Synthetic process for sulfurized calcium alkyl phenolate clearing agent

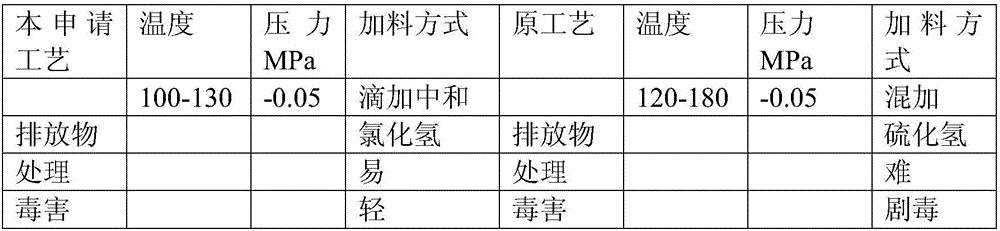

A technology of sulfurized alkylphenol calcium and sulfurized alkylphenol, which is applied in additives, petroleum industry, lubricating compositions, etc., can solve problems such as hydrogen sulfide poisoning, and achieve the effect of easy alkali value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1), add 51.2g of dodecylphenol into the there-necked flask with stirring, install the condenser tube and the absorption bottle, add 22.4g of calcium oxide and 18g of water in the absorption bottle and stir well;

