Preparation method of high refractive index sulfur-containing optical copolymerized resin

A technology of copolymer resin and high refractive index, which is applied in the field of preparation of high refractive index sulfur-containing optical copolymer resin, can solve the problems of low refractive index and narrow range of refractive index, and achieve the effect of increasing the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

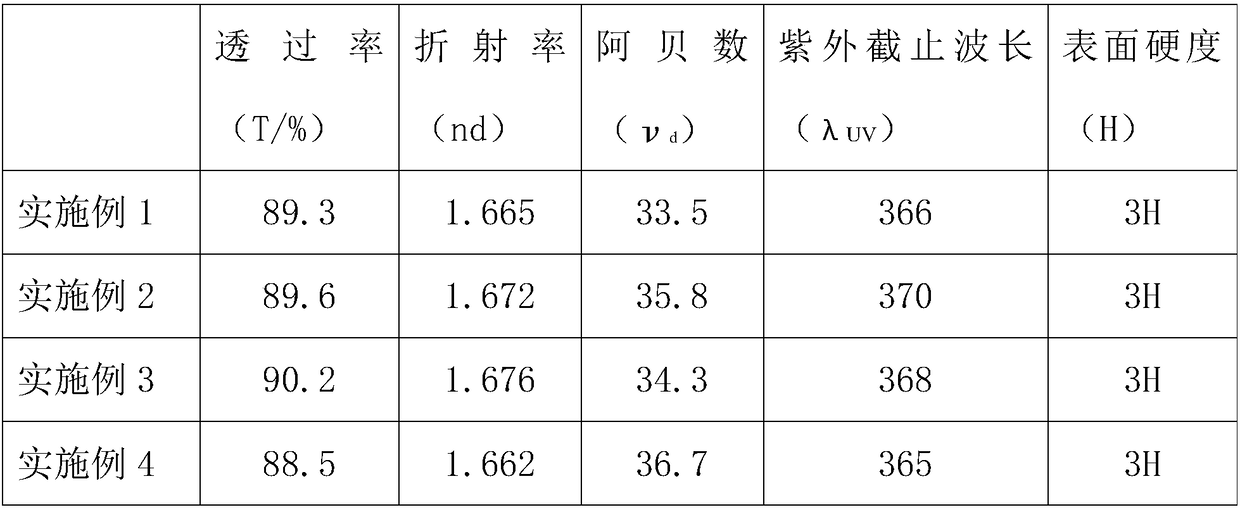

Embodiment 1

[0020] A preparation method of high refractive index sulfur-containing optical copolymer resin, comprising the steps of:

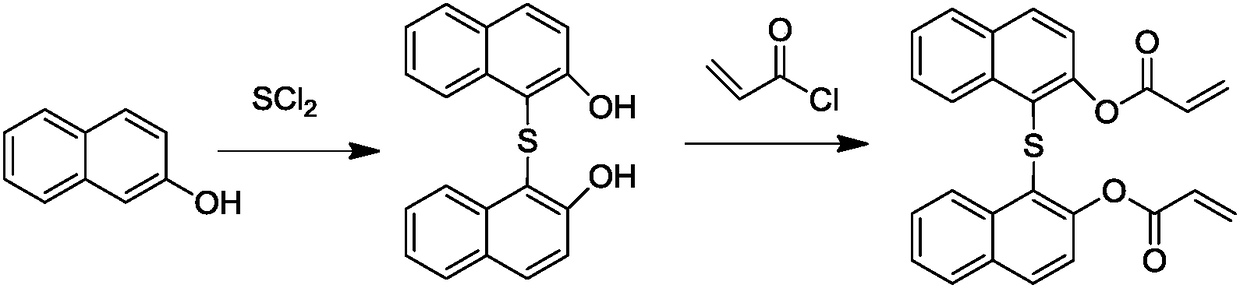

[0021] S1, 2-naphthol is added to be dissolved in the mixed solvent that is 1:1 toluene and ethyl acetate by weight ratio and dissolve completely, add sulfur dichloride under ice-bath condition, sulfur dichloride and 2-naphthol The molar ratio is 1:2.1, stirring and reacting at 10°C for 4h, heating the reaction solution to 90°C, distilling off most of the solvent, freezing until solids are precipitated, filtering, recrystallizing from absolute ethanol, filtering, and drying to obtain 1 , 1'-thiobis(2-naphthol);

[0022] S2. Dissolve 1,1'-thiobis(2-naphthol) in dichloromethane, add excess triethylamine to carry out alkalization reaction under stirring condition, triethylamine and 1,1'-thiobis(2 -naphthol) at a weight ratio of 1:1, then dropwise add acryloyl chloride under salt bath conditions, control the temperature of the reaction system at 5°C, stir for...

Embodiment 2

[0025] A preparation method of high refractive index sulfur-containing optical copolymer resin, comprising the steps of:

[0026] S1, 2-naphthol is added to be dissolved in the mixed solvent that is 2:1 toluene and ethyl acetate by weight ratio and dissolve completely, add sulfur dichloride under ice-bath condition, sulfur dichloride and 2-naphthol The molar ratio was 1:1.9, stirred and reacted at 20°C for 2h, the temperature of the reaction liquid was raised to 100°C, and most of the solvent was distilled off, then frozen until solid precipitated, filtered, recrystallized from absolute ethanol, filtered, and dried to obtain 1 , 1'-thiobis(2-naphthol);

[0027] S2. Dissolve 1,1'-thiobis(2-naphthol) in dichloromethane, add excess triethylamine to carry out alkalization reaction under stirring condition, triethylamine and 1,1'-thiobis(2 -naphthol) with a weight ratio of 1:1.5, then dropwise add acryloyl chloride under salt bath conditions, control the temperature of the reactio...

Embodiment 3

[0030] A preparation method of high refractive index sulfur-containing optical copolymer resin, comprising the steps of:

[0031] S1, 2-naphthol is added to be dissolved in the mixed solvent that is 1.5:1 toluene and ethyl acetate by weight ratio and dissolve completely, add sulfur dichloride under ice-bath condition, sulfur dichloride and 2-naphthol The molar ratio was 1:2, stirred and reacted at 15°C for 3h, the temperature of the reaction solution was raised to 95°C, and most of the solvent was distilled off, then frozen until solid precipitated, filtered, recrystallized from absolute ethanol, filtered, and dried to obtain 1 , 1'-thiobis(2-naphthol);

[0032] S2. Dissolve 1,1'-thiobis(2-naphthol) in dichloromethane, add excess triethylamine to carry out alkalization reaction under stirring condition, triethylamine and 1,1'-thiobis(2 -naphthol) at a weight ratio of 1:1.2, then dropwise add acryloyl chloride under salt bath conditions, control the temperature of the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com