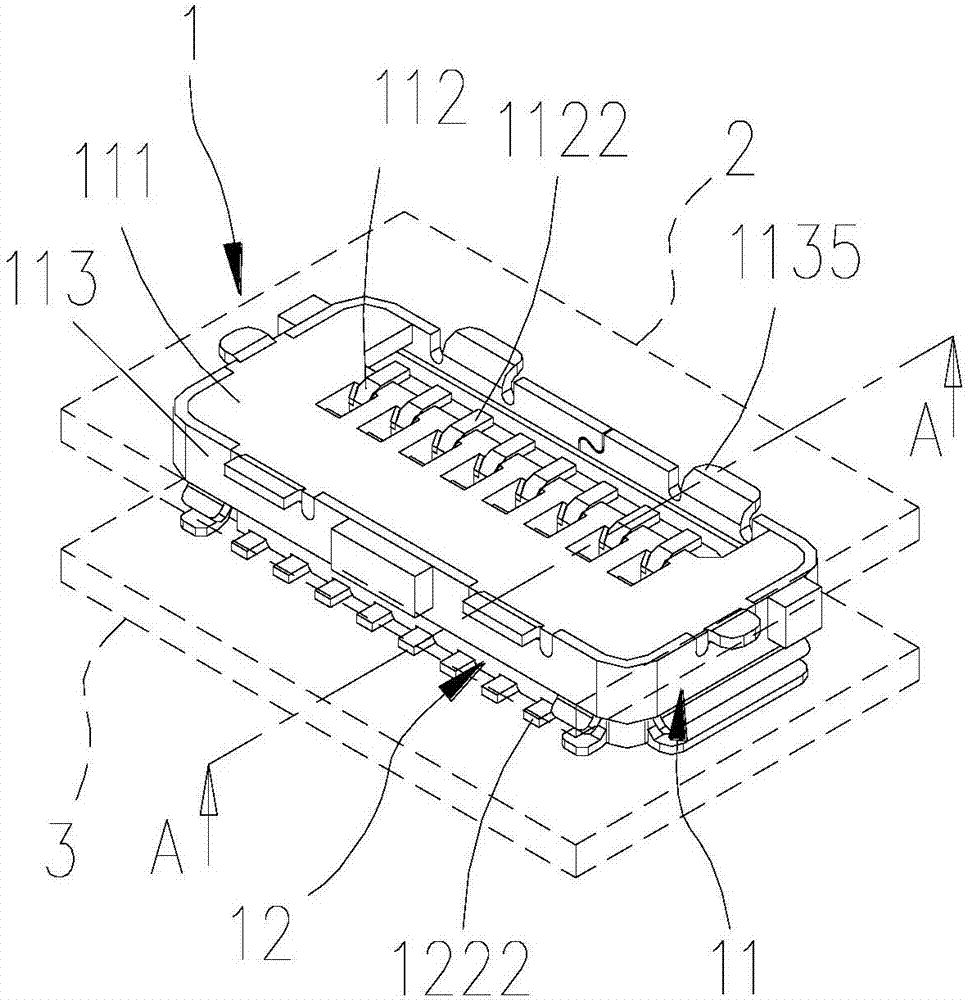

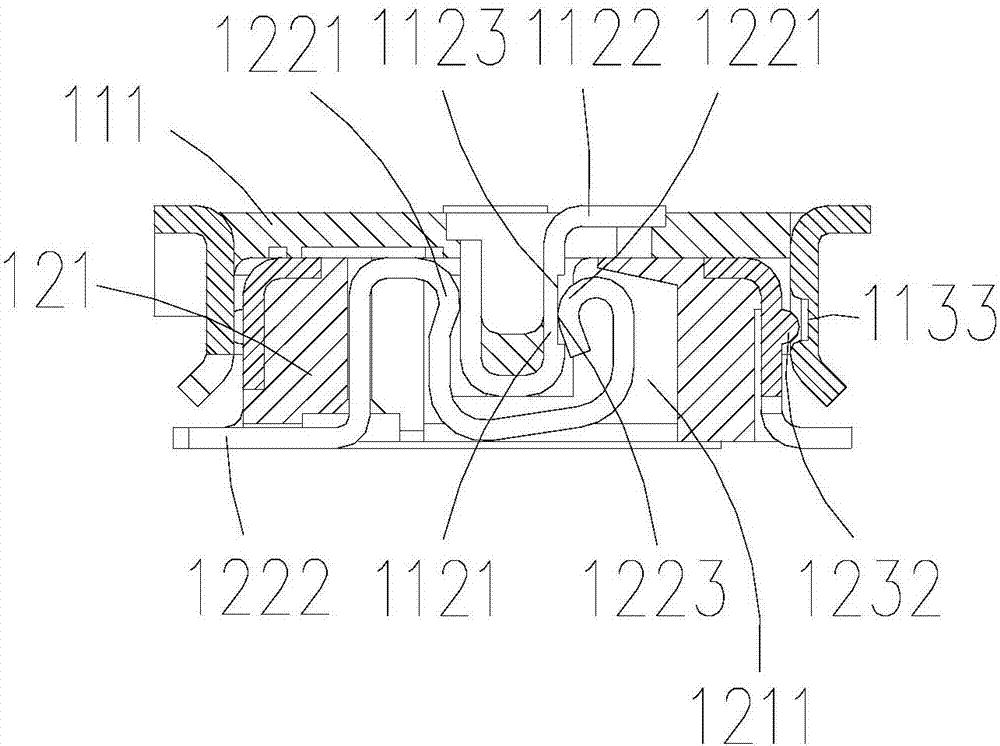

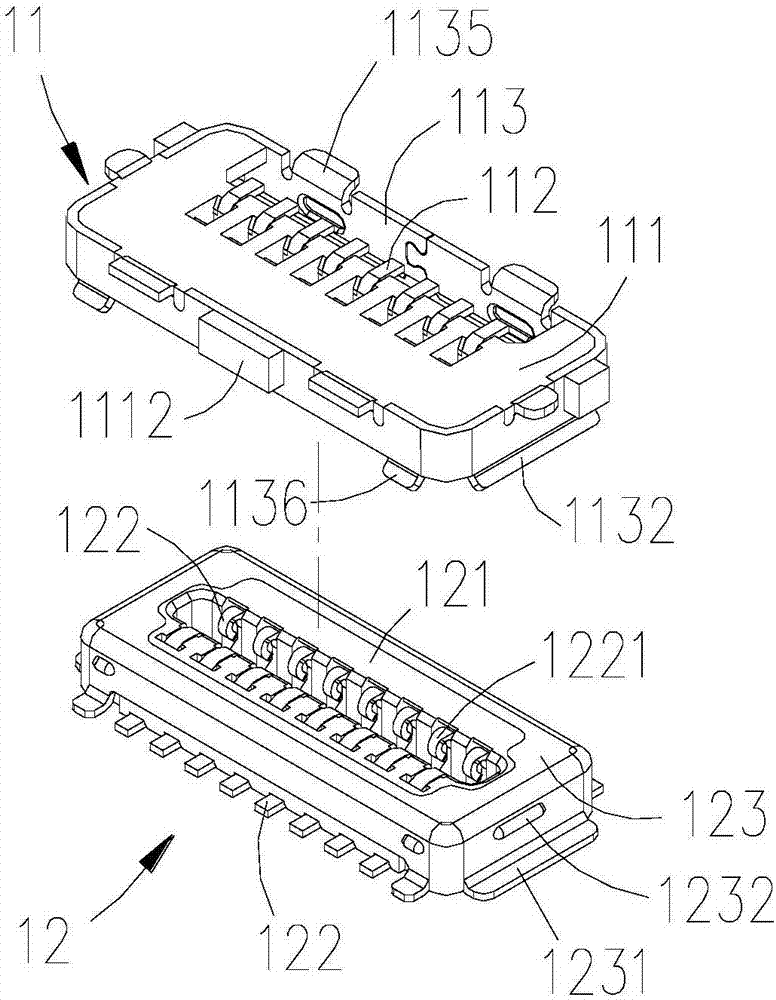

Board-to-board connector assembly

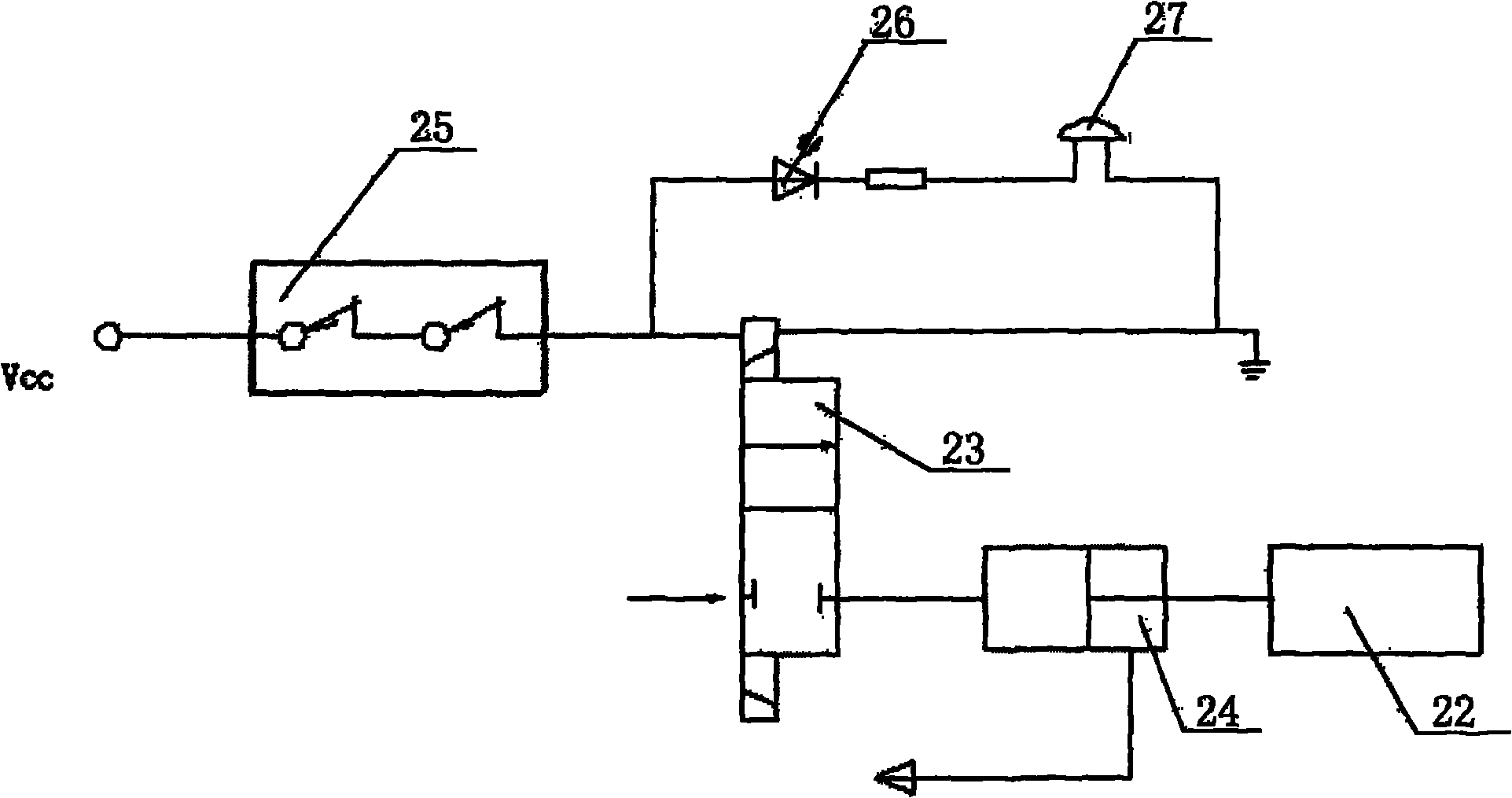

InactiveCN106935995AReduce usageEffective engagementCoupling device detailsTwo-part coupling devicesElectrical conductorBoard-to-board connector

The invention discloses a board-to-board connector assembly, through the improvement of the structure of the male end board connector and the female end connector, a joint structure is designed to ensure the effective engagement of the male end board connector and the female end connector , and due to the design of the joint structure, the male end board connector and the female end board connector can be effectively joined even when the contact area is insufficient, so the joint height between the male end board connector and the female end board connector can be reduced, It can be applied to various thin and light electronic devices at present. In addition, the board-to-board connector assembly of the present invention has a plurality of conductors, which can transmit multiple signals at the same time, so as to effectively save the number of connectors used in electronic equipment, and facilitate the adoption of various thin and light electronic equipment.

Owner:TARNG YU ENTERPRISE

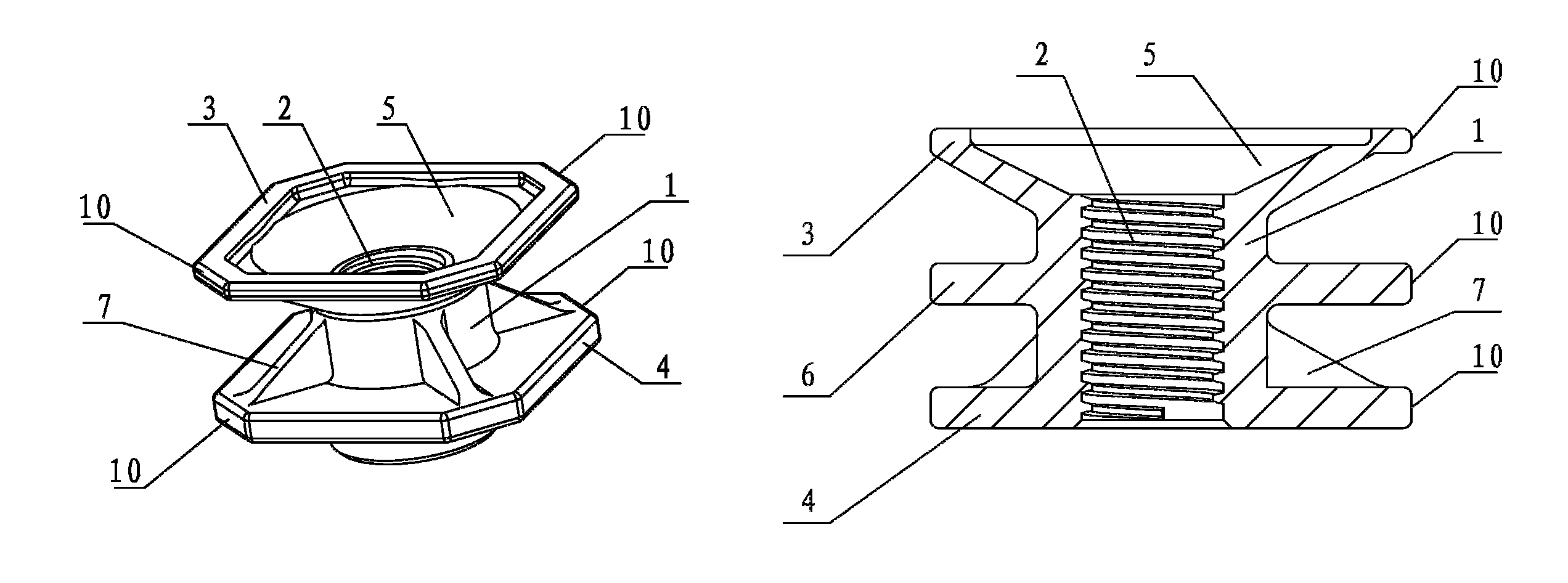

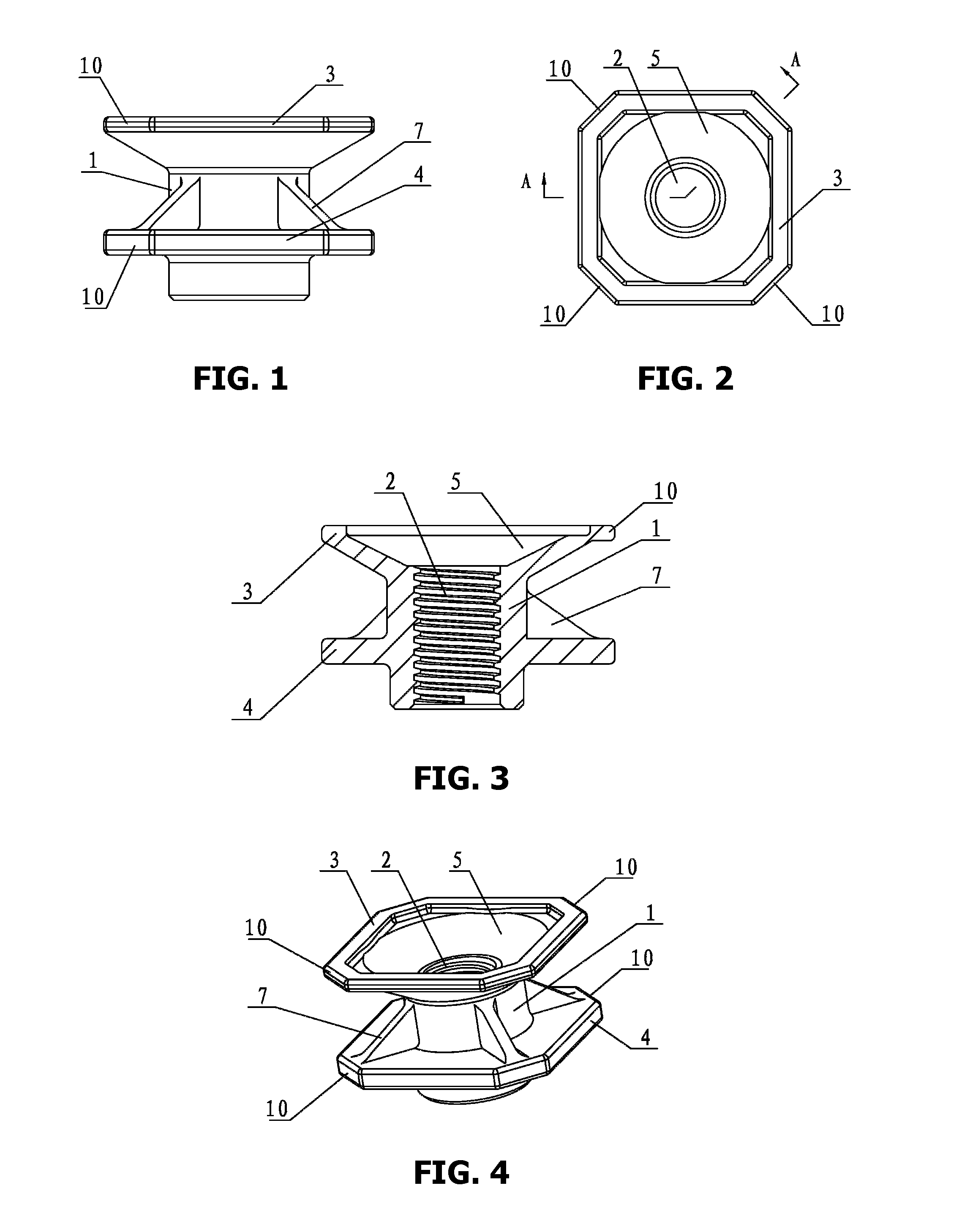

Semi-trailer support loading nut

InactiveUS8622677B2Increasing anti-rotating moment capabilityHigh strengthWashersNutsInter layerEngineering

A semi-trailer leg loading nut includes a screwed hole provided on a nut column and connecting two ends of the nut. Said nut is a two-layered structure formed of a top layer and an under layer or a three-layered structure formed of a top layer, an intermediate layer and an under layer. The outer outline of at least two layers of the nut is a square with the same cutting angle. The side length of the two layers of squares is equal. The outer outline projection of the two layers of squares overlap with each other along the column axis direction. The outer outline projection of the other layer is within the overlapped projection of the two layers along the column axis direction. A funneled oil cup or an oil groove is provided on the top layer of the nut and communicates with the screwed hole. A bottom of the under layer of the nut is plane and is pressed on a loading plate in a quadrate pipe to transfer load.

