Welding tool used for double-acting type friction stir welding or double-acting type friction stir spot welding, and welding device using same

A jointing tool and friction stir technology, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems such as the joint tool cannot move forward and backward smoothly, and the movement is bad, so as to achieve the effect of effective joint and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

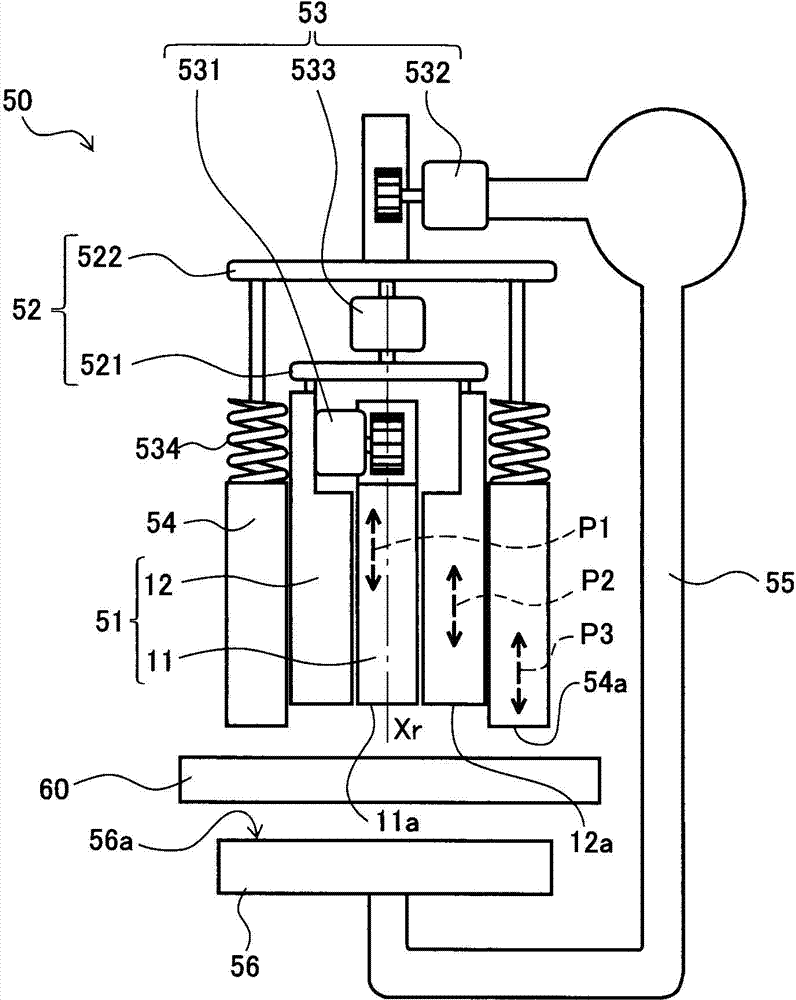

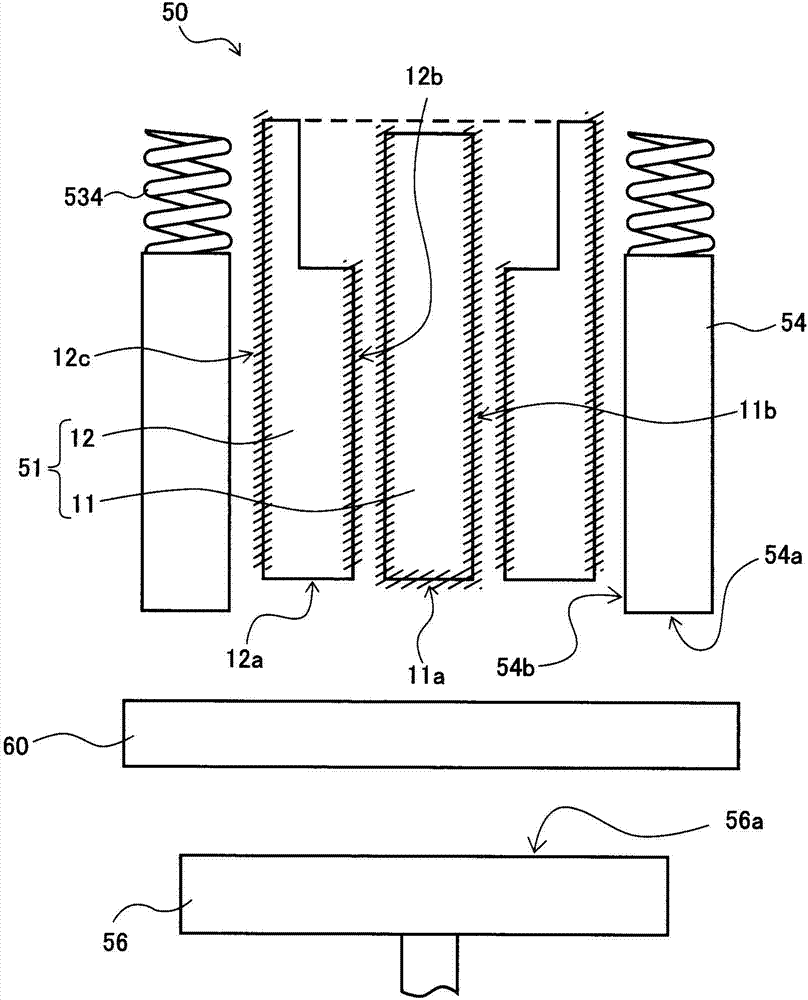

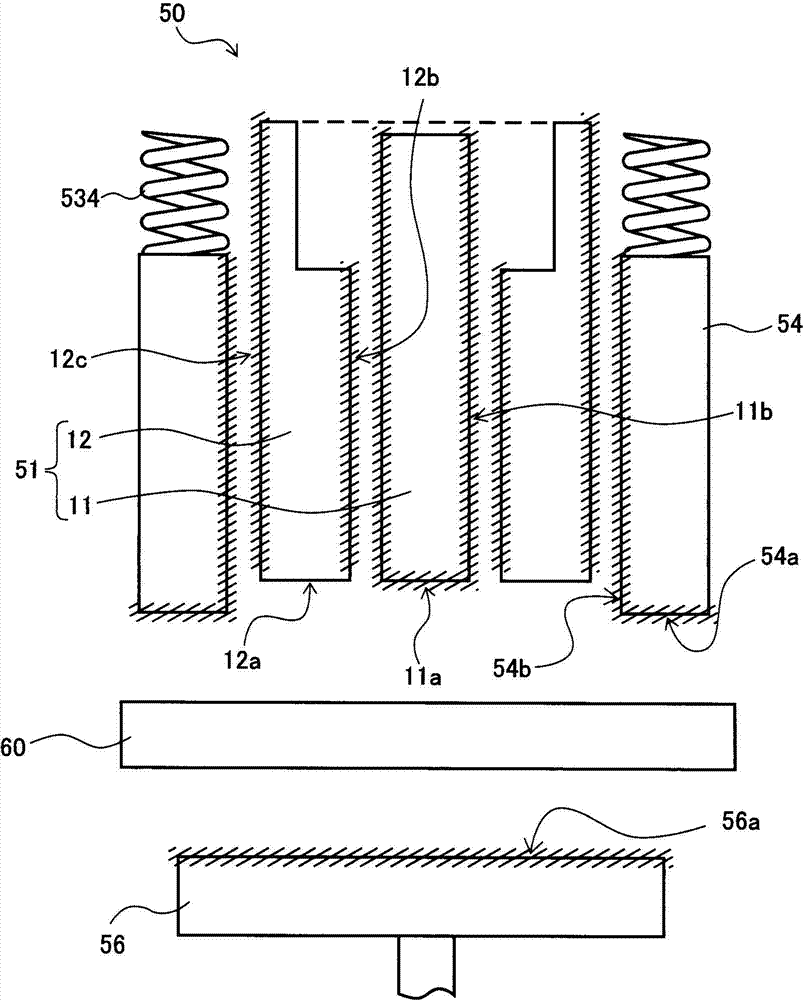

[0109]First, as the friction stir welding device 50, a double-action FSJ manipulator system manufactured by Kawasaki Heavy Industries, Ltd. was used, and as the rotary tool 51, a pin member 11 coated with hydrogen-free DLC was used as the rotary tool 51, and the pin member 11 was made to move forward and backward. It accommodates a cylindrical shoulder member 12 whose entirety is coated with hydrogen-free DLC except the abutting surface 12 a , and a cylindrical holding member 54 located outside the shoulder member 12 . In this rotary tool 51 , the outer diameter of the portion (the pin member 11 and the shoulder member 12 ) that moves forward and backward relative to the workpiece 60 is 6 mm, and the outer diameter of the clamping member 54 that accommodates the portion that moves forward and backward is 6 mm. is 12mm.

[0110] Next, as the object 60 to be joined, a member in which an aluminum material (AL6061-T6) with a thickness of 0.025 inches (approximately 0.635 mm) and a...

Embodiment 2)

[0117] As the rotary tool 51 , a pin member 11 with an outer diameter of 3.0 mm, a shoulder member 12 with an outer diameter of 6.0 mm and an inner diameter of 3.03 mm, and a clamp member 54 with an outer diameter of 12 mm and an inner diameter of 6.03 mm were prepared. In addition, hydrogen-free DLC coating was performed on the pin member 11 , the shoulder member 12 , and the clamp member 54 .

