Insulator replacement device

A technology of insulators and clamps, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing the time and risk of aerial work, unable to guarantee the fit of the clamp head, inconvenient disassembly and assembly, etc., to achieve good promotion prospects and practical value, The effect of improving stability and improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

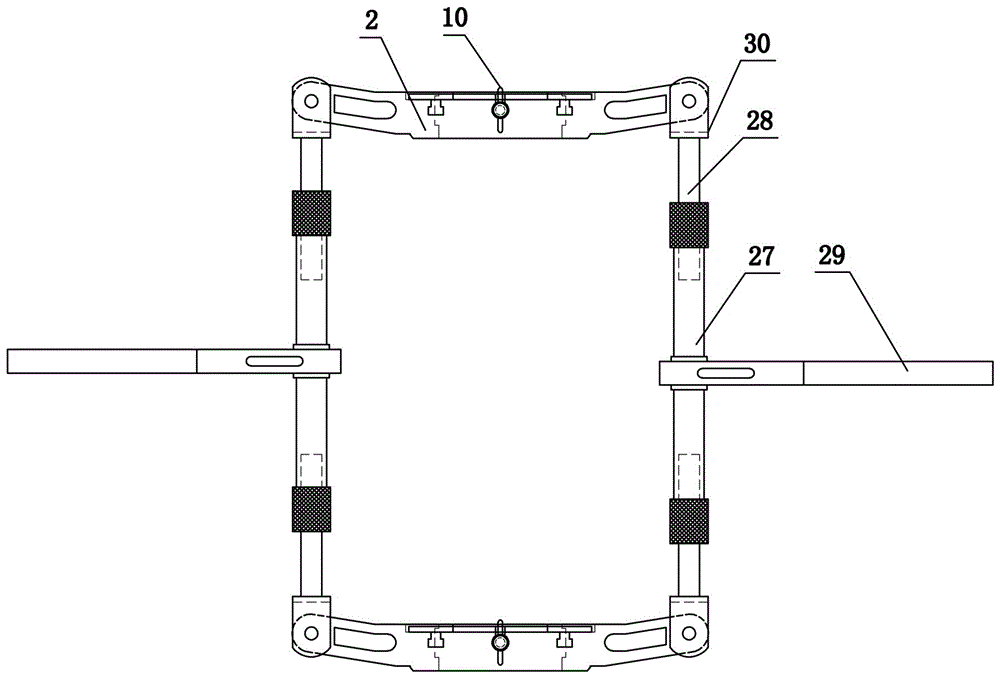

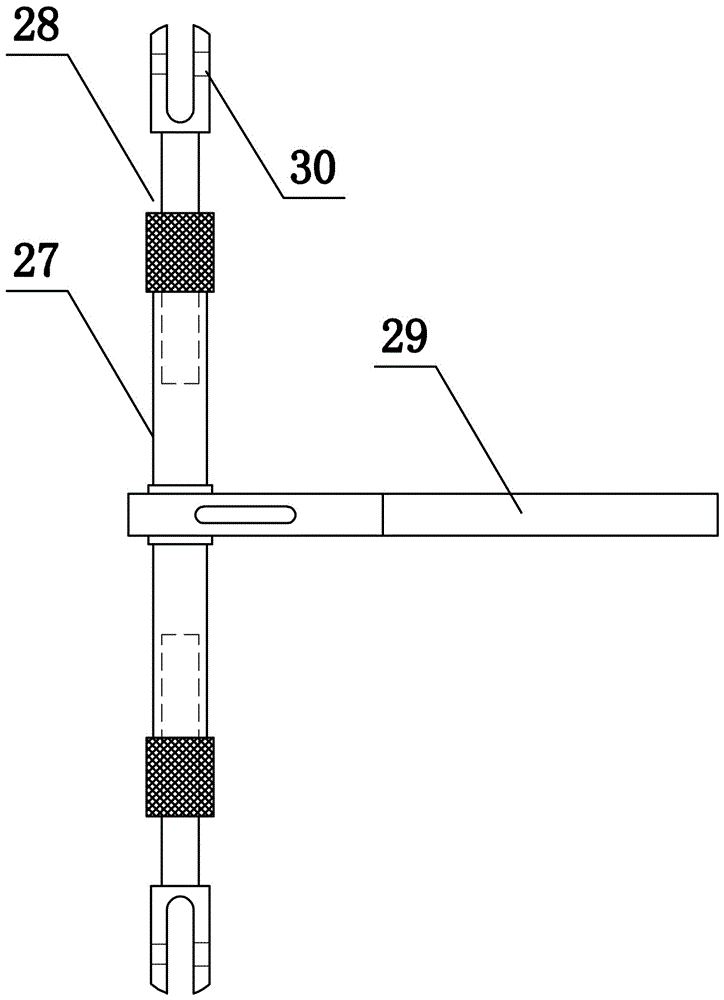

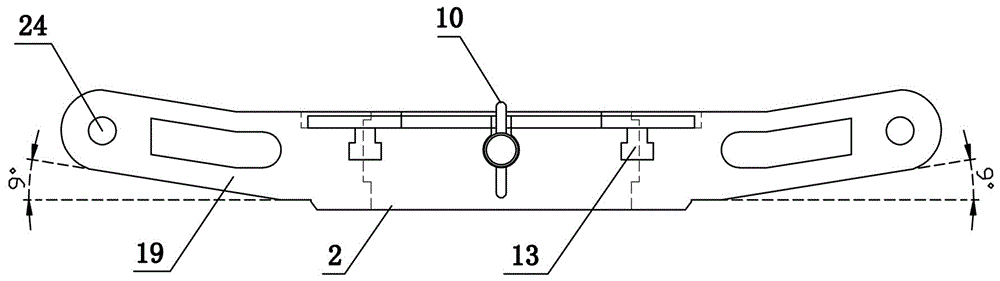

[0044] like Figure 1 to Figure 9 As shown, the present invention includes a fixture and a length adjustment mechanism, and the fixture is two including an upper fixture and a lower fixture, and both the upper fixture and the lower fixture include a fixedly connected first clamping plate 1 and a second clamping plate 2 The opposite end surfaces of the first clamping plate 1 and the second clamping plate 2 are arc-shaped and enclose a columnar cavity 3 for accommodating the insulator steel cap. The upper end surface of the first clamping plate 1 is provided with a first receiving groove 4, and the second The upper end surface of clamping plate 2 offers the second accommodation groove 5, and the first accommodation groove 4 and the second accommodation groove 5 are semi-circular structure and both surround and form the annular accommodation groove, the first accommodation groove 4 is slidingly set and first The first adjusting ring 6 matching the receiving groove 4, the second a...

Embodiment 2

[0052] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 10 to Figure 12 As shown, an extension rod 31 is set between the left length adjustment mechanism and the upper jig, and a tension sensing module 32 is set between the right length adjustment mechanism and the upper jig. The output end of the tension sensing module 32 is electrically connected to the control module, and the control module is electrically connected to the The display module 33 and the control module (not shown) are integrated inside the display module 33 . It should be pointed out that both ends of the extension tube 31 and the tension sensing module 32 are provided with connecting parts to connect with the length adjusting mechanism and the fixture.

Embodiment 3

[0054] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 13 As shown, the side end surfaces of the first clip 1 and the second clip 2 are provided with a third receiving groove 25, and a positioning plate 26 is slidably arranged in the third receiving groove 25, and a screw thread matched with the limit nut 10 is provided on the positioning plate 26. A through hole is provided on the connecting plate 9. When this structural design is in use, the positioning plate 26 is pressed outwardly in the third receiving groove 25 by turning the limit nut 10, so as to realize the fixing of the limit nut 10 to the connecting plate 9. The nut 10 is connected with the threaded through hole on the connecting plate 9 , and this structural design has a better and more stable fixing effect on the first adjusting ring 6 and the second adjusting ring 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com