Stirring device for material production

A stirring device and material technology, applied to mixers with rotating stirring devices, mixer accessories, dissolving, etc., can solve the problems of low quality of material stirring, uneven stirring of stirring devices, incomplete stirring, etc., to increase stability, The effect of increasing quality and increasing practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

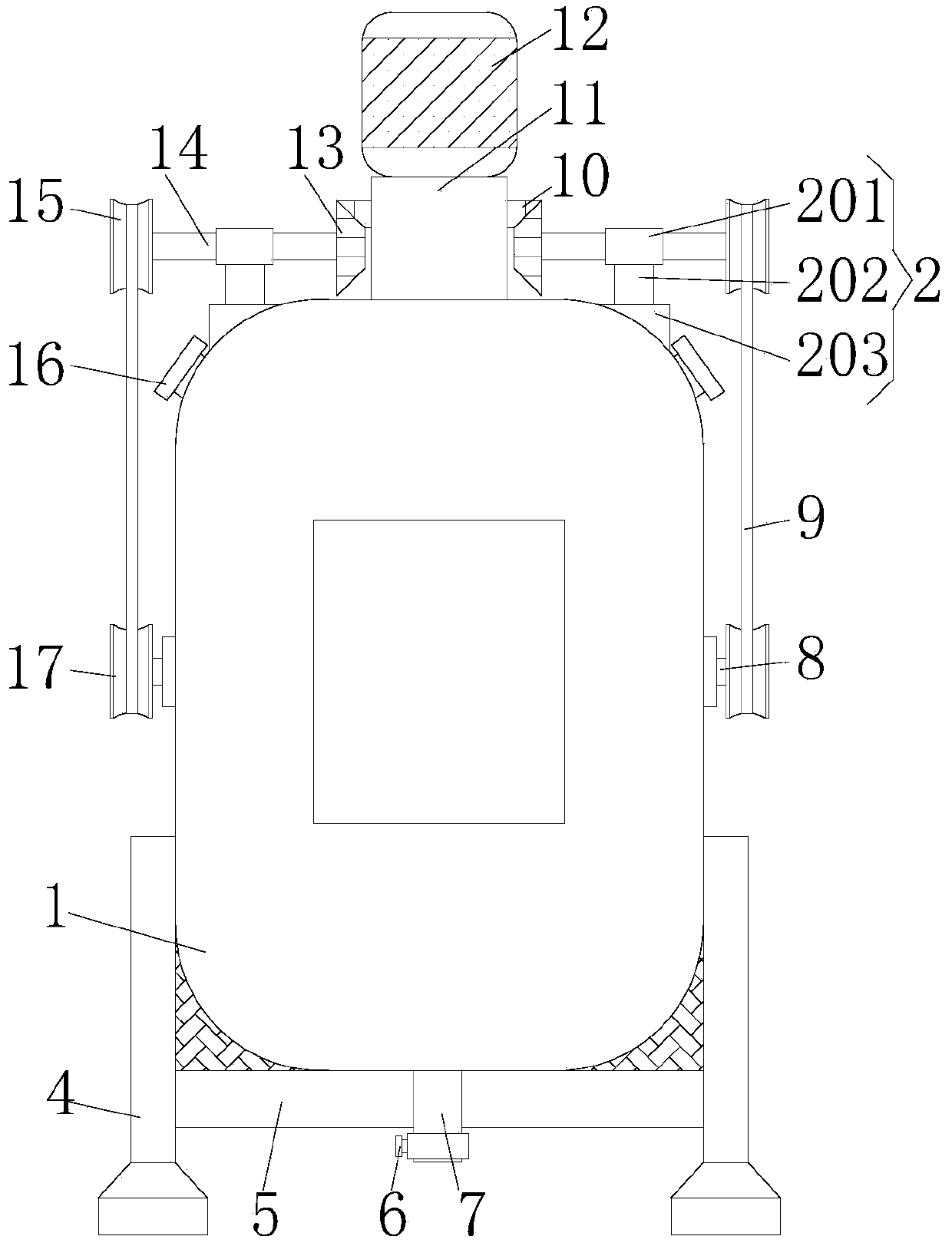

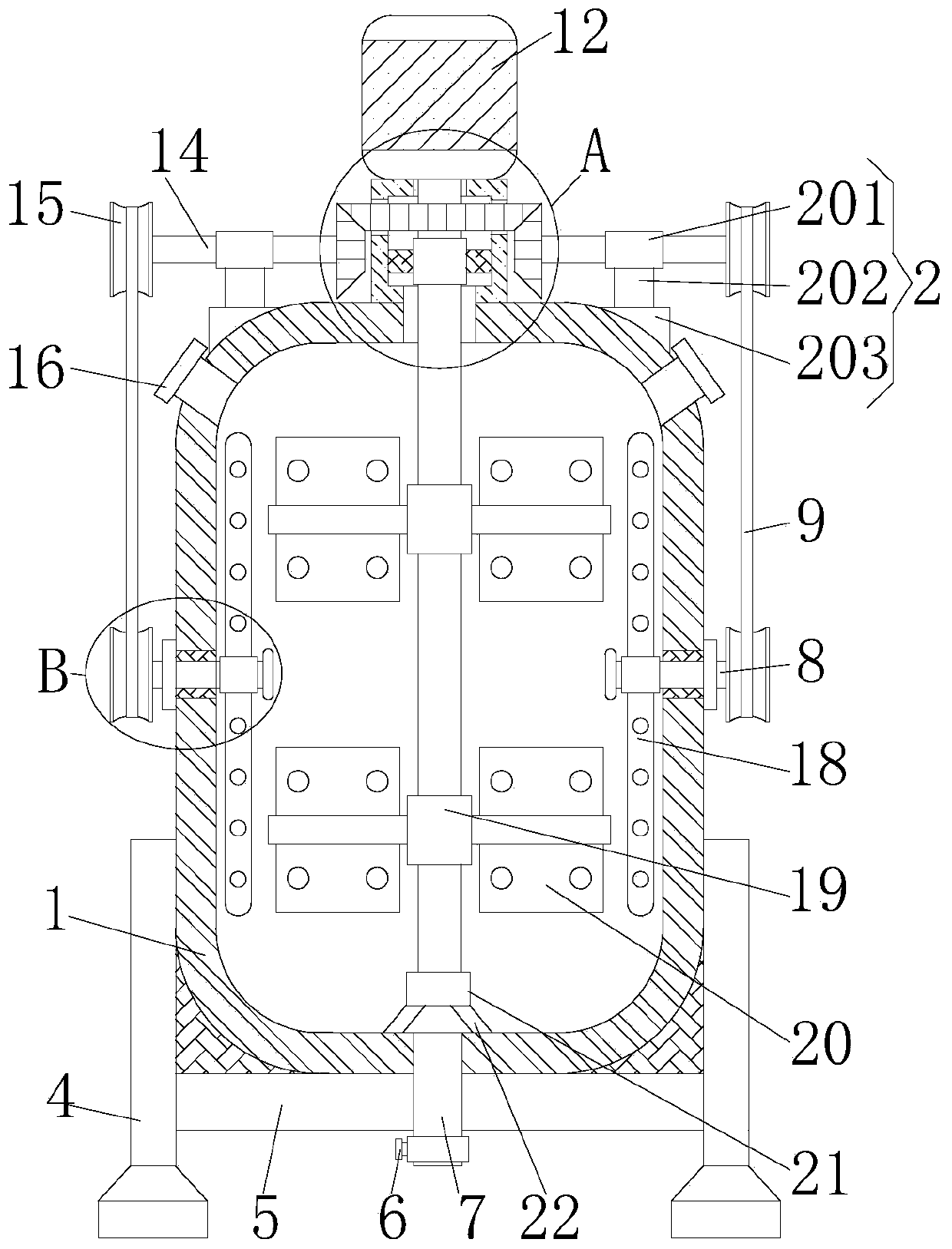

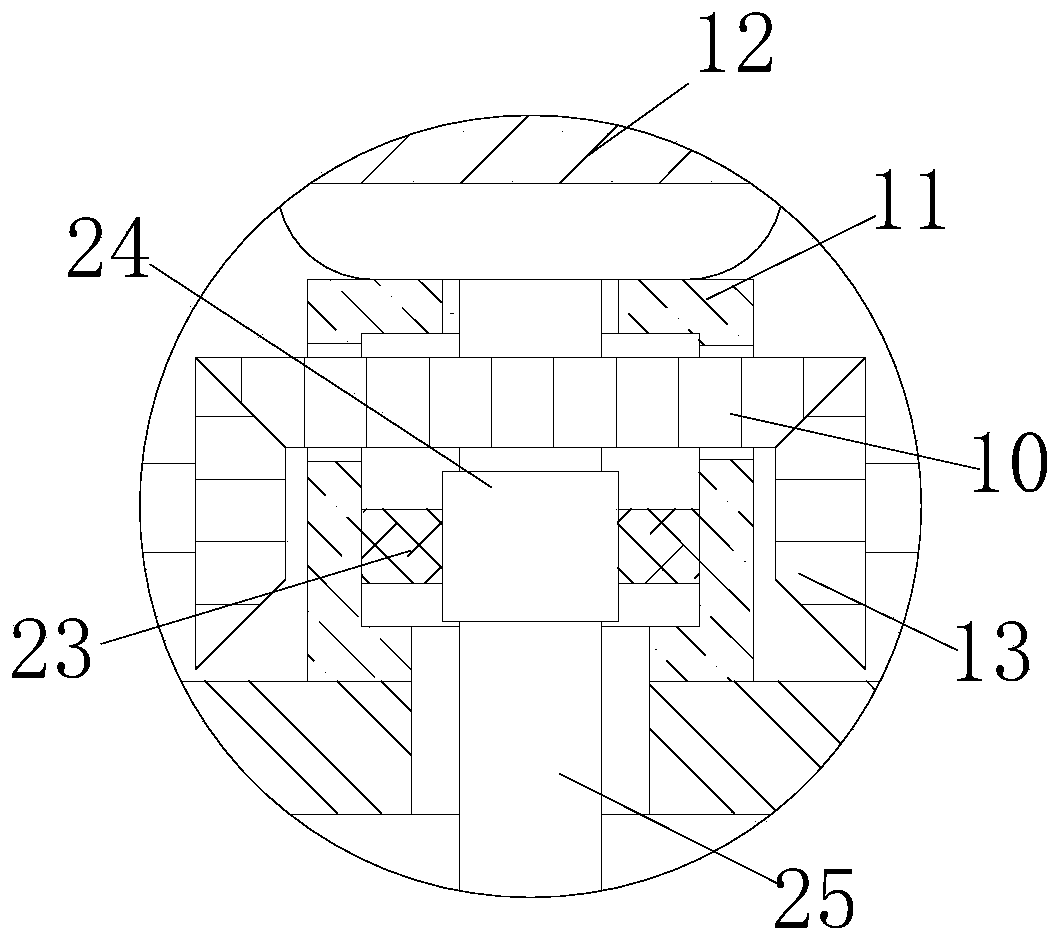

[0032] see Figure 1-4, a mixing device for material production, including a mixing box 1, the four corners of the bottom of the mixing box 1 are fixedly connected with cushion blocks, and the side of the cushion block close to the bottom plate 5 is fixedly connected with the bottom plate 5, and the opposite side of the two rotating shafts 8 They are all fixedly connected to the limit block, and by setting the spacer, the function of limiting and fixing the mixing box 1 is effectively realized. By setting the limit block, the limit effect on the second stirring blade 18 is effectively realized. The stirring box 1 is fixedly connected with a bottom