Semi-automatic set screw assembling machine

A set screw, semi-automated technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, inaccurate screw thread length, easy to appear slipping phenomenon, etc., to improve production efficiency , The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

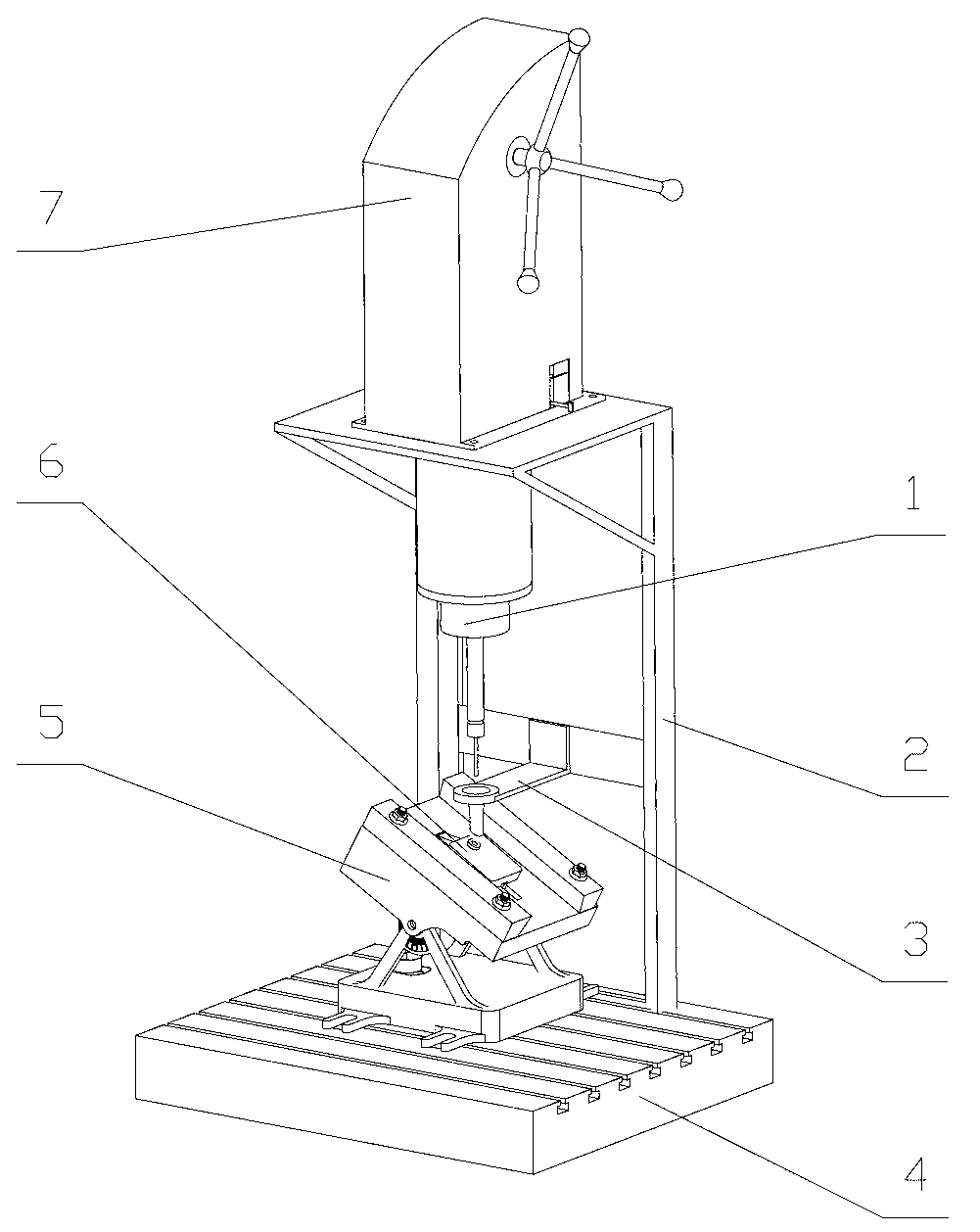

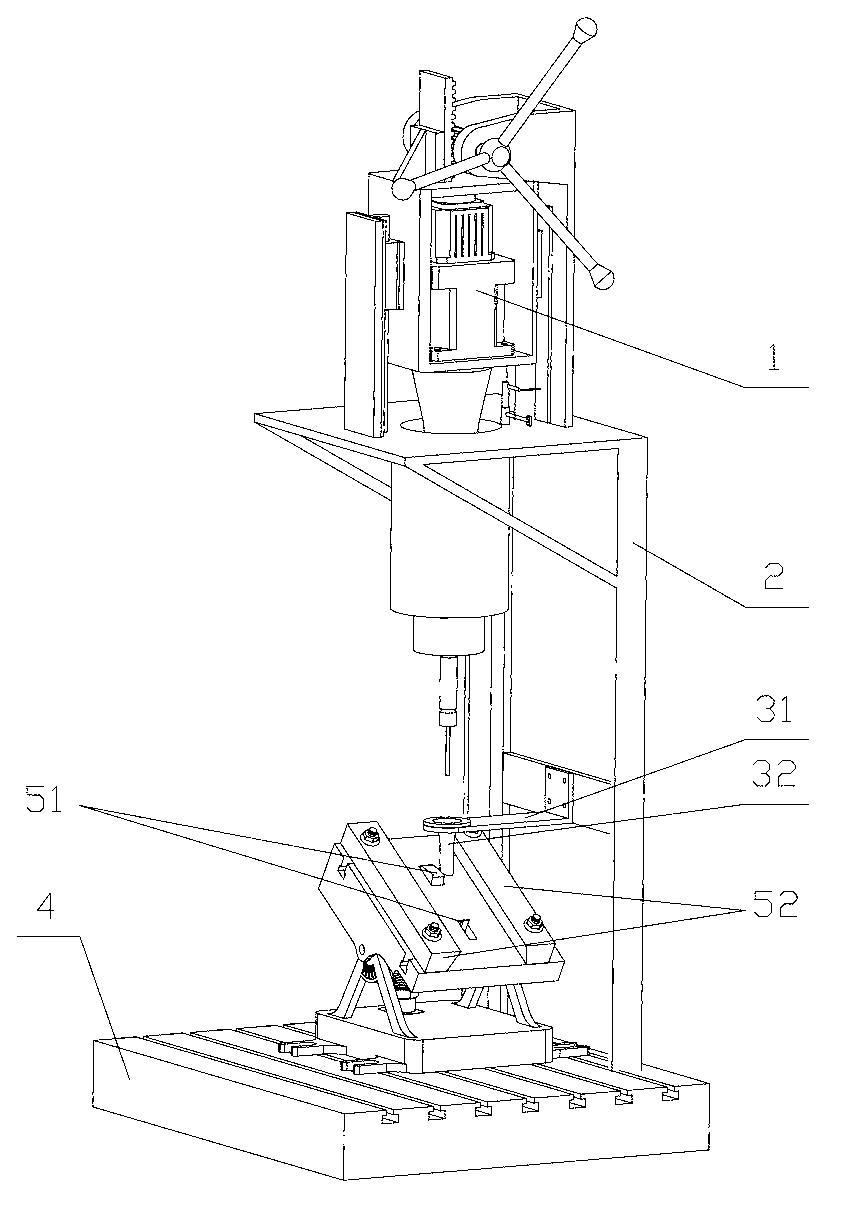

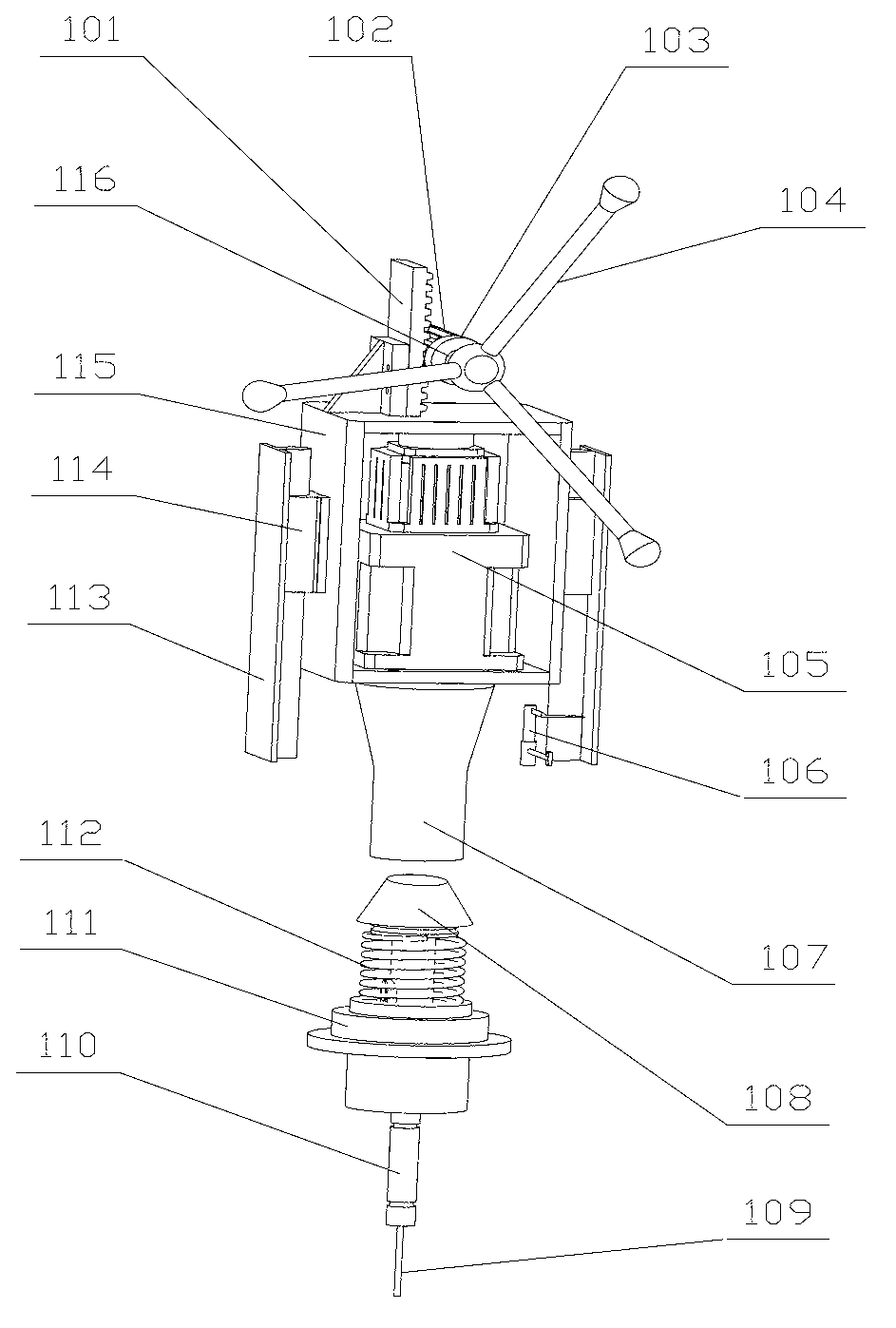

[0023] Such as Figure 1-Figure 4 As shown, the semi-automatic set screw assembly machine is composed of a screw-in device 1, a bracket 2, a screw guide device 3, a base plate 4, and a workbench 5. The bracket 2 is fixed on one side of the base plate 4, the workbench 5 is arranged on the upper surface of the base plate 4, the guide device 3 and the screw-in device 1 are arranged vertically above the workbench 5 in turn and are respectively connected with the support 2, the screwdriver 109, the guide sleeve 32 and 6 screw holes of the part to be fixed are coaxial. There is a T-shaped slot on the bottom plate 4, which is used to fix the workbench 5. The workbench 5 is divided into upper and lower parts. The lower part is connected with the bottom plate 4 by bolts. The screw rod adjusts the inclination angle, movable inclined p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com