Method for preparing sulfur dichloride

A technology of sulfur dichloride and disulfide dichloride, applied in chemical instruments and methods, chemical/physical processes, sulfur and halogen compounds, etc., can solve problems such as harm to the health of operators, environmental pollution, and inconvenience in implementation , to achieve the effect of facilitating popularization and application, no environmental pollution, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

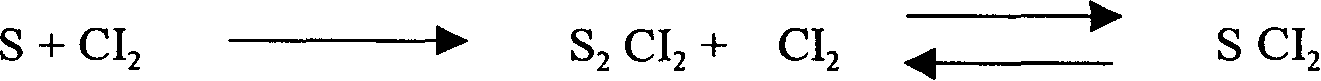

Method used

Image

Examples

Embodiment 1

[0017] In the preparation method of sulfur dichloride described in the present invention, the molar ratio of chlorine gas to sulfur is 2.05:1. Add sulfur and iron trichloride catalyst corresponding to 0.15% by weight of sulfur dichloride in the reaction kettle, then feed chlorine gas, control the reaction temperature to be 90-100°C, and control the reaction pressure to gauge pressure 0.1-0.15Mpa. Get disulfur dichloride;

[0018] Cool disulfur dichloride to 2-8°C, and feed chlorine gas to the set ventilation rate to produce sulfur dichloride product;

[0019] Add sulfur dichloride ethyl phosphite stabilizer of 0.2% by weight of sulfur dichloride after resting, obtain the finished product of sulfur dichloride with good stability, the purity reaches more than 98%, the storage period can reach 3 months, and the purity is not less than 95%. Easy to store and use.

[0020] Under the completely identical situation of other conditions, only the different stabilizers used for the pr...

Embodiment 2

[0023] In the preparation method of sulfur dichloride described in the present invention, the molar ratio of chlorine gas to sulfur is 2.06:1. Add sulfur and its equivalent iron trichloride catalyst of 0.12% by weight of sulfur dichloride in the reaction kettle, then feed chlorine gas, control the reaction temperature to be 80-90°C, and the reaction pressure to be controlled at a gauge pressure of 0.15-0.18Mpa. Get disulfur dichloride;

[0024] Cool disulfur dichloride to -6~-1°C, and then pass chlorine gas into it to produce sulfur dichloride product;

[0025] After standing still, 0.4% by weight of sulfur dichloride is added as a butyl phosphite stabilizer to obtain a finished product of sulfur dichloride.

Embodiment 3

[0027] In the preparation method of sulfur dichloride described in the present invention, the molar ratio of chlorine gas to sulfur is 2.03:1. Add sulfur and zinc chloride catalyst equivalent to 0.16% by weight of sulfur dichloride in the reaction kettle, then feed chlorine gas, control the reaction temperature to 110-120°C, and control the reaction pressure to a gauge pressure of 0.1-0.12Mpa to obtain Disulfur dichloride;

[0028] Cool disulfur dichloride to -8~-4°C, and then pass chlorine gas into it to produce sulfur dichloride product;

[0029] After resting, 0.5% by weight of sulfur dichloride is added as a dimethyl hydrogen phosphite stabilizer to obtain a finished product of sulfur dichloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com