Synthetic method of perchloromethyl mercaptan

A technique for the synthesis of perchloromethanethiol and its synthesis method, which is applied in the synthesis of organic chemical raw material perchloromethylmercaptan, and in the field of synthesis of perchloromethylmercaptan, which can solve the problem of affecting personal health during operation, potential safety hazards of carbon disulfide, and increased production costs and other issues to achieve the effect of low cost, short response time and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

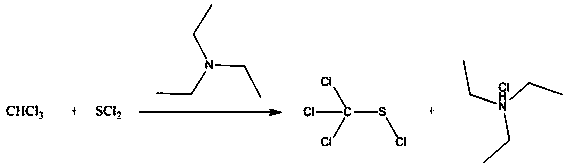

Method used

Image

Examples

Embodiment 1

[0024] Add 154.10g of chloroform and 124.39g of triethylamine into a 1L reaction kettle, control the temperature at 10°C, start stirring, and slowly add 126.58g of sulfur dichloride into the system dropwise. After about 2 hours, sulfur dichloride drops After the addition is complete, keep stirring at this temperature for about 2h, and the reaction is complete. Suction filter the obtained reaction solution to remove the by-product triethylamine hydrochloride, then add about 100g of water for washing to remove a small amount of unreacted triethylamine, then raise the temperature of the collected lower layer to 65°C, and evaporate a small amount of Unreacted chloroform finally obtained 210.6g of yellow oily liquid, namely perchloromethanethiol, with a yield of 92.21% based on sulfur dichloride and a density of 1.69 after detection.

[0025] Use perchloromethanethiol as the raw material to carry out the synthesis experiment of anti-scorch agent E. The specific method is: control t...

Embodiment 2

[0027] Add 151g of chloroform and 116.34g of triethylamine into a 1L reaction kettle, control the temperature at 10°C, start stirring, slowly add 118.39g of sulfur dichloride into the system, and after about 2 hours, add sulfur dichloride dropwise Complete, keep the temperature and continue to stir for about 2h, the reaction is complete. Suction filter the obtained reaction solution to remove the by-product triethylamine hydrochloride, then add about 100g of water for washing to remove a small amount of unreacted triethylamine, then raise the temperature of the collected lower layer to 65°C, and evaporate a small amount of Unreacted chloroform finally obtained 199.2 g of yellow oily liquid, namely perchloromethanethiol, with a yield of 93.25% based on sulfur dichloride and a density of 1.69 after detection, meeting the requirements for use.

Embodiment 3

[0029] Add 167.28g of chloroform and 118.15g of triethylamine into a 1L reaction kettle, control the temperature at 0°C, start stirring, and slowly add 120.23g of sulfur dichloride into the system dropwise. After about 1 hour, sulfur dichloride drops After the addition was completed, the temperature was maintained and stirring was continued for about 1 h, and the reaction was completed. Suction filter the obtained reaction solution to remove the by-product triethylamine hydrochloride, then add about 100g of water for washing to remove a small amount of unreacted triethylamine, then raise the temperature of the collected lower layer to 65°C, and evaporate a small amount of Unreacted chloroform finally obtained 195.78g of yellow oily liquid, namely perchloromethanethiol, with a yield of 90.24% based on sulfur dichloride and a density of 1.69 after detection, meeting the requirements for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com