Efficient oil removal device for rare earth material liquid

A rare earth material liquid and high-efficiency technology, which is applied in the direction of improving process efficiency, can solve the problems of rare earth material liquid high efficiency and oil removal, and achieve high oil removal efficiency, safe and reliable performance, and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

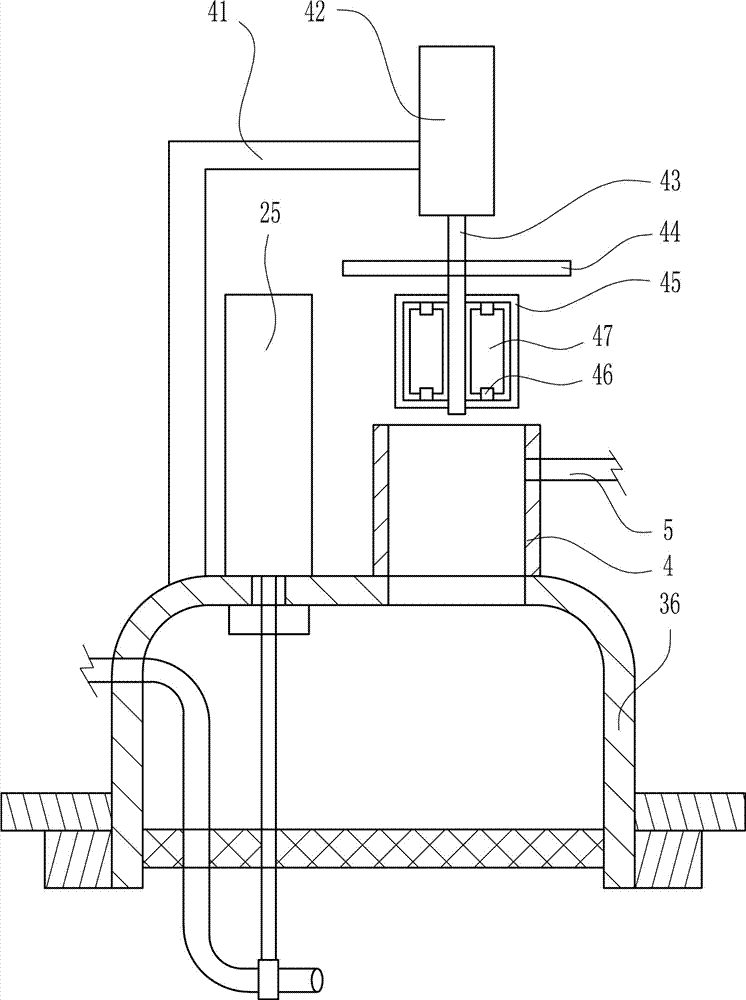

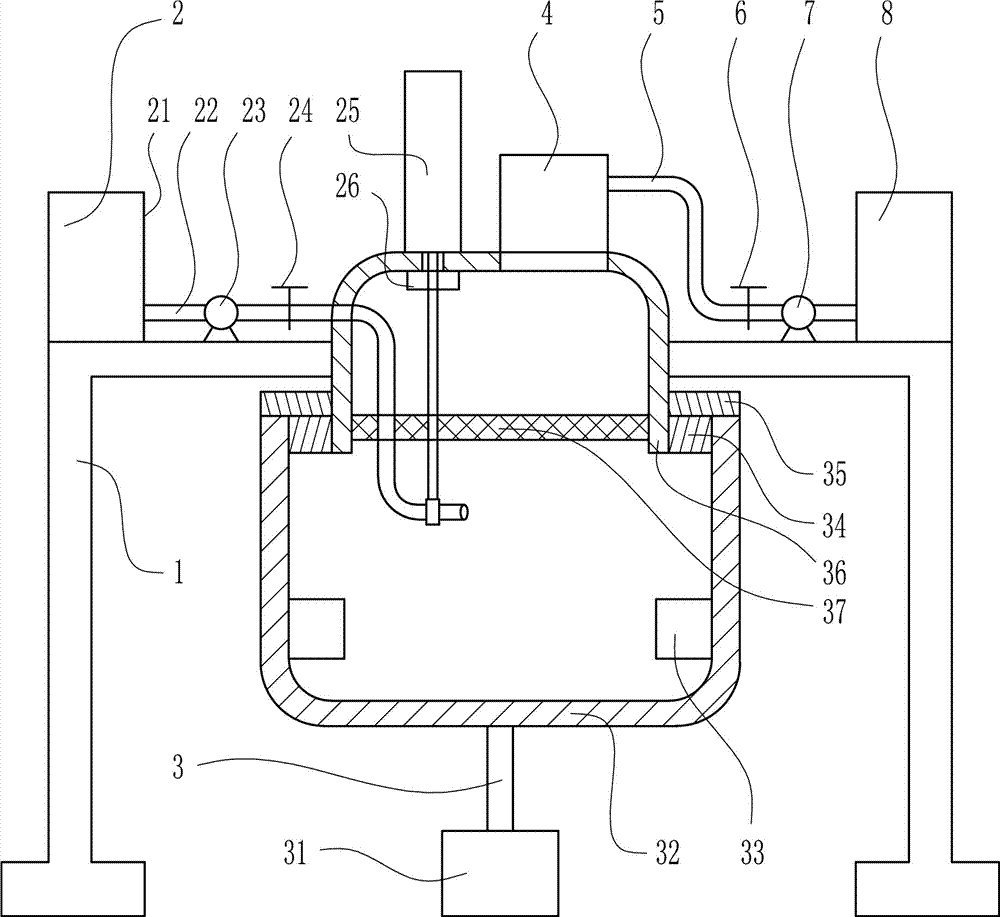

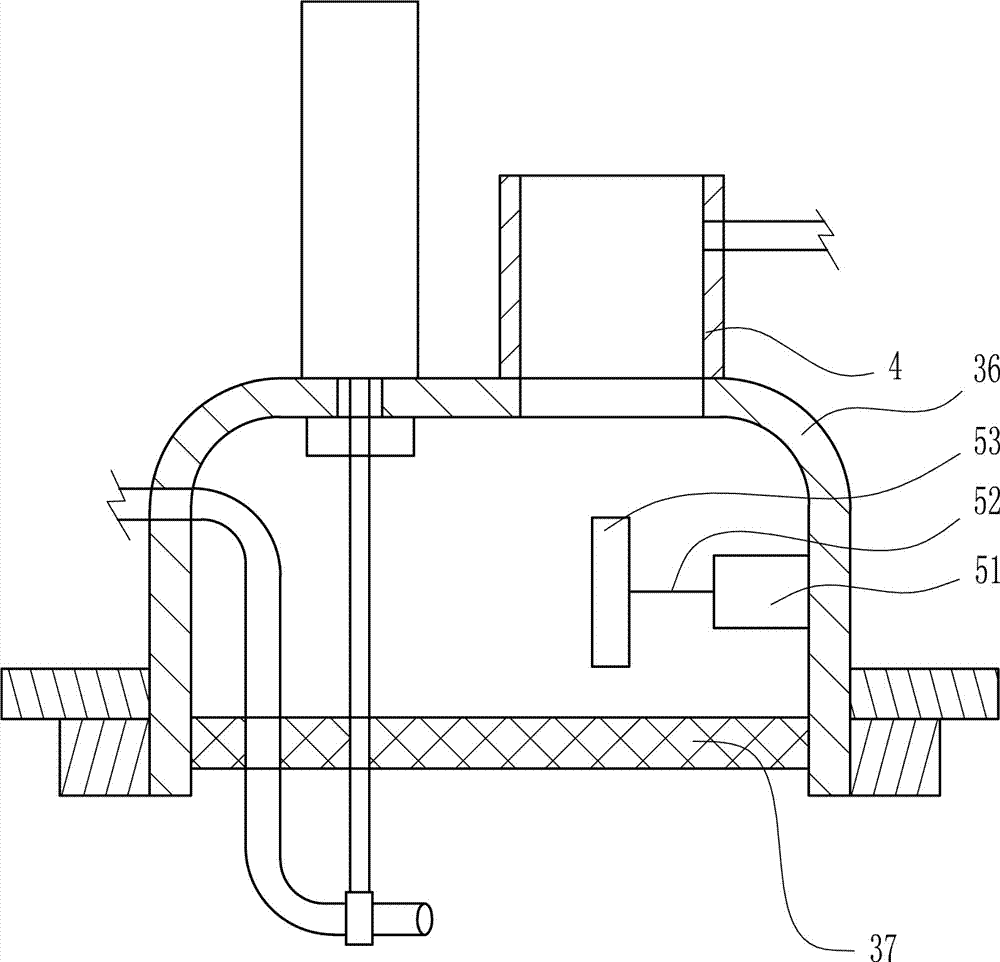

[0027] A high-efficiency oil removal device for rare earth feed liquid, such as Figure 1-3 As shown, it includes a large L-shaped support 1, a feed liquid conveying device 2, a rotating device 3, a jacking pipe 4, a connecting pipe 5, a valve I6, a high-pressure pump I7 and a receiving liquid tank 8; the large L-shaped support 1 is left-right symmetrical The material and liquid conveying device 2 is arranged above the large L-shaped bracket 1, the rotating device 3 is arranged between the large L-shaped brackets 1 symmetrically arranged on the left and right, the jacking pipe 4 is arranged above the rotating device 3, and the connecting pipe 5 The left end