Owner:GUANGDONG FUWA ENG MFG CO LTD

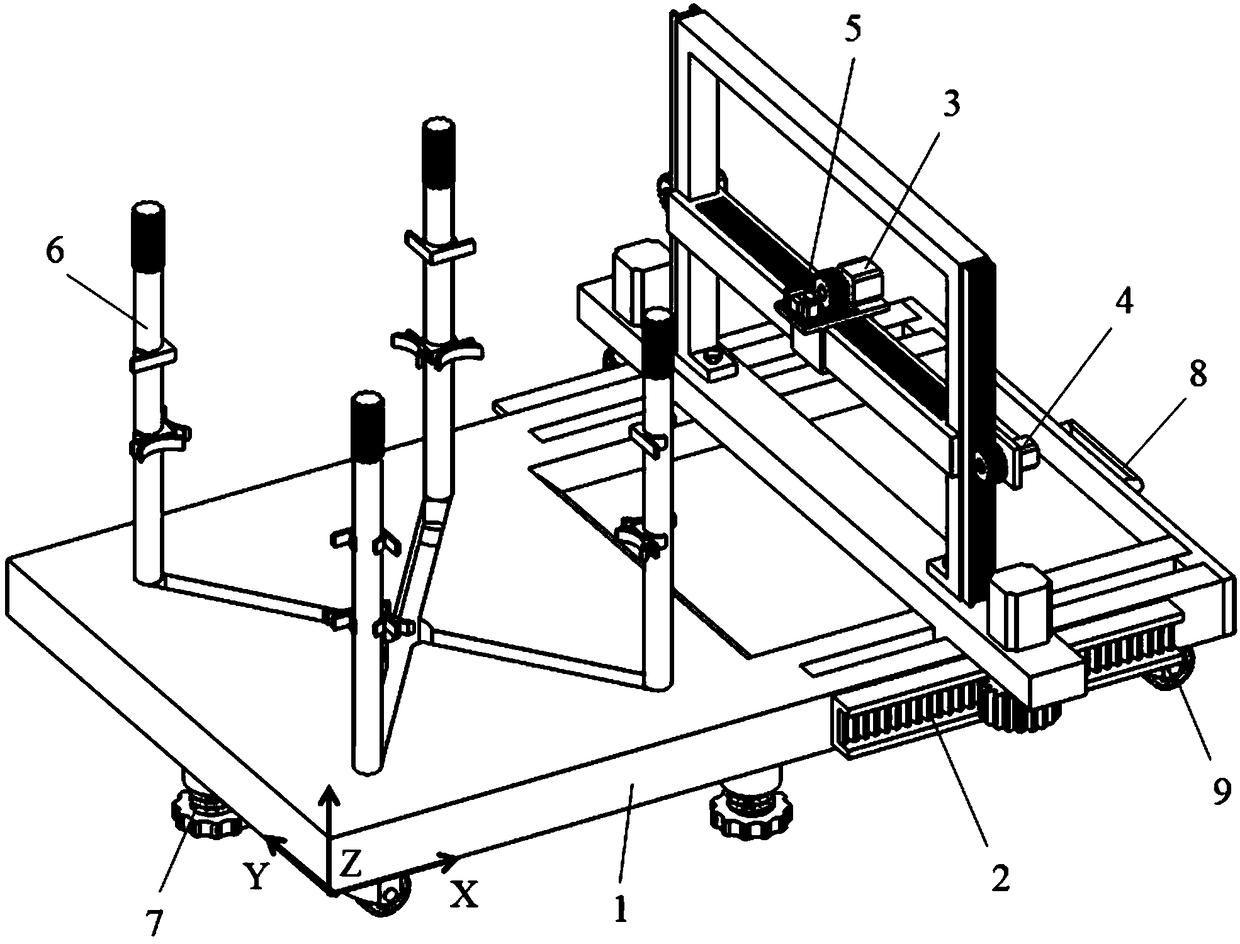

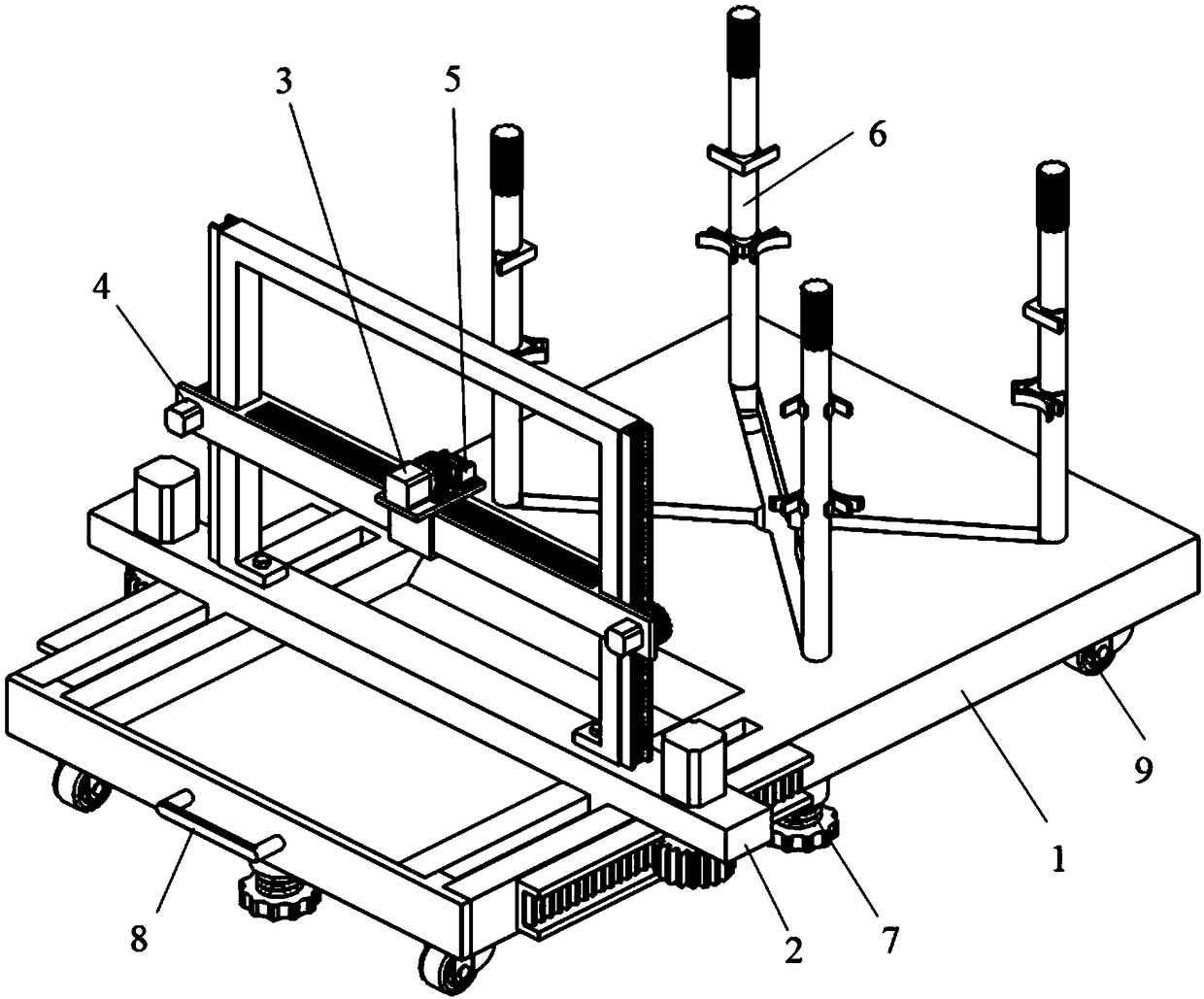

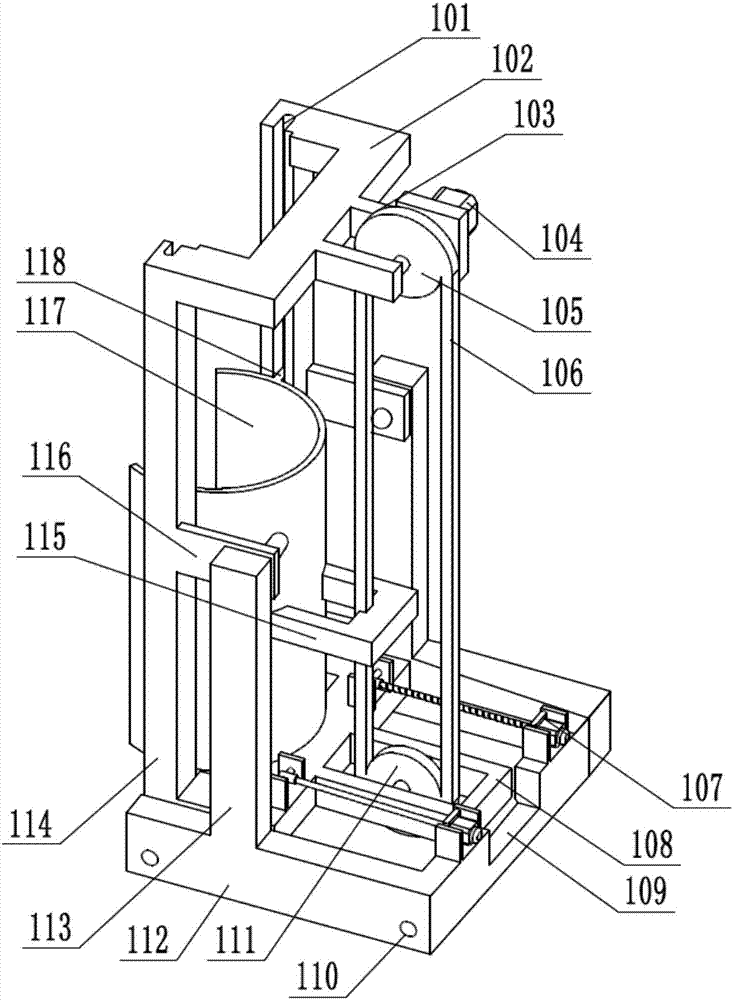

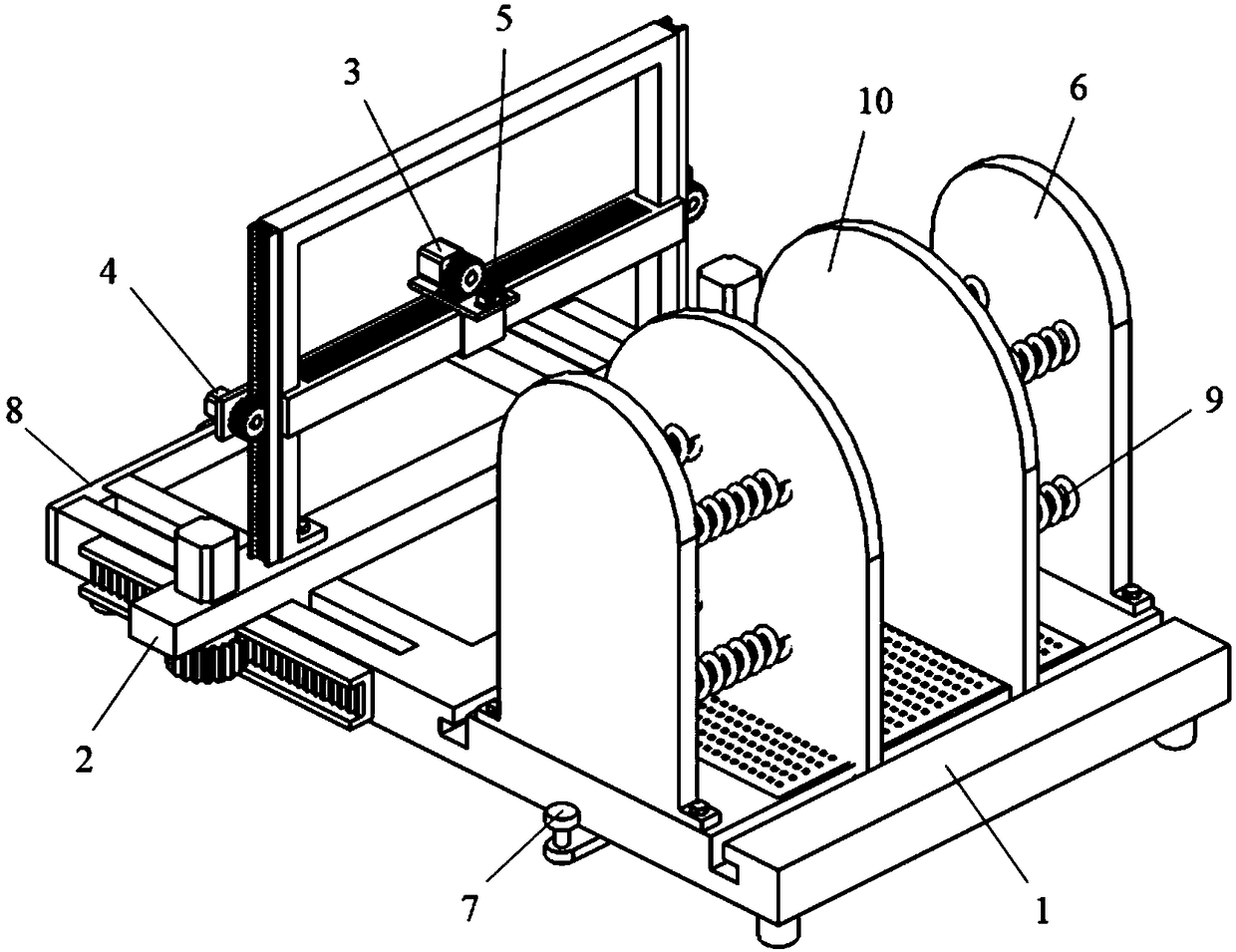

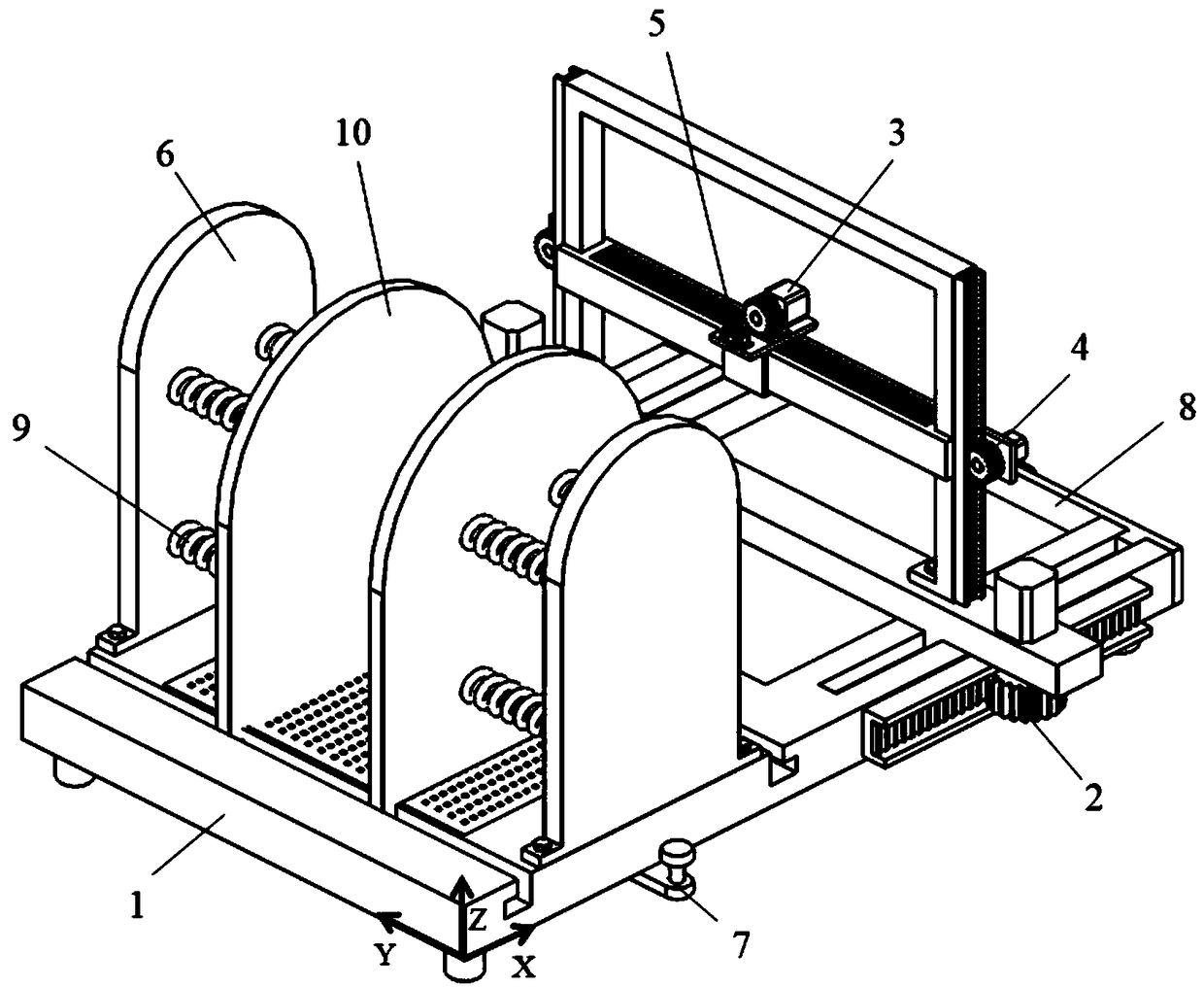

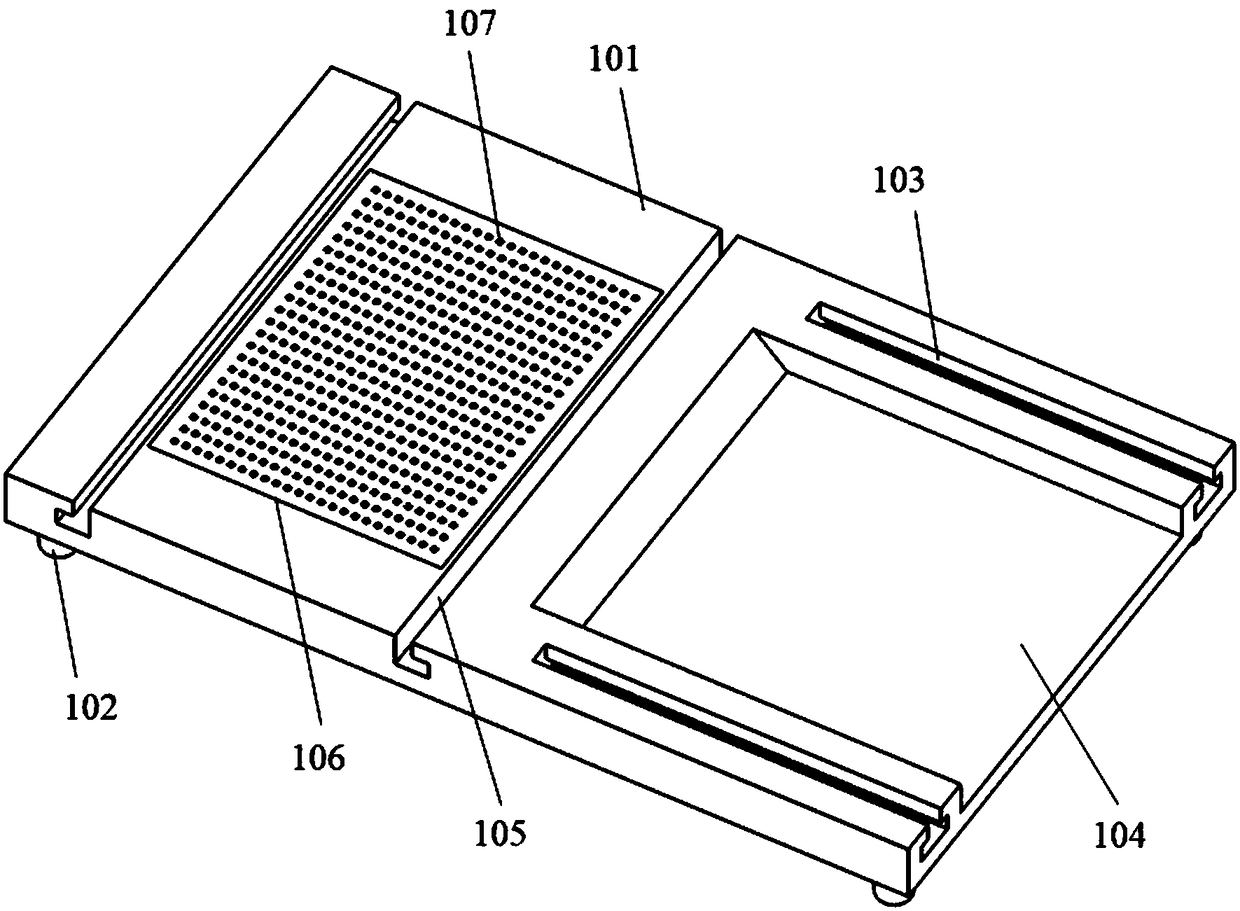

Easy-to-move laser cleaning device

InactiveCN109048068AEasy to moveAchieve fixationWelding/cutting auxillary devicesAuxillary welding devicesLinear motionAutomatic control

The invention relates to a laser cleaning device, in particular to an easy-to-move laser cleaning device, and belongs to the technical field of laser cleaning. The easy-to-move laser cleaning device comprises a supporting mechanism, an X-axis motion mechanism, a Y-axis motion mechanism, a Z-axis motion mechanism, a laser cleaner, gripping mechanisms, adjustment mechanisms, a blocking plate and swivel wheels. A control system of the easy-to-move laser cleaning device automatically determines a cleaning path by analyzing images before laser cleaning, and can effectively improve the working efficiency. A cleaning result is judged through the analysis on images after laser cleaning; if the cleaning result is unsatisfactory, the cleaning task is performed once again until the cleaning result issatisfactory so as to ensure a satisfactory cleaning effect; and the cleaning effect is good. The control system automatically controls the coordinated motion of a first driving motor, a second driving motor and a third driving motor according to the cleaning path to separately drive the linear motion of the X-axis motion mechanism, the Y-axis motion mechanism and the Z-axis motion mechanism so as to drive a laser cleaning head of the laser cleaner to complete the cleaning task.

Owner:孟凡森

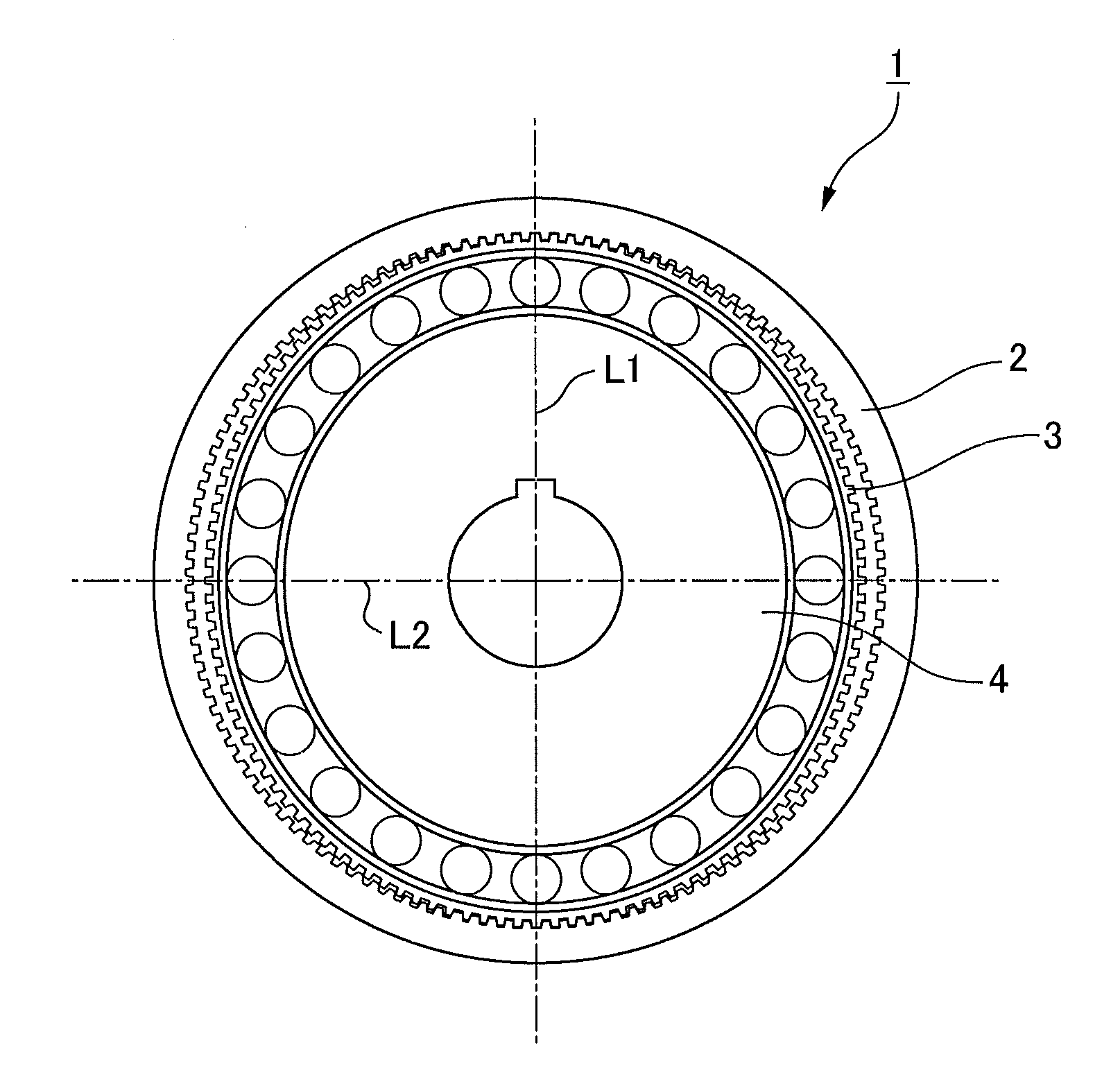

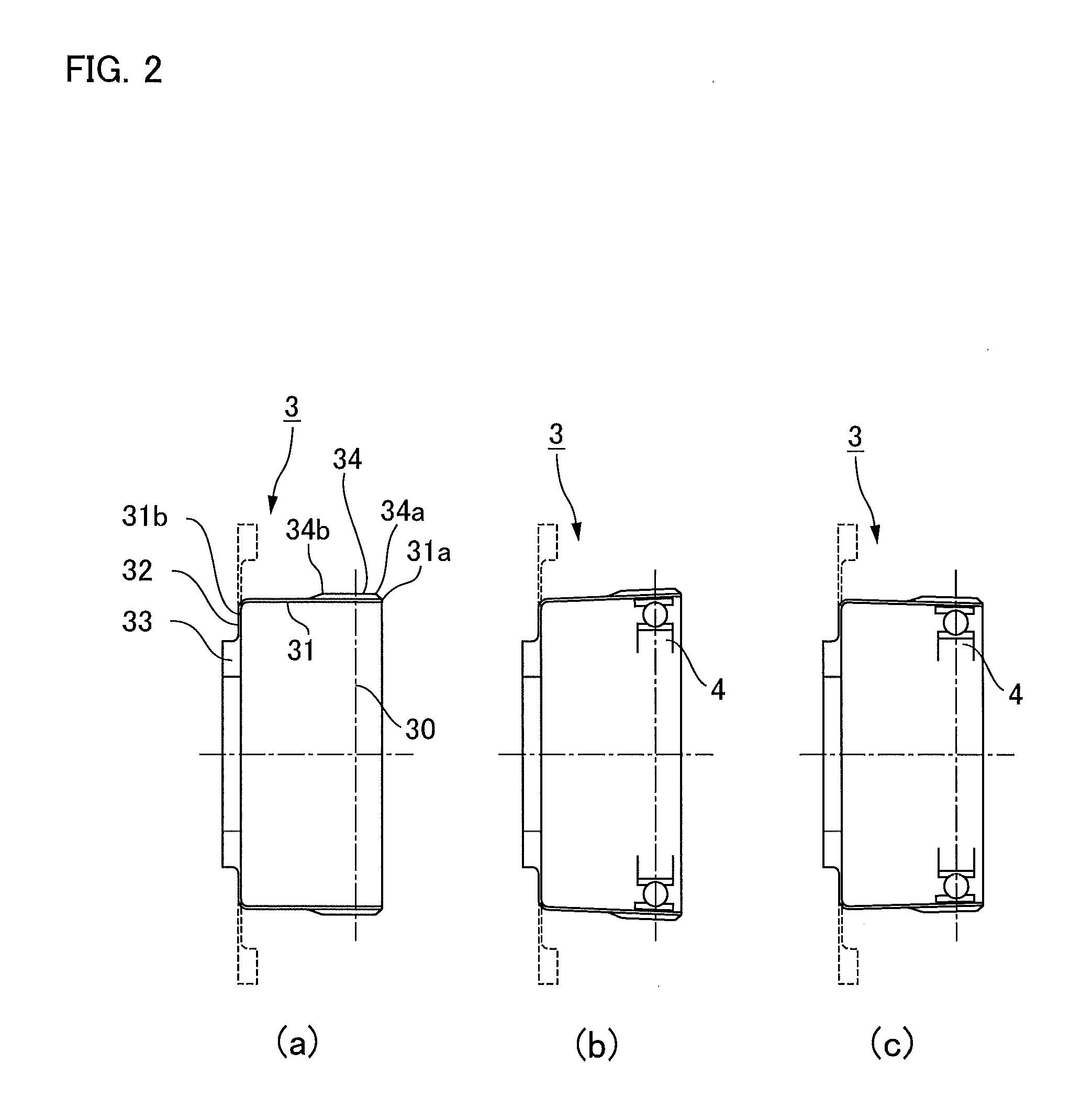

Screwdriver ratchet device with built-in ratchet and application thereof

ActiveCN101767319ASimple structureEffective engagementSpannersWrenchesEngineeringMechanical engineering

The invention relates to a structure of a ratchet screwdriver, in particular to a screwdriver ratchet device, a ratchet screwdriver handle and a ratchet screwdriver. The screwdriver ratchet device with the built-in ratchet comprises a ratchet pawl seat, a ratchet shaft, an outer clamping ring and two ratchet pawls; wherein the two sides of a central shaft hole of an annular body of the ratchet pawl seat are respectively provided with a ratchet pawl mounting port, the ratchet pawls are respectively arranged in the ratchet pawl mounting ports; the ratchet shaft, the outer clamping ring and the ratchet pawl seat into a whole are connected by the ratchet shaft; the ratchet pawls are of arch type and are provided with dummy clubs and ratchets, the ratchet shaft is provided with strip teeth, compression springs which can maintain the ratchets and the strip teeth engaged are respectively arranged in the ratchet mounting ports; the inner ring of the annular side wall of the outer clamping ring is provided with two notches, an inclined plane is arranged on the notches, and when the outer clamping ring is rotated towards one side, the inclined plane can force the dummy club on one ratchet pawl so that the ratchets on the ratchet pawl and the strip teeth can be disengaged. The invention simplifies the structure of the ratchet device, reduces the production cost, and has the advantage of long service life.

