Coupling bionic straw-soil uniform mixed burying combined machine

A technology that combines working machine and soil, applied in agricultural machinery and implements, agriculture, shovels, etc., can solve problems such as poor straw decomposition effect, poor burying uniformity of straw returning machines and tools, slow nutrient release, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

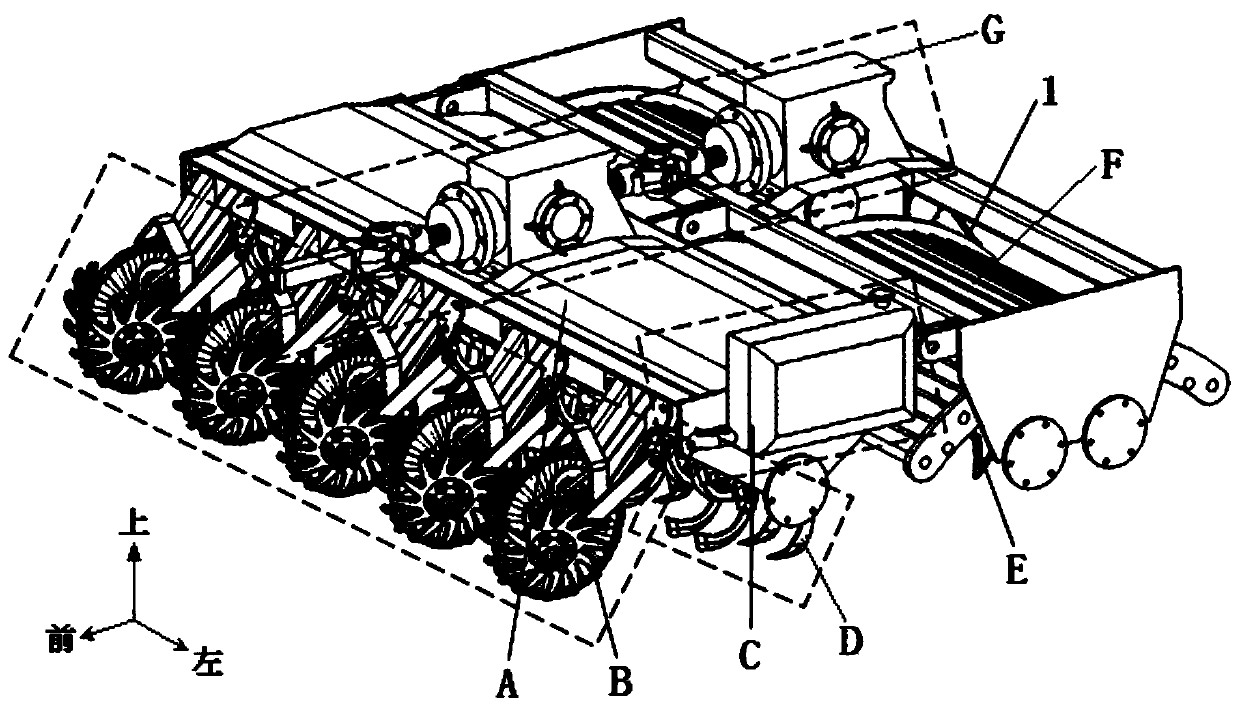

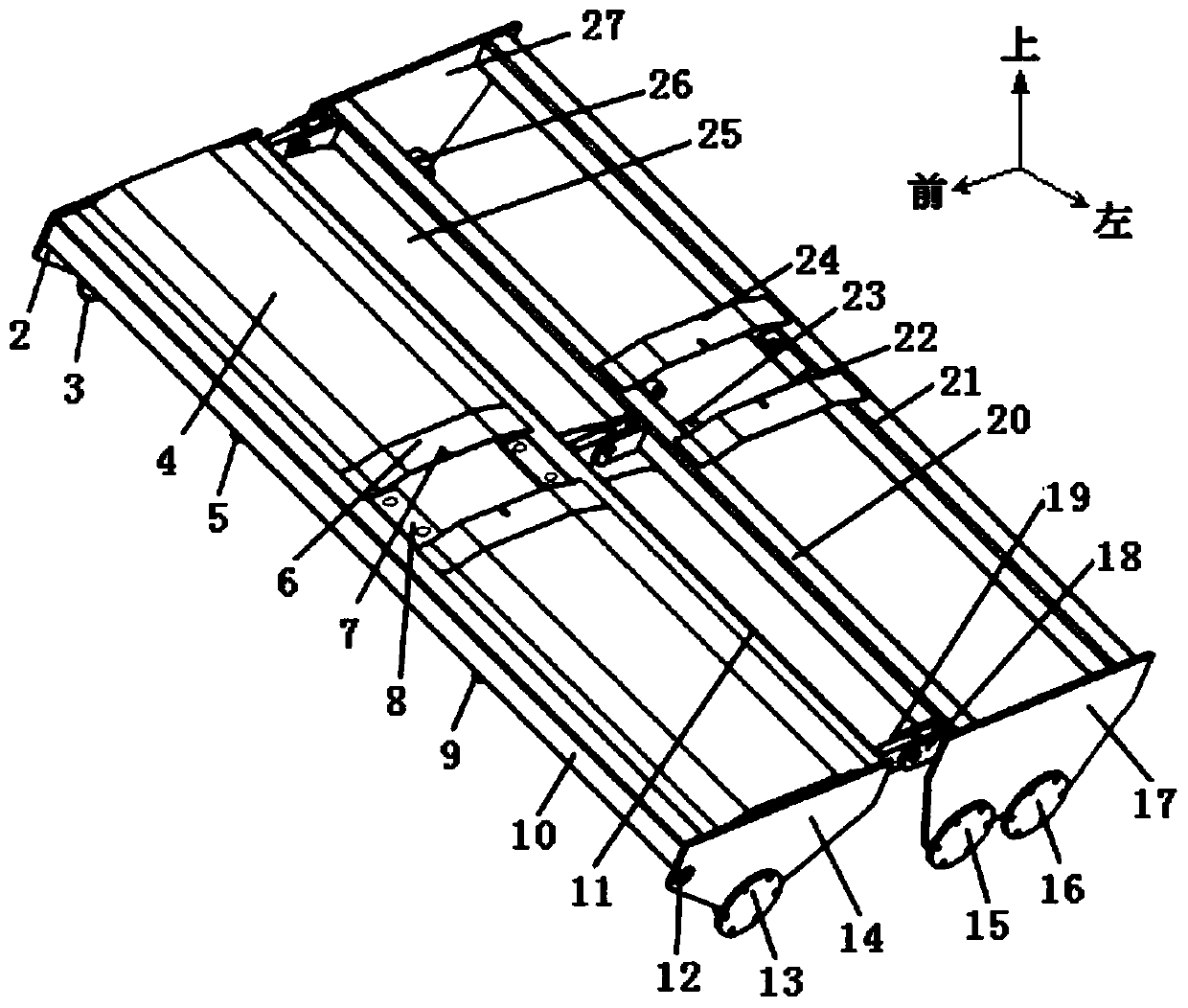

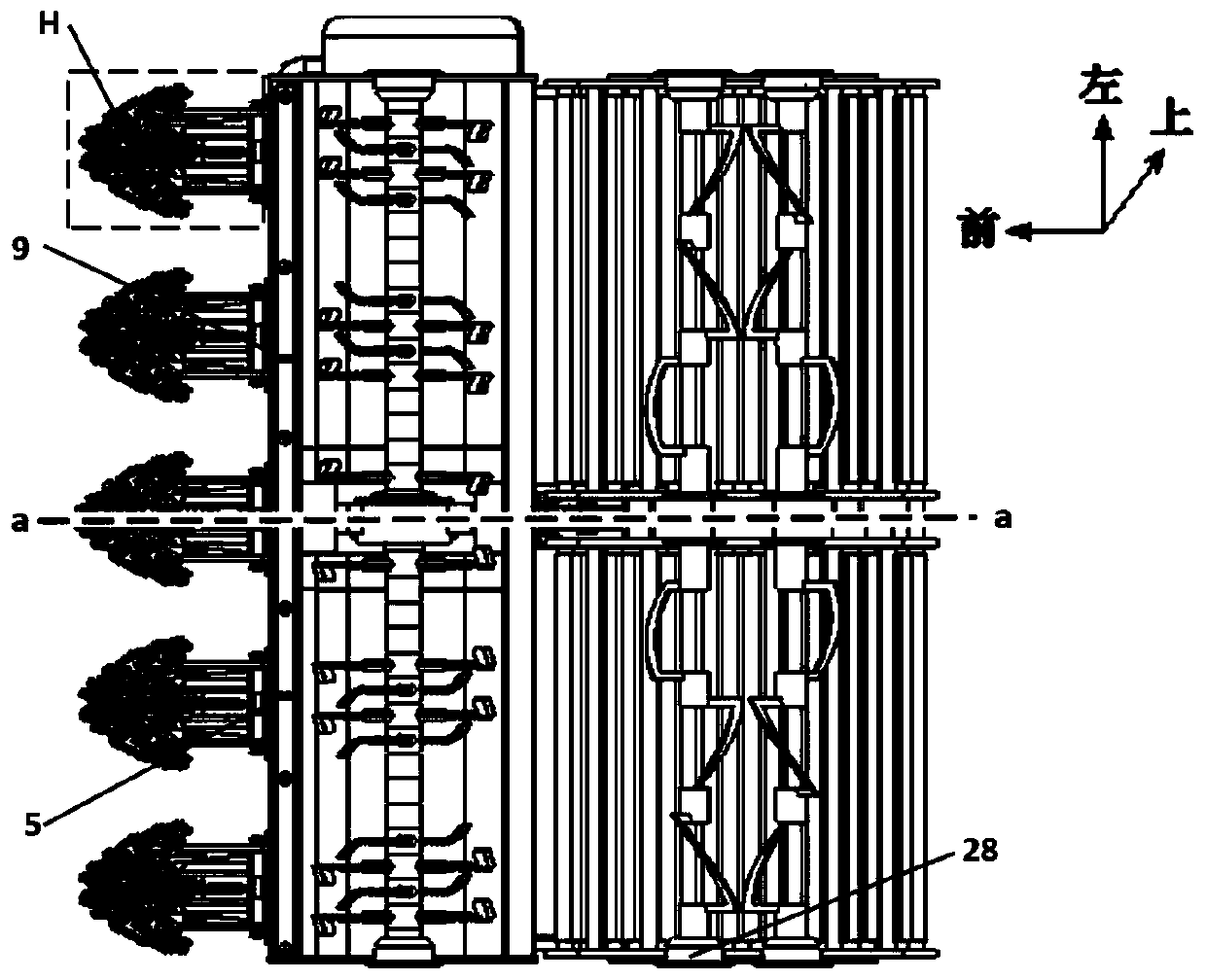

[0046] Example 1, such as figure 1 with image 3 As shown, the present invention is composed of a hooking device A, a weeding device B, a spraying device C, a bionic rotary tilling device D, a mixing device E, a transmission and covering device F, a power transmission device G, and a chain 1, wherein the grassing device B is composed of 5-7 existing grass-pull wheel sets H with the same structure, and is characterized in that: the grass-pull wheel sets H are uniformly distributed and fixed on the front surface of the beam I10 of the hooking device A; the material of the spraying device C The pipe 29 is fixedly connected to the bottom surface of the beam I10 via the support frame Ⅰ5 and the support frame Ⅱ9 of the hooking device A; the material box 32 of the spraying device C is fixedly connected to the left side plate I14 of the hooking device A; the speed change of the power transmission device G Box I 59 is fixed to the fixed plate group I 8 of the hitch A; the rib group I 60 ...

Embodiment 2

[0054] Embodiment 2, the structure of this embodiment is the same as that of embodiment 1, the difference is that the spraying device C can be adjusted to spray high-temperature steam or pesticides on the straw, and remove the residues on the straw through sterilization and pest control. Source of bacteria and worm eggs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com