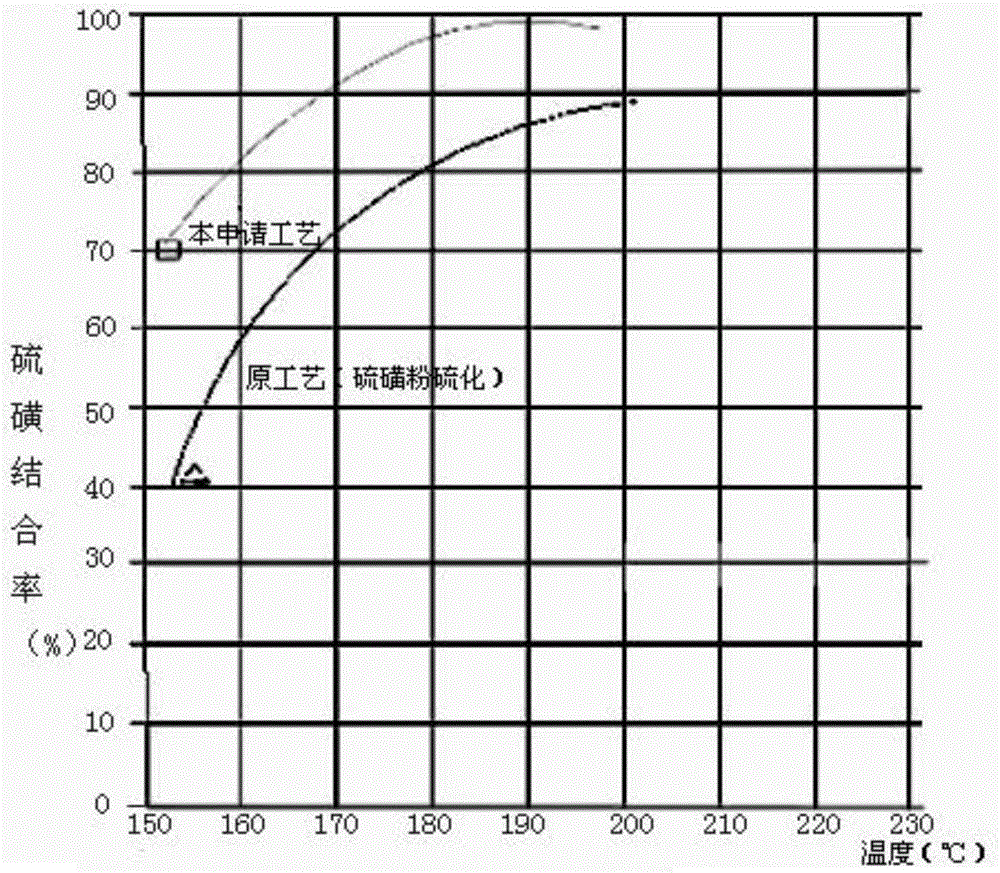

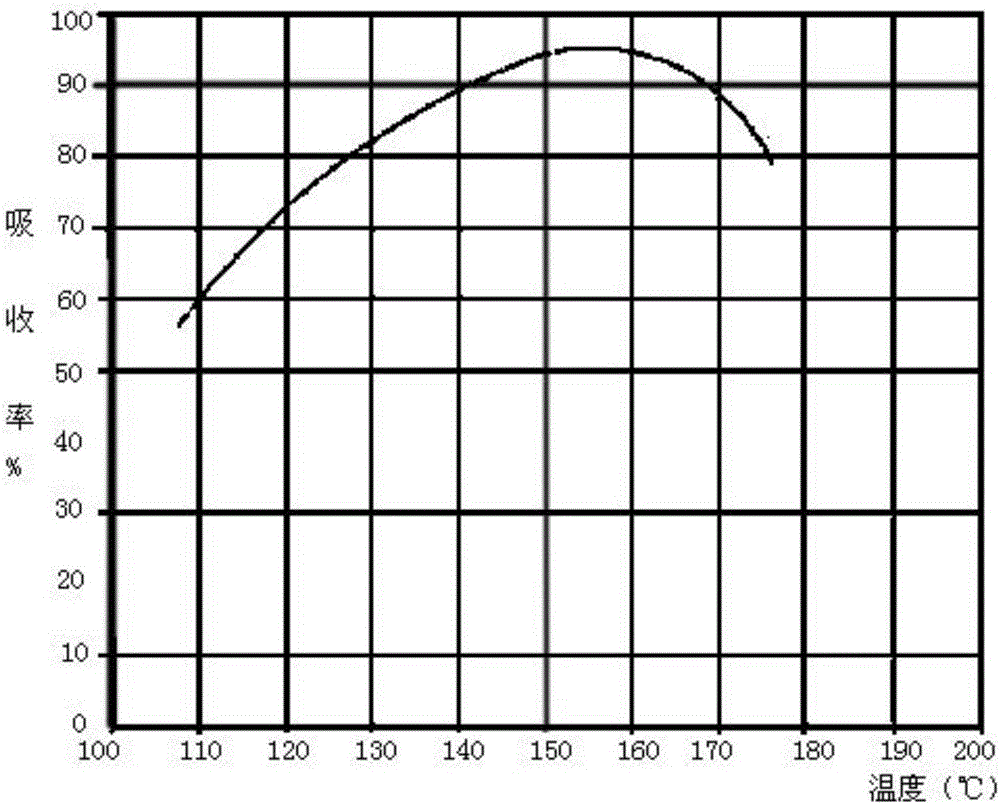

[0044] (2) Weigh 13.5g of sulfur monochloride with a dropping bottle, raise the temperature of dodecylphenol in the three-necked bottle to 120°C, and start adding sulfur monochloride dropwise to the three-necked bottle; continue to heat up after all the drops are completed 180 ℃ ~ 190 ℃, constant temperature for 2 hours for vulcanization; after the vulcanization is completed, take samples for the total acid value, control the total acid value to be greater than 210KOHmg / g, and pour it into the neutralization tank after passing the test;

[0045] (3) After pouring the sulfurized alkylphenol into the neutralization tank, add 32.35g of base oil and 30g of calcium chloride aqueous solution, according to the acid value of the sulfurized alkylphenol, add 20g of calc...

Embodiment 2

[0052] (1), add 51.2g of dodecylphenol into the there-necked flask with stirring, install the condenser tube and the absorption bottle, add 22.4g of calcium oxide and 18g of water in the absorption bottle and stir well;

[0053] (2) Weigh 13.5g of sulfur monochloride with a dropping bottle, raise the temperature of dodecylphenol in the three-necked bottle to 120°C, and start adding sulfur monochloride dropwise to the three-necked bottle; continue to heat up after all the drops are completed 170 ℃ ~ 180 ℃, constant temperature for 1 hour for vulcanization; after the vulcanization is completed, take samples for the total acid value, control the total acid value to be greater than 210KOHmg / g, and pour it into the neutralization tank after passing the test;

[0054] (3) After pouring the sulfurized alkylphenol into the neutralization tank, add 32.35g of base oil and 30g of calcium chloride aqueous solution, according to the acid value of the sulfurized alkylphenol, add 20g of calci...

Embodiment 3

[0061] (1), add 51.2g of dodecylphenol into the there-necked flask with stirring, install the condenser tube and the absorption bottle, add 22.4g of calcium oxide and 18g of water in the absorption bottle and stir well;

[0062] (2) Weigh 13.5g of sulfur monochloride with a dropping bottle, raise the temperature of dodecylphenol in the three-necked bottle to 120°C, and start adding sulfur monochloride dropwise to the three-necked bottle; continue to heat up after all the drops are completed 150 ℃ ~ 160 ℃, constant temperature for 2 hours for vulcanization; after the vulcanization is completed, take samples for the total acid value, control the total acid value to be greater than 210KOHmg / g, and pour it into the neutralization tank after passing the test;

[0063] (3) After pouring the sulfurized alkylphenol into the neutralization tank, add 32.35g of base oil and 30g of calcium chloride aqueous solution, according to the acid value of the sulfurized alkylphenol, add 20g of calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com