Owner:ZHEJIANG SANDING TOOLS +1

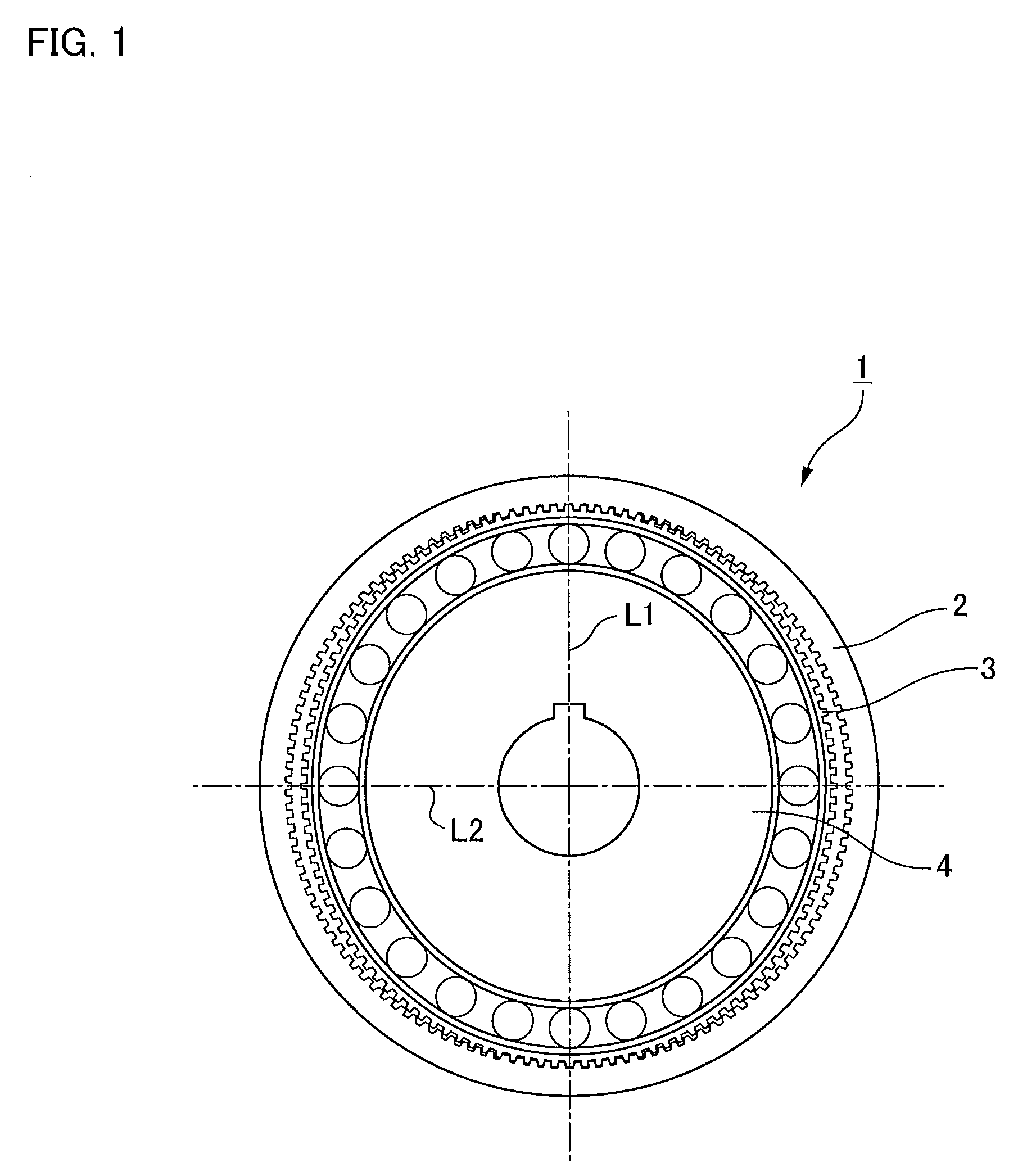

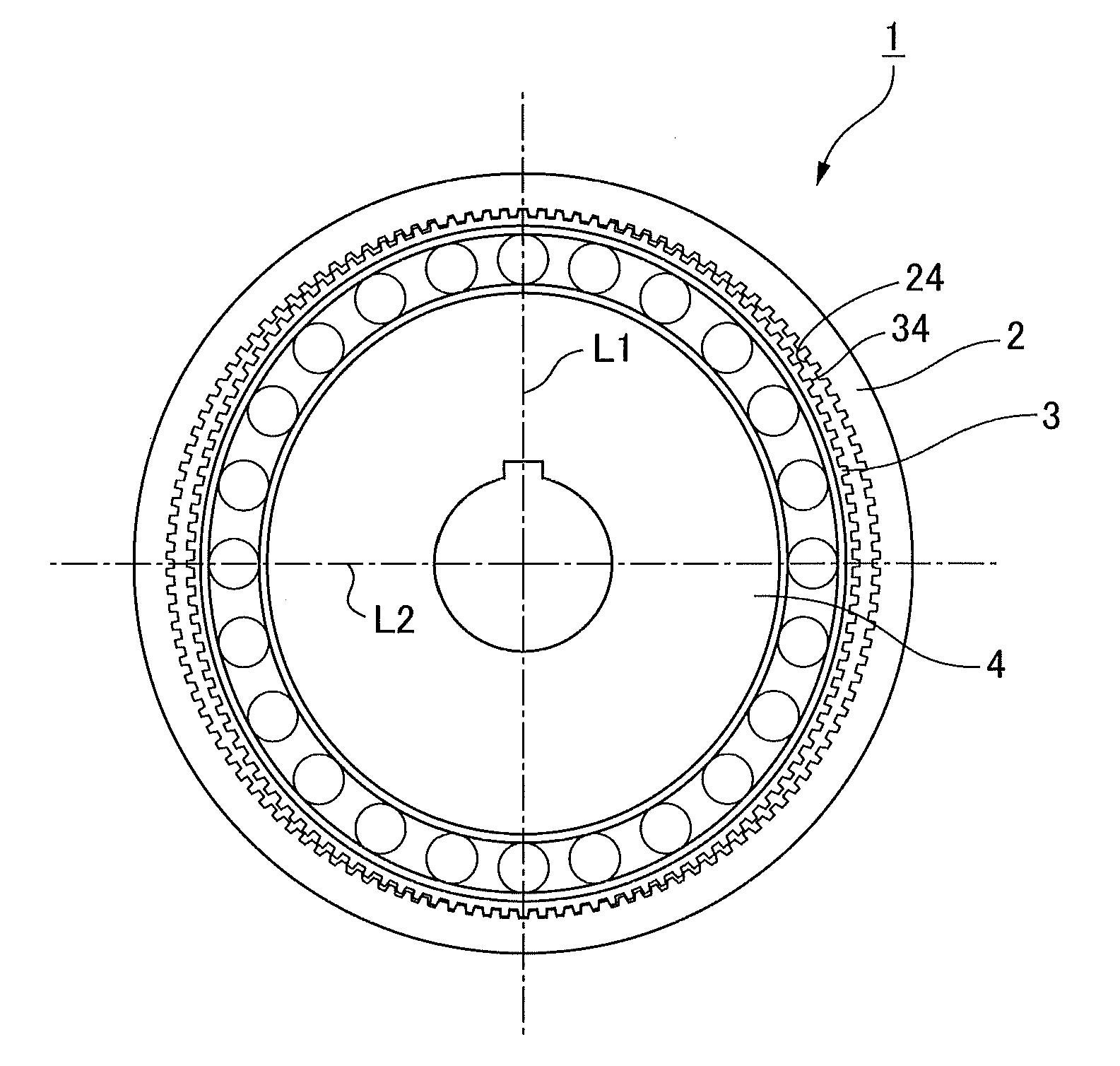

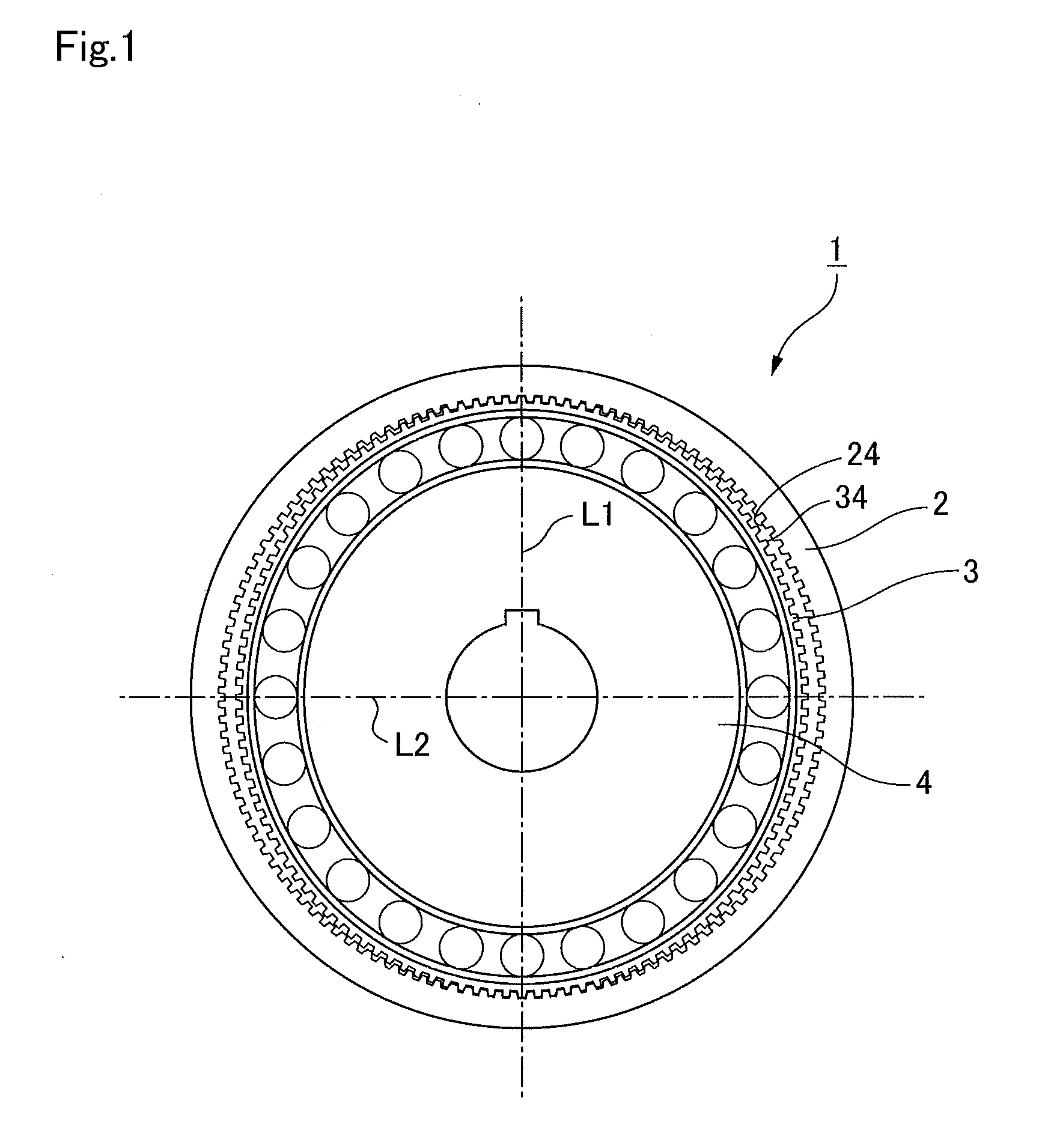

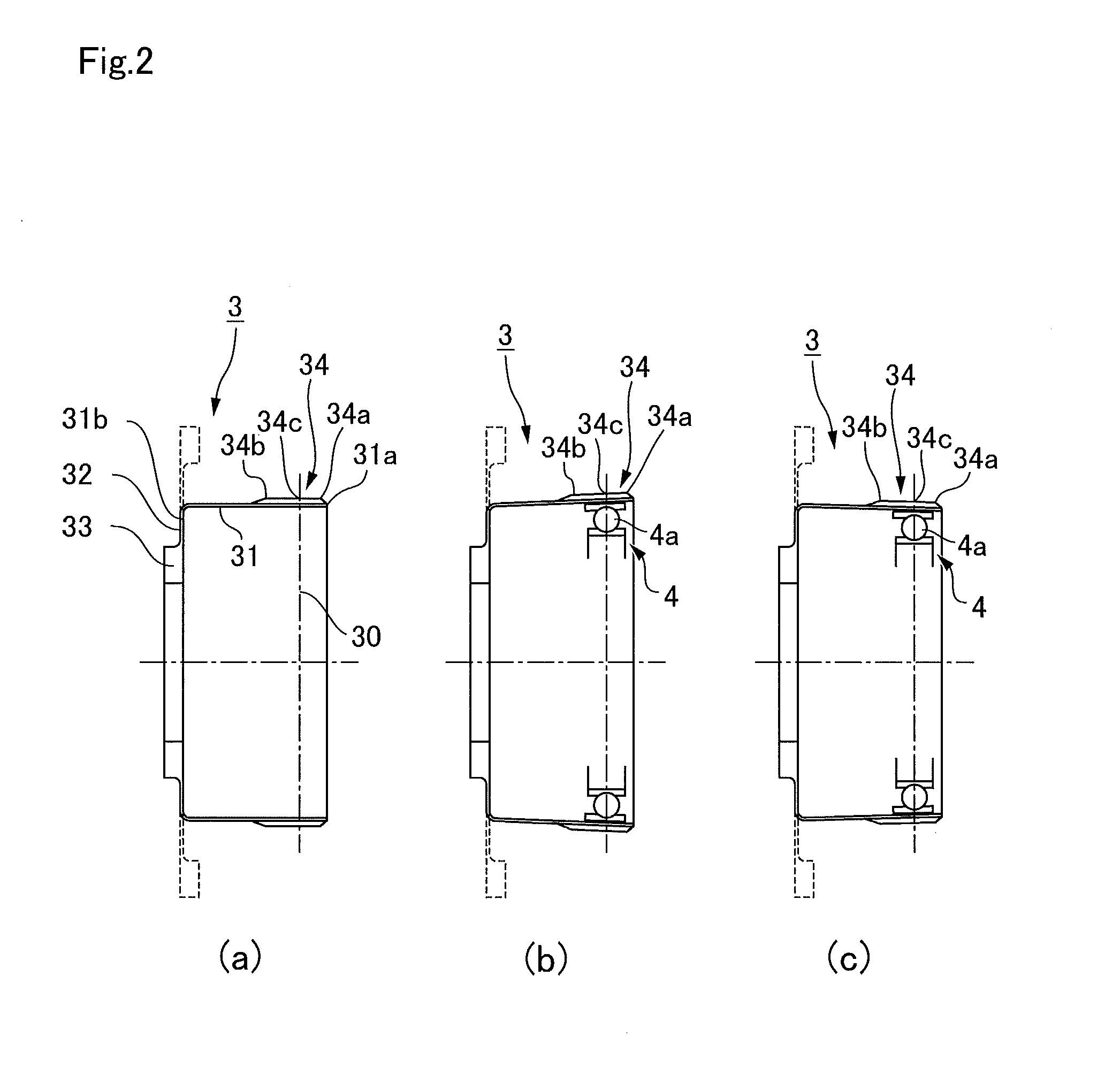

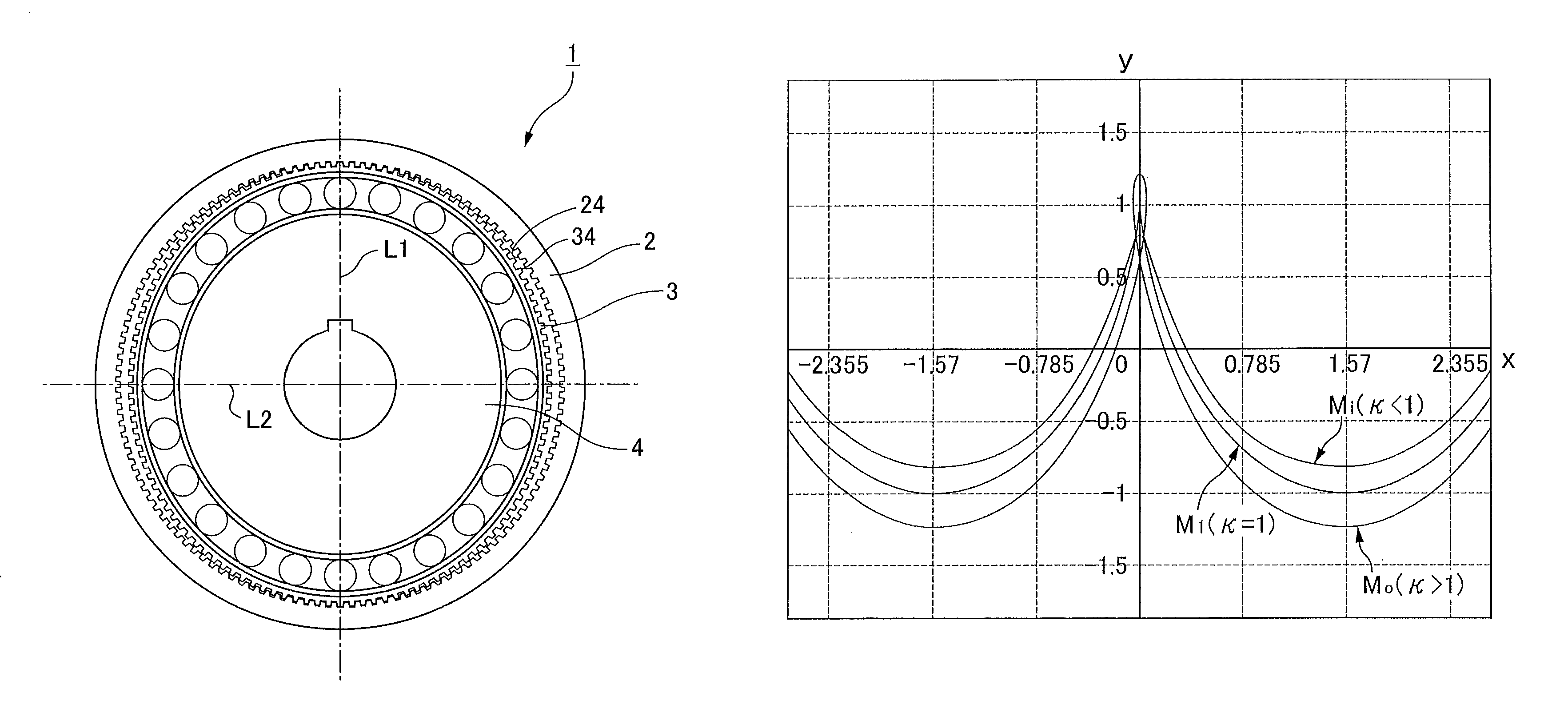

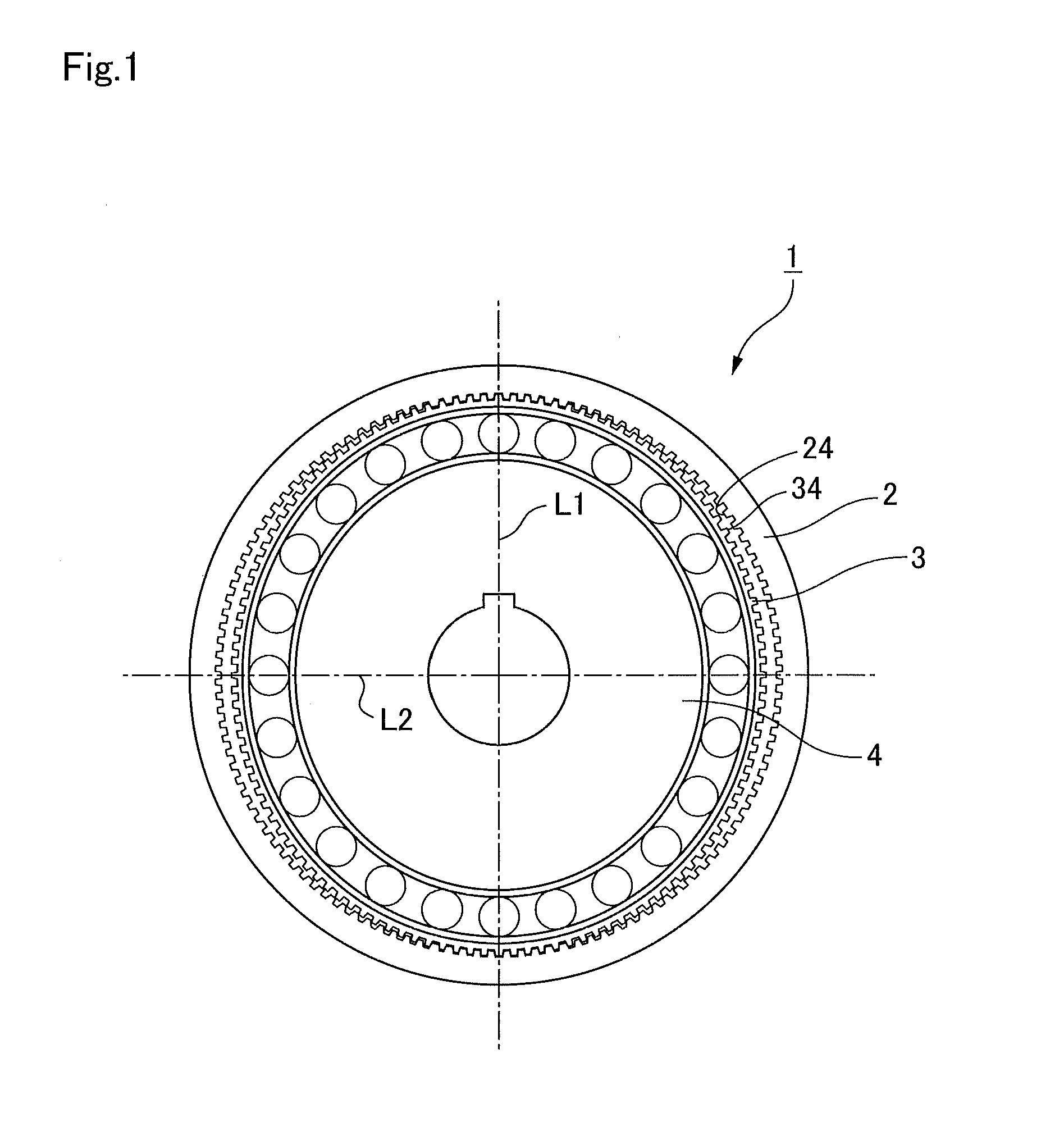

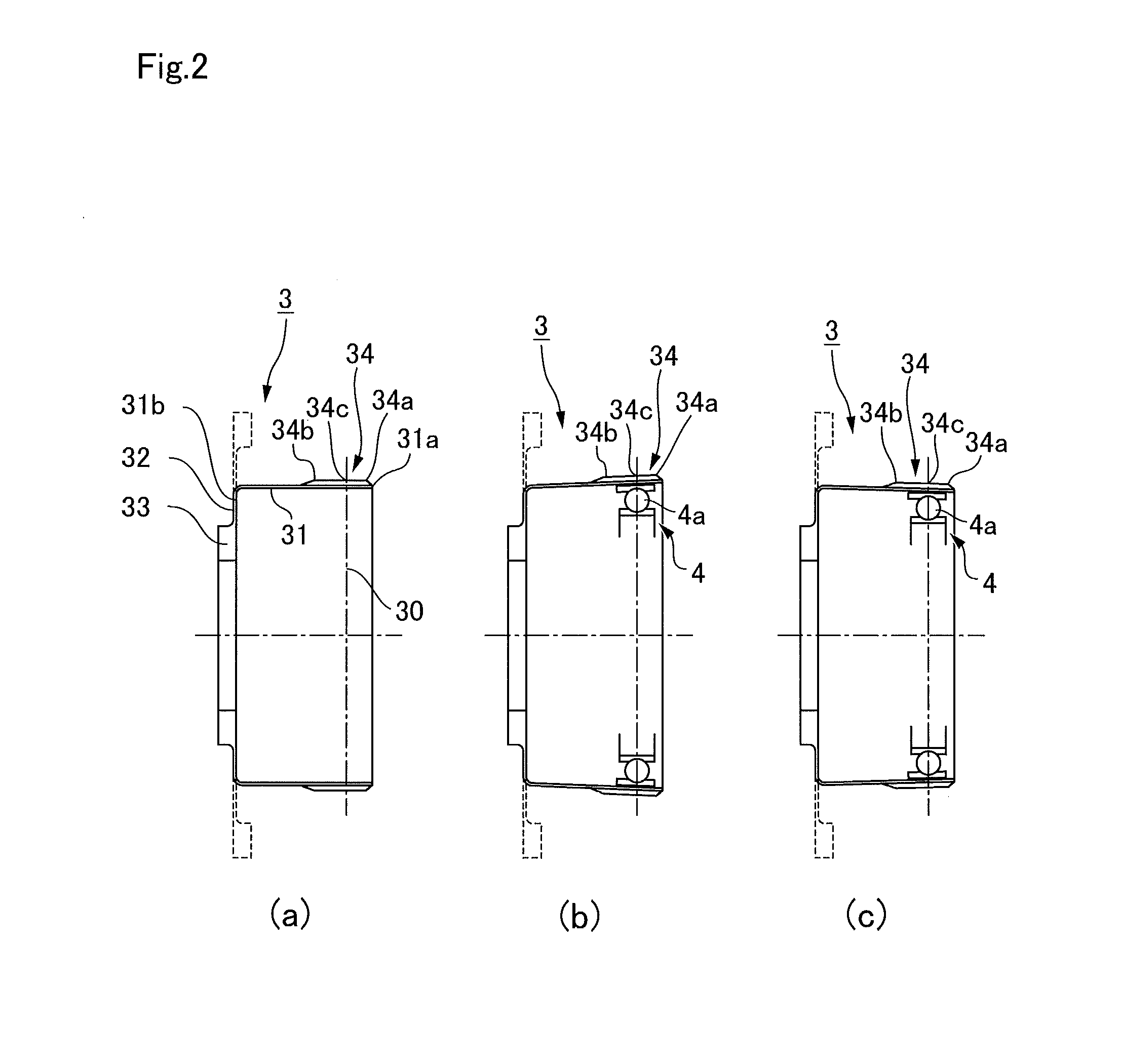

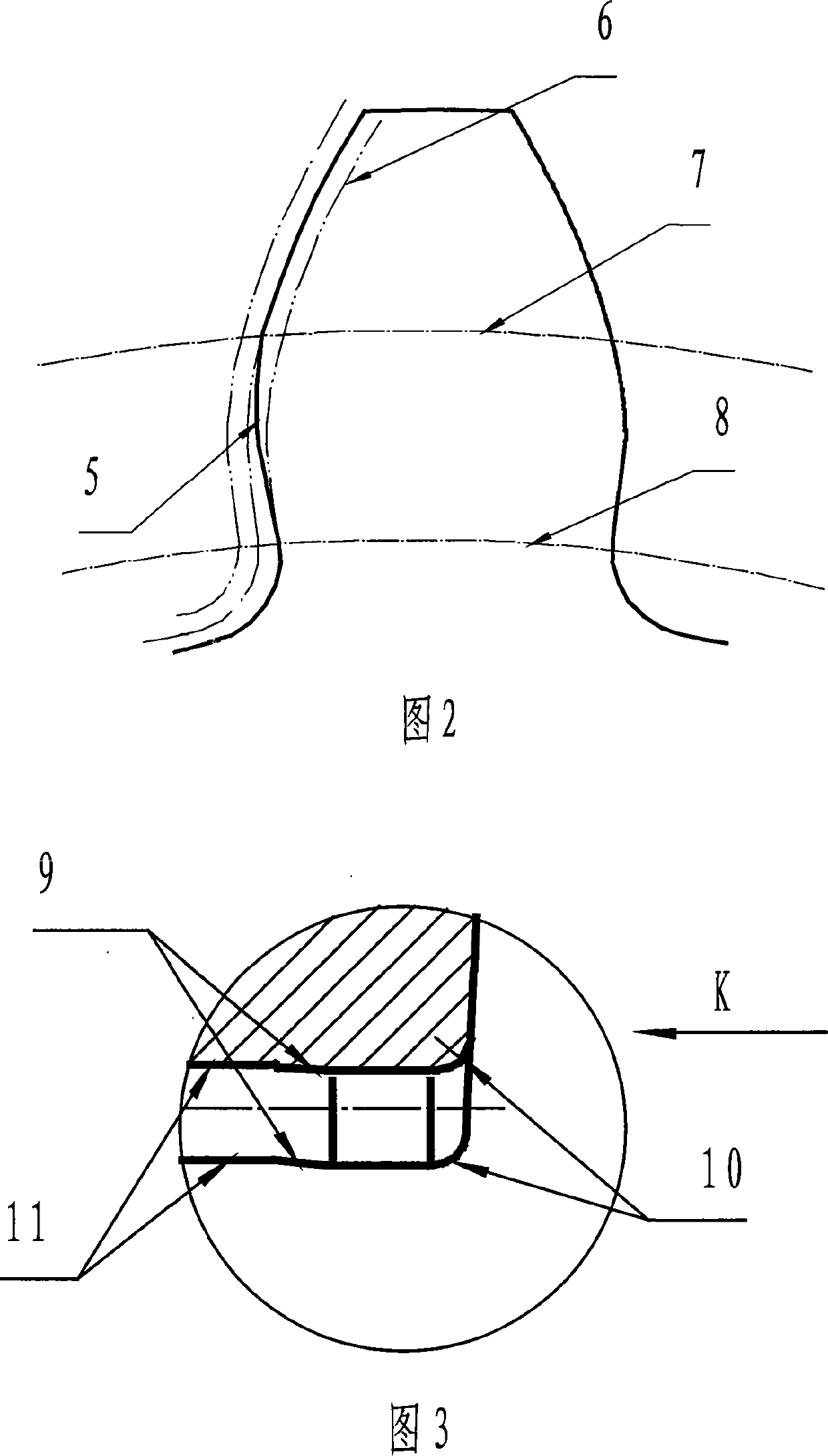

Wave gear device having three-dimensionally contactable shifted tooth profile

ActiveUS20110237382A1Reasonable meshing engagementEffective engagementToothed gearingsGearing elementsStrain wave gearingRack and pinion

Disclosed is a wave gear device (1) for setting the flexible state of the principal section (30) of a flexible external gear in a normal-deflection state (at a deflection coefficient κ=1). The moving locus of a tooth profile in the principal section (30) is determined by a rack approximation, and a similar curve (BC), which is obtained by similarly transforming a curve (AB) cut from that moving locus, is used to define the fundamental addendum shape of the tooth profile in the principal section. The portion of the tooth profile of the flexible external gear other than the principal section is shifted so that both each negative-deflection side moving locus (M3), which is obtained in each plane of rotation to deflect in a negative deflection state (at the deflection coefficient κ<1) closer to the diaphragm side than the principal section and each positive-deflection side moving locus (M2), which is obtained in each plane of rotation to deflect in a positive deflection state (at the deflection coefficient κ>1) closer to the front end opening side than the principal section, may become curves (M3a and M2a) to contact at the bottom (a point (P)) of a normal-deflection moving locus (M1). The partial meshing engagement can also be held at the section other than the principal section in the tooth trace direction, so that the load torque performance of the wave gear device can be advantageously improved.

Owner:HARMONIC DRIVE SYST IND CO LTD

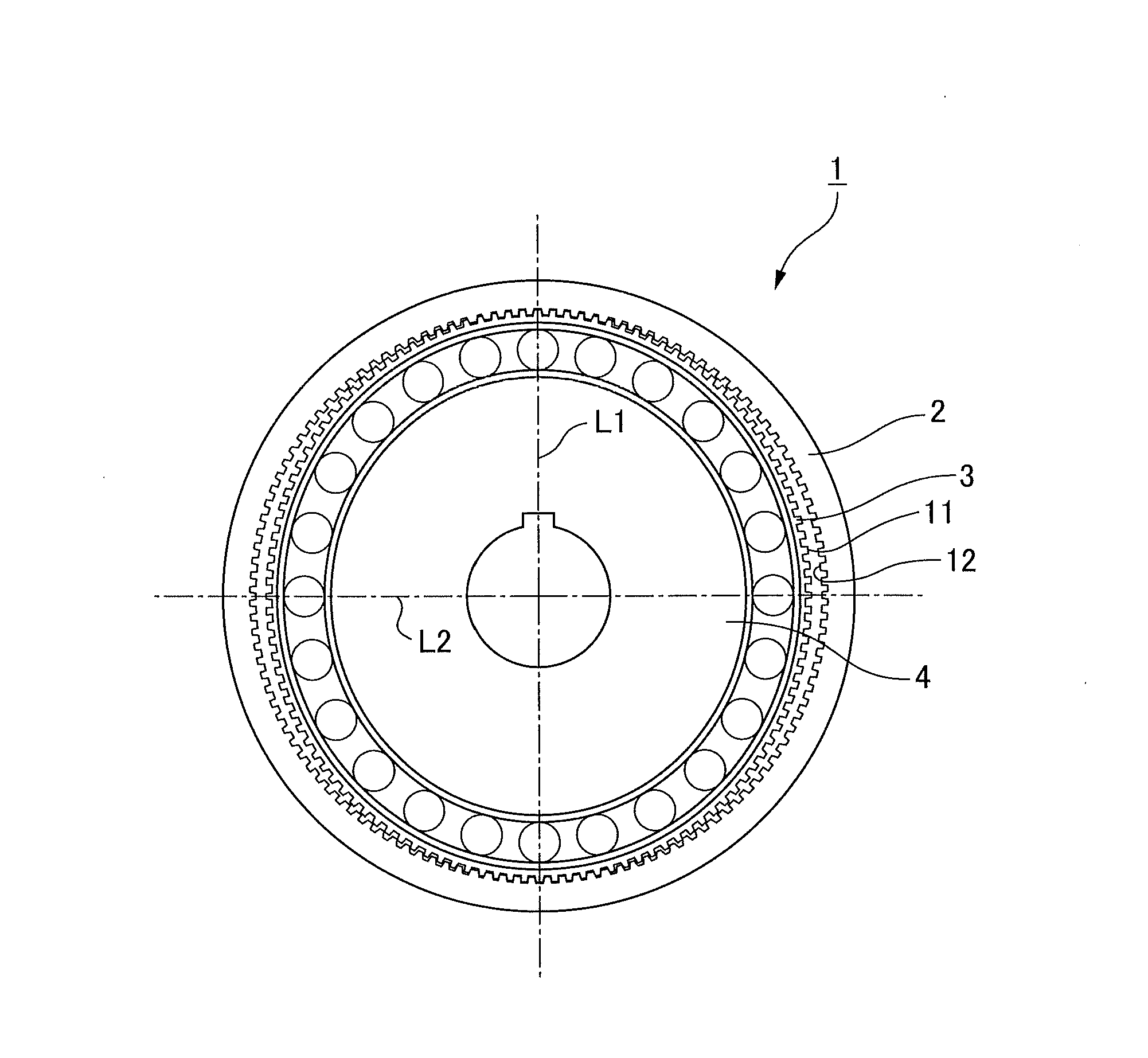

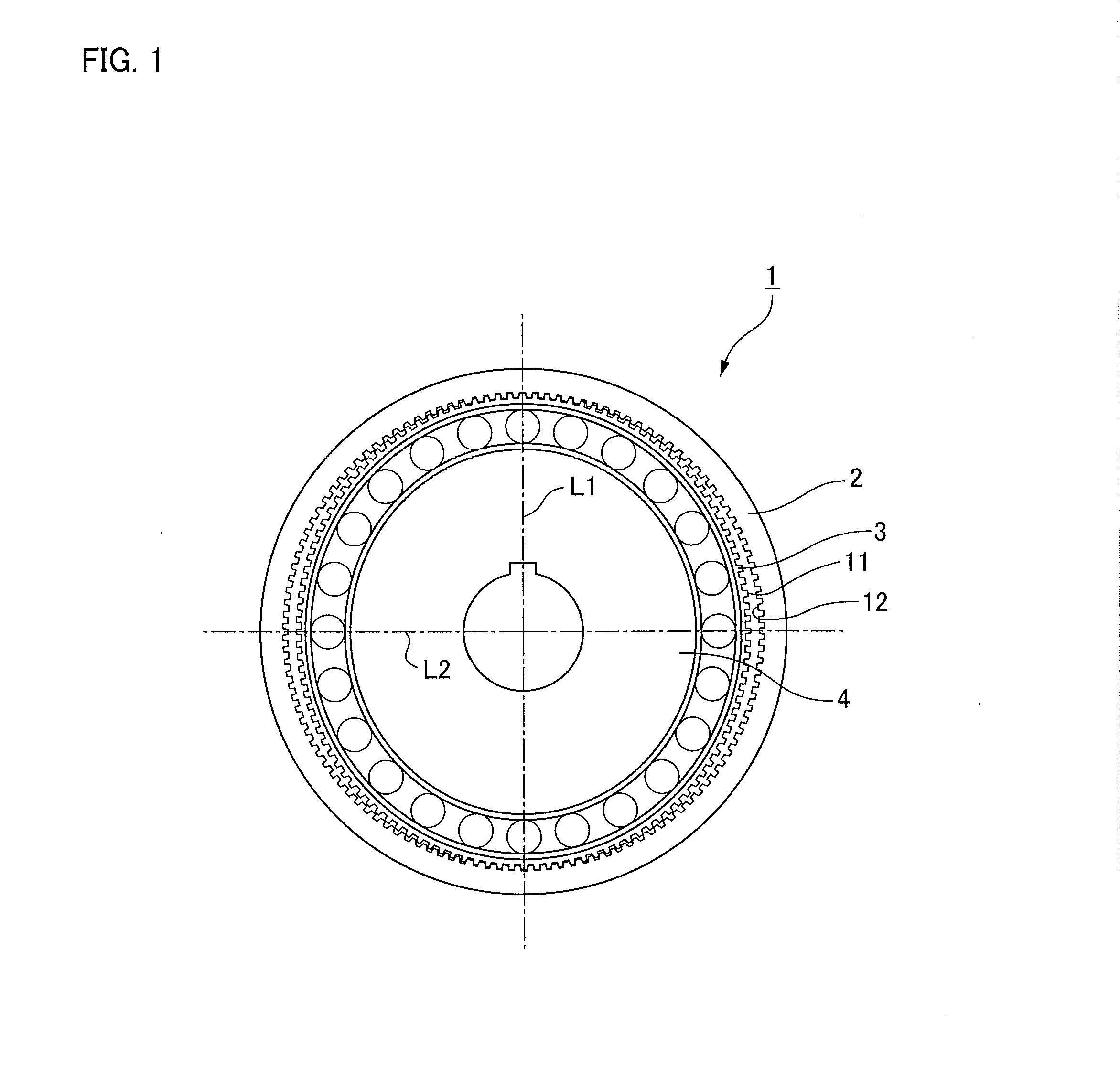

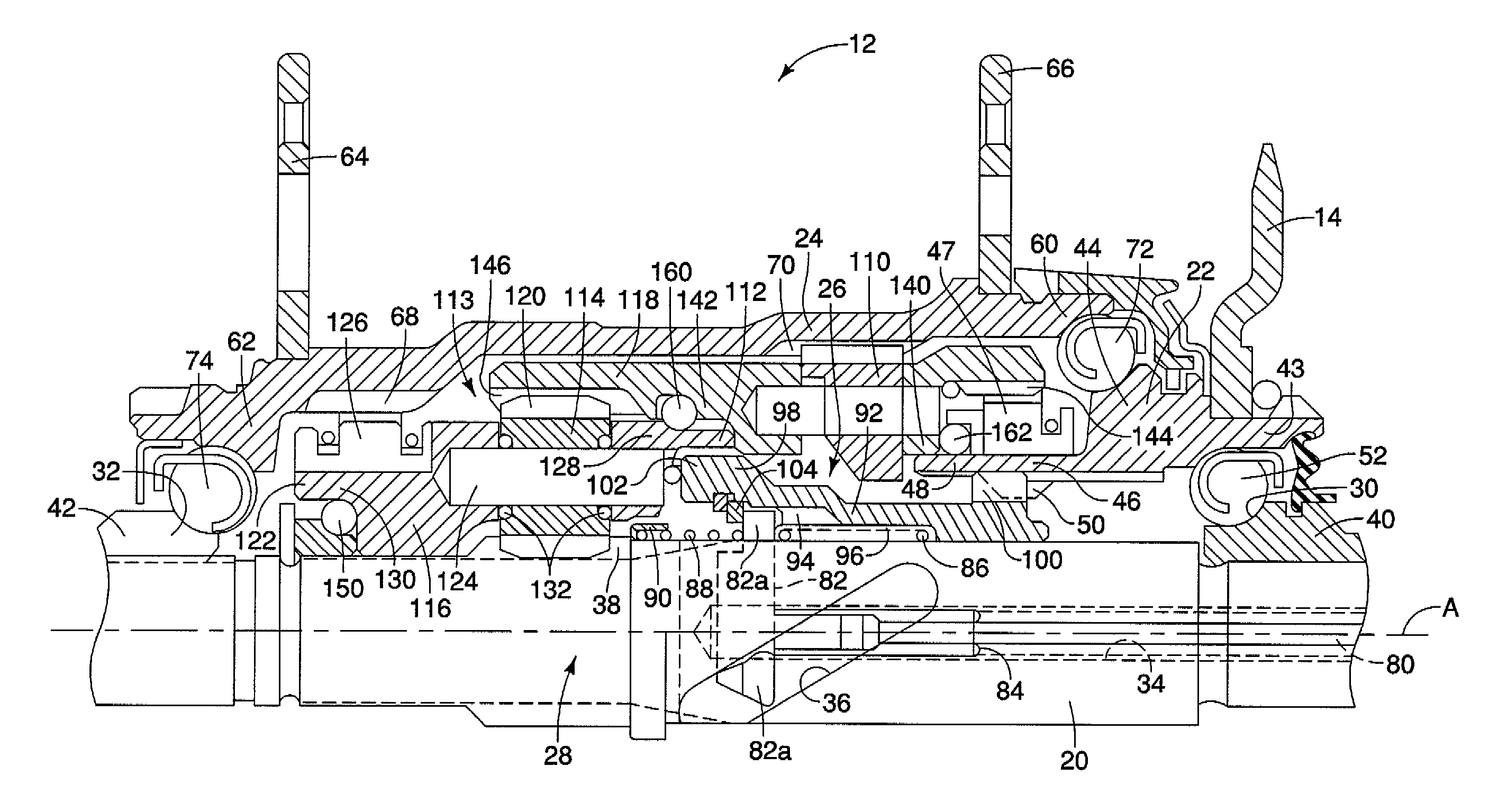

Wave gear device having three-dimensional continuous contact tooth profile

ActiveUS20120285283A1Effective engagementHigh torquePortable liftingGearing elementsEngineeringEntire tooth

In a wave gear device, similarity curve tooth profiles for defining the tooth-face tooth profile of each of a flexible externally toothed gear and a rigid internally toothed gear is determined from the movement trajectory, relative to a tooth of the rigid internally toothed gear, of a tooth of the flexible externally toothed gear at a main cross-section at which the deflection factor is κ=1. Tooth profile curves, which have been subjected to profile shifting corresponding to the difference between the deflection factor κo (>1) of the opening-end cross-section of the flexible externally toothed gear and the deflection factor κ of the main cross-section, are determined from the similarity curves; and the tooth profile curves are used to form the tooth-face tooth profile portions of the two gears. High-gear-tooth compound tooth profiles, defined from the tooth-face tooth profile portions, straight-line tooth profile portions continuing from the tooth-face tooth profile portions, and appropriate tooth-flank tooth profile portions for avoiding interference are used as tooth profiles of the internal teeth and the external teeth. Also, taking coning of the flexible externally toothed gear into account, negative profile shifting is applied from an opening-end cross-section to an inner-end cross-section of the flexible externally toothed gear, and rational meshing between the two gears is obtained along the entire tooth trace.

