Chemical reaction stirring device with solid-liquid separation feeding way

A solid-liquid separation and stirring device technology, which is applied in the direction of feeding device, sampling device, chemical/physical/physical chemical fixed reactor, etc., can solve the problems of product sampling difficulty, inconvenient cleaning, complicated operation, etc., and achieve the mixing effect Good, convenient sampling, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

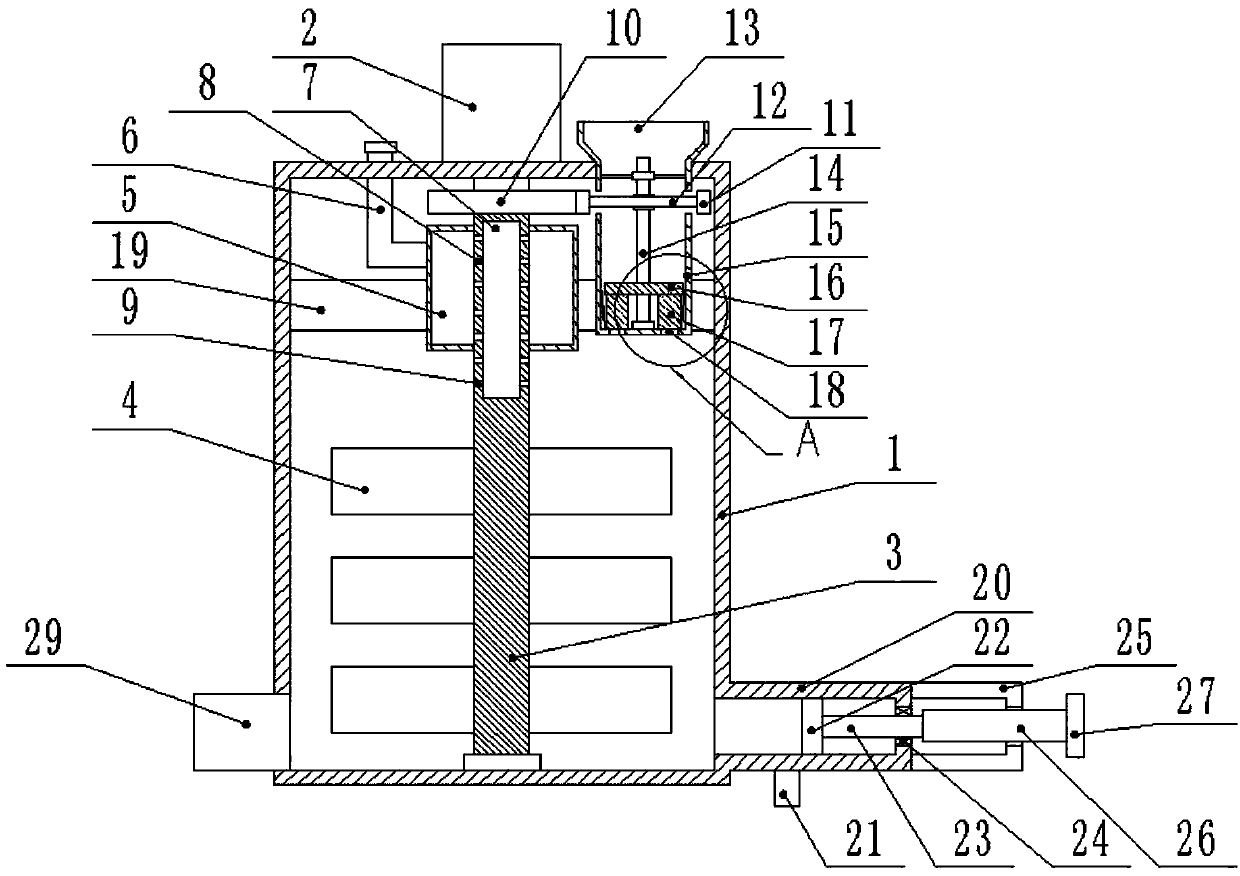

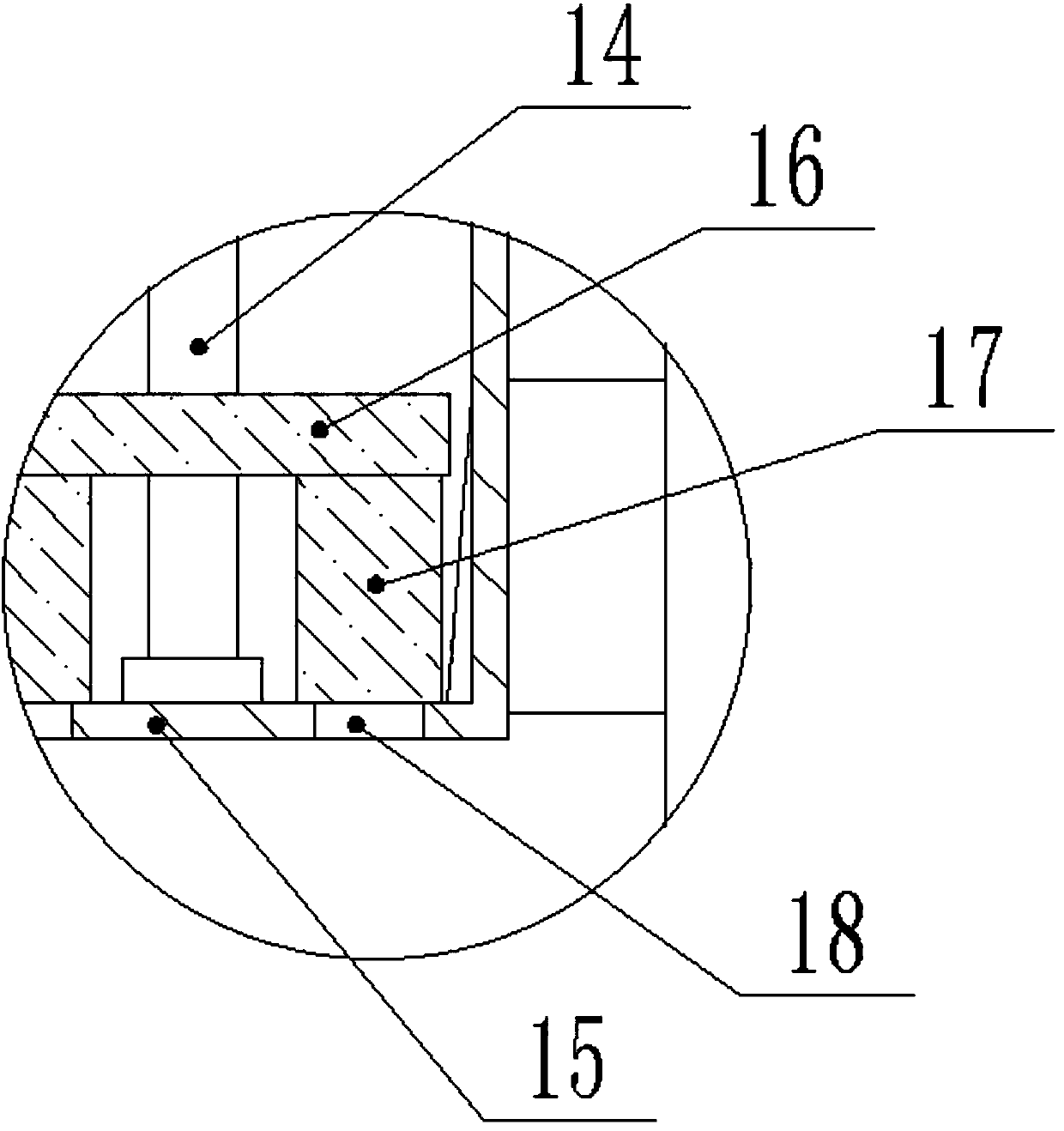

