Multifunctional mixture blending device

A kind of mixed material and multi-functional technology, which is applied in the direction of mixer, transportation and packaging, mixer with rotating stirring device, etc., can solve the problems of uneven mixing, waste of time, manpower and economy, low mixing efficiency, etc., to achieve Stir fully and evenly, with high degree of automation, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

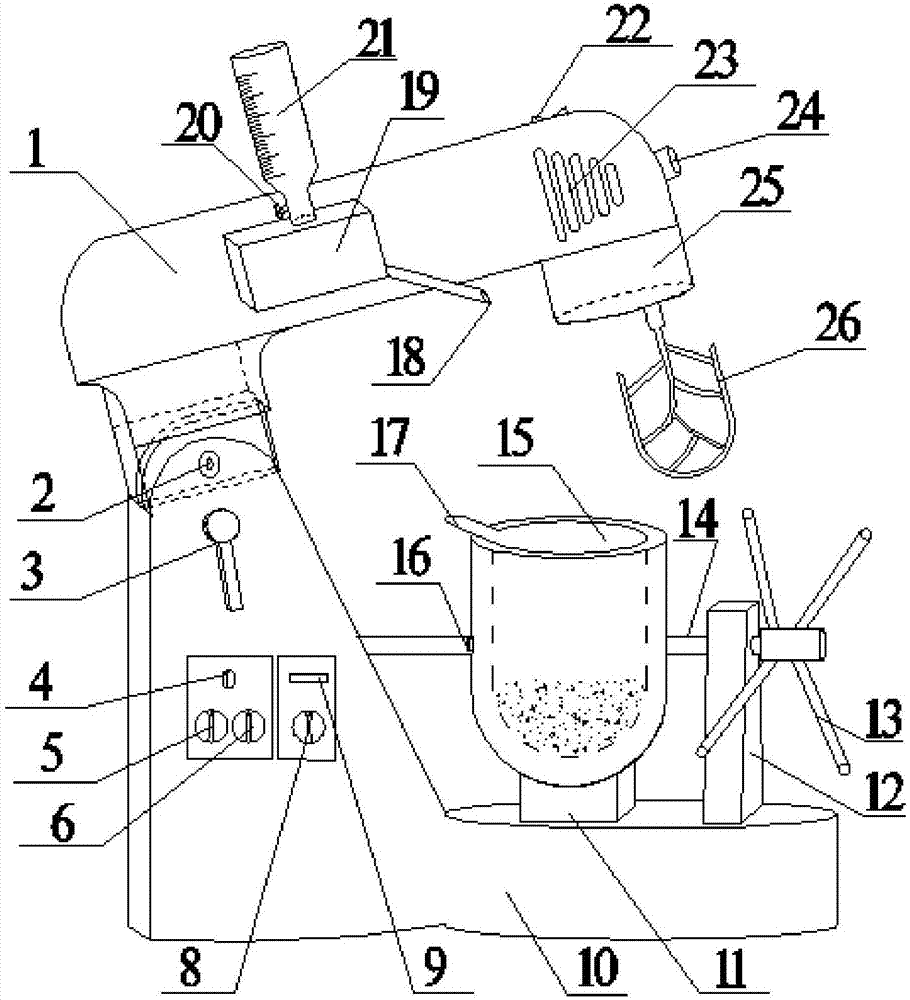

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

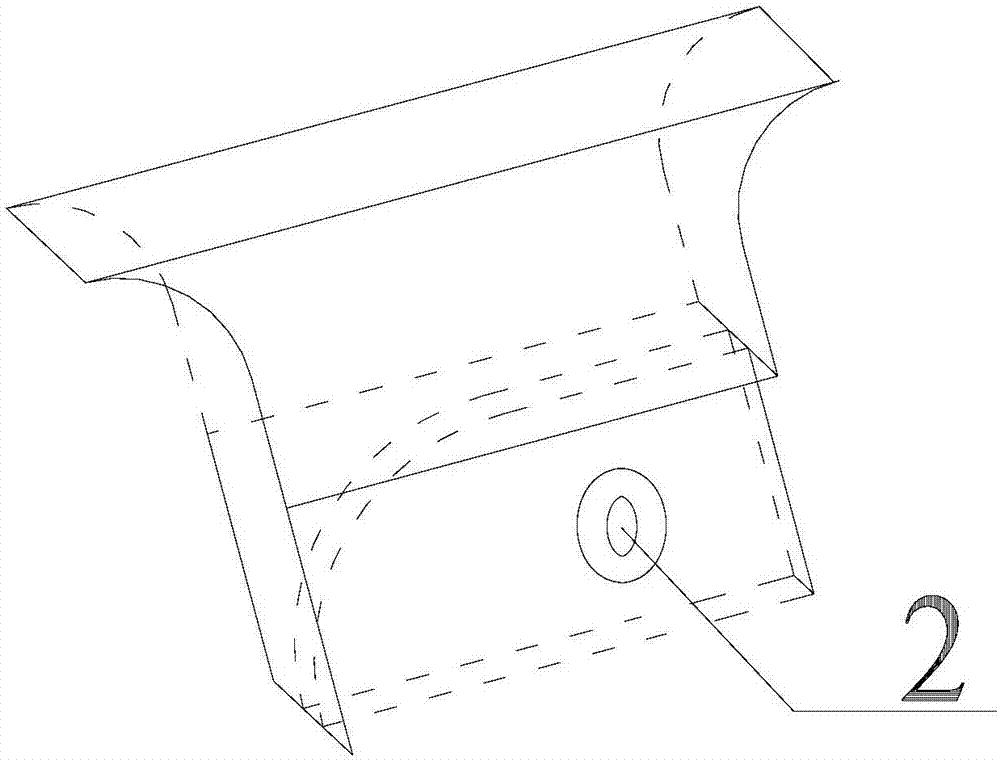

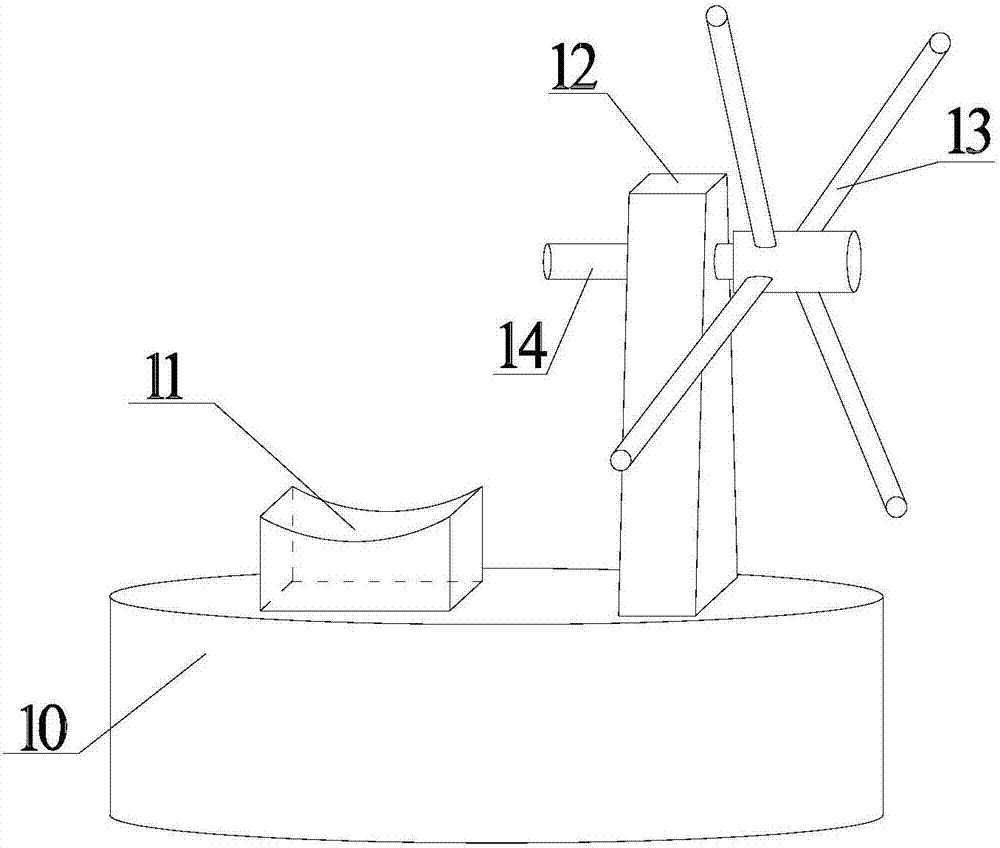

[0025] Such as Figure 1 to Figure 4 Shown, a kind of multifunctional mixing material stirring device comprises stirring device, unloading device, heating device and water supply device, and wherein stirring device comprises eccentric stirring rod and is used to hold the mixing bucket 15 of mixing material, and wherein eccentric stirring rod comprises The eccentric seat 25 arranged at the output end of the driving motor 1, the stirring blade 26 is installed at the lower end of the eccentric seat 25, the driving motor 1 drives the stirring blade 26 to revolve through the eccentric seat 25, and also makes the stirring leaf 26 rotate by itself, and the fixed end of the driving motor 1 passes through the motor The rotating shaft 2 is installed on the base 10, the drive motor 1 can rotate relative to the base 10, the base 10 is provided with a motor control handle 3 for con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com