Dissimilar material weld joint formed by joining iron type material and aluminum type material, and weld joining method

A technology for welding joints and heterogeneous materials, applied in the direction of welding/welding/cutting items, welding equipment, laser welding equipment, etc., can solve problems such as cracks, and achieve easy joint formation, excellent joint strength, high joint strength and ductility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

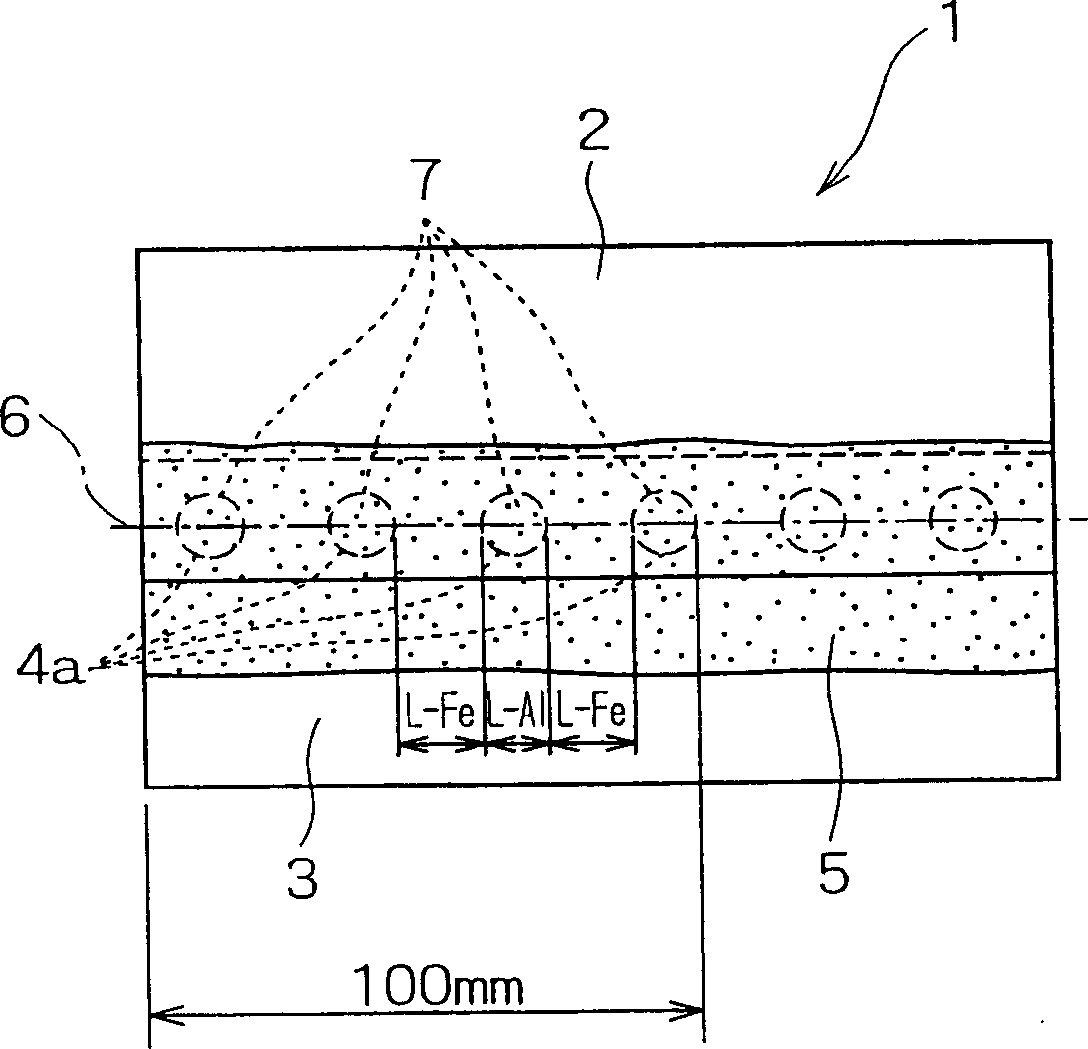

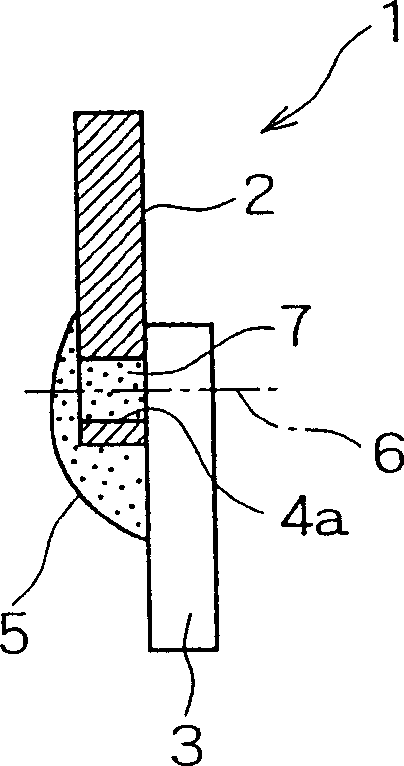

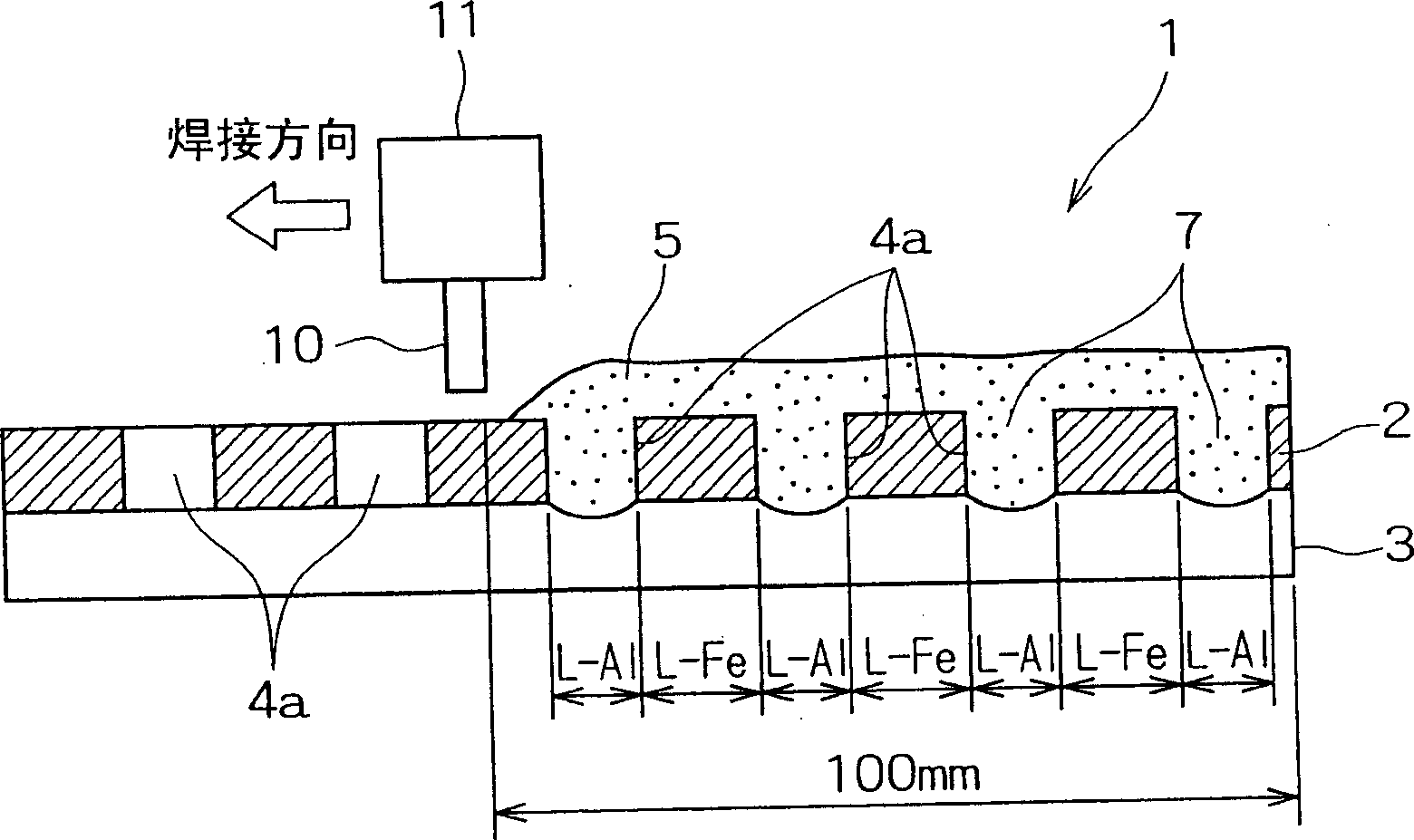

[0096] The present inventors placed steel plates in which voids (holes) were formed according to the present invention (from mild steel sheet SPCE to high-strength steel plates up to 980MPa) on aluminum alloy plates (A5182), and lap-welded them using various aluminum welding wires test, whereby a dissimilar material welded joint is prepared, and then the dissimilar material welded joint is evaluated.

[0097] In Table 1, conditions (grade and thickness), wire conditions (grade), welding conditions (current, voltage and welding speed), pore conditions (shape and parameter P value), evaluation results (presence