Owner:HARMONIC DRIVE SYST IND CO LTD

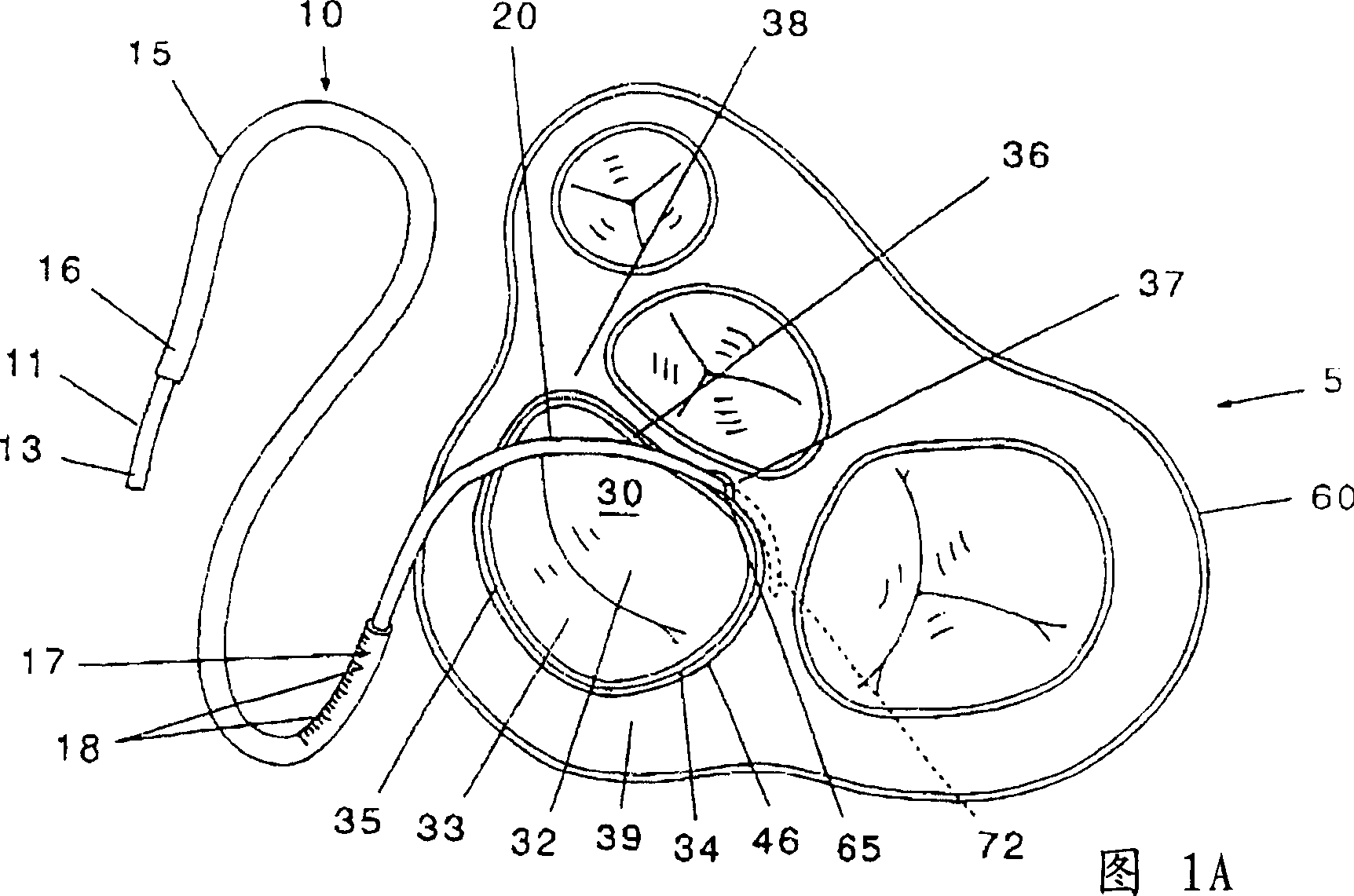

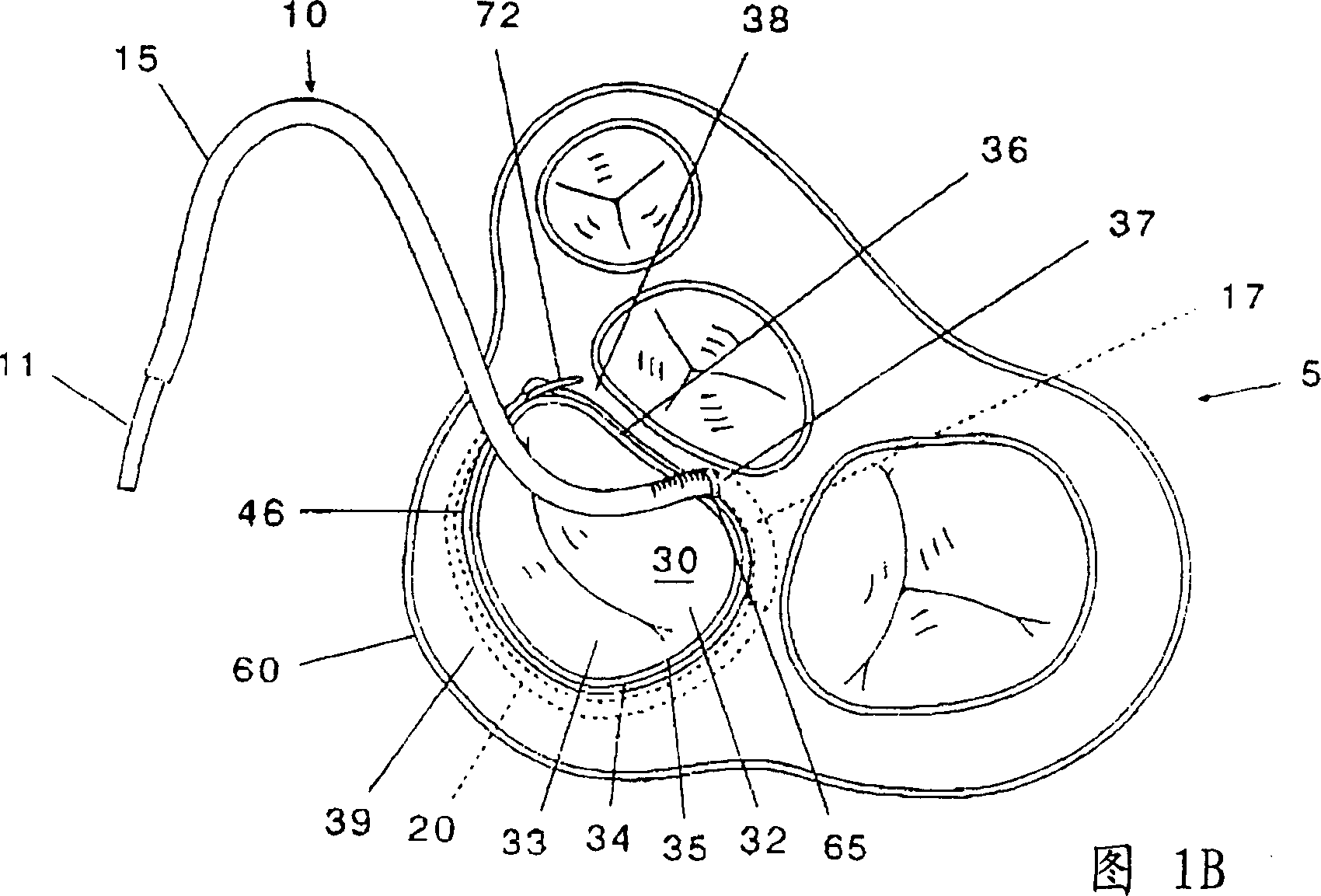

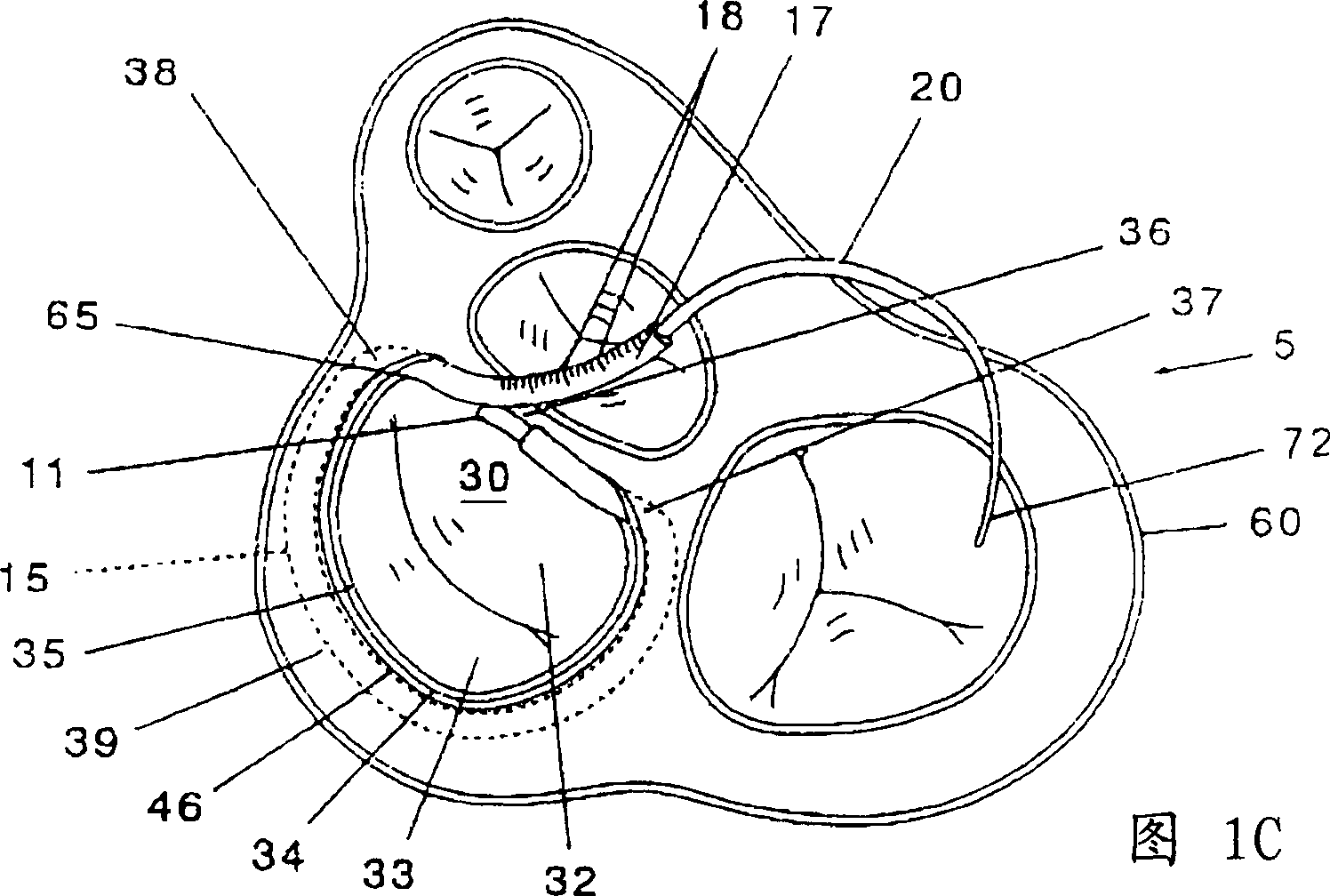

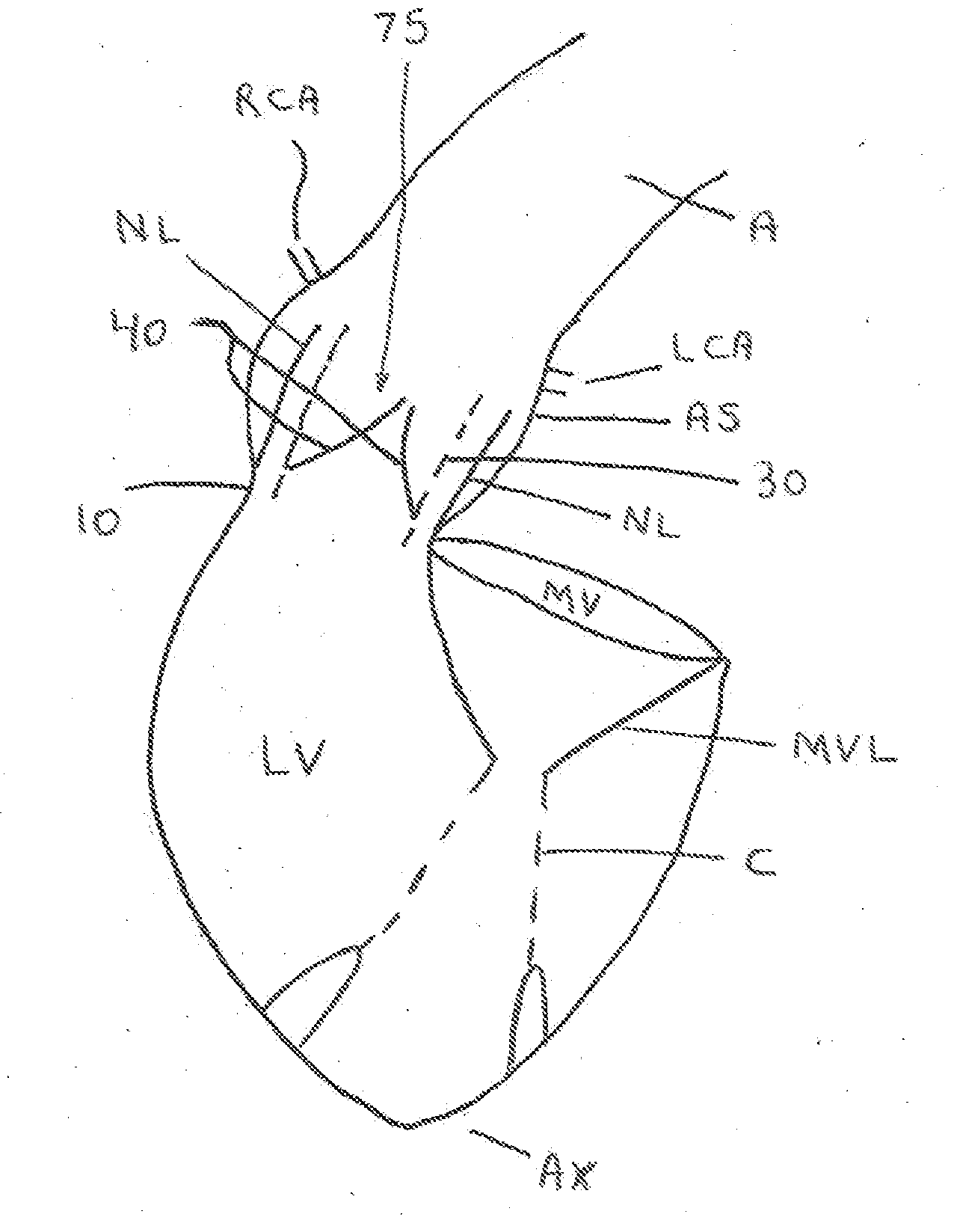

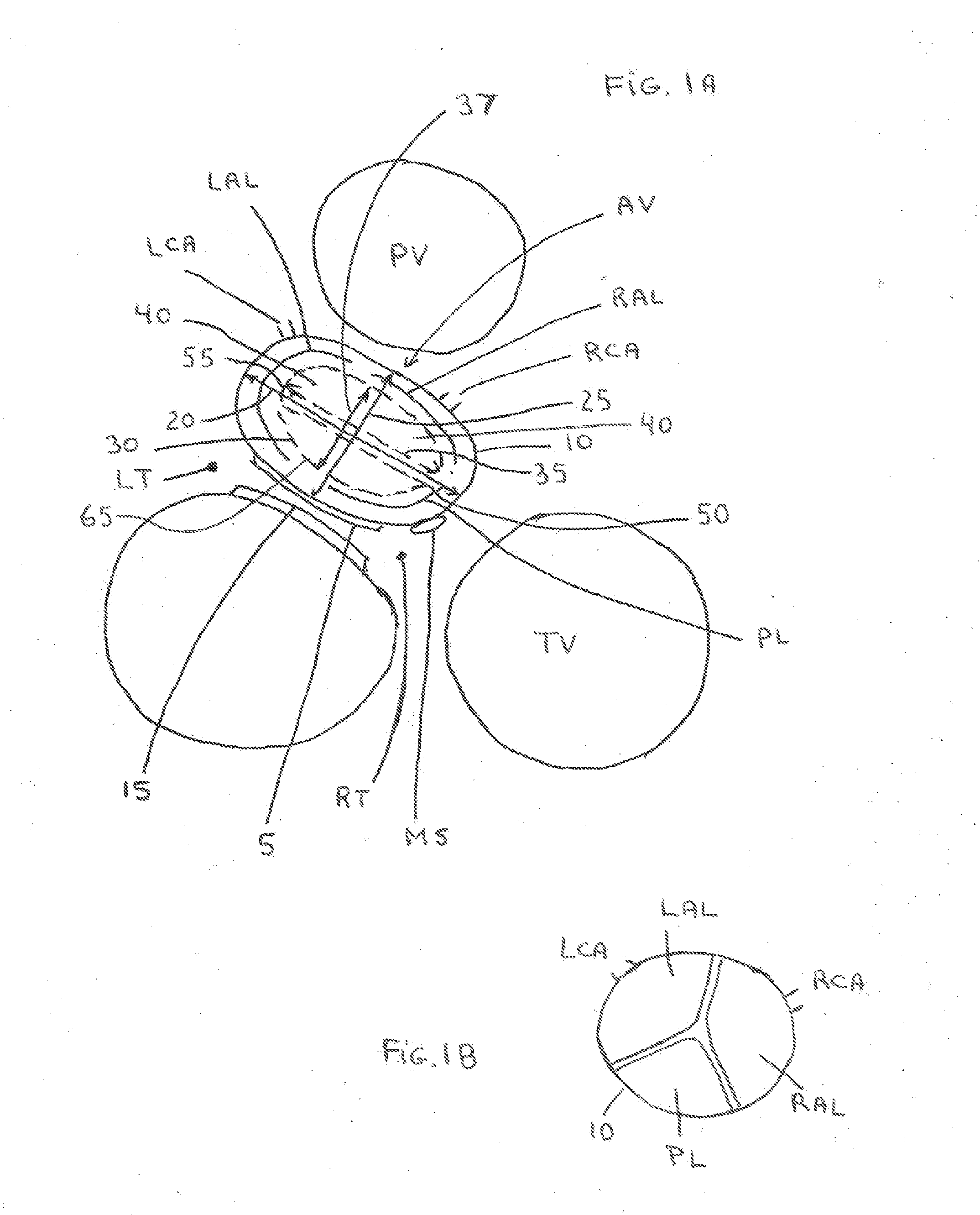

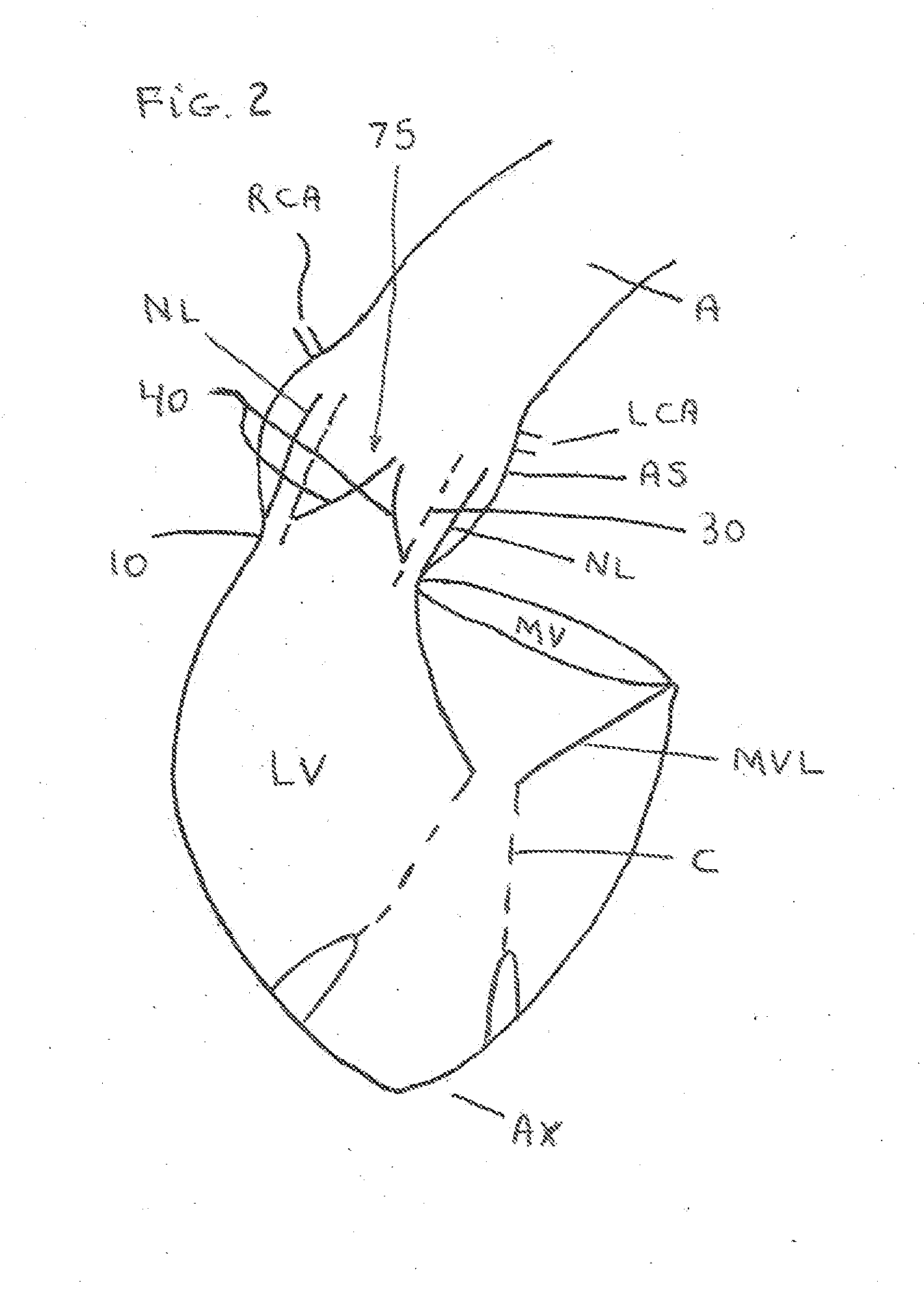

Mitral valve annuloplasty ring and method

InactiveCN1391453APrevent loss of flexibilityGuaranteed flexibilitySurgical needlesAnnuloplasty ringsAnnuloplasty ringsCardiology

A mitral valve annuloplasty ring and method for implanting a mitral valve annuloplasty ring to treat mitral insufficiency by reestablishing the normal shape and contour of the mitral valve annulus. The annuloplasty ring is flexible and can be readily adjusted to different sizes and shapes. The method substantially eliminates scarring subsequent to the annuloplasty procedure to maintain flexibility of the ring and the annulus indefinitely.

Owner:卡迪亚克·康赛普茨公司

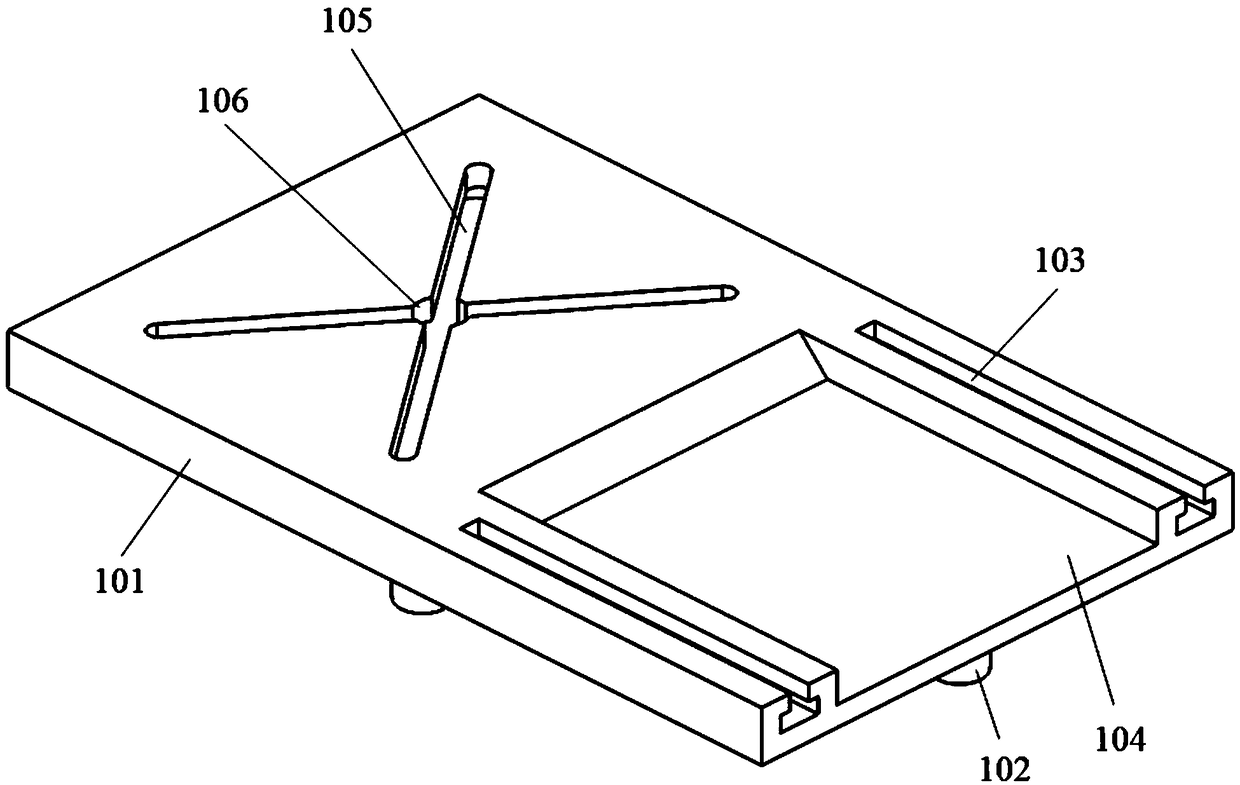

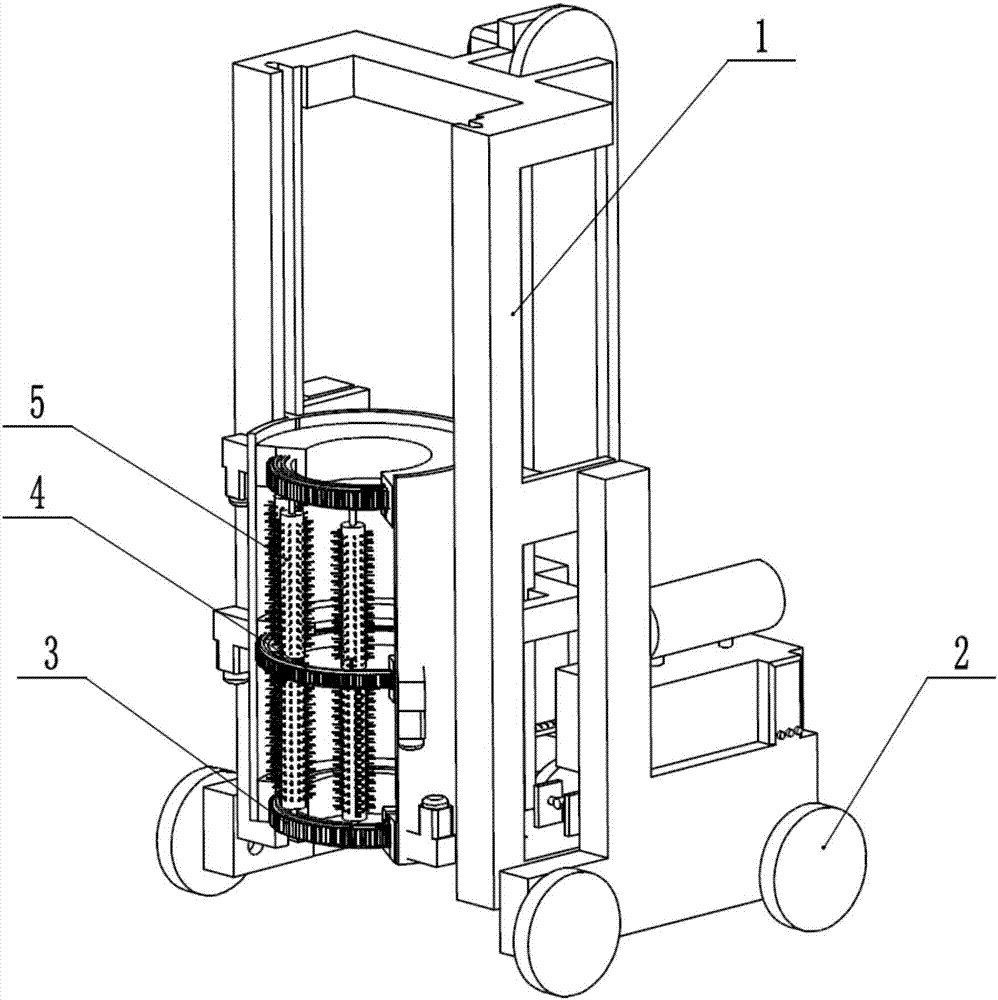

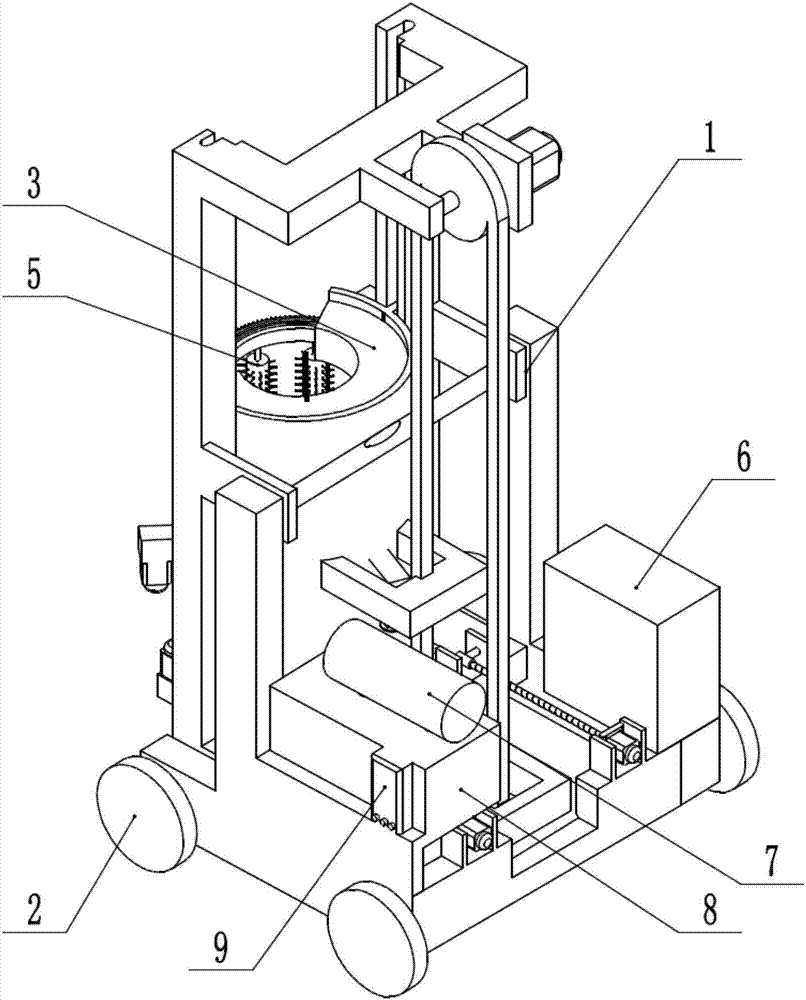

Trunk liquid masking device

ActiveCN107150007AAchieve angle adjustmentEasy to moveLiquid surface applicatorsCoatingsEngineeringChassis

The invention discloses a trunk liquid masking device and belongs to the field of environmental sanitary greening equipment. The trunk liquid masking device is composed of a positioning mechanism, car wheels, two guiding mechanisms, a rotary mechanism, a liquid masking mechanism, a storage battery, a conveying pump, a liquid barrel and a controller. The car wheels are arranged at the lower end of the positioning mechanism. The guiding mechanisms are arranged on the left side of the positioning mechanism. The rotary mechanism is arranged in the middle position between the two guiding mechanisms. The two guiding mechanisms are in mirror symmetry about the rotary mechanism. The liquid masking mechanism is fixedly connected with the rotary mechanism. The storage battery is arranged on the upper right side of the positioning mechanism. The liquid barrel is arranged on the lower right side of the positioning mechanism. The conveying pump is arranged at the upper end of the liquid barrel. The controller is arranged on the side face of the liquid barrel. The controller is electrically connected with the positioning mechanism, the guiding mechanisms, the rotary mechanism, the storage battery and the conveying pump. The angle between a vertical frame and a chassis is adjusted through an adjusting mechanism of the positioning mechanism, and stable rotation of the liquid masking mechanism is achieved through cooperation of the rotary mechanism and the guiding mechanisms.

