Preparation method of platinum-carbon catalyst for efficient azithromycin synthesis

A platinum-carbon catalyst and azithromycin technology, applied in chemical instruments and methods, preparation of sugar derivatives, organic chemistry, etc., can solve the problems of activated carbon pore collapse, increase of platinum nanoparticles, and increase of platinum loss, and achieve uniform and rapid heating , convenient sampling and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

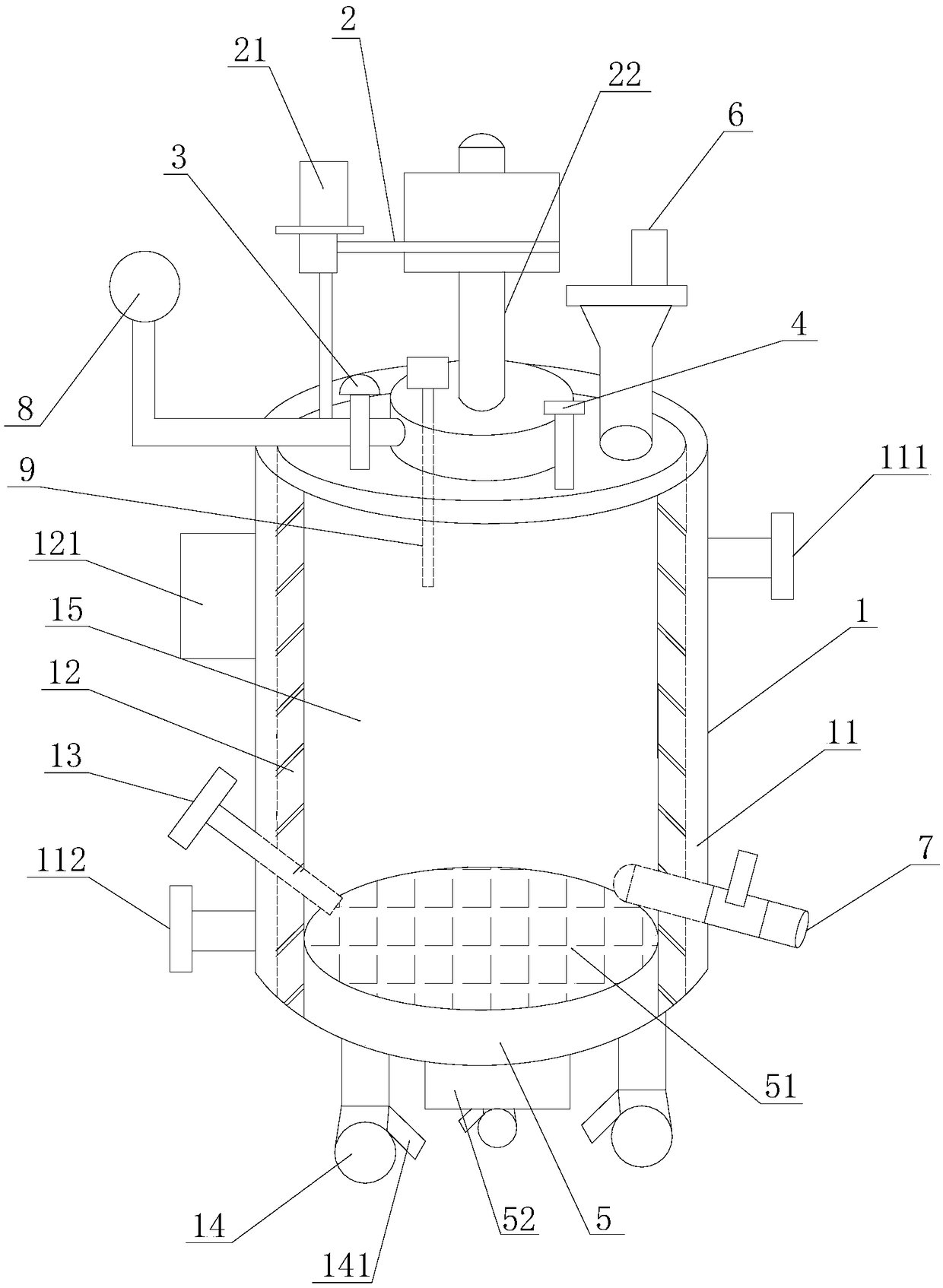

Image

Examples

preparation example Construction

[0019] A kind of preparation method of efficient azithromycin synthetic platinum carbon catalyst of the present invention comprises the following steps:

[0020] a) Put the platinum precursor into water, stir and dissolve, add an organic acid to continue stirring and dissolving, the organic acid and the platinum precursor undergo a complexation reaction, and use an alkaline solution to adjust the pH of the solution;

[0021] b) gac is dropped into the solution of step a for impregnation;

[0022] c) After the impregnation is completed, transfer the solution in step b to the autoclave, first replace the air in the autoclave with nitrogen, then heat up the autoclave, then quickly pass hydrogen into the autoclave and keep it warm for 20 After ~1000 minutes, cool down and release the pressure;

[0023] d) After filtering and washing the solution in step c, the platinum carbon catalyst is obtained.

[0024] Specifically, the platinum precursor described in step a is a mixture of ...

Embodiment 1

[0031] In a 1000ml flask, add 300g of water and weigh 2.38g of H 2 PtC l6 ·6H 2 O was put into it and stirred to dissolve. Then add 2.36 grams of citric acid and continue stirring to dissolve. Raise the temperature to 40-45°C. Use 10% sodium hydroxide solution to adjust the pH between 5.5 and 5.6. Another 29.1 g of activated carbon was added. Keep warm overnight. Transfer to a high-pressure hydrogenation kettle, rapidly raise the temperature to 80° C., rapidly inject hydrogen gas to 3 MPa, and keep the temperature for 2 hours. After cooling, filtering and washing, 30 g of dry product equivalent of 3% Pt / C catalyst was obtained.

[0032] In a 1000ml flask, add 500 grams of methanol, cool to 5-10°C, add 100 grams of 6,9-imino ether, stir to dissolve, use hydrochloric acid (hydrochloric acid, citric acid, acetic acid, perchloric acid, hydrobromic acid can also be used) One or two or more of them are mixed) to adjust the pH to between 6.0 and 6.5. Transfer to an autoclave...

Embodiment 2

[0034] In a 1000ml flask, add 300g of water and weigh 3.98g of H 2 PtC l6 ·6H 2 O was put into it and stirred to dissolve. Then add 3.93 grams of citric acid and continue stirring to dissolve. Raise the temperature to 25-30°C. Use 10% sodium carbonate solution to adjust the pH between 5.5 and 5.6. Another 28.5 grams of activated charcoal was added. Keep warm overnight. Transfer to a high-pressure hydrogenation kettle, rapidly raise the temperature to 90° C., and rapidly pass hydrogen to 4 MPa, and keep the temperature for 2 hours. After cooling, filtering and washing, 30 g of dry product equivalent of 5% Pt / C catalyst was obtained.

[0035] In a 1000ml flask, add 500g of methanol, cool to 5-10°C, add 100g of 6,9-imide ether, stir to dissolve, use hydrochloric acid (hydrochloric acid, citric acid, acetic acid, perchloric acid, hydrobromic acid can also be used to One or two or more mixtures) to adjust the pH to between 6.0 and 6.5. Transfer to an autoclave and add the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com