Process for producing layered lithium nickel oxide, and lithium secondary cell employing it

A technology of lithium secondary battery and manufacturing method, applied in lithium oxide;/hydroxide, oxide/hydroxide preparation, nickel compound and other directions, can solve the problem of low fundamental structural stability of positive electrode material, and achieve high Effect of capacity and electrochemical properties, improved thermal stability, and high-efficiency electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

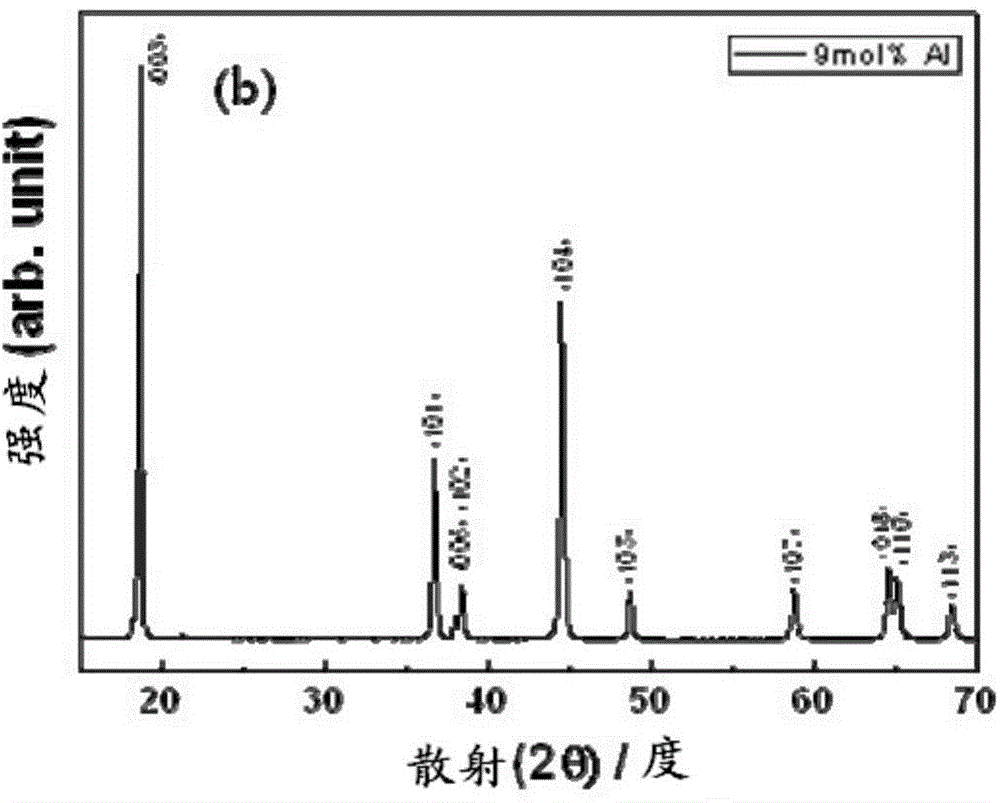

[0053] Add 2 g of Ni as a precursor compound to a mixed solution obtained by dissolving 0.4 g of aluminum acetate in 30 ml of ethanol 0.89 co 0.11 (OH) 2 , and mixed at 200 rpm for 1 hour, the solvent was evaporated using a heating plate to obtain a powder, and then the above powder was vacuum-dried at 100°C.

[0054] With the obtained powder and LiOH·H 2 The molar ratio of O was Li / (Ni+Co+Al)=1.03, and pulverized and mixed in a mortar. With respect to the above-mentioned mixture, the heat treatment process was continuously implemented at 450° C. for 5 hours and at 750° C. for 18 hours under an oxygen atmosphere.

Embodiment 2

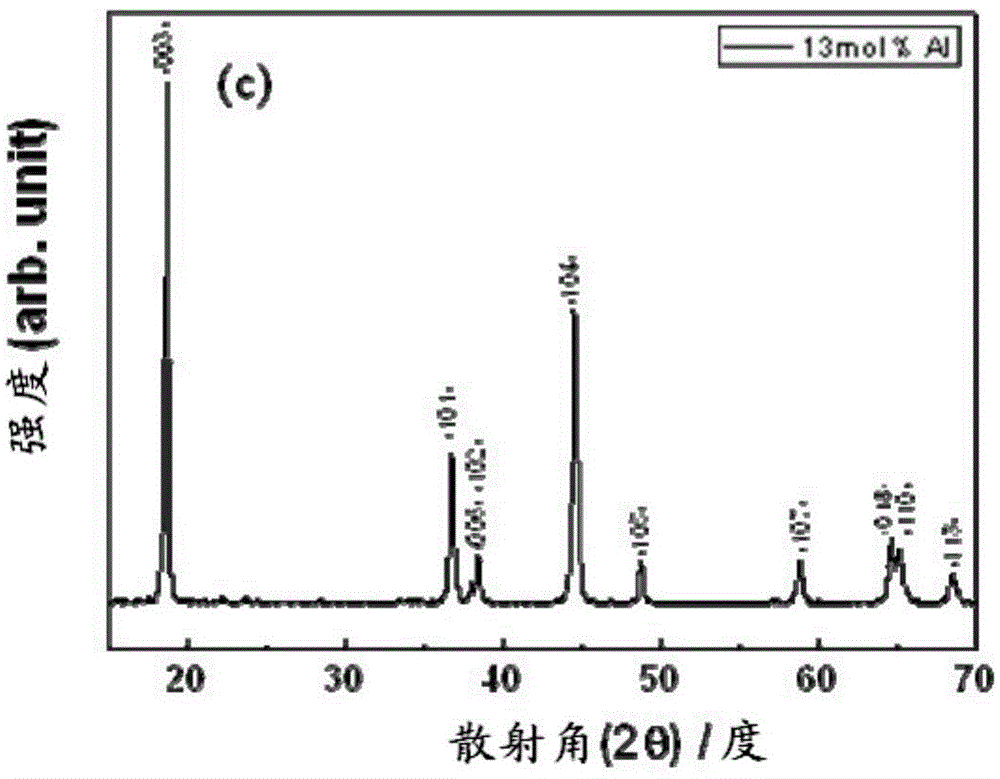

[0056] It manufactured by the method similar to Example 1 except having dissolved 0.6 g of aluminum acetate in 30 ml of ethanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com