Owner:中资蓝天生态环境科技有限公司

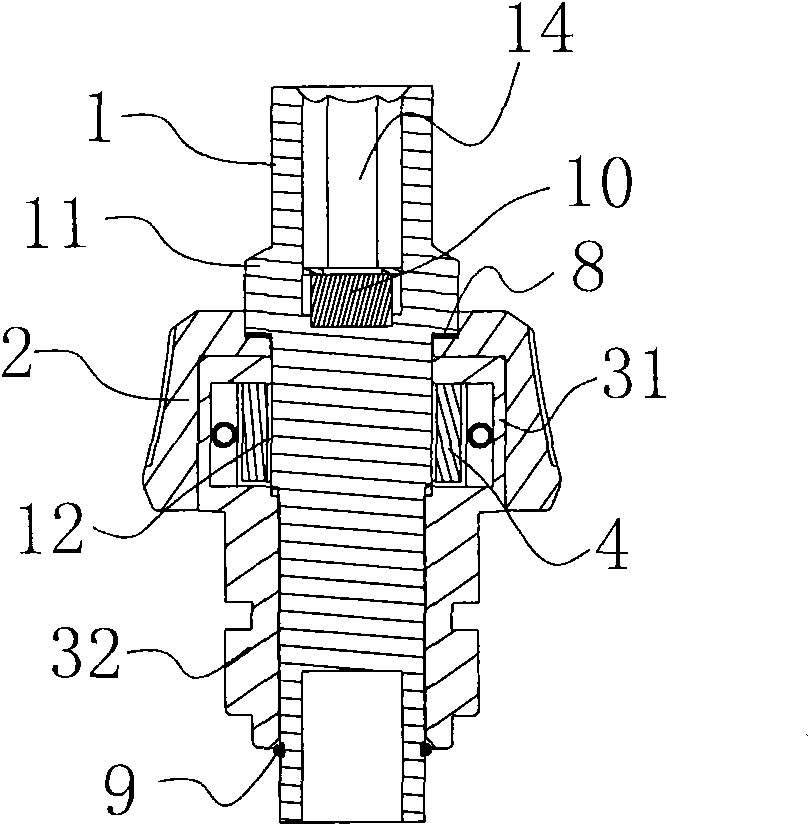

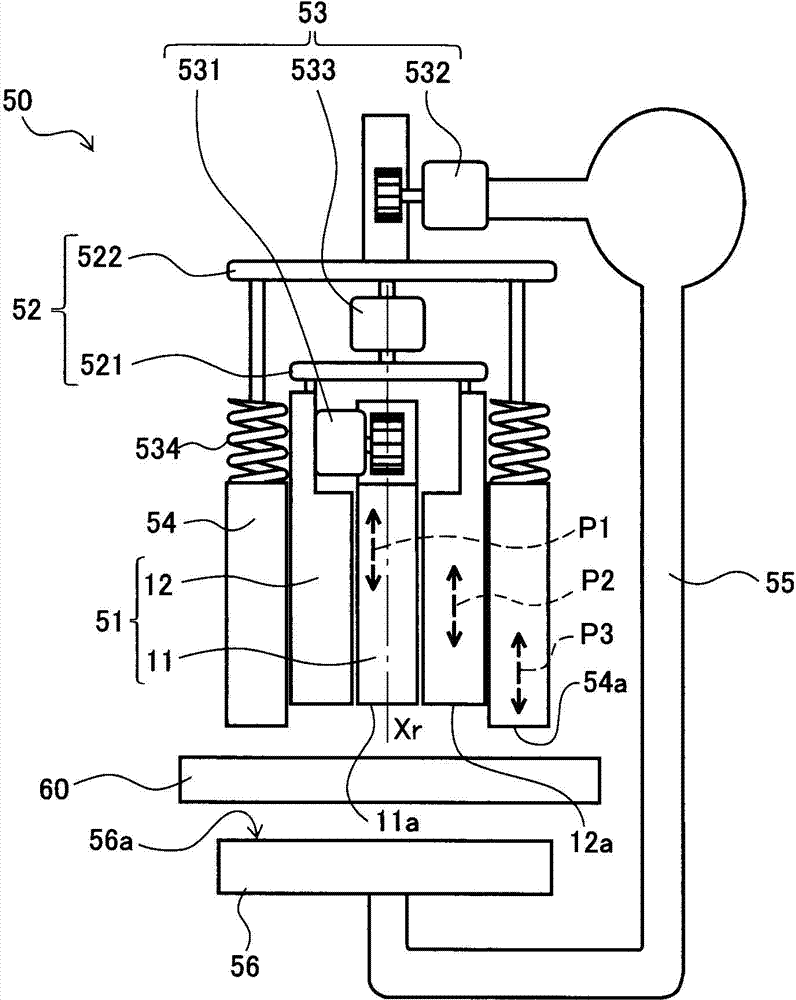

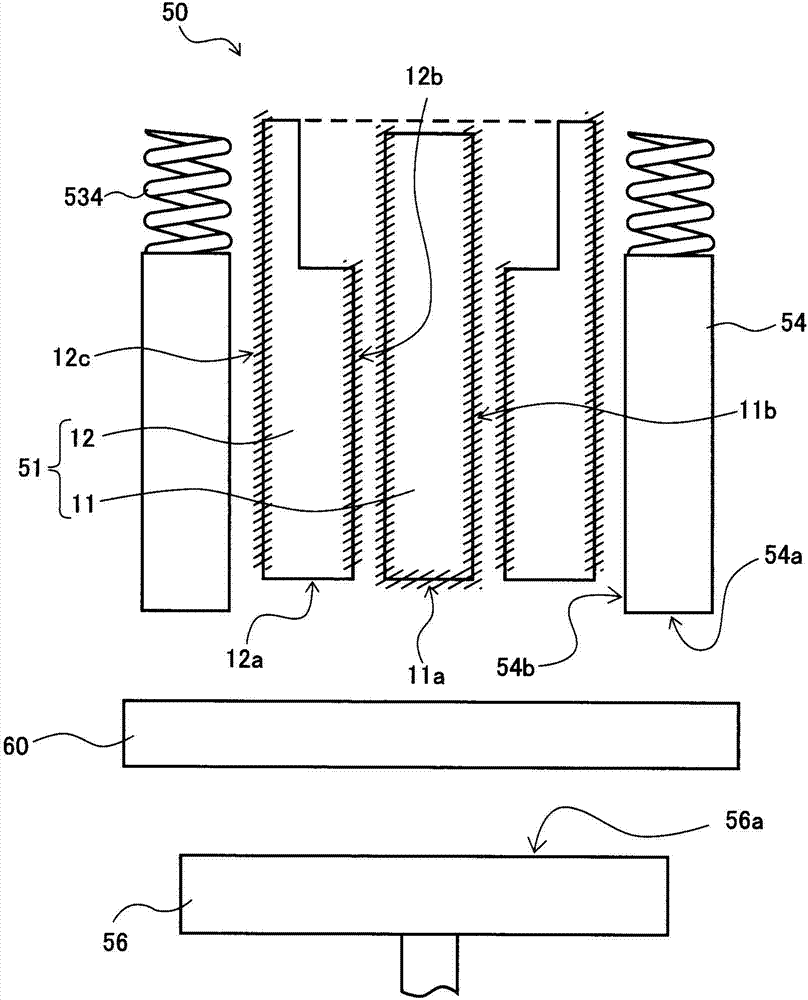

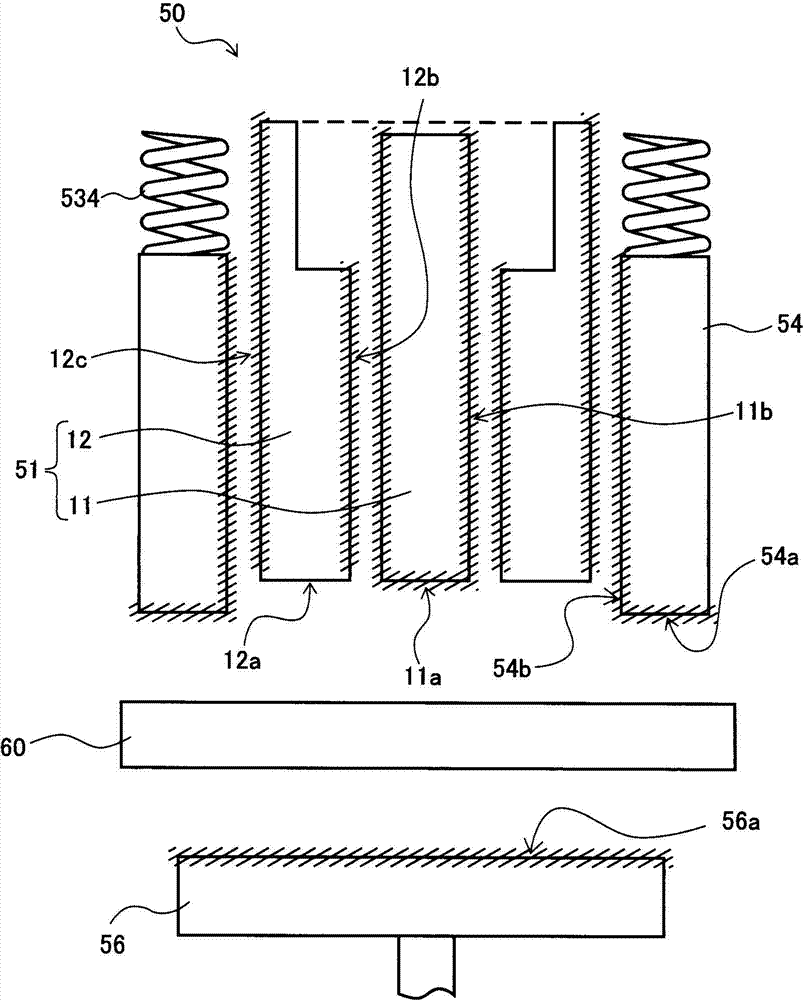

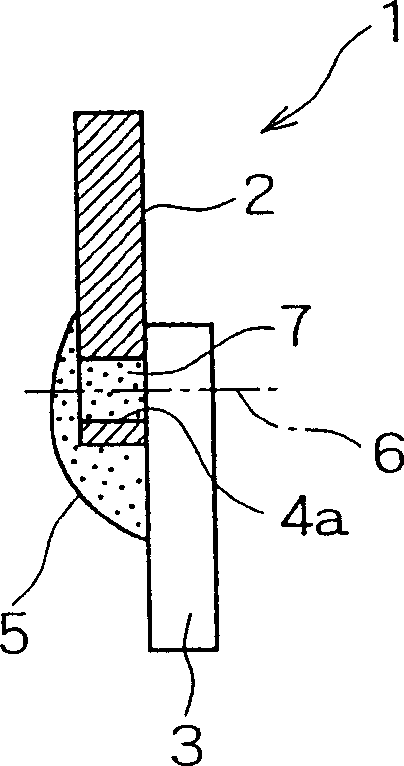

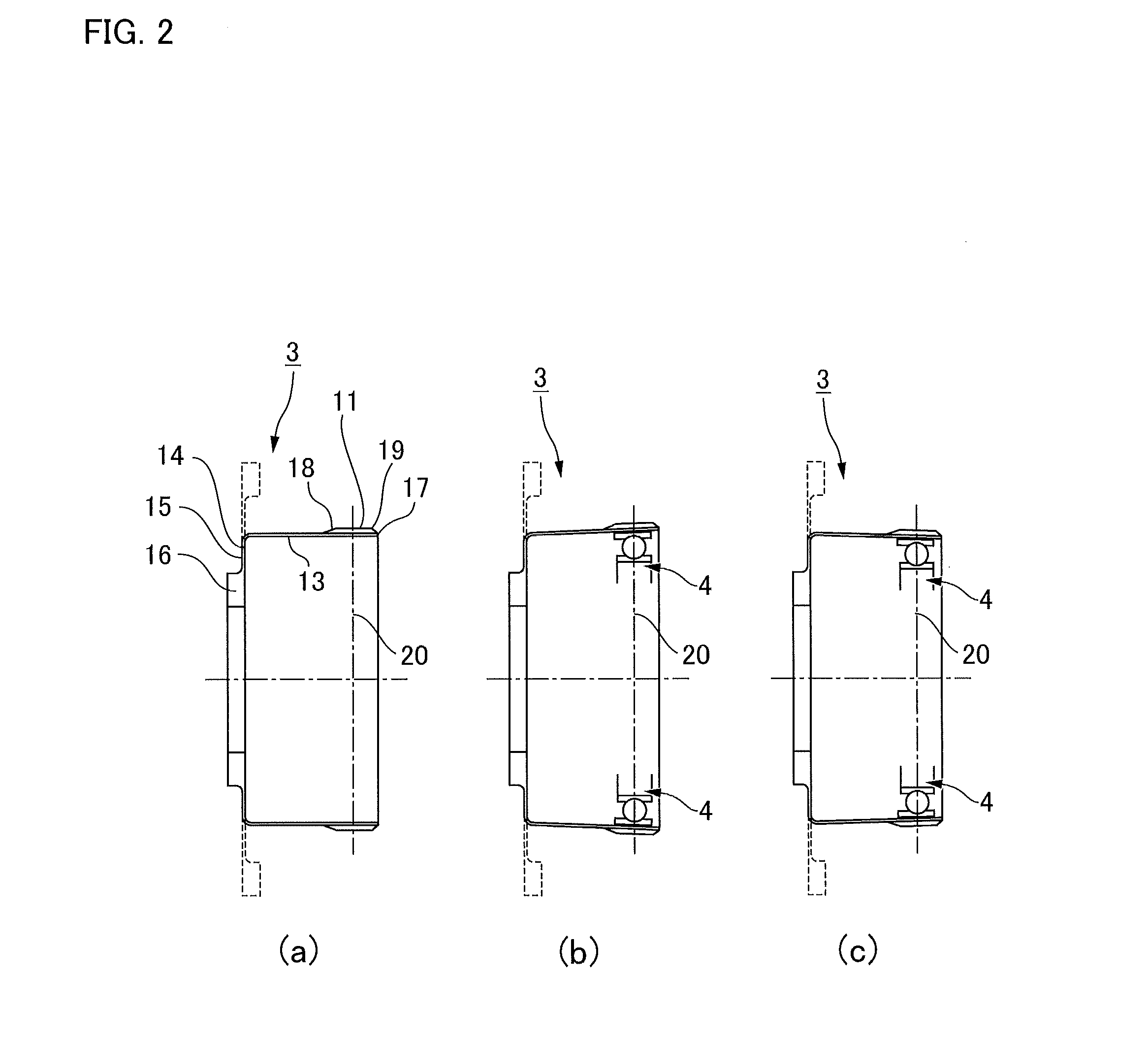

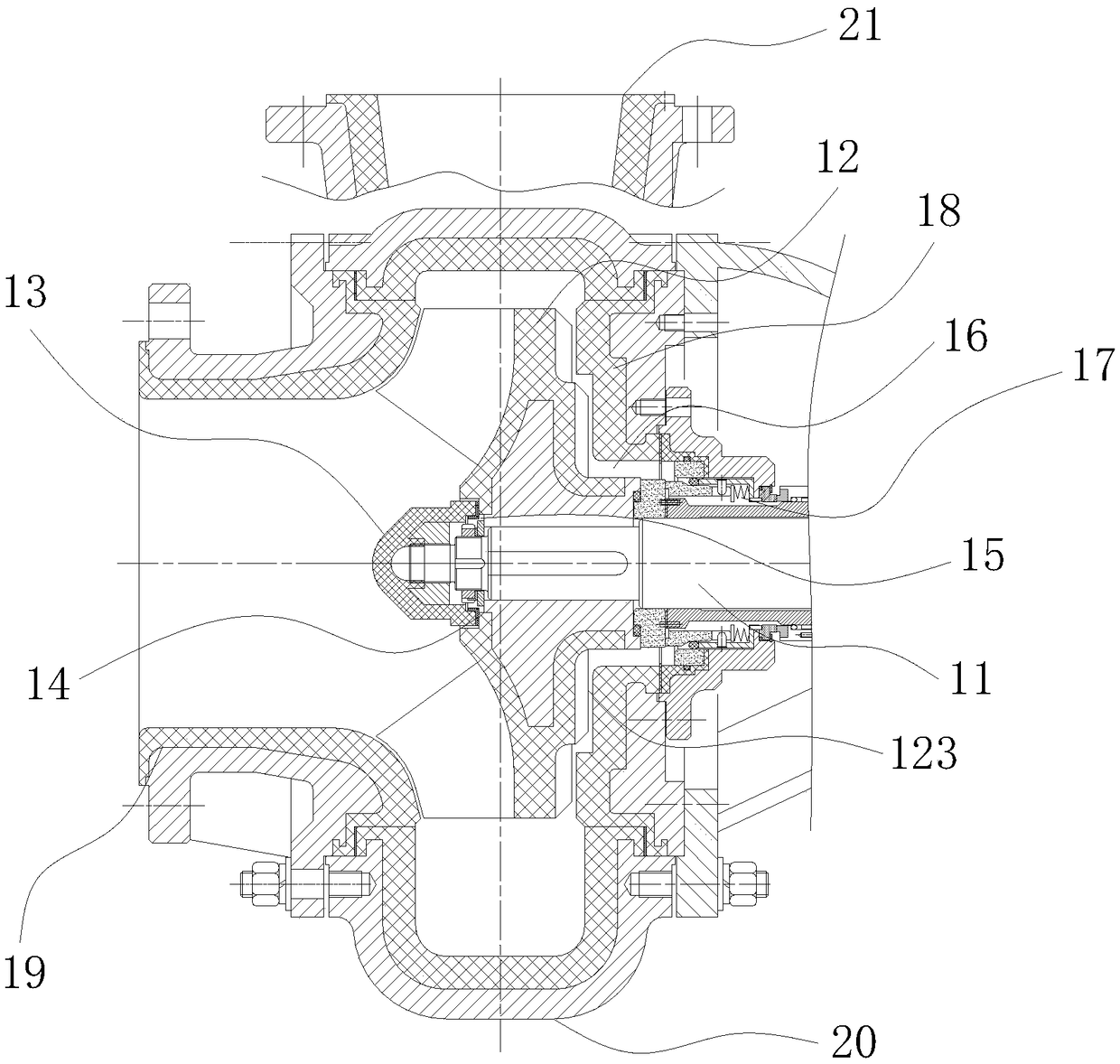

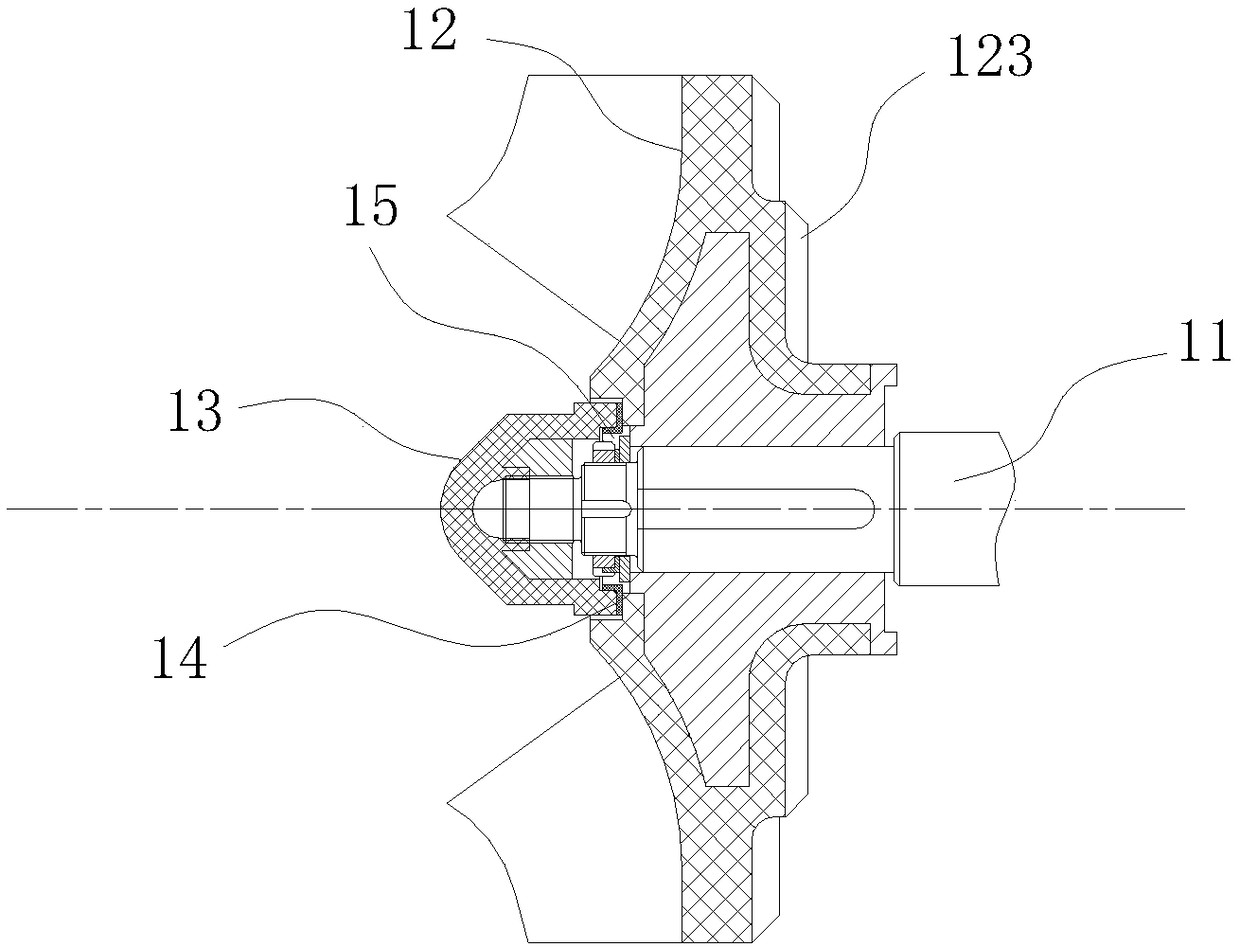

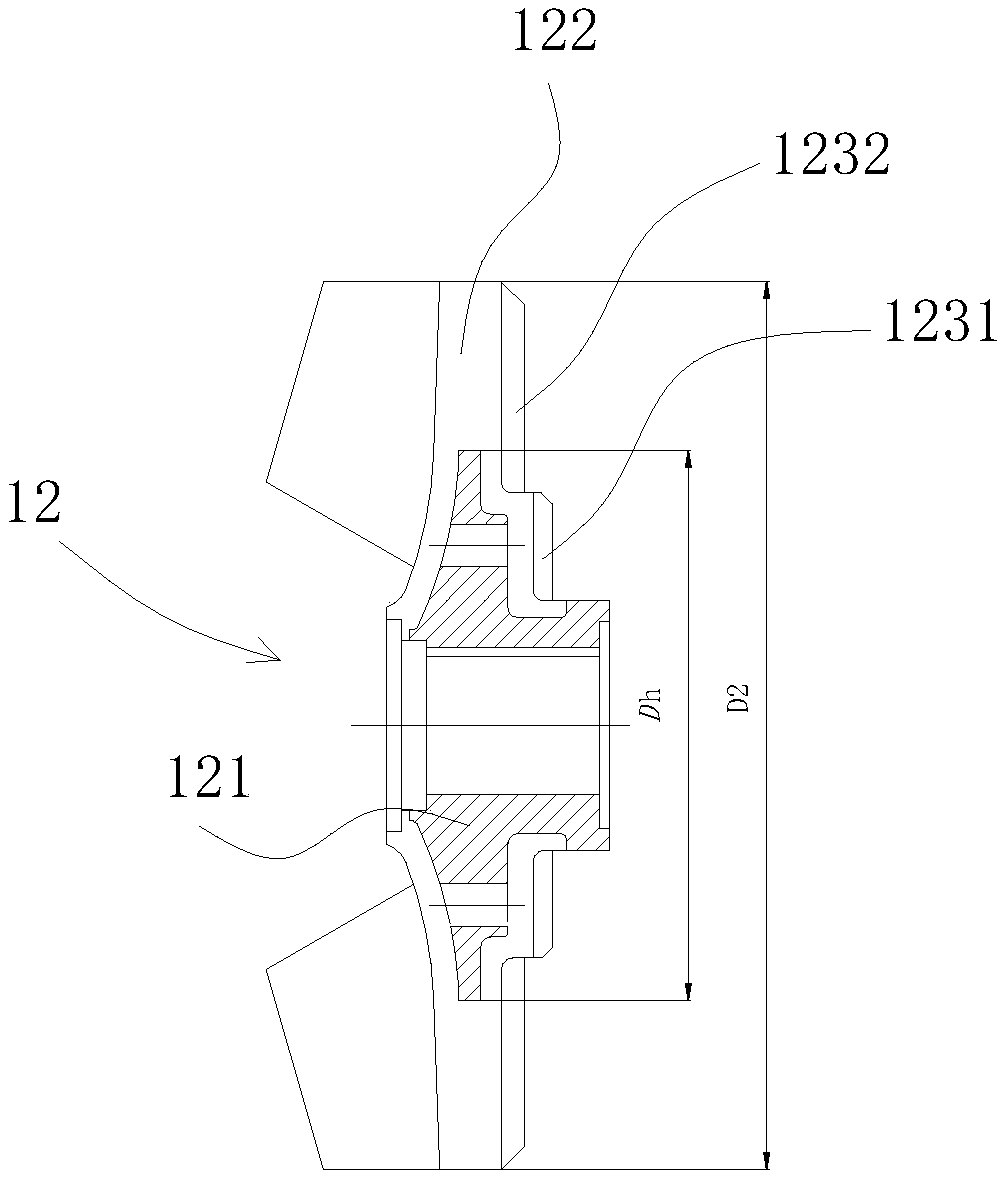

Welding tool used for double-acting type friction stir welding or double-acting type friction stir spot welding, and welding device using same

ActiveCN104507631AImprove qualityEffective engagementNon-electric welding apparatusEngineeringSpot welding

This double-acting type friction stir welding tool is configured from at least a columnar pin member (11), and a shoulder member (12) which has a cylindrical shape located outside the pin member (11) and rotates around the same axis as the pin member (11). In the pin member (11), a contact surface (11a) with an object to be welded (60) and an outer peripheral surface (11b) have non-affinity for the object to be welded (60). In the shoulder member (12), an inner peripheral surface (12b) facing the pin member (11) and an outer peripheral surface (12c) have non-affinity for the object to be welded (60), and only a contact surface (12a) with the object to be welded (60) has affinity for the object to be welded (60). Further, the clearance between the pin member (11) and the shoulder member (12) can be made suitable.

Owner:KAWASAKI HEAVY IND LTD

Oval Aortic Valve

InactiveUS20130023980A1Soft flexureLarge external forceHeart valvesBlood vesselsLoop of HenleMitral valve leaflet

An oval valve for use in transcutaneous aortic (TAVI) or mitral valve implantation or for direct access valve implantation. The oval leaflet frame or stent provides a better seal with the oval native annulus to reduce perivalvular leaks. The valve leaflets are a bileaflet configuration to provide improved leaflet coaptation independent of the amount of ovality of the native valve annulus. The bileaflet configuration is less dependent upon the diameter and perimeter of the native valve annulus and provides leaflet coaptation without intravalvular leakage.

Owner:DRASLER WILLIAM JOSEPH

Drive axle shaft clutch

InactiveCN101780766AReduce mechanical energy lossExtend light-load glide distanceClutchesControl devicesClutchTowing

The invention relates to a vehicle clutch, in particular to a drive axle shaft clutch. At present, the drive axle installed on various motor vehicles is not capable of cutting off the torque; when the vehicle needs light loading in driving, since all pulling and non-effect interlocking pieces cannot be cut off, a large amount of energy is consumed, and the internal friction is always neglected since the advent of vehicles. The drive axle shaft clutch comprises a drive axle shaft; an axle shaft clutch is installed on the drive axle shaft; the housing of the drive axle is provided with a clutch and the mounting inspecting hole of a differential gear; the disengaging bar of the axle shaft clutch is respectively connected with an air valve and an air cylinder; and an alarming circuit comprising a light-emitting diode and a buzzer is installed between the air valve and a brake mechanism. The clutch is capable of safely, reliably and efficiently cutting off or bonding power in time, and has small volume, high transmission efficiency and low cost.

