Desulphurization pump with combined impeller rotor

A desulfurization pump and composite technology, applied in the field of desulfurization pumps, can solve the problems of increasing the displacement coefficient of the blade inlet and outlet, increasing the cost of users, increasing the cost of materials, etc., so as to save material costs, improve operating efficiency, and reduce self-weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

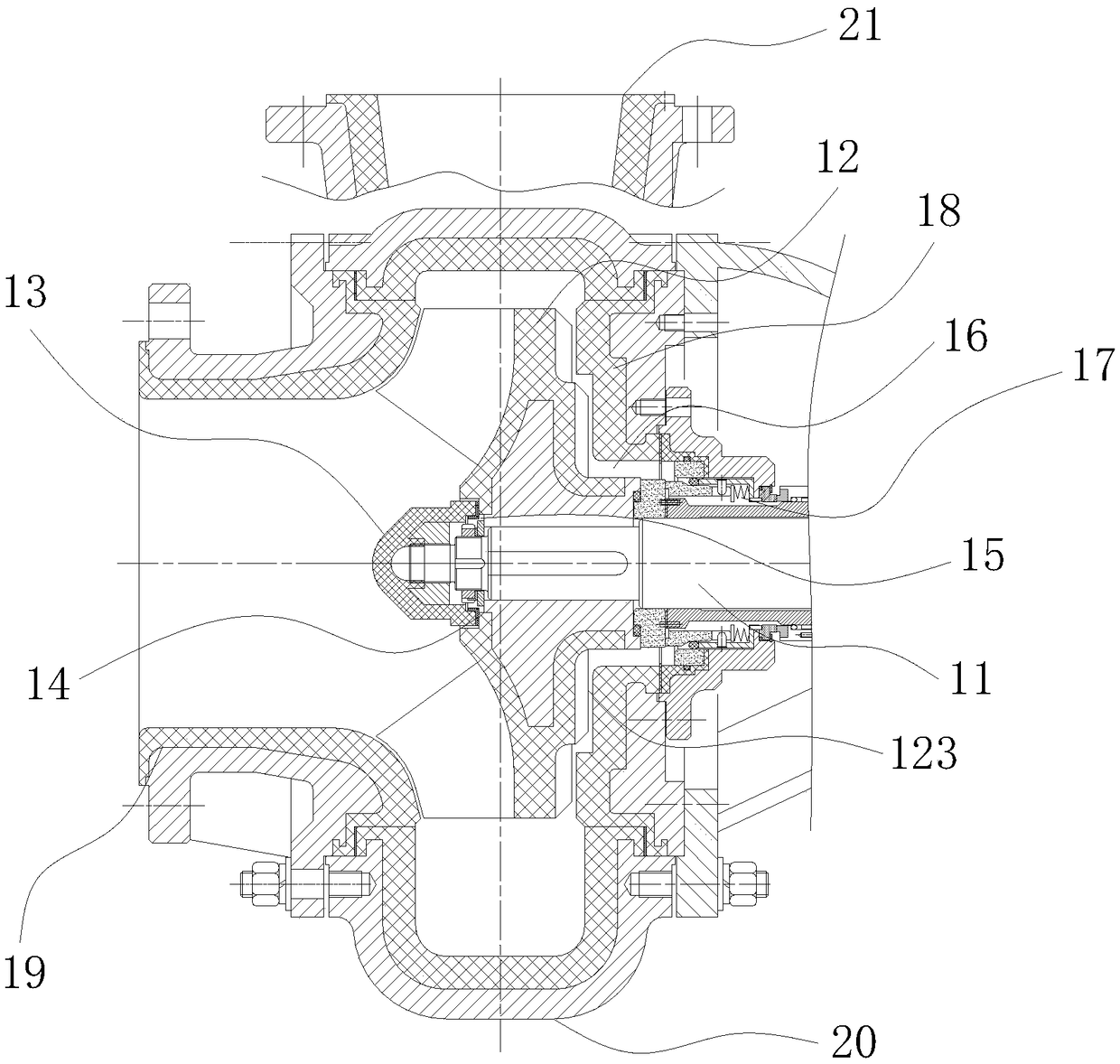