of bead cracking and tensile strength and elongation of the joint) and others. Here, AC power is used for all welding. Then, in order to facilitate the test for evaluating the present invention, a circular shape was adopted as the pore shape formed in all ferrous materials, and the pore diameter was used as a size parameter.

[0098] The aluminum alloy steel plate and t...

Embodiment 2

[0111] The present inventors used an AC power source and various aluminum welding wires under various heat output conditions by arc welding, by joining the steel sheets shown in Table 2 ("GA" in the "Type" column means hot-dip galvanized steel sheet) ) and aluminum alloy plates to prepare welded joints. In this steel sheet, circular voids (2R, R denoting circular equivalent radii) with diameters shown in Table 2 were previously formed at intervals (length of non-void portion) shown in Table 2. In arc welding, Ar gas (flow rate of 20-25 l. / min.) is used as shielding gas. The angle of the welding torch was set at 80°. Here, the Mg content in the aluminum welding wire used here is as follows; 0.05% or less (for A4043-WY), 4.3 to 5.2% (for A5183-WY), 4.5 to 5.5% (for A5356-WY) and 2.4 to 3.2% (for A5554-WY).

[0112] The prepared welded joints were visually inspected to determine the presence of weld cracks, and the weld strength of the welded joints was measured. Weld cracks ...

Embodiment 3

[0120] The present inventors used a DC power source and various aluminum welding wires under various heat output conditions by arc welding, by joining the steel sheets shown in Table 4 ("GA" in the "Type" column means hot-dip galvanized steel sheet) ) and aluminum plate to prepare welded joints. In these steel sheets, circular pores (2R, R denoting circular equivalent radii) having diameters shown in Table 4 were formed in advance at intervals (lengths of non-void portions) shown in Table 4. In arc welding, Ar gas (flow rate of 20-25 l. / min.) is used as shielding gas. The angle of the welding torch was set at 80°.

[0121] The prepared welded joints were visually inspected to judge the presence of weld cracks, and the welding strength of the welded joints was measured in the same manner as in Example 2. The results obtained are shown in Table 5.

[0122] It can be clearly seen from Table 4 and Table 5 that in the case of DC power supply, when the welding conditions (heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com