Environment-friendly industrial waste gas treatment process

A technology for treating process and industrial waste gas, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. The effect of promoting adequate response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

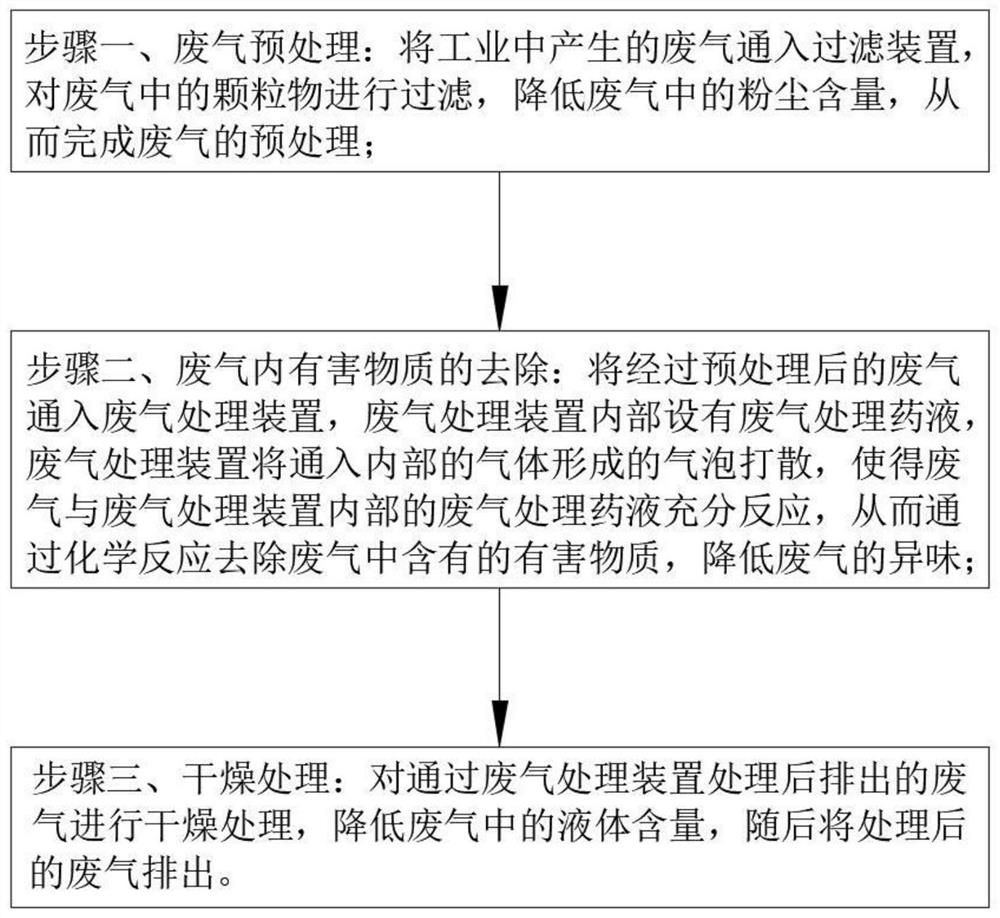

Method used

Image

Examples

Embodiment approach

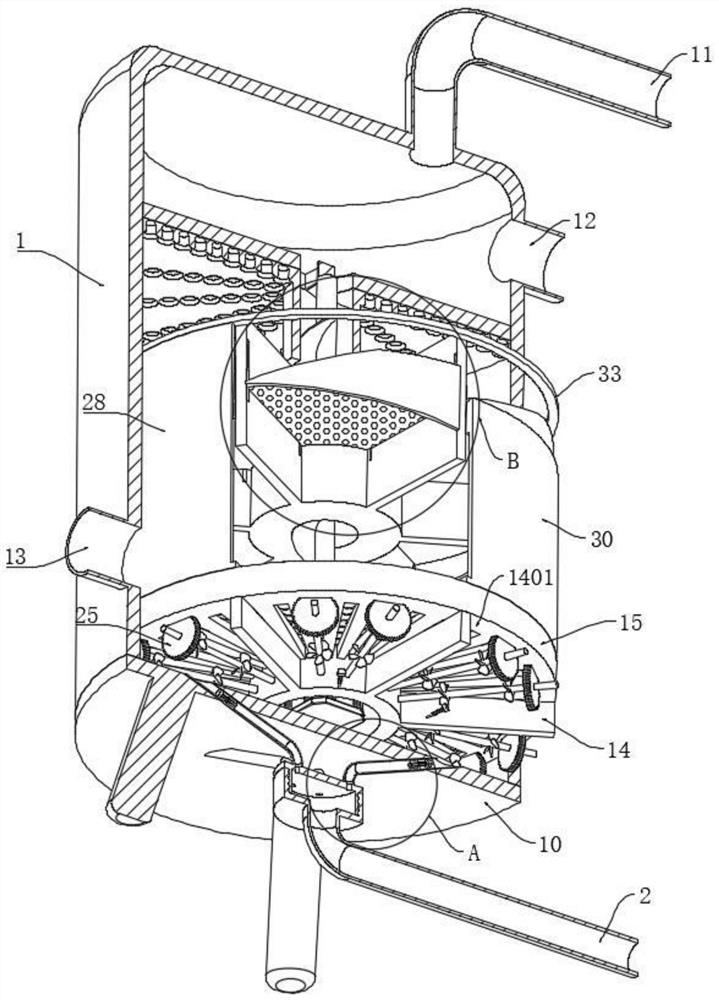

[0038] As an embodiment of the present invention, the one-way valve includes a fixed plate 6, which is fixed inside the connecting pipe 5, and one end of the fixed plate 6 is slid toward the sealing plate 10, and a piston 7 is inserted therein, and the piston 7 is far away from the fixed plate 6. One end of the spring 8 is fixedly connected with a spring 8, and the end of the spring 8 away from the fixed plate 6 is fixedly connected with the inner wall of the connecting pipe 5. The end array of the fixed plate 6 is penetrated with a plurality of first circular through holes 9, and the piston 7 is sealed at the second The opening of a circular through hole 9; when working, when the gas passes through the connecting pipe 5, the pressure of the gas flow pushes the piston 7, so that the piston 7 can move back to the fixed plate 6, so that the piston 7 will move the first circular through hole The hole 9 is exposed, so that the gas passes through the first circular through hole 9, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com