[0118] In this structure, the gap between the pin member 11 and the shoulder member 12 is set so that the difference between the outer diameter of the pin and the inner diameter of the shoulder reaches 0.03mm, and the gap between the shoulder member 12 and the clamping member 54 is set to the outer diameter of the shoulder. The difference from the inner diameter of the clamping member reaches 0.03 mm. Using this rotary tool 51 , the object 60 to be joined was joined 30 times in the same manner as in the first embodiment described above.

[0119] When checking the joint of the object ...

reference example 1

[0124] In the rotary tool 51, as the shoulder member 12, a member with an outer diameter of 6.0 mm and an inner diameter of 3.05 mm is used, and as the clamping member 54, a member with an outer diameter of 12 mm and an inner diameter of 6.05 mm is used. In Example 2, the to-be-joined object 60 was joined similarly.

[0125] In addition, in this structure, the clearance between the pin member 11 and the shoulder member 12 is set so that the difference between the outer diameter of the pin and the inner diameter of the shoulder is 0.05 mm, and the clearance between the shoulder member 12 and the clamping member 54 is set as the axis The difference between the outer diameter of the shoulder and the inner diameter of the holding member is set to be 0.05 mm.

[0126] When checking the joint of the object to be joined 60 after construction, no major problem in appearance was observed in either the contact portion of the pin member 11 or the contact portion of the shoulder member 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com