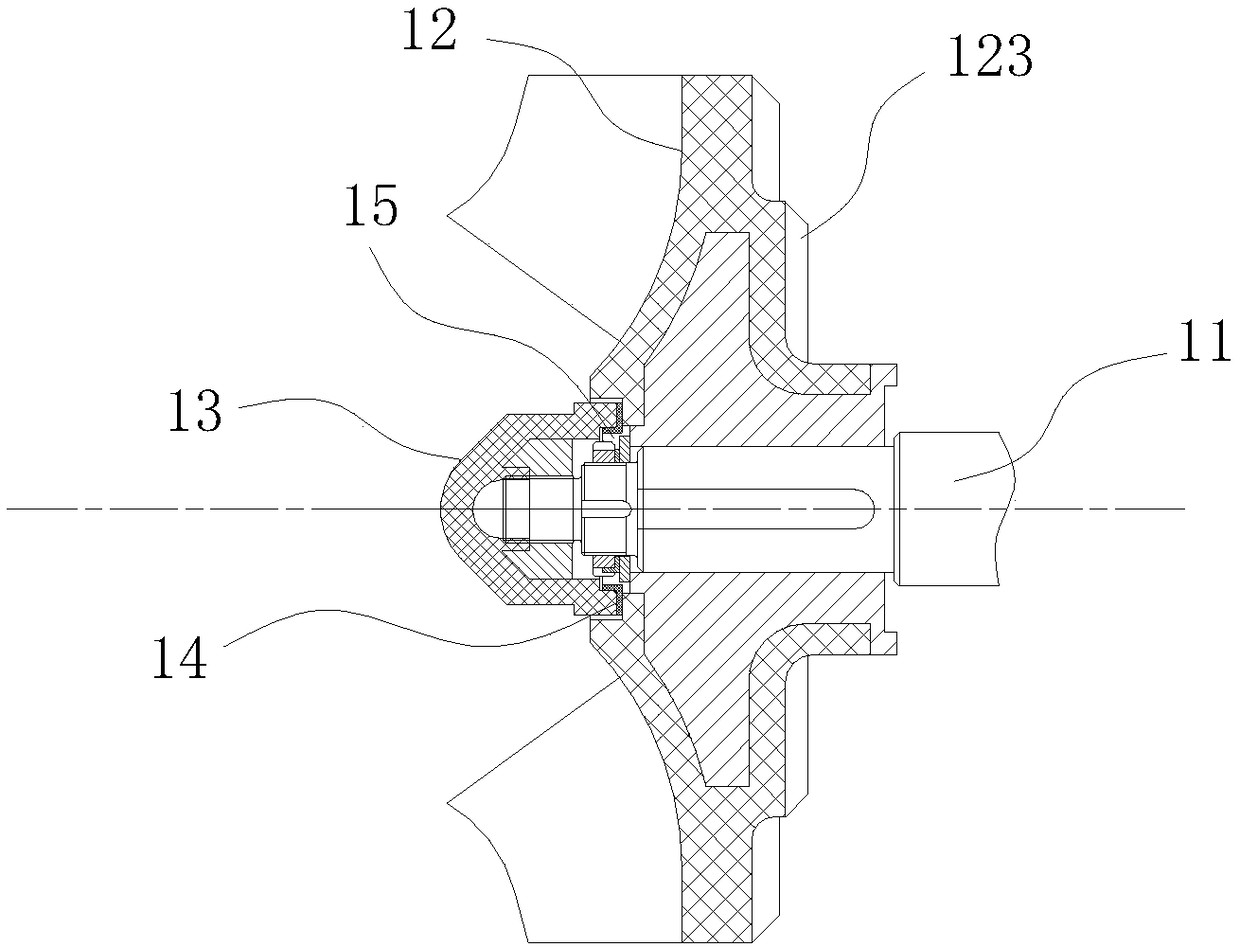

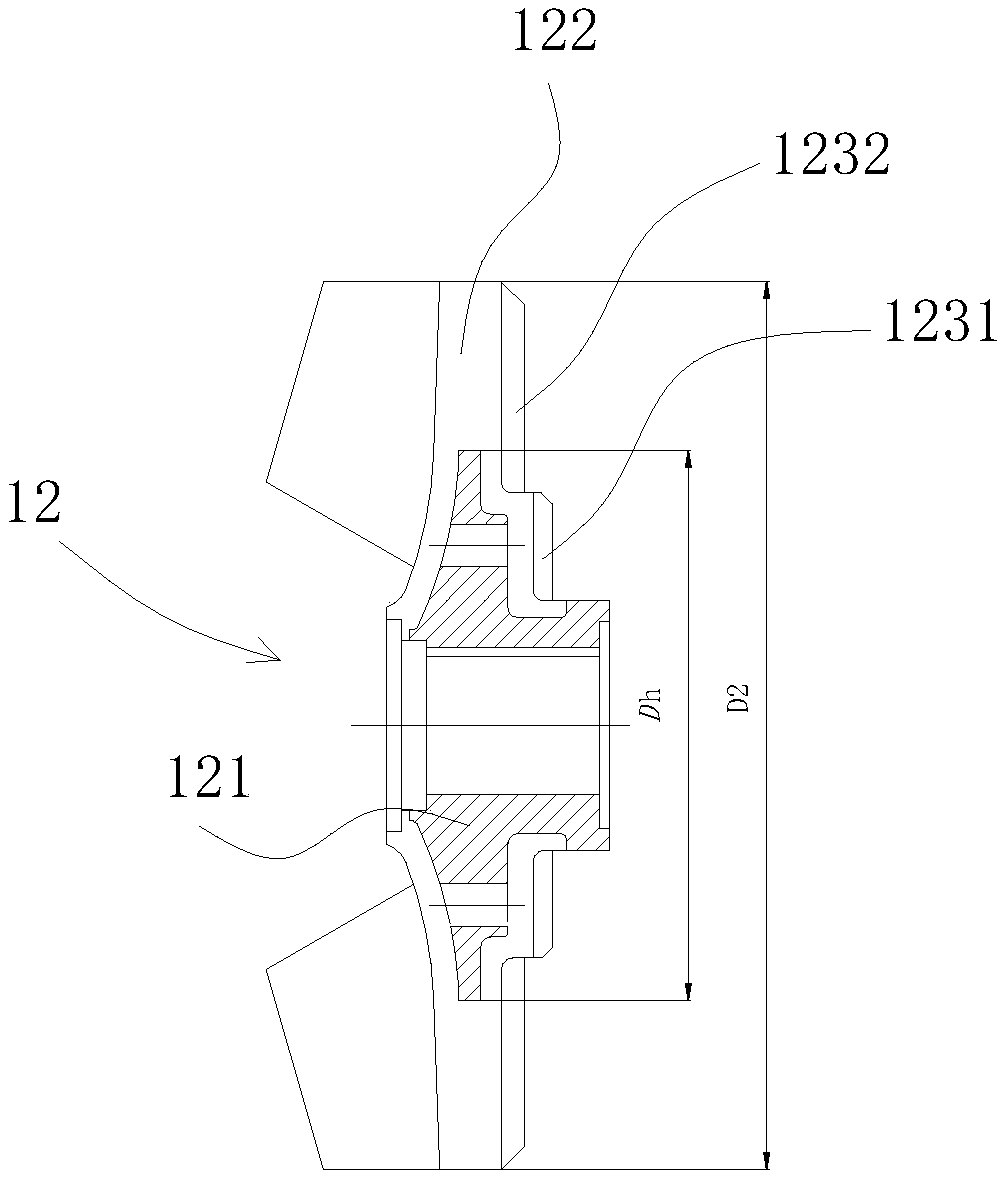

[0035] Such as figure 1 , 2 , 3, and 4 show: the present invention includes composite impeller rotor, pump housing 20, pump inlet part 19, pump outlet part 21 and pump rear cover plate 18, described pump inlet part 19, pump outlet part 21, pump rear The cover plate 18 is installed on the pump housing 20 and encloses and forms a pump chamber for accommodating the composite impeller rotor. The inner surface of the pump chamber formed by the pump casing 20 , the pump inlet part 19 , the pump outlet part 21 and the pump rear cover plate 18 is all provided with a non-metallic lining (ultra-high molecular weight polyethylene). The pump chamber is wear-resistant and corrosion-resistant, more suitable for conveying granular media, and easy to install and disassemble the composite impeller rotor.

[0036]The composite impeller rotor includes an impeller body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com