High-strength and high-ductility magnesium alloy capable of being dissolved rapidly and preparation method thereof

A high-elongation, high-strength technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of low reaction rate between magnesium alloy and medium, inability to meet industrial applications, and decrease in alloy elongation. Achieve the effect of improving alloy strength, increasing speed and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

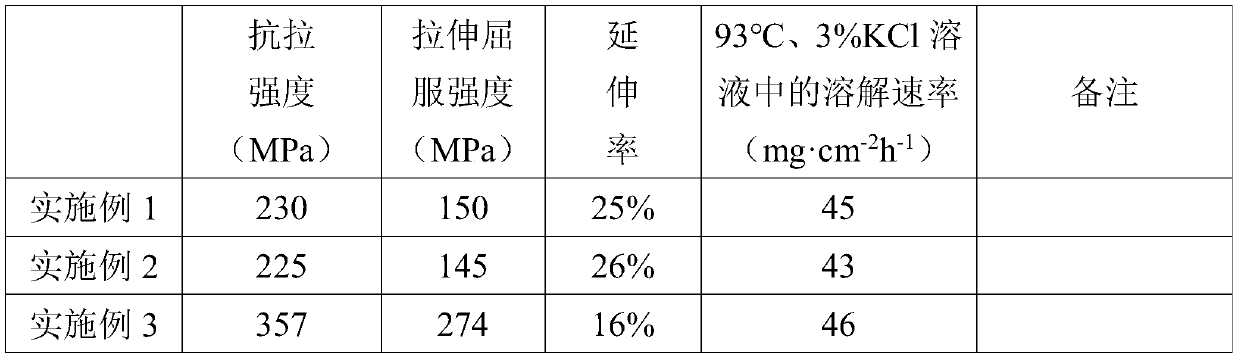

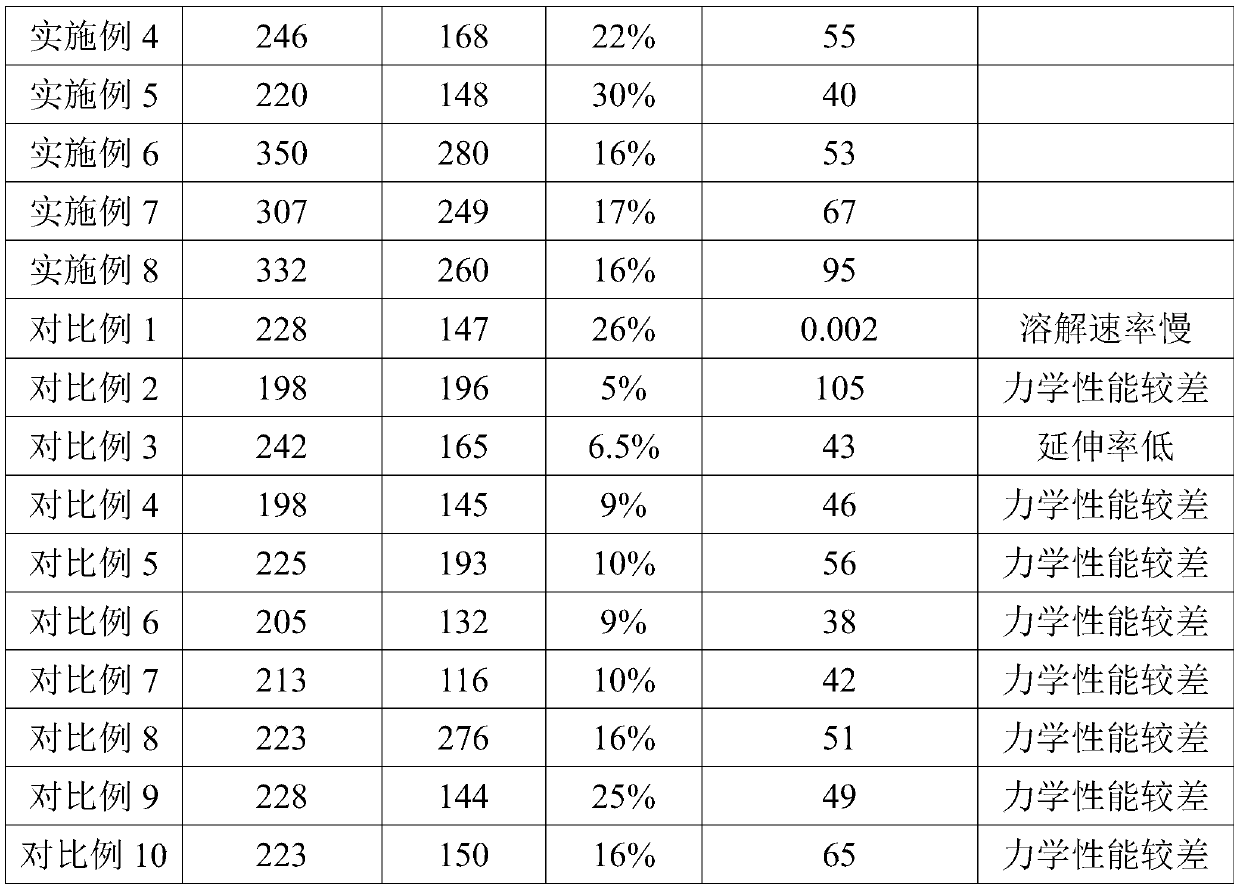

Examples

Embodiment 1

[0033] The rapidly dissolving high-strength and high-elongation magnesium alloy described in this embodiment is composed of the following elements in mass percentage: Gd 2.5%, Y 1.0%, Al 1.0%, Zn 0.5%, Zr 0.4%, Sc 0.01%, Cu 1.5%, Li 0.25%, Ni 0.25%, Ga 0.25%, In 0.25%, and the rest is Mg.

[0034] The preparation method of the fast-dissolving high-strength and high-elongation magnesium alloy described in this embodiment, the specific steps are as follows:

[0035] S1. Weigh pure Mg, pure Al, pure Zn, pure Ga, pure In, Mg-Gd master alloy, Mg-Y master alloy, Mg-Zr master alloy, Mg-Sc master alloy, Mg- Cu master alloy, Mg-Li master alloy, Mg-Ni master alloy;

[0036] S2. Preheating the raw materials except pure Ga in step S1 at 150° C. for 2 hours;

[0037] S3. Mix all the raw materials, heat the mixed raw materials to 720°C in a crucible resistance furnace, melt for 30 minutes, add the first refining agent, refine for 30 minutes, remove the inclusions in the melt, and then use...

Embodiment 2

[0044] The fast-dissolving high-strength and high-elongation magnesium alloy described in this embodiment is composed of the following elements in mass percentage: Gd 1.5%, Y 0.5%, Al 0.1%, Zn 0.1%, Zr 0.2%, Sc 0.001%, Cu 0.1%, Li 0.01%, Ni 0.01%, Ga 0.01%, In 0.01%, and the rest is Mg.

[0045] The preparation method of the fast-dissolving high-strength and high-elongation magnesium alloy described in this example is the same as that in Example 1.

Embodiment 3

[0047] The fast-dissolving high-strength and high-elongation magnesium alloy described in this embodiment is composed of the following elements in mass percentage: Gd 14.5%, Y 2.0%, Al 2.0%, Zn 1.0%, Zr 0.5%, Sc 0.02%, Cu 2.0%, Li 0.5%, Ni 0.5%, Ga 0.5%, In 0.5%, and the rest is Mg.

[0048] The preparation method of the fast-dissolving high-strength and high-elongation magnesium alloy described in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com