Owner:于宥源

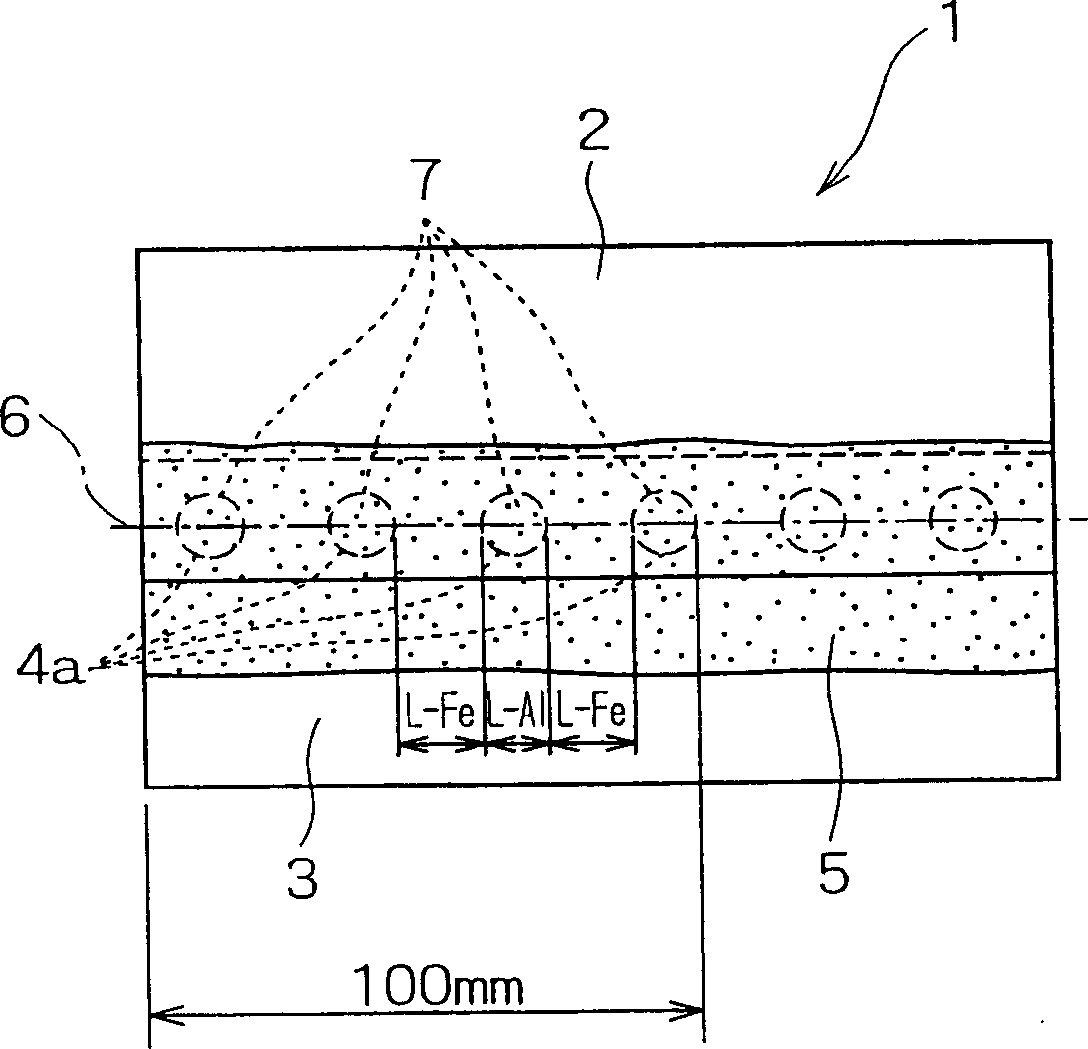

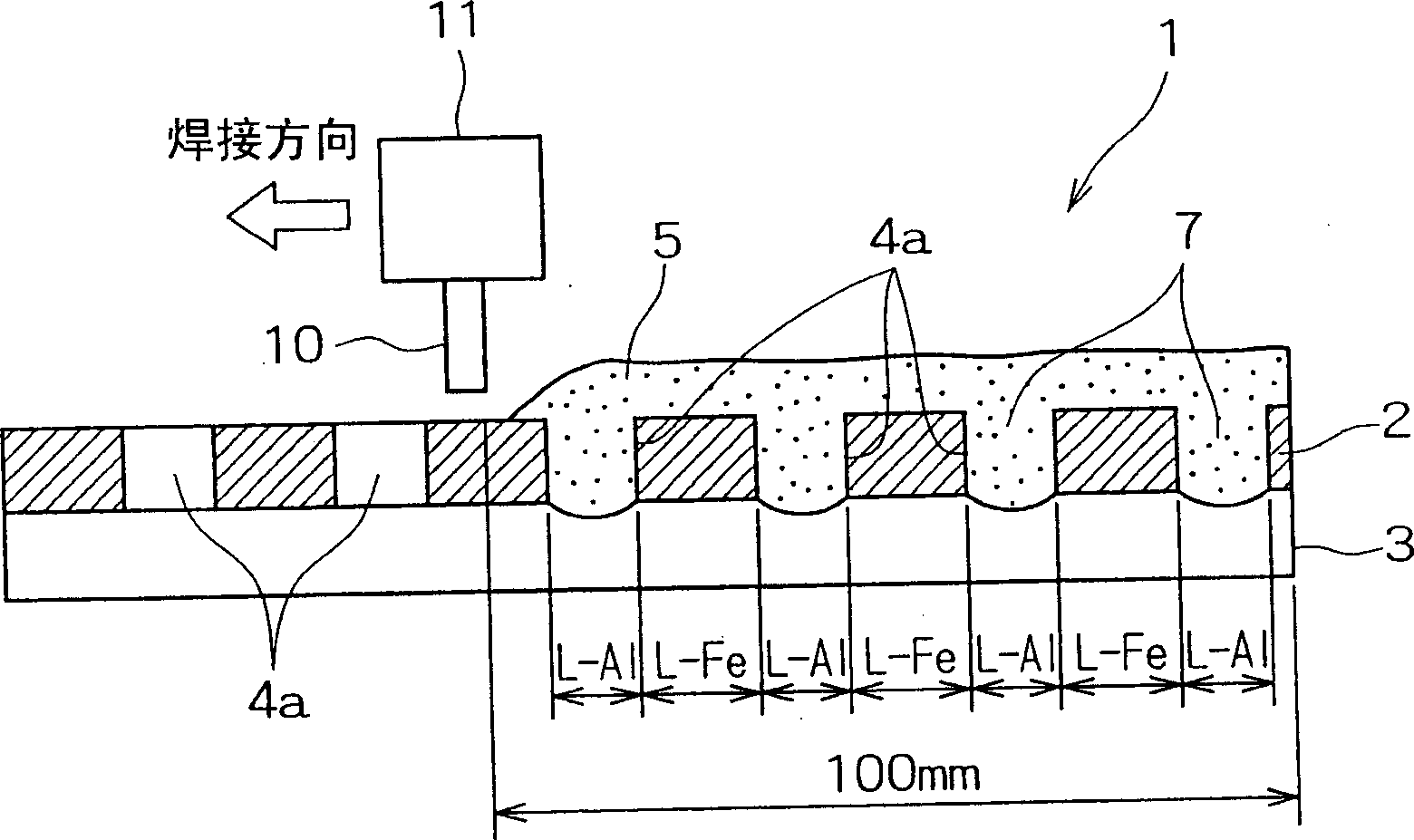

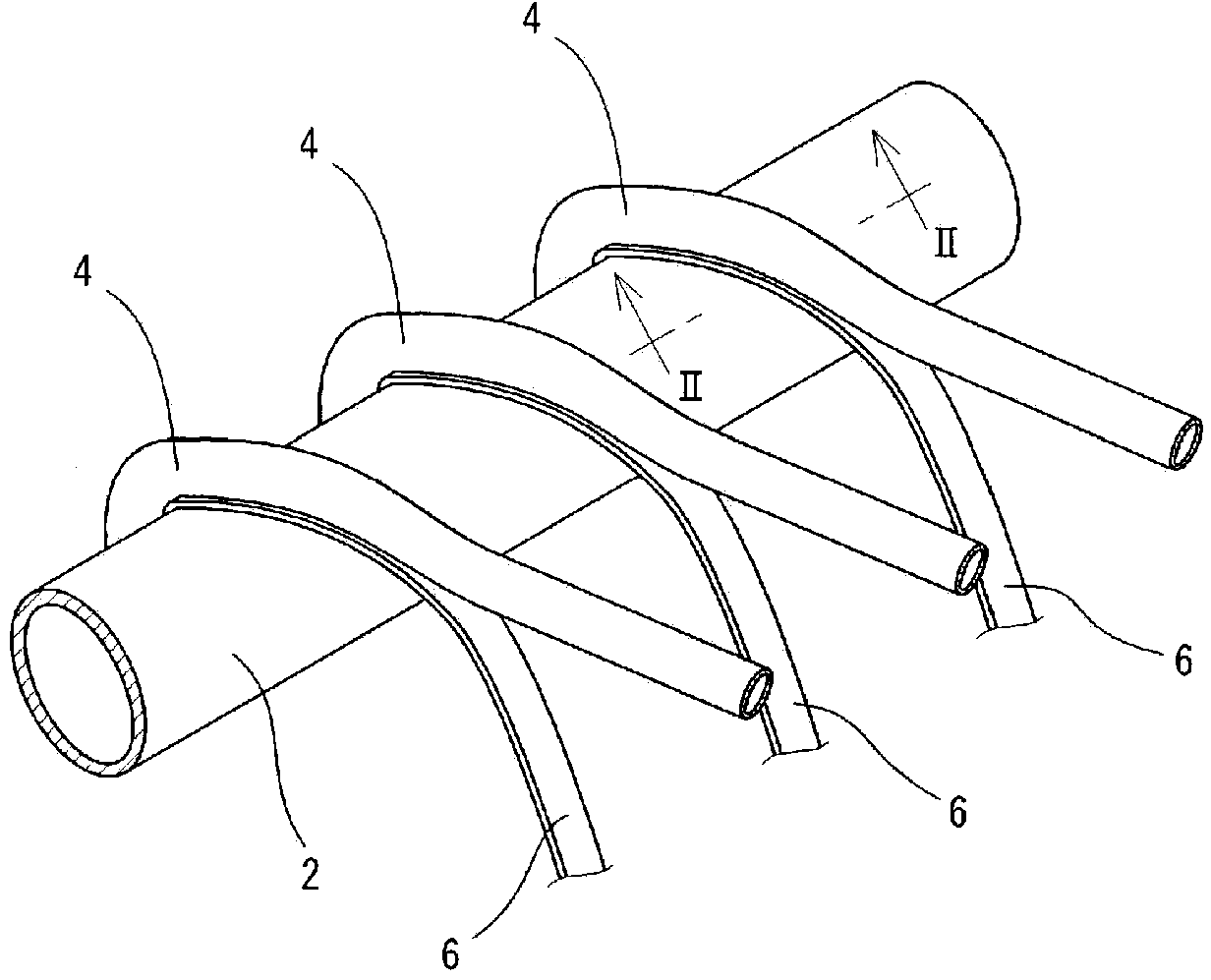

Dissimilar material weld joint formed by joining iron type material and aluminum type material, and weld joining method

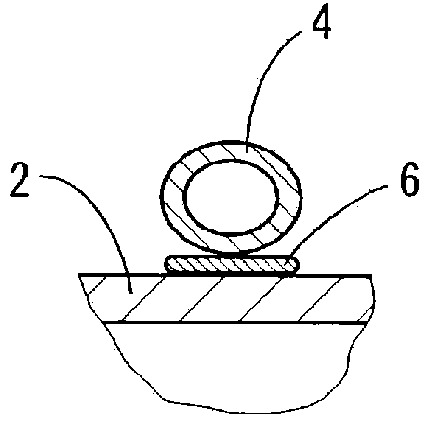

InactiveCN1706585AImprove joint strengthImprove ductilityArc welding apparatusWelding/soldering/cutting articlesHigh intensityWeld line

Disclosed are a welded joint of dissimilar materials and a welding method for stably producing the joint. The joint is formed by joining iron-based materials and aluminum-based materials, and it has not only high strength but also excellent ductility. A dissimilar material welded joint 1 formed by joining a ferrous material 2 and an aluminum-based material 3, wherein: pores 4a are formed in advance at predetermined intervals along a welding line 6 on the side of the ferrous material 2; and aluminum-type materials are welded so that said pores 4a are filled with molten aluminum 7; and the ratio (L-Al) / (L-Fe) of length (L-Al) to length (L-Fe) is minimum The value is 0.5-7, wherein (L-Al) is the length of the aluminum-based welding material 10 used to fill the pores 4a along the welding line 6 on the longitudinal section, and (L-Fe) is the The ferrous material 2 adjacent to the pores 4a filled with the aluminum-based welding material 10 is along the length of the welding line 6 on the longitudinal section containing the welding line 6; the length ( Both (L—Al) and (L—Fe) are lengths per 100 mm of the length of the welding line 6 formed after welding.

Owner:KOBE STEEL LTD

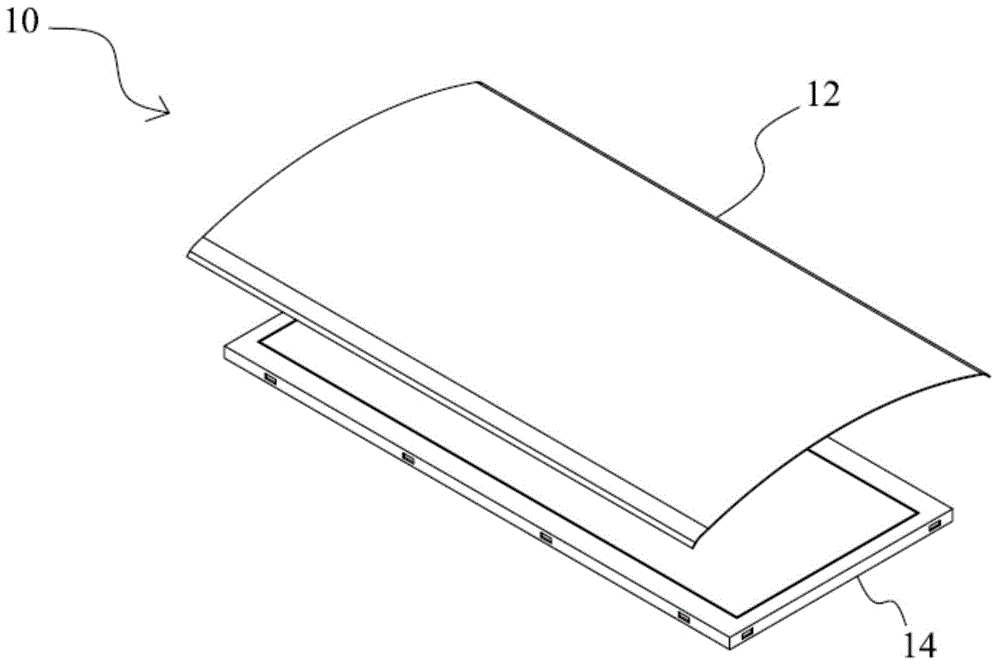

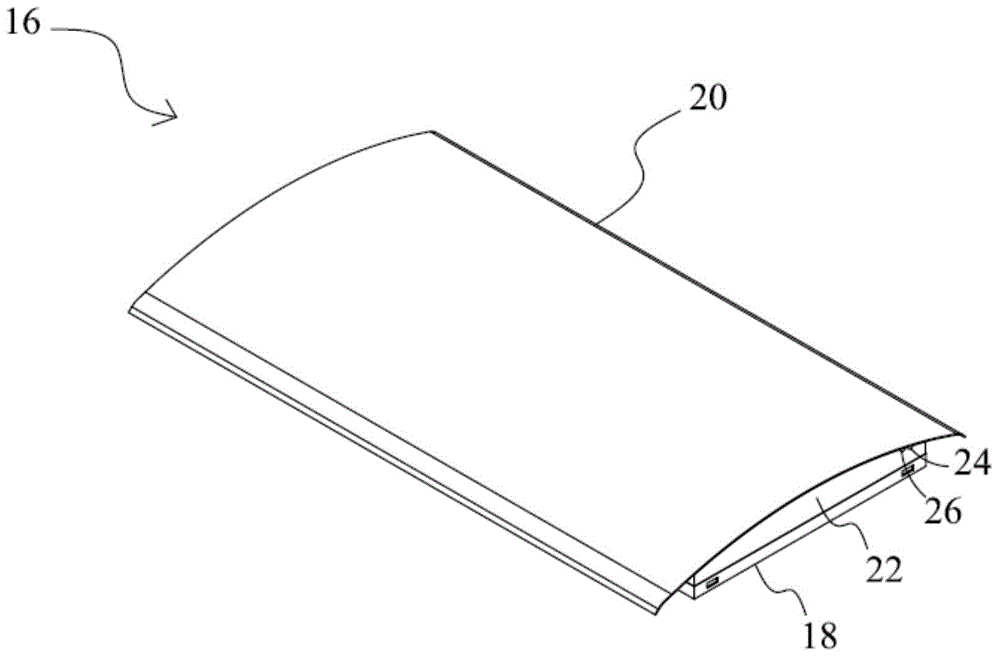

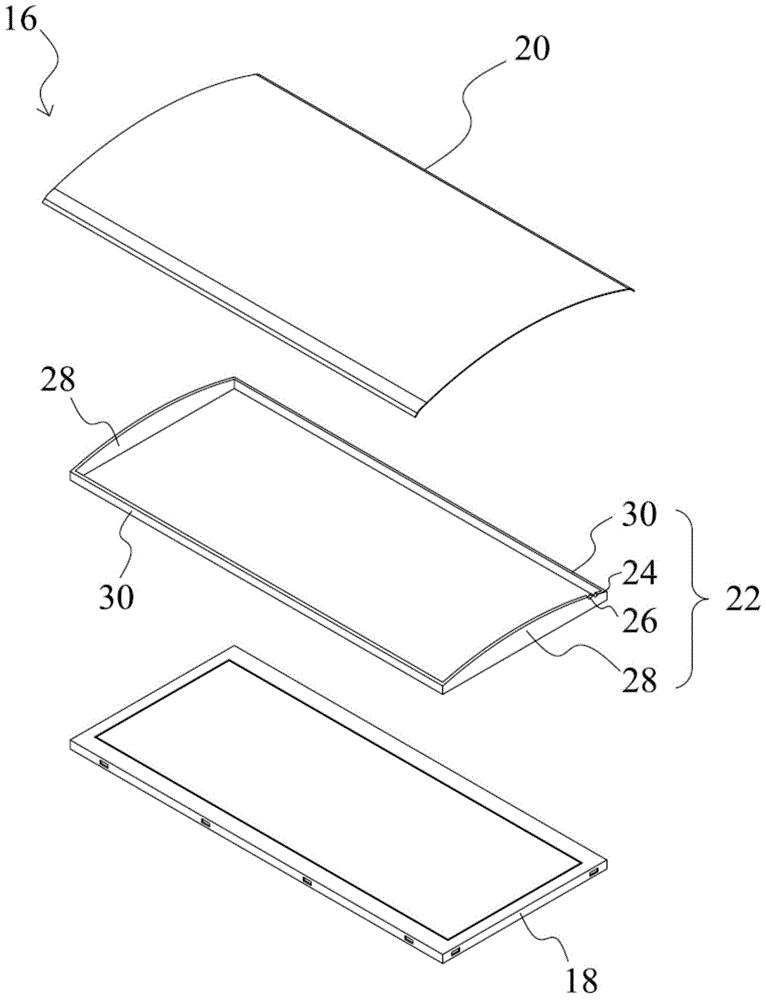

Vehicle-mounted touch device with curved surface structure

ActiveCN104951130AEffective engagementIncrease the wiping processInput/output processes for data processingAdhesiveComputer module

The invention discloses a vehicle-mounted touch device with a curved surface structure. The vehicle-mounted touch device with the curved surface structure comprises a display module, a frame and a curve surface touch panel, wherein the frame is positioned between the display module and the curved surface touch panel and can be connected with the display module and the curved surface touch panel, so that accommodating space is formed among the frame, the display module and the curved surface touch panel; adhesives are injected into the accommodating space via an injection hole in the frame; gas pressure in the accommodating space is discharged via a gas discharging hole in the frame; the accommodating space is filled with the adhesives so that the display module, the frame and the curved surface touch panel which are connected to one another are adhered; the injection amount of the adhesives can be controlled so as to meet requirements of the volume of a concave surface in the curved surface touch panel; the circumstance that the adhesives are scattered about due to extrusion is avoided; residual adhesive wiping or cleaning frequency is reduced; and attractiveness and completeness of the device are improved.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

Wave gear device having three-dimensional continuous contact tooth profile

In a wave gear device, similarity curve tooth profiles for defining the tooth-face tooth profile of each of a flexible externally toothed gear and a rigid internally toothed gear is determined from the movement trajectory, relative to a tooth of the rigid internally toothed gear, of a tooth of the flexible externally toothed gear at a main cross-section at which the deflection factor is κ=1. Tooth profile curves, which have been subjected to profile shifting corresponding to the difference between the deflection factor κo (>1) of the opening-end cross-section of the flexible externally toothed gear and the deflection factor κ of the main cross-section, are determined from the similarity curves; and the tooth profile curves are used to form the tooth-face tooth profile portions of the two gears. High-gear-tooth compound tooth profiles, defined from the tooth-face tooth profile portions, straight-line tooth profile portions continuing from the tooth-face tooth profile portions, and appropriate tooth-flank tooth profile portions for avoiding interference are used as tooth profiles of the internal teeth and the external teeth. Also, taking coning of the flexible externally toothed gear into account, negative profile shifting is applied from an opening-end cross-section to an inner-end cross-section of the flexible externally toothed gear, and rational meshing between the two gears is obtained along the entire tooth trace.

Owner:HARMONIC DRIVE SYST IND CO LTD

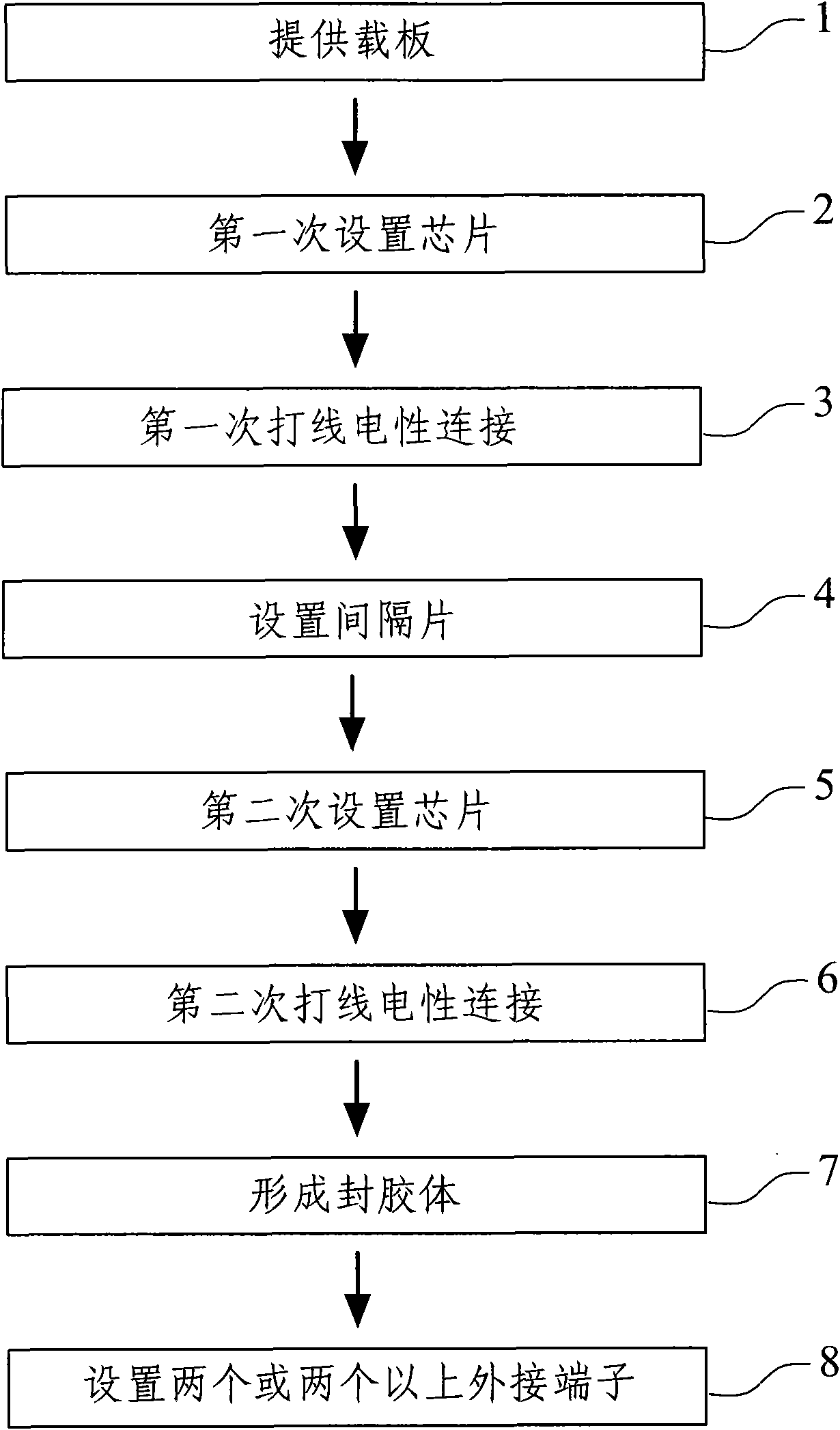

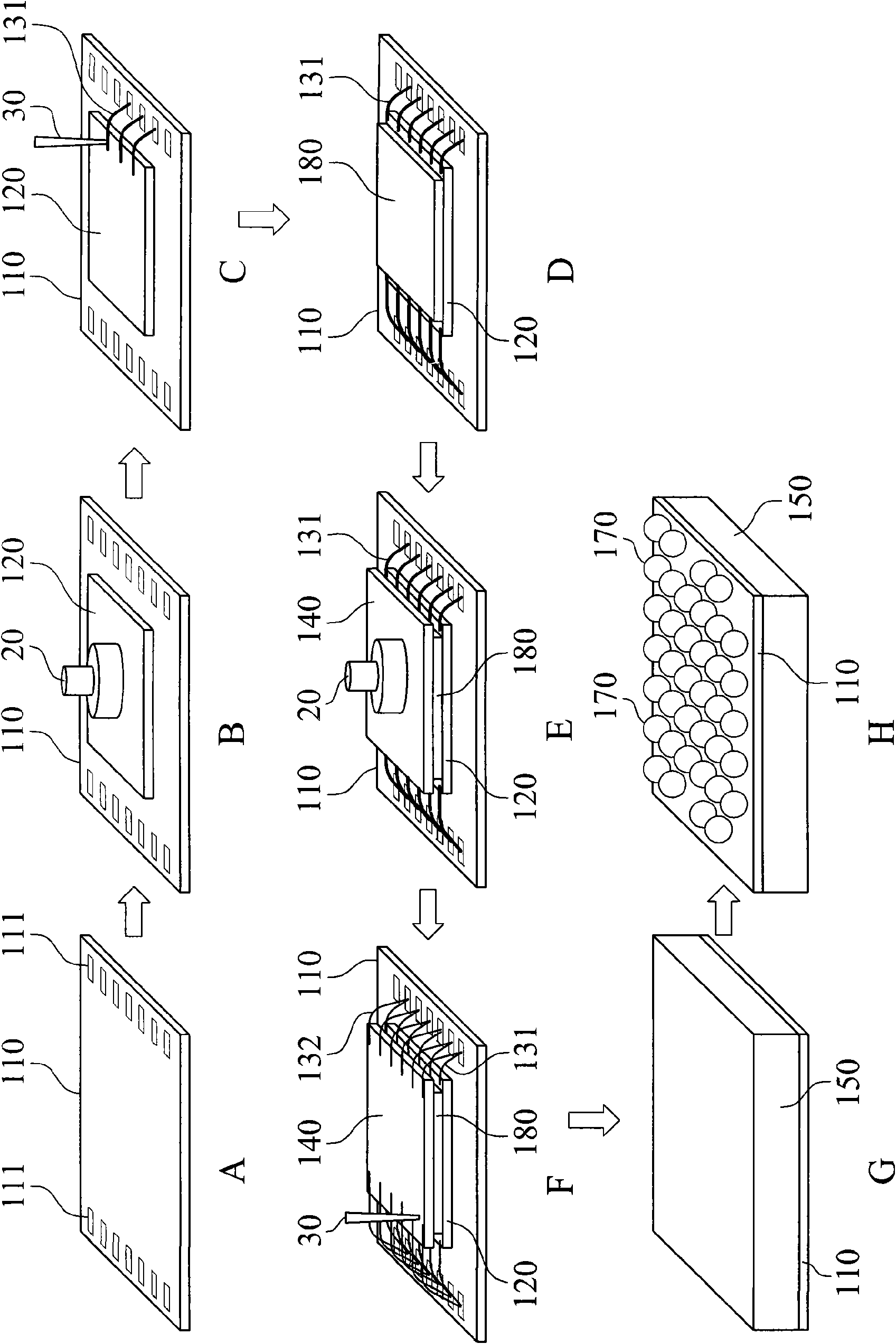

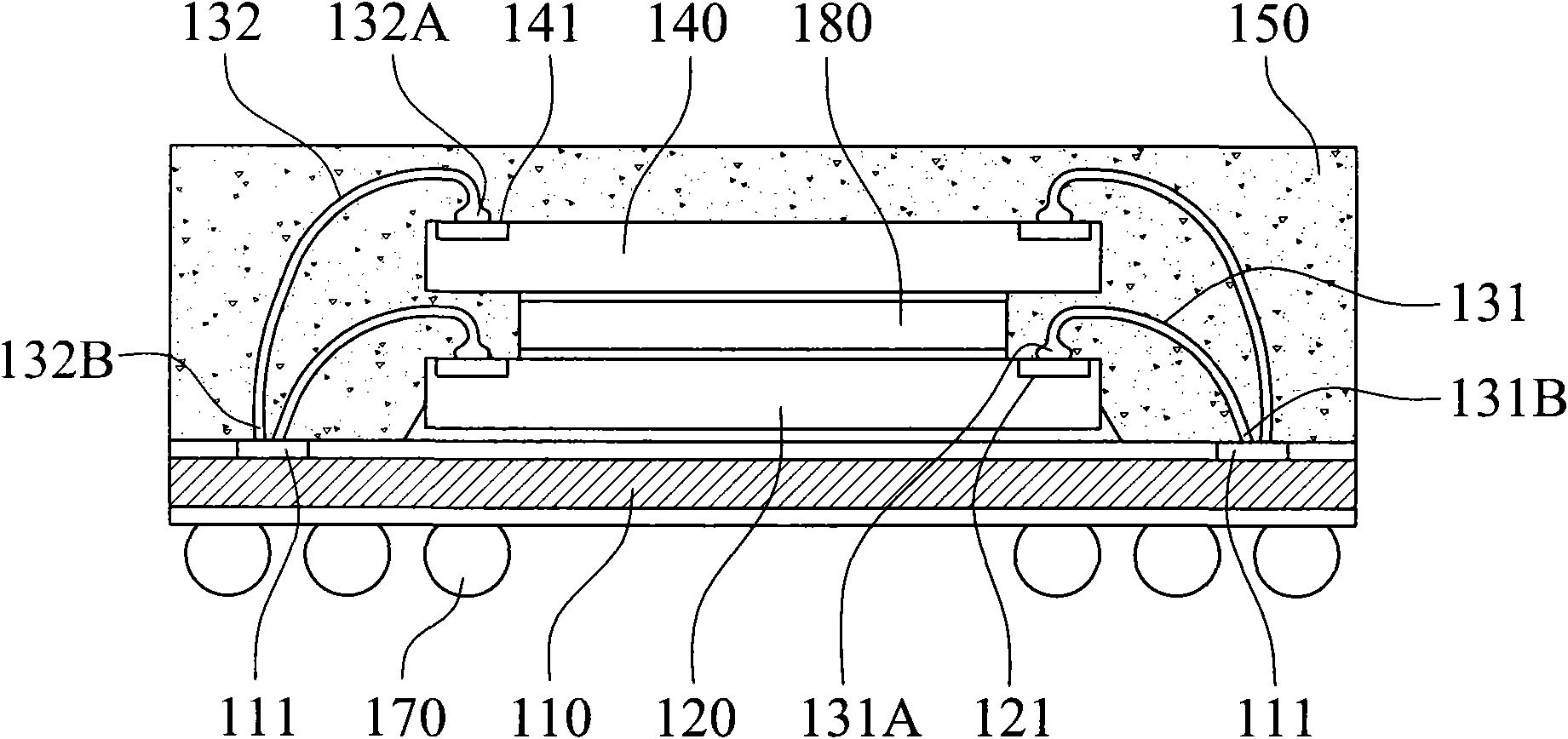

Multi-chip stacking method for halving routing procedure and structure thereof

InactiveCN101552214AReduce consumptionShorten the stacking processSemiconductor/solid-state device detailsSolid-state devicesFinger jointChip stacking

The invention discloses a multi-chip stacking method for halving routing procedure, comprising the following steps: firstly, providing a support plate having two or more finger joints and arranging at least one first chip on the support plate; then, routing to form two or more bonding wires to connect a first electrode of the first chip to the finger joints; arranging at least one second chip on the first chip face to face, and meanwhile, joining the second electrode of the second chip to one end of the bonding wires on the first electrodes, so that the second chip is electrically connected to the support plate through the bonding wires. The invention also discloses a multi-chip stacking structure for halving routing procedure. Therefore, the invention can shorten the procedure period and save cost, ensures that the bonding wires are located at the routing end on the chip and connected to the first electrode, and avoids line disconnection and line breasting.

Owner:POWERTECH TECHNOLOGY

Wave gear device having three-dimensional contacting involute positive deflection tooth profile

ActiveUS20130081496A1Amount of bending is greatHigh torqueGearboxesToothed gearingsDeflection coefficientGear wheel

In a wave gear device, an involute tooth profile with the low pressure angle α (<20°) is employed as a basic tooth profile of external teeth of a flexible external gear. In the principal section of the external teeth, the tooth depth thereof satisfies 2κ0mn=2(1+c) mn (deflection coefficient κ0=1+c, 0<c<0.5), which is larger than the standard one. The shifting of the teeth which takes into account coning is performed along the tooth trace direction of the external teeth, so that straight portions of a rack tooth profile on the respective sections perpendicular to the axis in the tooth trace direction of the external teeth are conformed as viewed along the tooth trace direction. The rack tooth profile of the involute tooth profile is a straight line.

