Lifting flotation machine for graphite production

A lift-type, flotation machine technology, applied in flotation, solid separation and other directions, can solve the problems of slow material mixing reaction, low device working efficiency, easy adhesion of bubbles on the inner wall of the tank, etc., to reduce the use of power equipment, improve Stirring effect, the effect of optimizing the flotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

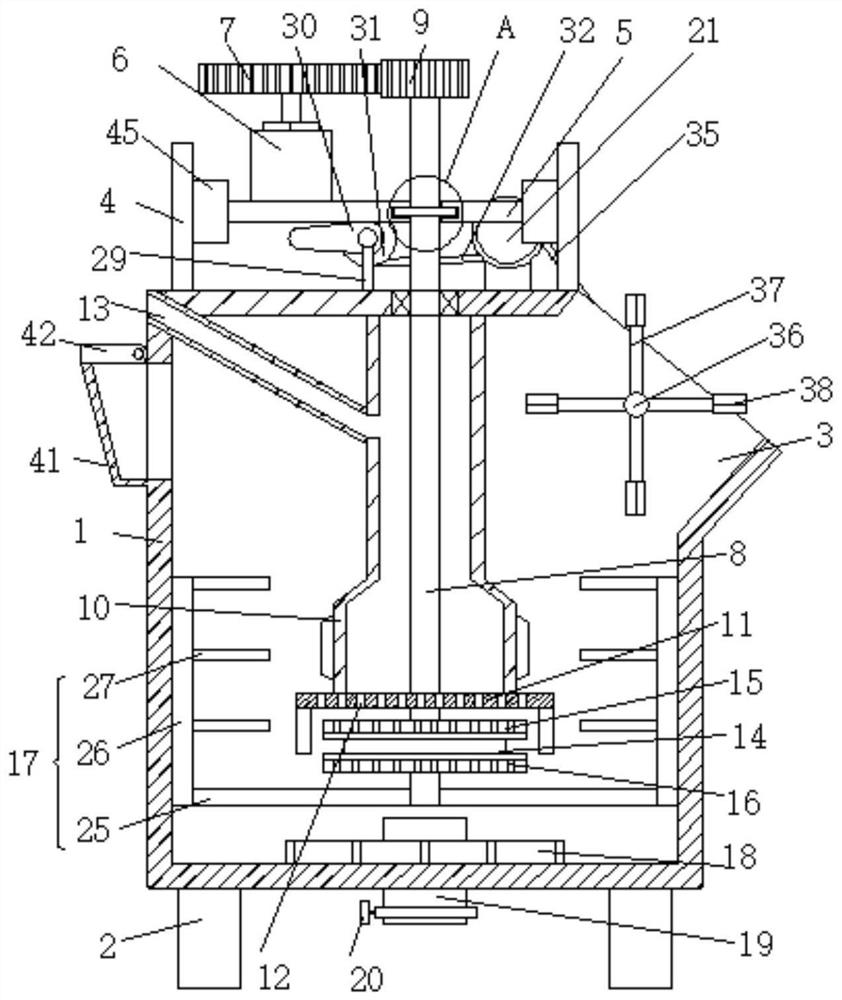

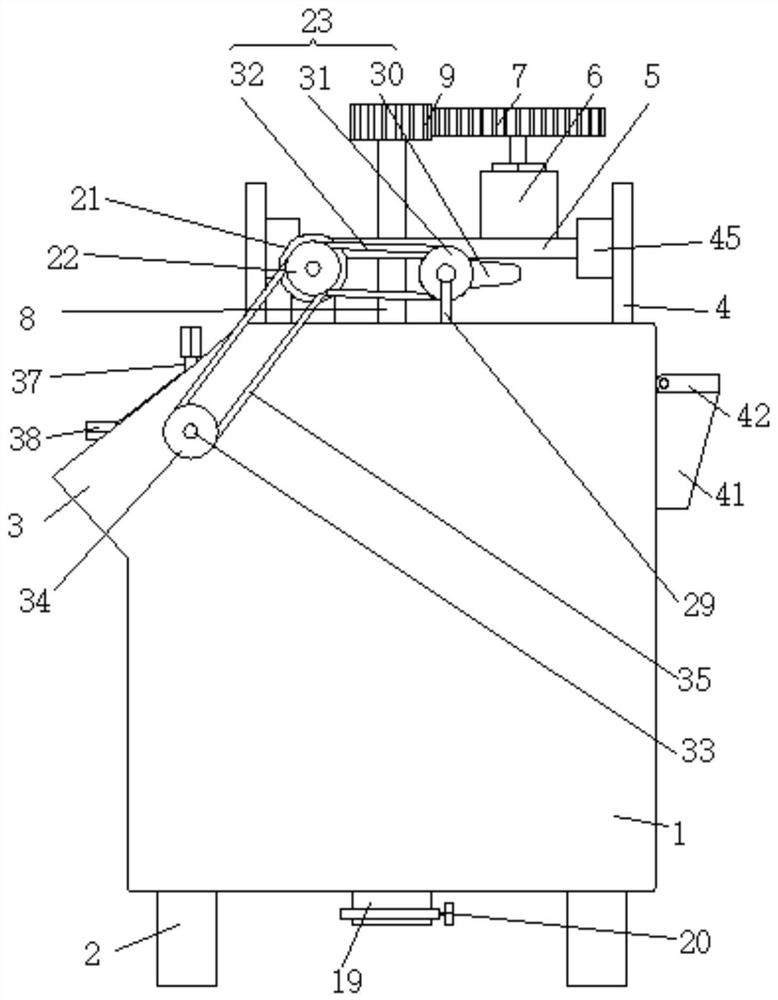

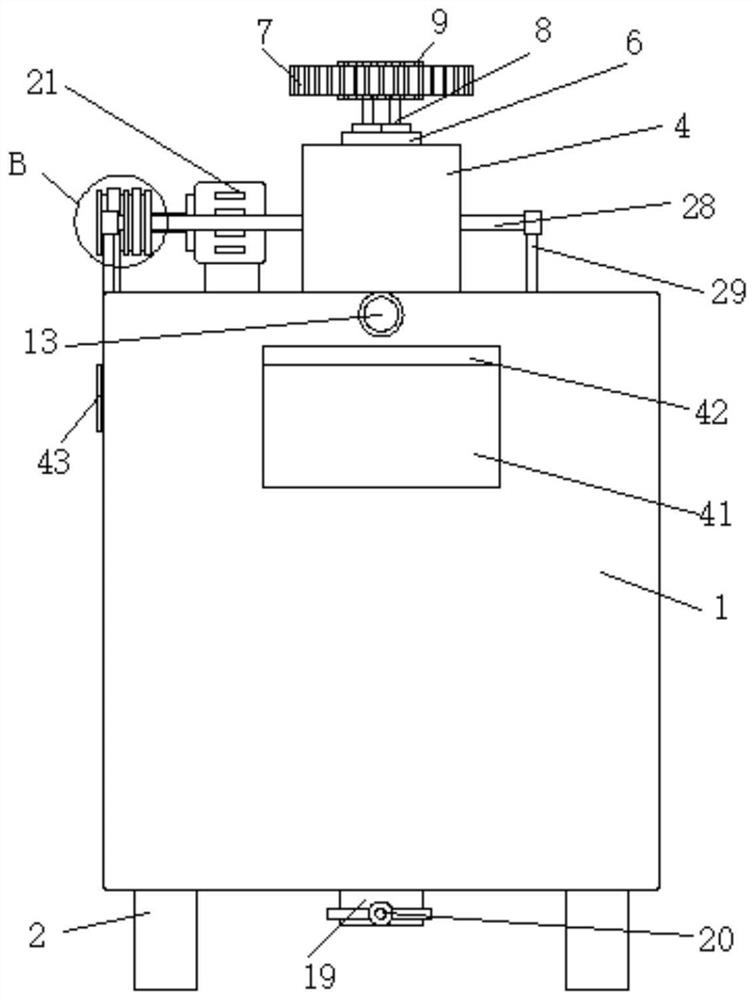

[0031] Embodiment one, such as Figure 1-8As shown, a lifting type flotation machine for graphite production includes a tank body 1, the tank body 1 is cylindrical, the outer bottom surface of the tank body 1 is fixedly connected with a plurality of vertically arranged support columns 2, and the upper end of the tank body 1 is An opening 3 is provided, and the upper surface of the upper wall of the tank body 1 is fixedly connected with two vertically arranged support plates 4, and a bottom plate 5 is horizontally arranged between the two support plates 4, and the bottom plate 5 is slidingly connected with the two support plates 4, The upper surface of the base plate 5 is fixedly connected with the first motor 6, the shaft of the first motor 6 is fixedly connected with the first gear 7 arranged horizontally, and one side of the first motor 6 is vertically provided with a main shaft 8, the main shaft 8 penetrates the base plate 5 and is connected with the The rotation connection...

Embodiment 2

