Preparation method of 3,5-dimethyl-4-chlorophenol

A technology of dimethylphenol and chlorophenol, which is applied in the field of preparation of 3,5-dimethyl-4-chlorophenol, can solve the problems of low PCMX content, incomplete chlorination reaction, high production cost, and achieve high content , Reduce the generation of by-products, improve the yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

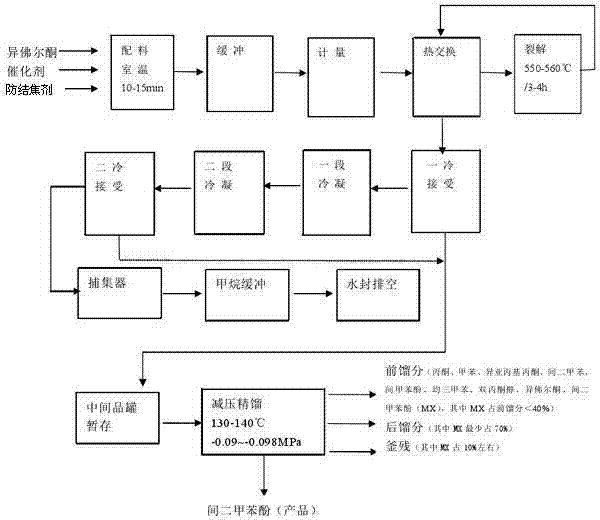

Method used

Image

Examples

Embodiment 1

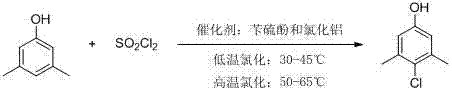

[0036] As shown in the route map, add 1000 kg of tetrachlorethylene and 500 kg (4 kmol) of substrate MX into the chlorination kettle, start stirring, control the temperature between 30 and 45 °C, dissolve the substrate MX, and add benzylthiophenol 0.5 kg, 2 kg of aluminum trichloride, and slowly add 540 kg (4 kmol) of sulfuryl chloride dropwise at this temperature. Add 54 kg (0.4 kmol) of sulfuryl chloride, dropwise for 1~1.5 h. After the dropwise addition is completed, remove tail gas at -0.02~-0.04 MPa and 50~65 °C for 1~2 h, and react according to [ 0029] road map carries out aftertreatment, obtains product 550 kg, yield 85.80% (based on the molar yield of MX), content 99.01%.

Embodiment 2

[0038] As shown in the route map, add 1000 kg of tetrachlorethylene to the chlorination kettle, start stirring with 500 kg (4 kmol) of substrate MX, and control the temperature between 30 and 45 °C to dissolve the substrate, add 0.5 kg of benzylthiophenol, three Aluminum chloride 2 kg, slowly add 560 kg (4.15 kmol) sulfuryl chloride dropwise at this temperature, the dropwise addition time is 4.5~5 h, after the dropwise addition, raise the temperature to 50~65 °C, and then add dropwise 70 kg (0.52 kmol) Sulfuryl chloride, the dropwise addition time is 1~1.5 h. After the dropwise addition is completed, at -0.02~-0.04 MPa, 50~65 ℃, after heat preservation to remove the tail gas for 1~2 h, the reactants are carried out according to the route diagram of [0029]. Processed product 560 kg, yield 87.3% (molar yield based on MX), content 98.81%.

Embodiment 3

[0040] As shown in the route map, add 1000 kg of tetrachlorethylene to the chlorination kettle, start stirring with 500 kg (4 kmol) of substrate MX, and control the temperature between 30 and 45 °C to dissolve the substrate, add 0.5 kg of benzylthiophenol, three Aluminum chloride 2.5 kg, slowly add 560 kg (4.15 kmol) sulfuryl chloride dropwise at this temperature, the dropwise addition time is 4.5~5 h, after the dropwise addition is completed, the temperature is raised to 50~65°C, and then 70 kg (0.52 kmol) is added dropwise Sulfuryl chloride, the dropwise addition time is 1~1.5 h. After the dropwise addition is completed, at -0.02~-0.04 MPa, 50~65 °C, keep removing the tail gas for 1~2 h, and the reactants are carried out according to the route diagram of [0029]. Process to get product 530 kg, yield 82.6% (molar yield based on MX), content 98.58%.

[0041] The directional chlorination process product of each embodiment PCMX, GC analysis result is:

[0042] Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com