Owner:HARMONIC DRIVE SYST IND CO LTD

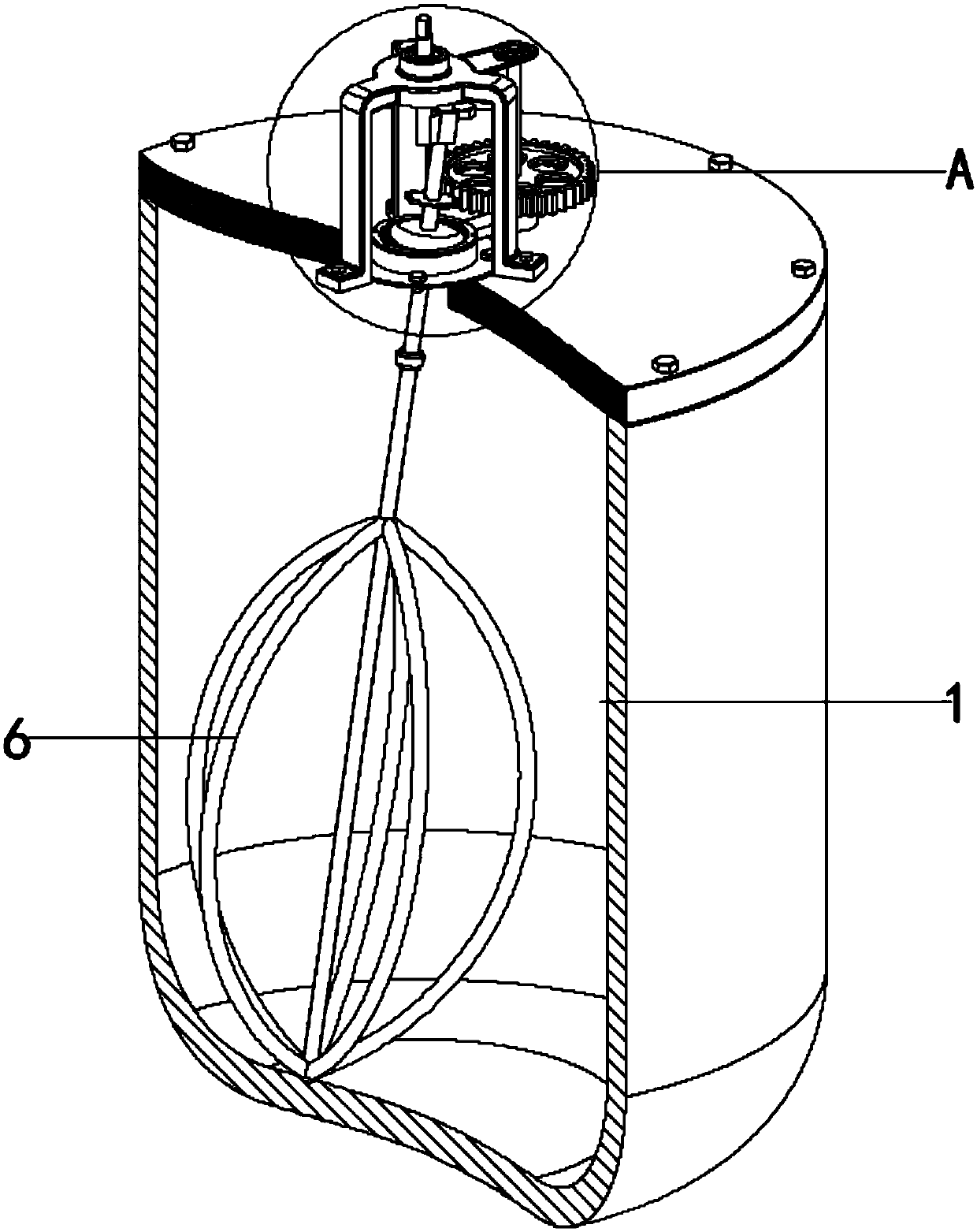

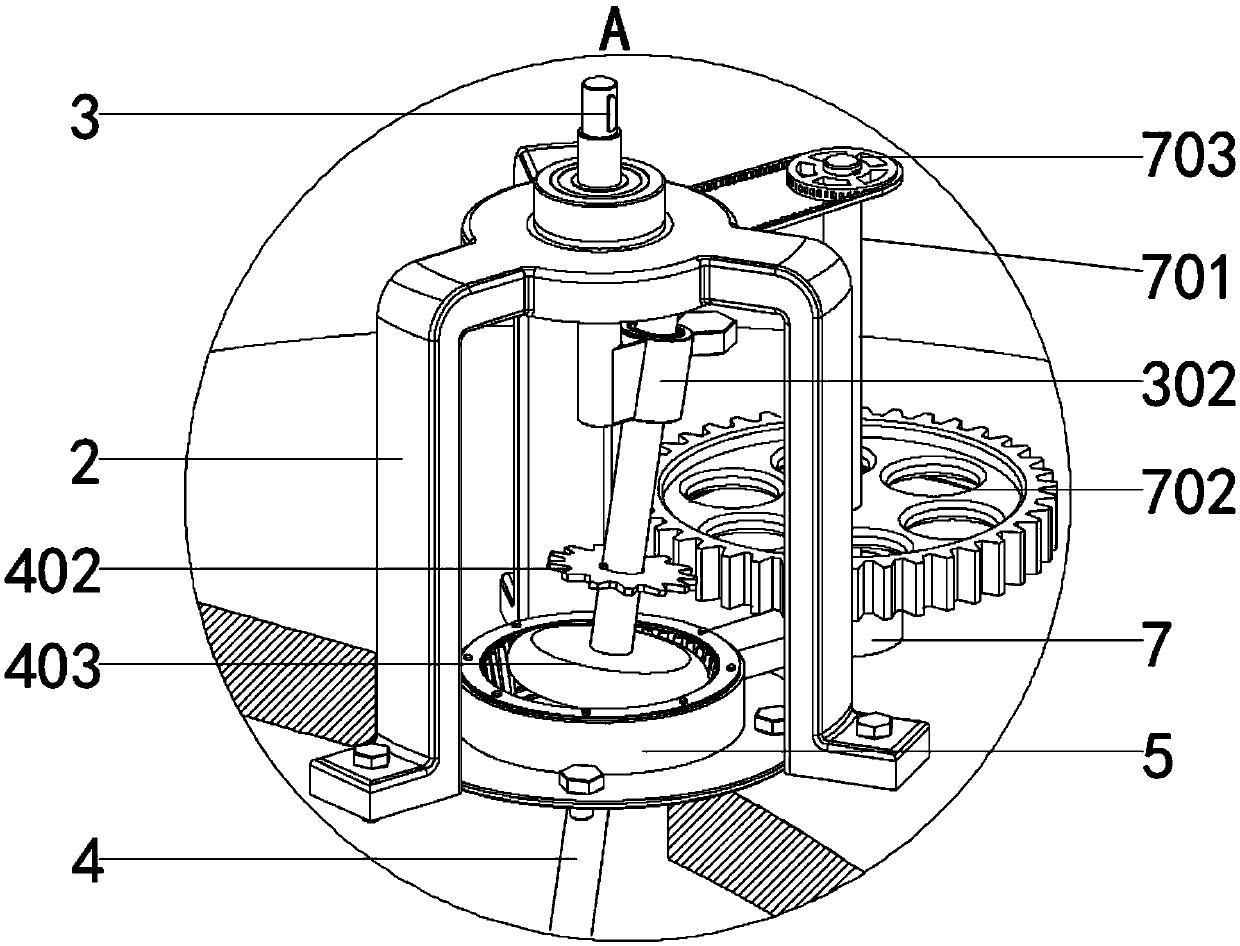

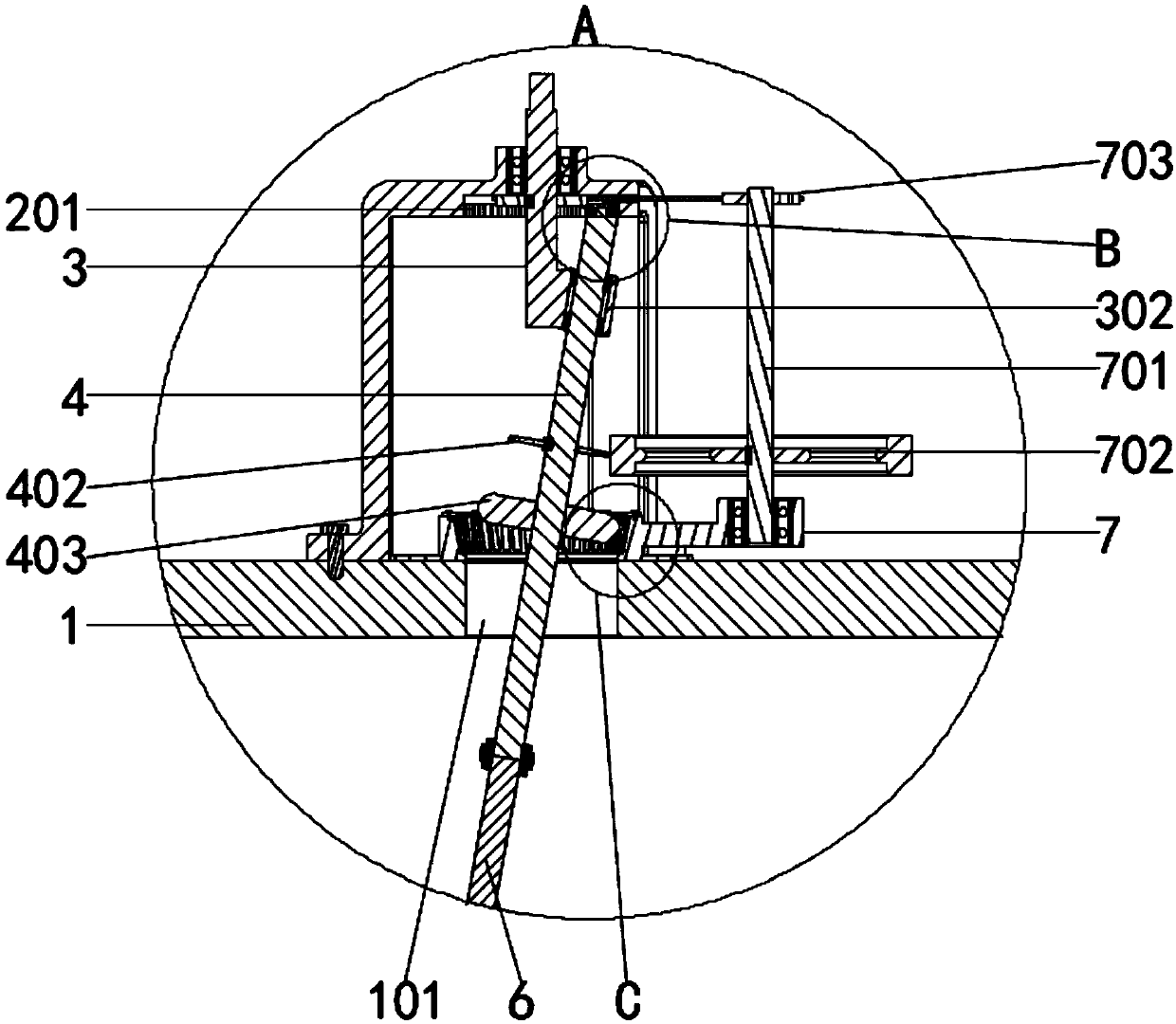

Chemical tank gyro wheel axle stirring device

InactiveCN108671823AImprove the mixing effectStir wellShaking/oscillating/vibrating mixersTransportation and packagingGear wheelCircular cone

The invention provides a chemical tank gyro wheel axle stirring device which comprises: a tank body, a through hole, a mounting frame, an inner gear ring, a mounting seat, a bulge, a bearing embeddinghole, a sleeving slot, a power shaft, a main synchronous belt wheel, an eccentric sleeve, a wheel shaft, a planet gear, a pinion, a gyro wheel, a rotary shaft, a gyro wheel seat, an upper cover, a roller slot, a roller wheel, a mounting flange, a through hole, a stirrer, a connecting seat, a driving rod, a main gear and a secondary synchronous belt wheel, wherein a cylindrical gyro wheel seat isarranged above the through hole; an integrated mounting flange is arranged at the bottom of the gyro wheel seat; the gyro wheel seat is fixed at the top of the tank body through the mounting flange and a bolt. According to the device provided by the invention, through improvement of a chemical tank gyro wheel axle stirring device, the device realizes the functions of cone swing type stirring and reverse autorotation stirring, and has the advantages of good stirring effect, long service life, stable stirring and the like, and thus effectively solves the problems and shortcomings in the prior art.

Owner:HUIZHOU WULING KANGTAI HEALTH TECH CO LTD

High-efficiency laser cleaner

InactiveCN109317472AAvoid damageAvoid inhalationCleaning processes and apparatusLaser beam welding apparatusLinear motionAutomatic control

The invention relates to a laser cleaner, in particular to a high-efficiency laser cleaner, and belongs to the technical field of laser cleaning. The high-efficiency laser cleaner comprises a supportmechanism, an X-axis movement mechanism, a Y-axis movement mechanism, a Z-axis movement mechanism, a laser cleaner, a supporting plate, an impurity storage box, a baffle plate, a connecting spring anda movable clamping plate. A control system of the high-efficiency laser cleaner automatically controls the coordinated movement of a first drive motor, a second drive motor and a third drive motor according to the cleaning path to respectively drive the linear motion of the X-axis motion mechanism, the Y-axis motion mechanism and the Z-axis motion mechanism, and then a laser cleaning head of thelaser cleaner is driven to complete a cleaning task. The control system adjusts the distance between the laser cleaner and the surface of a to-be-cleaned object through a laser focus tracking system in real time, so that the cleaning distance can be kept at the optimal cleaning distance all the time, and the distance between the laser cleaner and the surface of the cleaned object can be accuratelycontrolled. The laser cleaner has the advantages of being good in cleaning effect, high in cleaning efficiency and capable of being suitable for laser cleaning of uneven metal surface.

Owner:李如意

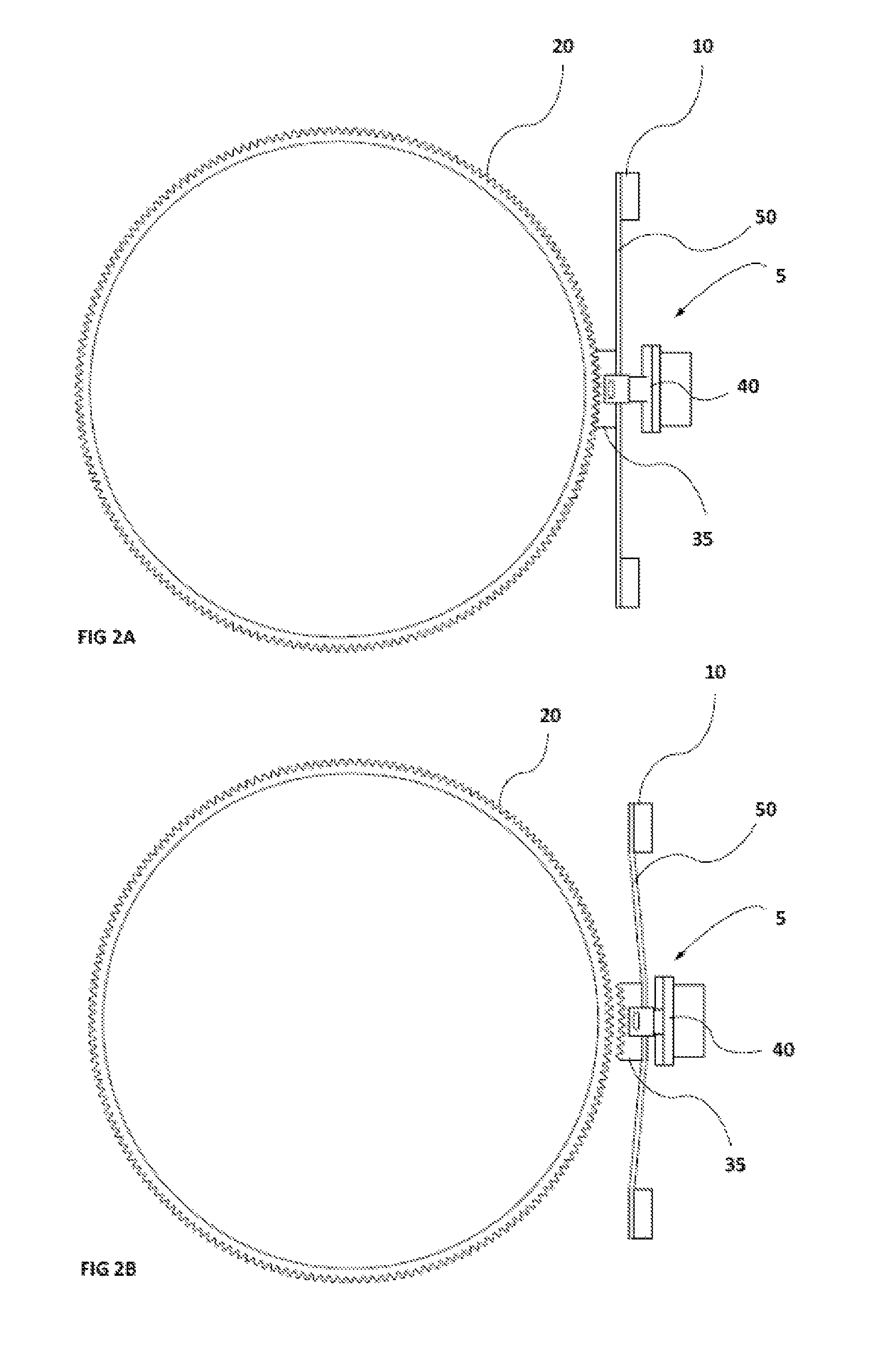

Yaw brakes for wind turbines

Yaw brakes for wind turbines are proposed, the wind turbines having a tower, a nacelle and a yaw system for rotating the nacelle with respect to the tower. The yaw brakes comprise a locking part, having a toothed profile at a side facing a toothed profile of an annular gear of the yaw system. The locking part of the yaw brakes is movable in a radial direction relative to the annular gear, between a brake position and a non-brake position. Brake discs and callipers may be eliminated.

Owner:GE RENEWABLE TECH WIND BV

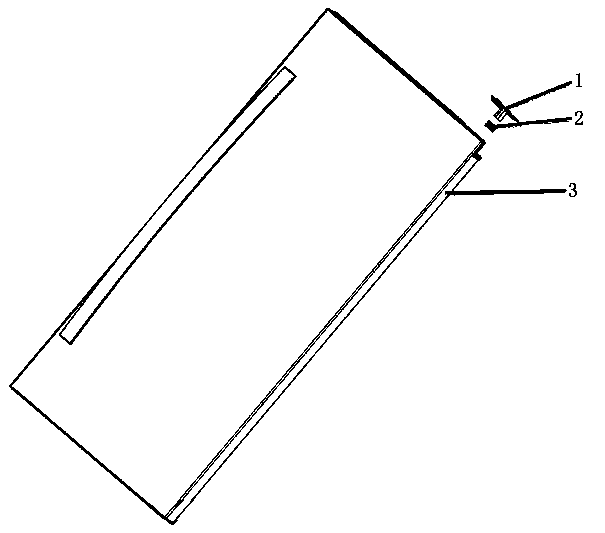

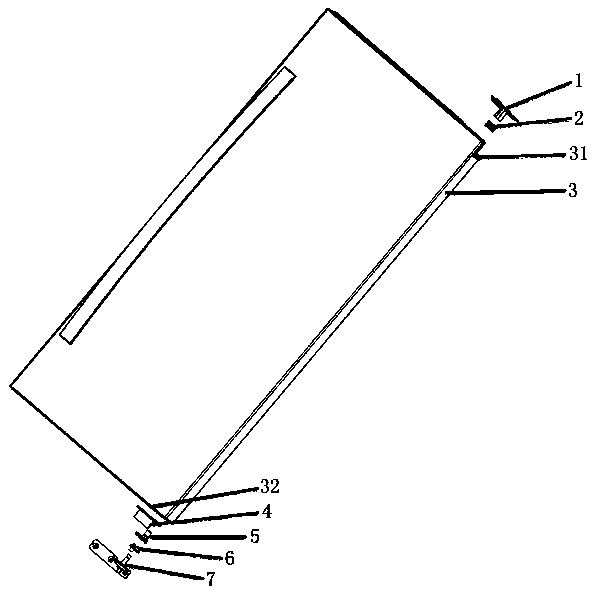

Refrigerator

InactiveCN103851862AReach the closed statePoor solutionDomestic cooling apparatusLighting and heating apparatusPre compressionEngineering

The invention relates to the technical field of a refrigerator, in particular to a door body assistive absorber structure of a refrigerator. The refrigerator comprises a door body and an upper hinge which is arranged between the door body and a refrigerator body, and the refrigerator also comprises a lower hinge which is fixed on the door body and used for supporting the door body, and a mesh assistive absorption mechanism is arranged between the lower hinge and the door body; a resilient structure which stays at a pre-compression state when the door body is closed is arranged between the door body and the upper hinge. When the door body is closed, the mesh assistive absorption mechanism is engaged together, the resilient structure is squeezed by the upper hinge and the door body to stay at the pre-compression state, so that the problem of the leakage of the cold quantity caused by the untight closing of the door body when the refrigerator is used can be solved through the structure. Meanwhile, the automatic closing force of the door body can be adjusted, the assistive absorption effect can be guaranteed, and the problem that the original assistive absorber is poor in universality can be solved.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

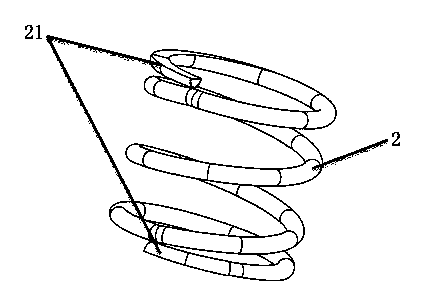

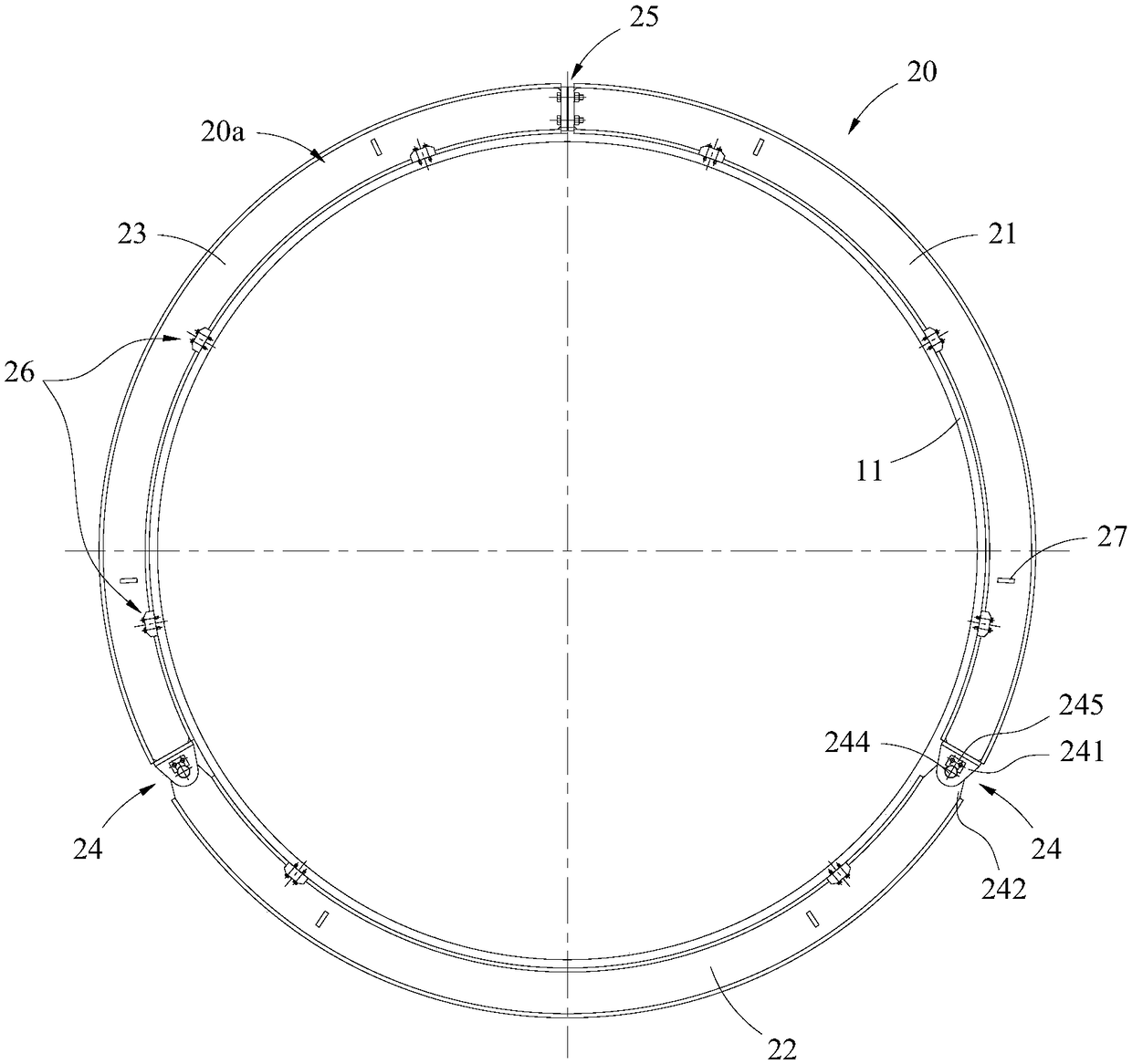

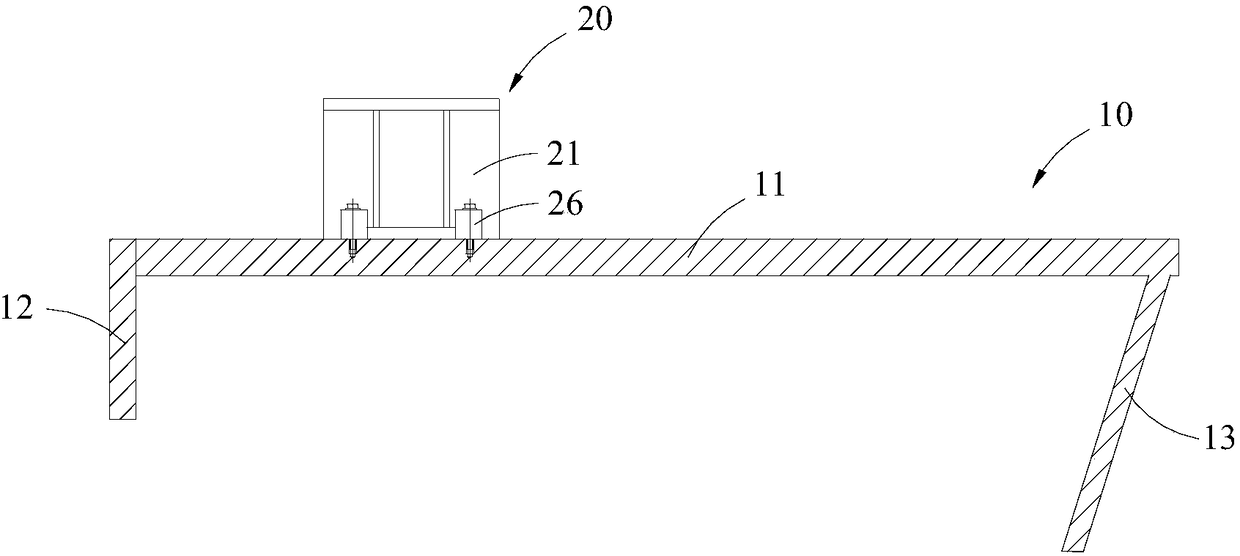

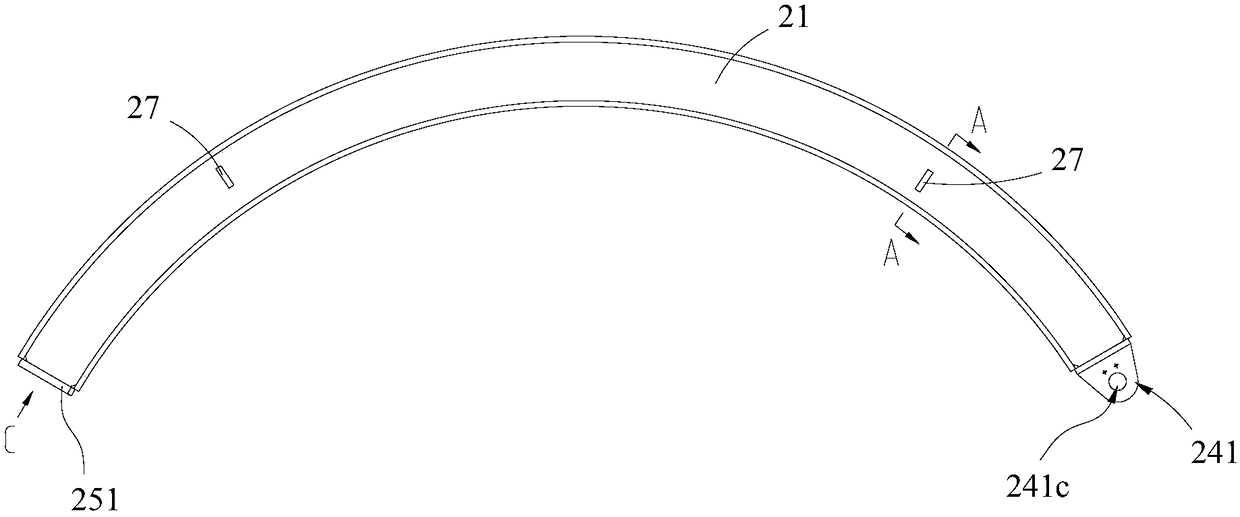

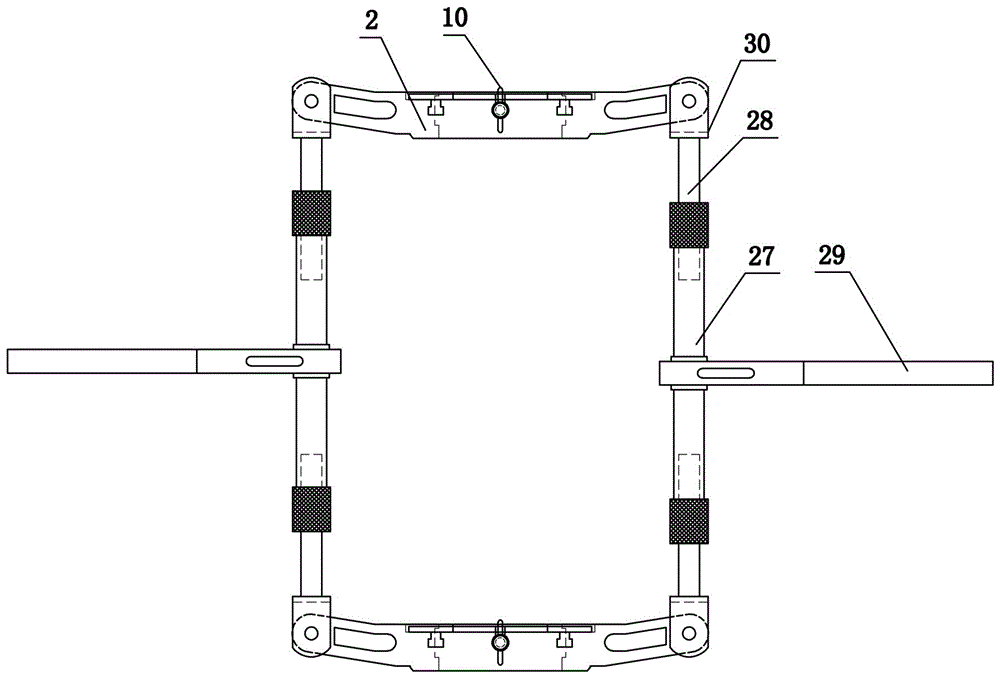

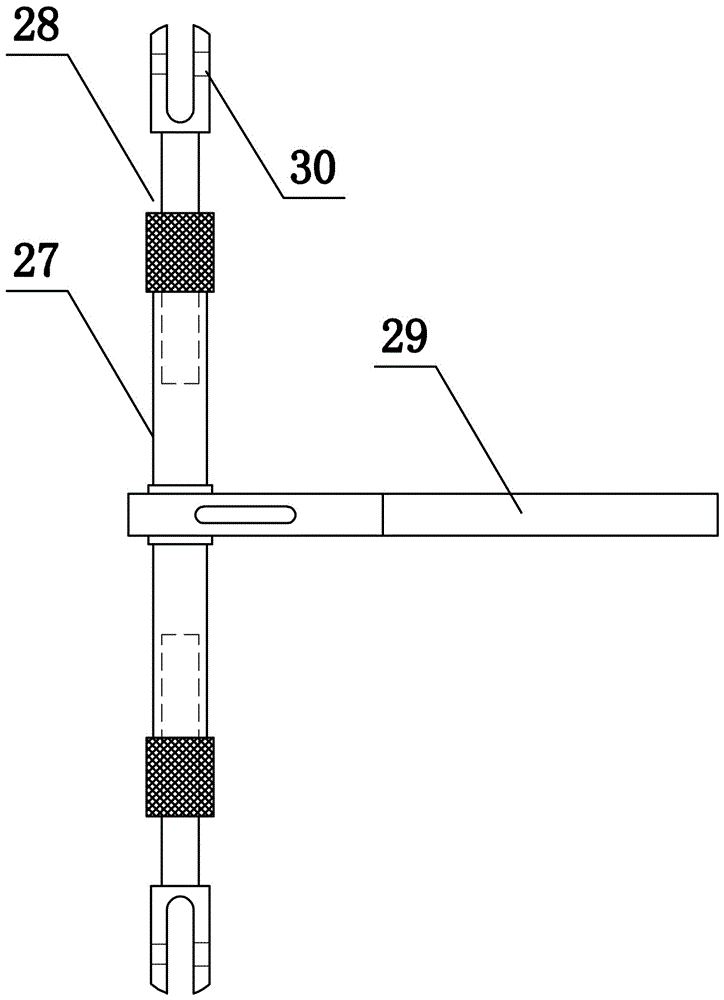

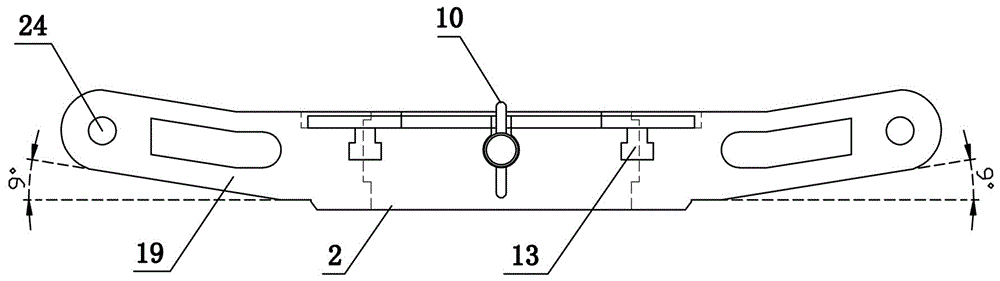

Rotor, motor, reinforcing ring tooling and mounting method thereof

ActiveCN108336839AImprove structural strengthAvoid deformationMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringMechanical engineering

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Insulator replacement device

ActiveCN106786172AIncrease contact areaImprove securityApparatus for overhead lines/cablesEngineeringElectrical and Electronics engineering

The invention discloses an insulator replacement device which comprises a clamp apparatus and a length regulation mechanism. The clamp apparatus comprises a first clamping plate and a second clamping plate which are fixedly connected; the first clamping plate and the second clamping plate are enclosed to form a cylindrical cavity; a first accommodating groove is formed on the upper end face of the first clamping plate; a second accommodating groove is formed on the upper end face of the second clamping plate; a first regulating ring is arranged in a sliding mode in the first accommodating groove; a second regulating ring is arranged in a sliding mode in the second accommodating groove; the center lines of arc holes interact with the center lines of the ring-shaped accommodating grooves; through slots are arranged on the side end faces of the first clamping plate and the second clamping plate; extension directions of the through slots point to the central axis of the cylindrical cavity; the upper ends of the through slots are communicated with the ring-shaped accommodating grooves; limiting pillars are arranged in a sliding mode in the through slots; limiting pins are vertically arranged at the upper end faces of the limiting pillars; the upper ends of the limiting pins extend out of the arc holes. According to the insulator replacement device disclosed by the invention, by regulating the positions of the arc holes, sliding of the limiting pillars in the through slots is implemented; and the insulator replacement device can be used for the replacement work of all types of suspended insulator strings in a substation.