and the right side wall of the jacking pipe 4 are connected by welding, the connecting pipe 5 communicates with the jacking pipe 4, the valve I6 and the high-pressure pump I7 are installed on the connecting pipe 5, and the valve I6 and the high-pressure pump I7 are both arranged on the rotating device 3 on the right side, t...

Embodiment 2

[0029] A high-efficiency oil removal device for rare earth feed liquid, such as Figure 1-3 As shown, it includes a large L-shaped support 1, a feed liquid conveying device 2, a rotating device 3, a jacking pipe 4, a connecting pipe 5, a valve I6, a high-pressure pump I7 and a receiving liquid tank 8; the large L-shaped support 1 is left-right symmetrical The material and liquid conveying device 2 is arranged above the large L-shaped bracket 1, the rotating device 3 is arranged between the large L-shaped brackets 1 symmetrically arranged on the left and right, the jacking pipe 4 is arranged above the rotating device 3, and the connecting pipe 5 The left end and the right side wall of the jacking pipe 4 are connected by welding, the connecting pipe 5 communicates with the jacking pipe 4, the valve I6 and the high-pressure pump I7 are installed on the connecting pipe 5, and the valve I6 and the high-pressure pump I7 are both arranged on the rotating device 3 on the right side, t...

Embodiment 3

[0032] A high-efficiency oil removal device for rare earth feed liquid, such as Figure 1-3 As shown, it includes a large L-shaped support 1, a feed liquid conveying device 2, a rotating device 3, a jacking pipe 4, a connecting pipe 5, a valve I6, a high-pressure pump I7 and a receiving liquid tank 8; the large L-shaped support 1 is left-right symmetrical The material and liquid conveying device 2 is arranged above the large L-shaped bracket 1, the rotating device 3 is arranged between the large L-shaped brackets 1 symmetrically arranged on the left and right, the jacking pipe 4 is arranged above the rotating device 3, and the connecting pipe 5 The left end and the right side wall of the jacking pipe 4 are connected by welding, the connecting pipe 5 communicates with the jacking pipe 4, the valve I6 and the high-pressure pump I7 are installed on the connecting pipe 5, and the valve I6 and the high-pressure pump I7 are both arranged on the rotating device 3 on the right side, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com