[0032] Embodiment two, such as figure 1 As shown, the stirring mechanism 17 includes a plurality of first connecting rods 25 arranged horizontally, and the plurality of first connecting rods 25 are all fixedly connected to the main shaft 8, and the plurality of first connecting rods 25 are all located below the impeller disc 14, and the plurality of first connecting rods 25 are all fixedly connected to the main shaft 8. The upper surface of one end of the connecting rod 25 away from the main shaft 8 is fixedly connected with a second connecting rod 26, and a plurality of second connecting rods 26 are all vertically arranged, and a plurality of second connecting rods 26 are in contact with the inner wall of the tank body 1. The second connecting rods 26 are all fixedly connected with a plurality of horizontally arranged stirring rods 27, and the plurality of stirring rods 27 are arranged at equal intervals, and the mixing of materials is promoted by the rotating stirring rods 27...

Embodiment 3

[0033] Embodiment three, such as Figure 1-4 , 6, the elevating mechanism 23 comprises the first rotating shaft 28 that is arranged horizontally, the first rotating shaft 28 two ends all rotate and connect the bracket 29, the two brackets 29 are all vertically arranged, and the bottom ends of the two brackets are all connected to the upper wall of the tank body 1. The upper surface is fixedly connected, the first rotating shaft 28 is fixedly connected with a cam 30, the cam 30 is in contact with the lower surface of the bottom plate 5, the first rotating shaft 28 is fixedly connected with a second pulley 31, and the second pulley 31 is connected to the first pulley through the first belt 32. 22 transmission connection, through the rotation of the cam 30, the bottom plate 5 is driven up and down, and then the first motor 6 and the main shaft 8 are driven to move up and down, so as to realize the lifting and promote the stirring of the stirring rod 27, which is more conducive to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com