Ratchet gear of screw driver and screw driver using ratchet gear

The technology of a ratchet device and a screwdriver is applied in the structure of a ratchet screwdriver and the field of the ratchet device of a screwdriver, which can solve the problems of high production cost and complex structure of the ratchet mechanism, and achieve the effects of long service life, simplified structure and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

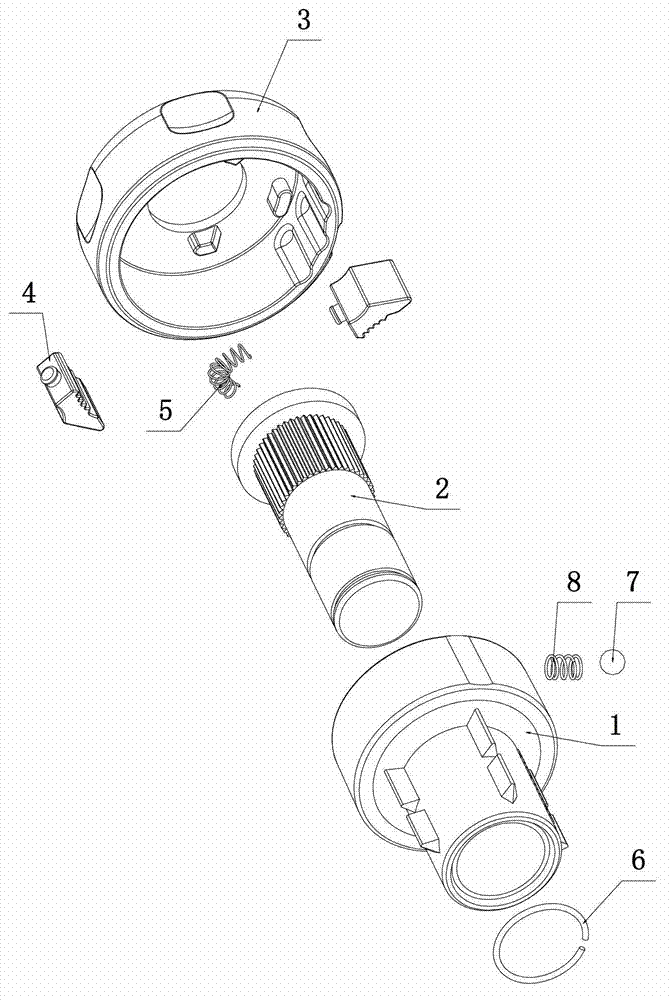

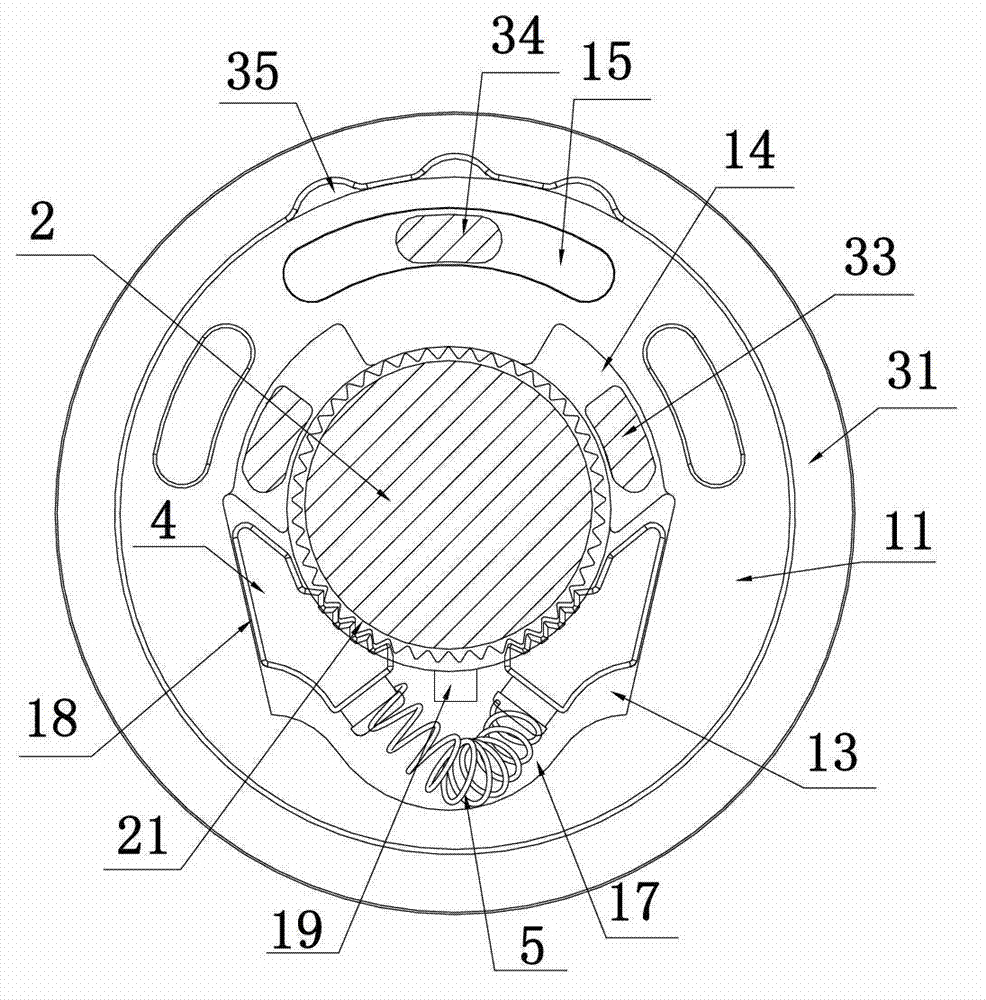

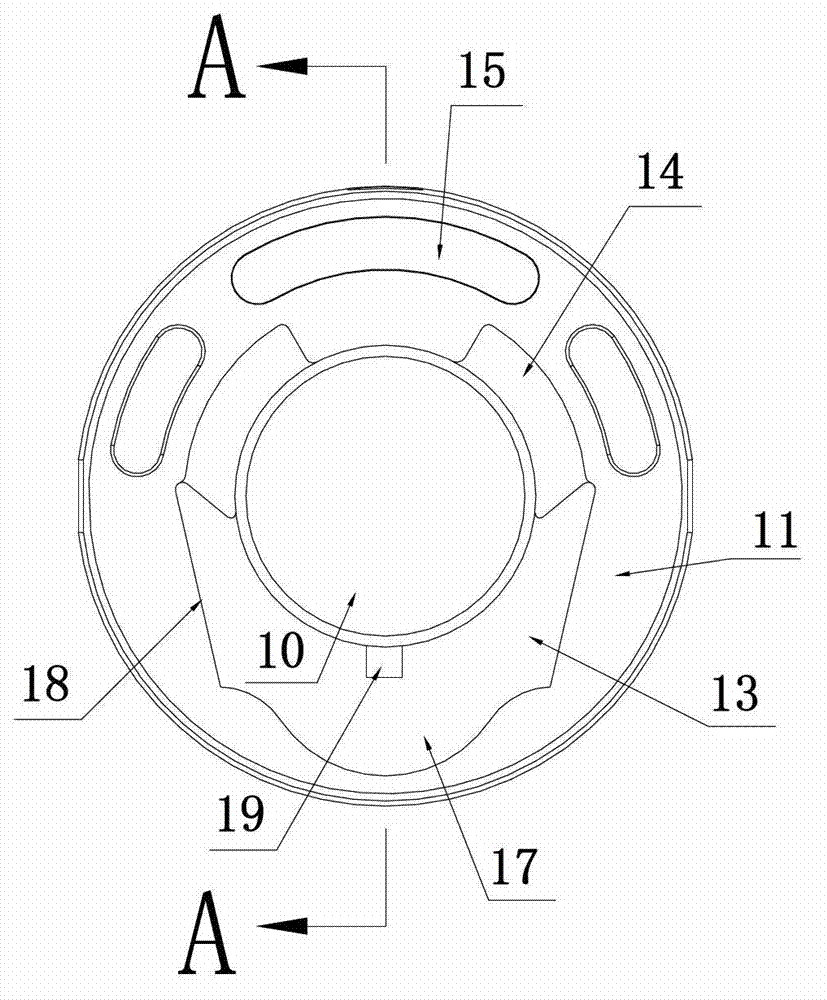

[0028] Such as figure 1 , figure 2 A screwdriver ratchet device is shown. The ratchet device includes a ratchet seat 1 , a ratchet shaft 2 , an outer collar 3 and two ratchets 4 . A first central shaft hole 10 is provided in the axial direction of the ratchet seat 1 . The front end of the ratchet seat 1 is an annular body 11 , and the rear end is a connecting portion 12 for connecting the screwdriver handle body. The outer collar 3 is composed of an annular bottom surface 31 and an annular outer ring 32 , the annular outer ring 32 is sheathed on the outer ring of the annular body 11 , and the annular bottom surface 31 is provided with a second central axis hole 30 . Such as Figure 7 , Figure 8 As shown, a connection port 24 is provided in the middle of the outer end of the ratchet shaft 2, and a magnetic steel 25 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com