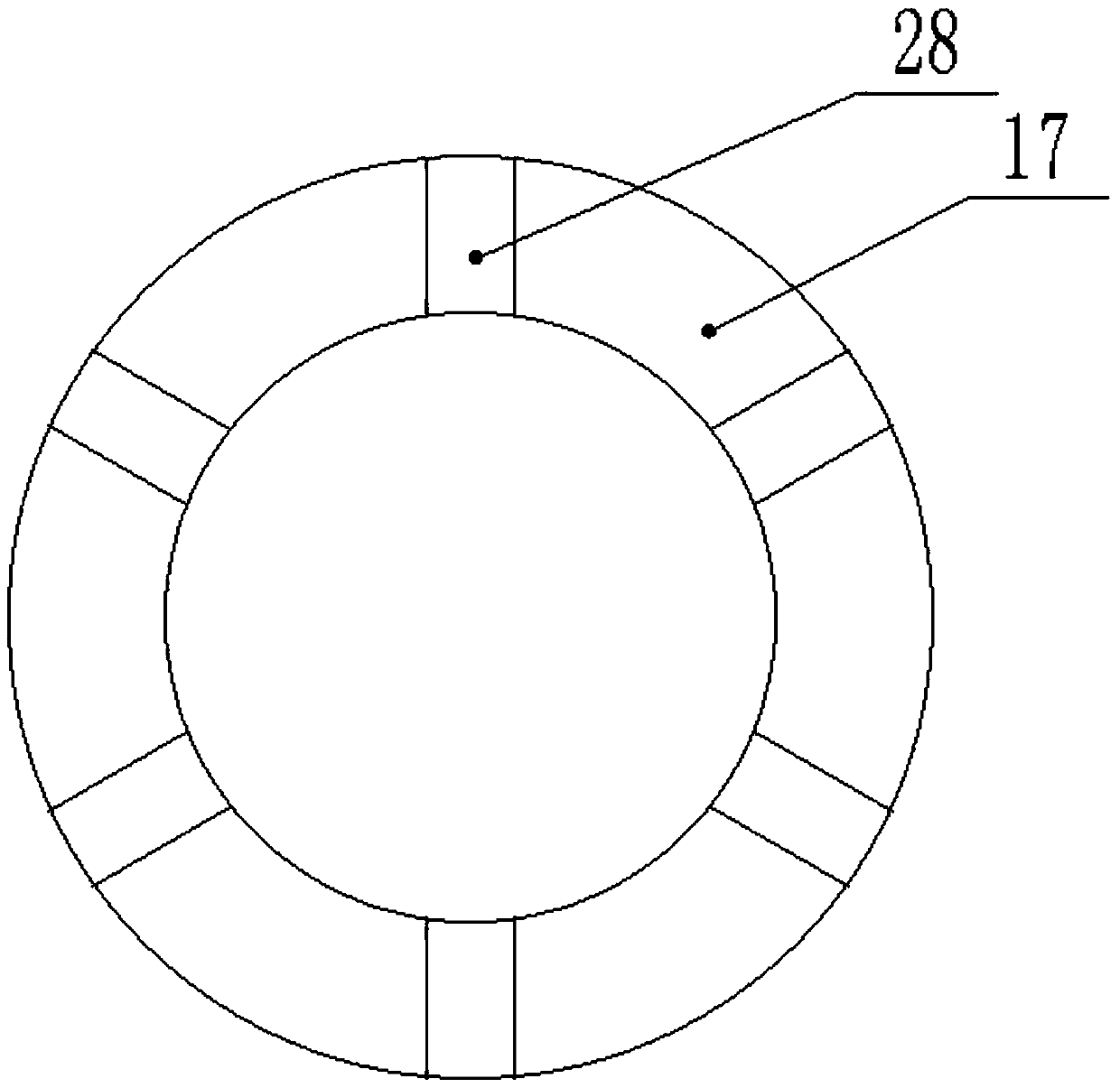

[0020] Please refer to the figure, in the embodiment of the present invention, a chemical reaction stirring device for solid-liquid separation and feeding includes a housing 1, a motor 2, a stirring shaft 3 and a stirring blade 4; the motor 2 is fixedly installed on the housing 1 The output shaft of the motor 2 extends vertically downwards into the housing 1, and a vertical stirring shaft 3 is fixedly connected to the lower end of the output shaft of the motor 2, and the lower end of the stirring shaft 3 is connected to the housing 1 through a bearing. At the bottom of the interior, several stirring blades 4 are provided, which are evenly and fixedly installed on the side wall of the stirring shaft 3. The motor 2 drives the stirring shaft 3 to rotate, and the stirring blade 4 stirs the materials in the housing 1 to make them mix. The upper end of the stirring shaft 3 is provided with a communication chamber 7, the length of the communication chamber 7 is 1 / 4 to 1 / 3 of the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com