plate 5, both sides of the bottom plate 5 are fixedly connected with supporting legs 4, the side of the mixing box 1 close to the supporting legs 4 is fixedly connected with the supporting legs 4, and both sides of the top of the mixing box 1 are connected with inlets. The material pipe 16, the bottom of the mixing box 1 is connected...

Embodiment 2

[0036] according to Figure 5 , the inside of the mixing box is provided with a screening device, the screening device includes a flushing unit 30 for diluting the material and a filtering unit 31 for filtering the debris; it is characterized in that: the flushing unit 30 includes a cleaning room 32, an oscillating dust removal device 33 located in the cleaning room, a spray device 34 located above the oscillating dust removal device, and a cloth guide 35 and a wire dividing member 36 located above the spray device; The oscillating dust removal device 33 includes a rollable inner rod 41, an outer cylinder 42 sleeved outside the inner rod, and a driving member 43 for driving the inner rod to rotate; the filter unit 31 includes a filter Canister 37, the filter screen 38 that is arranged in the filter canister and the recycling device 39 that is used to collect and recycle the filtered water; between the said filtering canister 37 and the said cleaning chamber 32 there is a guide...

Embodiment 3

[0039] The outer surface of the inner rod 41 is configured with a special-shaped structure, and there is a gap between the outer cylinder 42 and the inner rod 41; a plurality of through holes 421 are distributed on the outer surface of the outer cylinder 42 at intervals, The outer surface of the inner rod 41 is set in a corrugated structure; the filter cartridge 37 has a first chamber 81 and a second chamber 82, and the filter screen 38 is arranged in the first chamber 81, The side of the first chamber 81 is set at the sewage outlet 811 used to discharge the impurities filtered on the filter; the locking part includes a chute 131 arranged on the adjustment track, and is passed through the chute. The locking piece 132 and the positioning hole 133 provided on the positioning plate and matched with the locking piece.

[0040] The water pumping part is arranged on the water delivery pipe, and the water pumping part is a water pump purchased directly on the market. Through the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com