Method for manufacturing heat exchanger and heat exchanger obtained by same

A manufacturing method and heat exchanger technology, applied in the direction of indirect heat exchangers, heat exchanger types, manufacturing tools, etc., can solve the problems of reduced strength, difficulty in joining, and insufficient supply of thin tubes and straight tubes. Achieve the effect of uniform thickness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

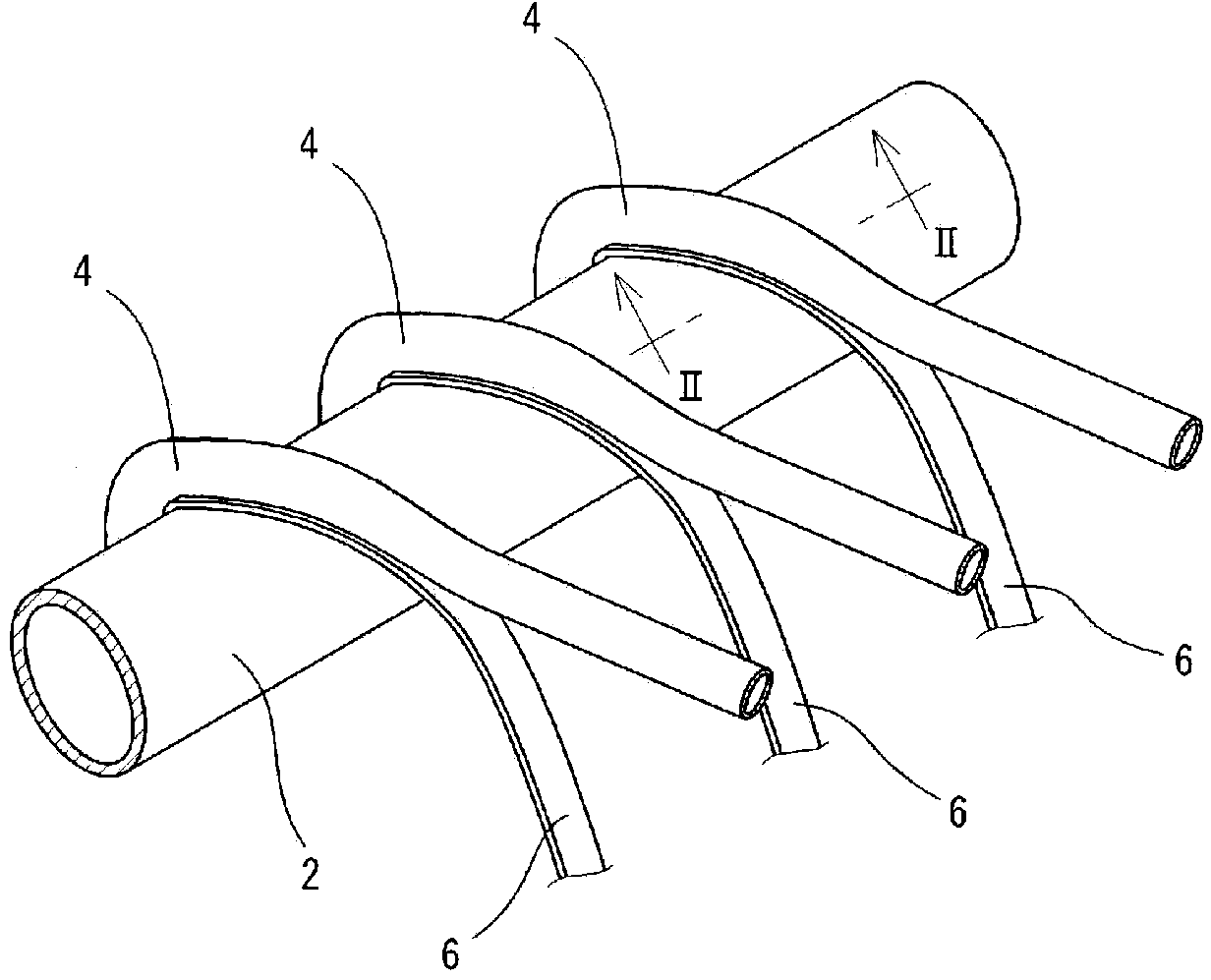

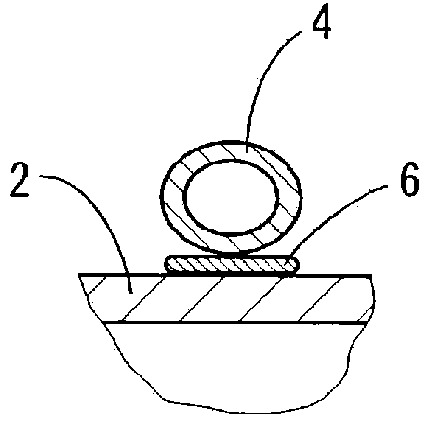

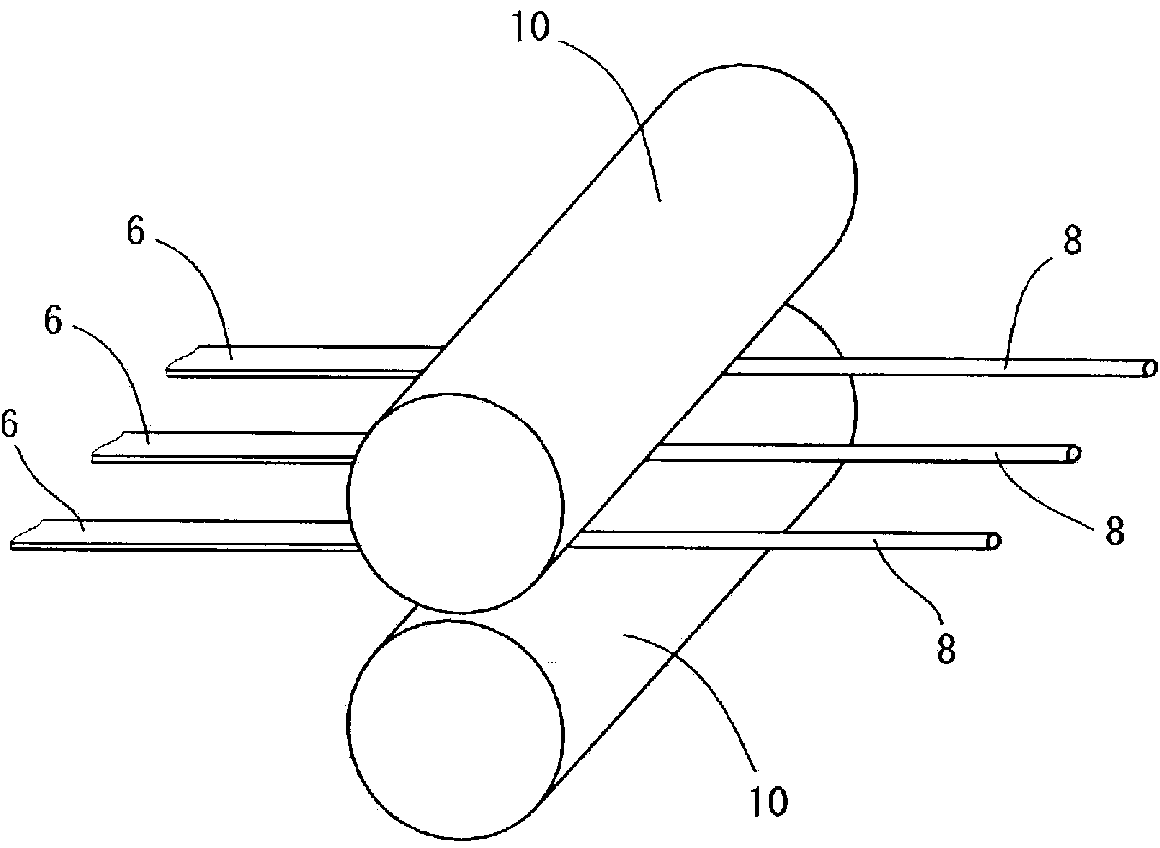

[0025] When manufacturing a heat exchanger for hot water supply that uses carbon dioxide as a refrigerant, one of the heat exchangers that is the object of the present invention, it is known to adopt a manufacturing method including a winding step for Winding one or more refrigerant tubes around the outer peripheral surface of a straight tube-shaped water pipe; joining step for joining the refrigerant tube to the outer peripheral surface of the water pipe; and bending step for bending the obtained joined body It is processed into a spiral shape or a racetrack shape, but here, according to the present invention, a strip-shaped solder sheet material is used as a bonding material, and the winding process of the refrigerant tube is performed.

[0026] Specifically, as figure 1 As shown, one or more, in this case three refrigerant tubes 4, are spirally wound on the outer peripheral surface of a straight tube-shaped large-diameter water tube 2 with a water passage in the tube. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com