Owner:国网河南省电力公司超高压公司 +1

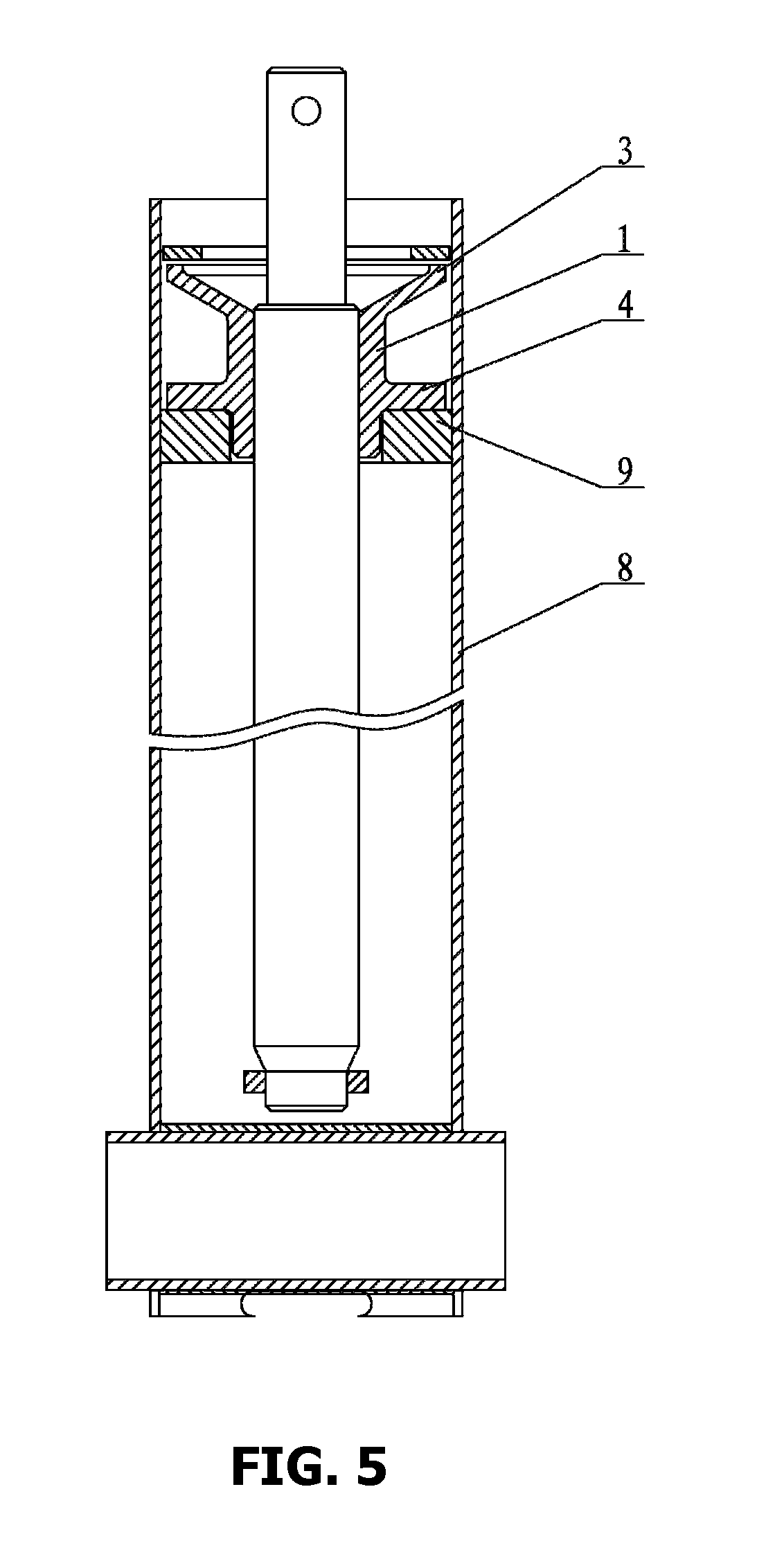

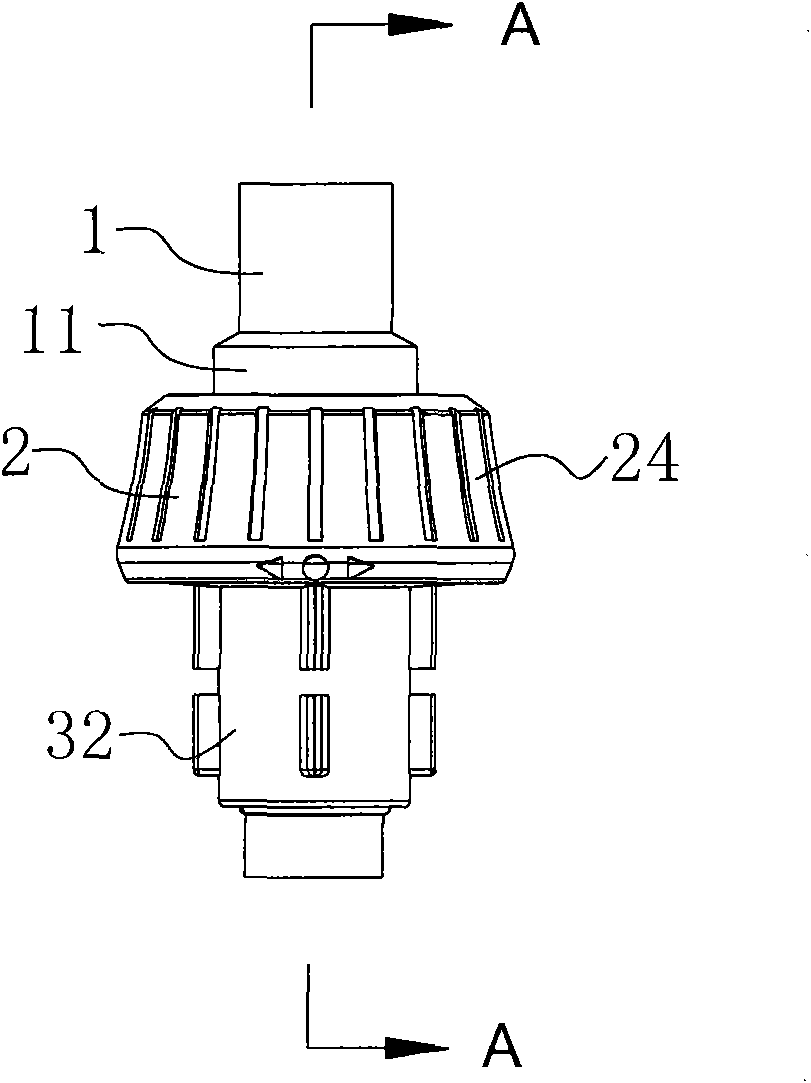

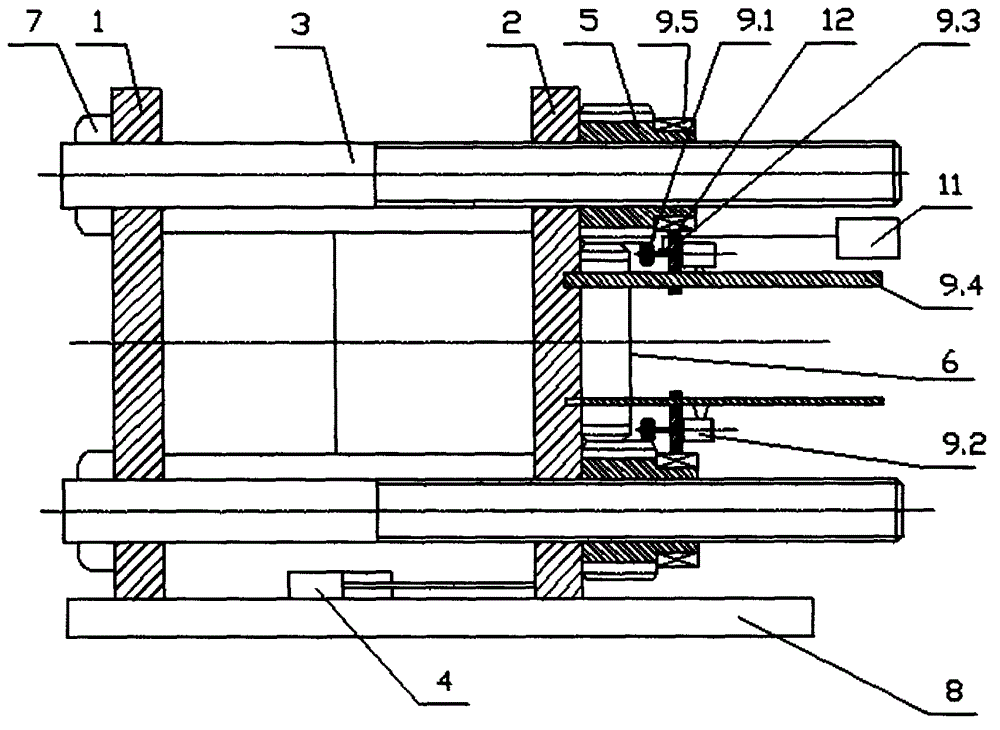

Self-locking clamping mechanism of injection molding machine

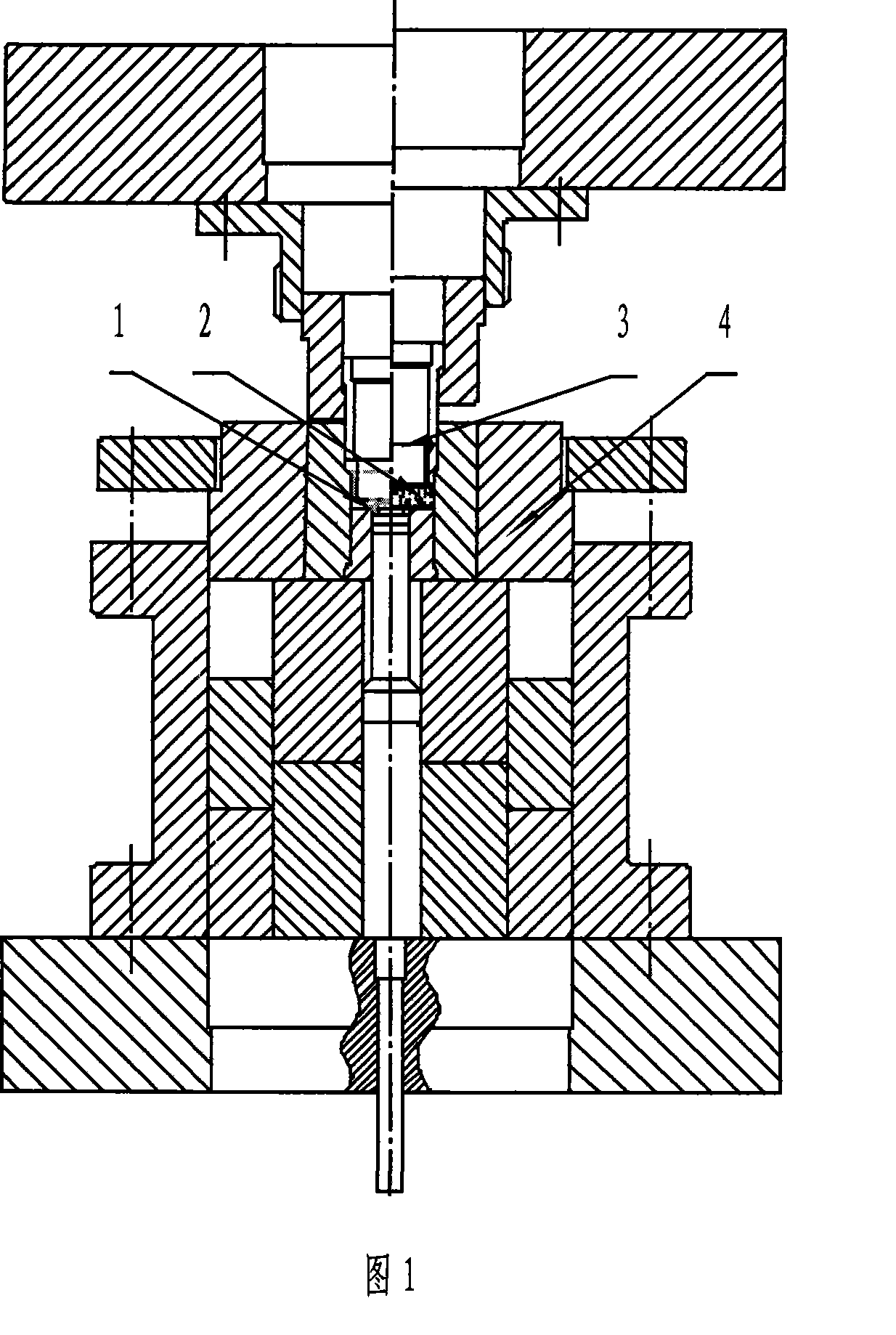

The inventiondiscloses a self-locking clamping mechanism of an injection molding machine. The self-locking clamping mechanism comprises a fixed mold plate (1), a movable mold plate (2), pull rods (3) and a mold moving oil cylinder (4), wherein the fixed mold plate (1) is fixed to one end of the pull rods (3), the movable mold plate (2) is arranged at the other end of the pull rods (3) in a sleeving manner, and a piston end of the mold moving oil cylinder (4) is connected with the movable mold plate (2) to drive the movable mold plate (2) to move. The clamping mechanism further comprises a mold locking structure, wherein the mold locking structure comprises rear nuts (5) corresponding to the pull rods (3) in a one-to-one mode, a large gear ring (6) and a power mechanism for driving the large gear ring (6) to rotate, the rear nuts (5) are screwed onto the pull rods (3), the outer edge of each rear nut (5) is in a gear shape, and the large gear ring is meshed with the rear nuts (5) respectively under the drive of the power mechanism and drives the rear nuts to rotate on the corresponding pull rods. The self-locking clamping mechanism does not need a mold locking oil cylinder and reduces the energy consumption of mold locking through self-locking between mechanisms.

Owner:CHINA JILIANG UNIV

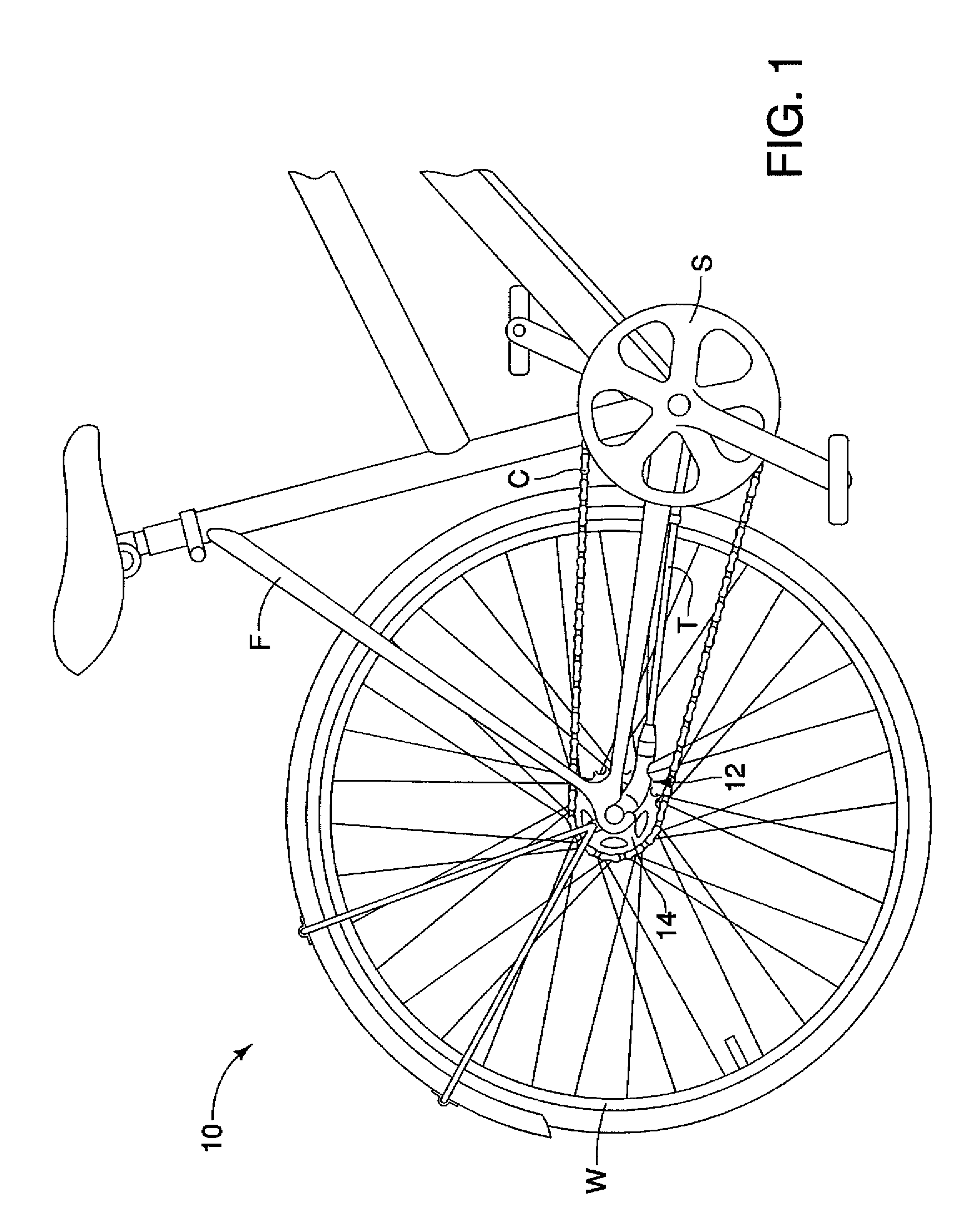

Bicycle internal hub transmission with helical gear

ActiveUS20090170654A1Eliminate and reduce unwanted noiseSmooth and quiet operationWheel based transmissionToothed gearingsEngineeringGear train

An internal hub transmission includes a hub axle, a driver rotatably supported by the hub axle, a hub shell rotatably supported by the hub axle, a power transmission mechanism and a shift mechanism. The power transmission mechanism is disposed between the driver and the hub shell for transmitting rotational power from the driver to the hub shell through a plurality of power transmission paths. The power transmission mechanism has at least one planetary gear mechanism that includes a sun gear, a planetary gear and a gear ring. The planetary gear is supported by a gear rack. The planetary gear has helical gear teeth and at least one of the sun gear and the gear ring is provided with helical gear teeth that mesh to helical gear teeth of the planetary gear.

Owner:SHIMANO INC

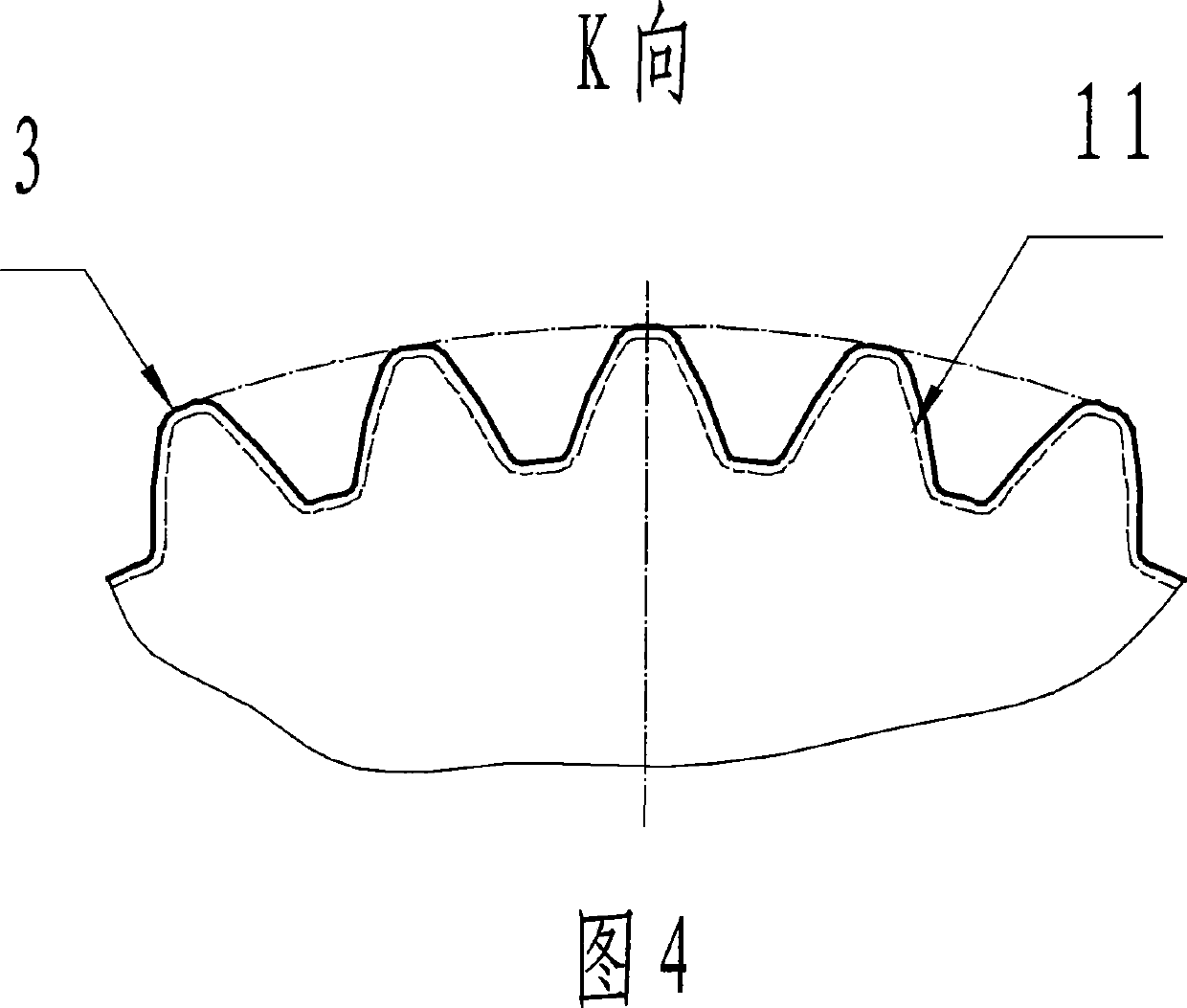

Blind hole internal gear precision forming method and internal tooth forming mold

InactiveCN101214510BGood consistency of precisionSave materialExtrusion diesHeat treatment process controlEntrance angleRough surface

The invention provides a blind hole internal gear fine forming method and an internal gear forming die relating to the metal machinery processing and metal pressing fields of no cutting. The technical steps includes: computer simulation analyzing to study out a process forming scheme-baiting to manufacture roughs-surface intenerating and lubricating processing-fine forming-cutting off redundant part. A convex die profile of an internal gear forming die is corrected according to a gear precision grade tolerance belt and the gear precision is 6 to 5 grade. The surface roughness of the convex die is smaller than 0.5 micron. The thickness of a surface nanometer coat is 0.002 to 0.004 millimeter. A die entrance angle of at end surface of the gear is transited by a semi-arc. An effective width of a minor first flank is between 1.5 and 3 millimeter. A double surface back gap of the minor first flank is 0.3 millimeter smaller than the minor first flank by average. The transition cone angle between the minor first flank of the convex die and a basic die is 3 to 6 degrees. A concave die is formed through interference pressure distribution by adopting 2 to 3 layers of compound dies. The magnitude of interference is 0.4 to 0.5 percent of a matched dimension of a die. The invention has the advantages of short technique line, high manufacture efficiency, good consistence of the gear precision and high intensity.

Owner:JIANGSU SUN WAY GRP FEIDA CO LTD

Desulphurization pump with combined impeller rotor

PendingCN109386497AEasy to install and removeLight weightSpecific fluid pumpsPump componentsImpellerCorrosion

The invention relates to a desulphurization pump with a combined impeller rotor. The desulphurization pump comprises the combined impeller rotor, a pump case, a pump inlet part, a pump outlet part anda pump back cover plate, wherein the pump inlet part, the pump outlet part and the pump back cover plate are installed on the pump case to form a pump cavity for containing the combined impeller rotor in an enclosure manner; the combined impeller rotor comprises an impeller body installed on a pump shaft, the impeller body comprises a metal hub lining and a nonmetal blade lining body with which the peripheral surface of the metal hub lining is wrapped in a compression-molding manner, and the nonmetal blade lining body is made from an ultrahigh molecular weight polyethylene material. Accordingto the desulphurization pump with the combined impeller rotor, the deadweight of the impeller body is reduced, and the material cost is saved; in addition, the strength of the impeller body is also guaranteed while it is avoided that the impeller rotor is too thick; the impeller body is resistant to wear and corrosion, and a vibration value of the pump can be reduced; meanwhile, processing is easy, the cost is low, and the running efficiency of the pump is greatly improved.

Owner:HEFEI UNIV OF TECH +1

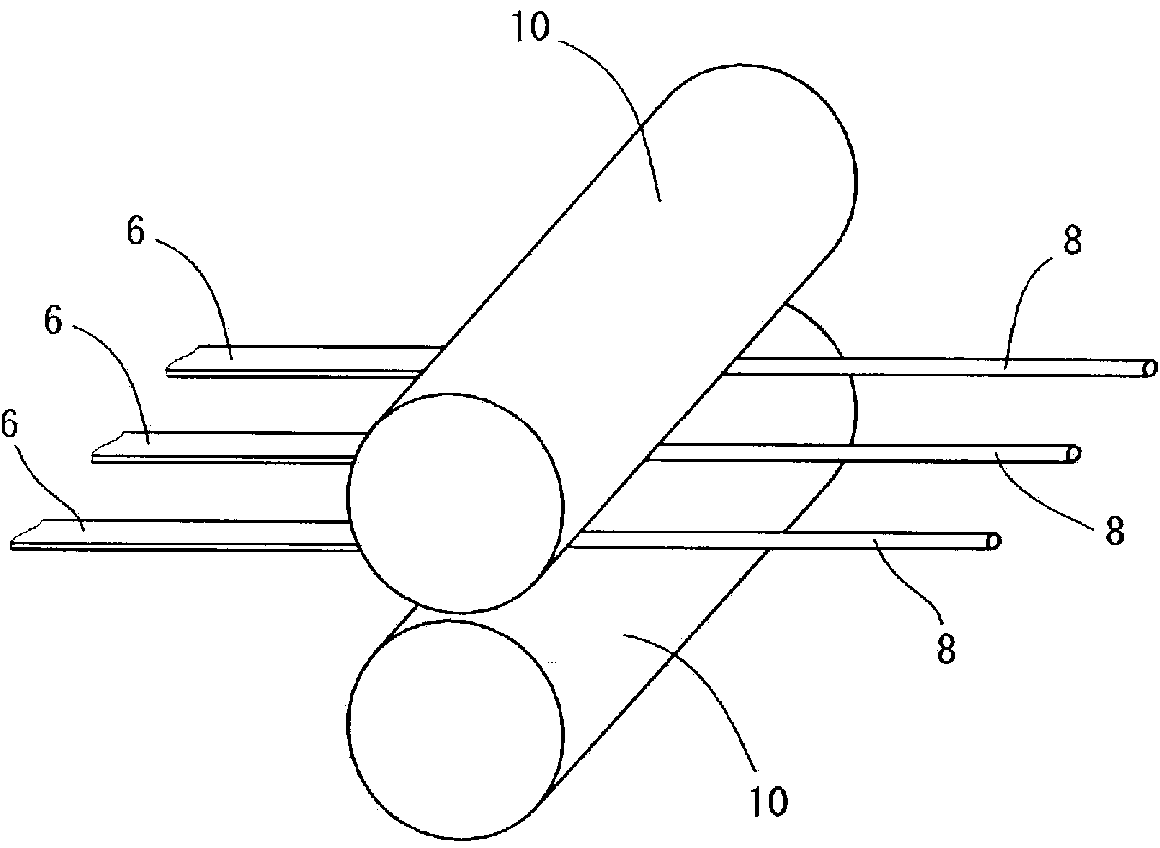

Method for manufacturing heat exchanger and heat exchanger obtained by same

InactiveCN104010755AStable supplyWon't wasteFurnace typesStationary tubular conduit assembliesEngineeringRefrigerant

Provided is a method of joining a large diameter water pipe to a small diameter refrigerant pipe to manufacture a heat exchanger, such that dropping of molten solder is advantageously prevented and effective joining of the water pipe to the refrigerant pipes is achieved while reduction in the strength of base materials is effectively suppressed. In the manufacture of a heat exchanger formed by joining a small diameter refrigerant pipe to the outer peripheral surface of a large diameter water pipe, strip-like solder plate material is used for the joining material, and after the solder plate material is mounted on the outer peripheral surface of a water pipe so as to be sandwiched with the refrigerant pipe, the solder plate material is melted by heating to a temperature that does not exceed 350 DEG C, and the water pipe and refrigerant pipe are joined.

Owner:UACJ COPPER TUBE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com