Process for preparing polyanilinechloride

A technology of polyaniline and chlorination, which is applied in the field of preparation of chlorinated polyaniline, and can solve problems such as poor yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

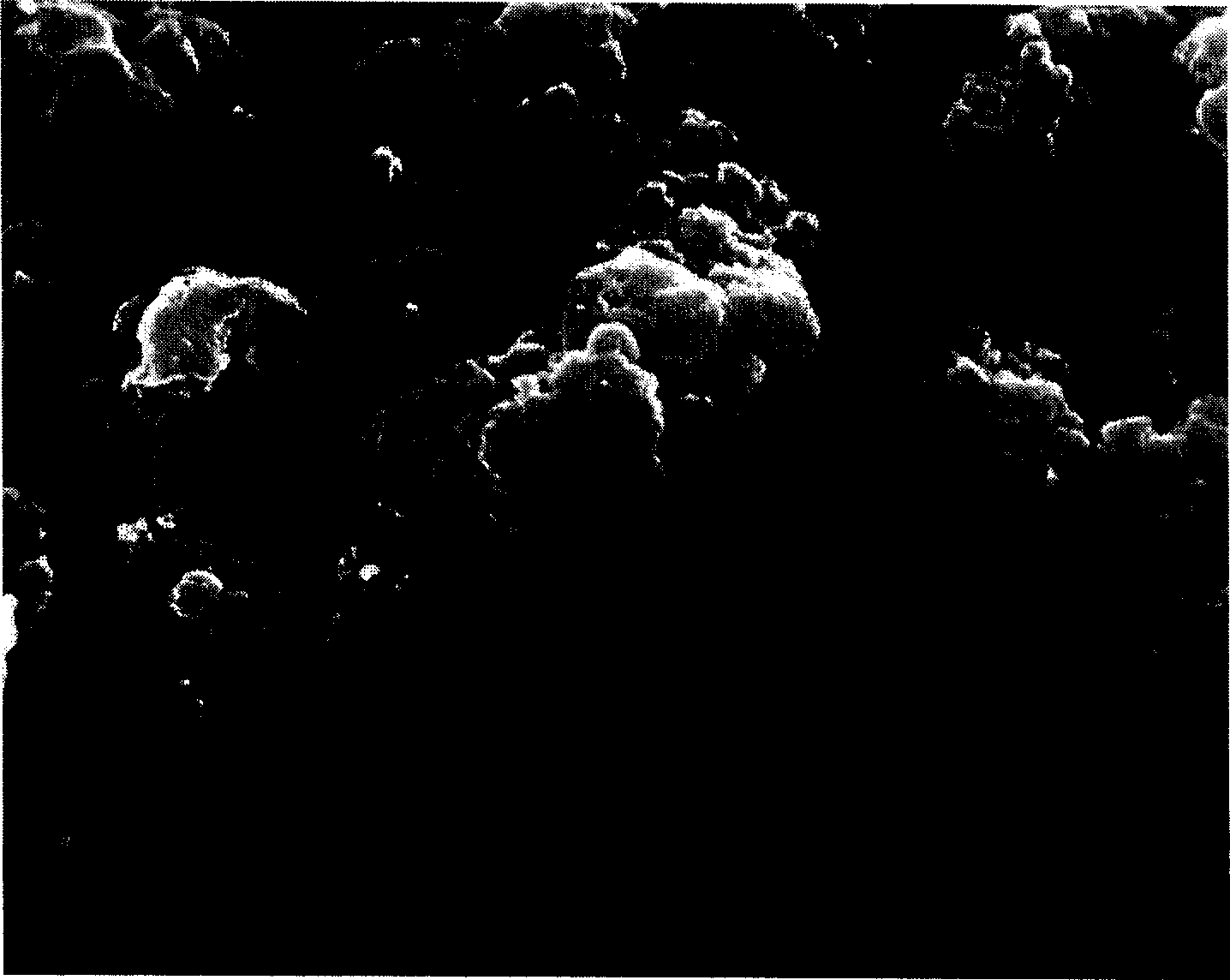

[0012] Add 3.0g (33mmol) polyaniline, 11.0g (82mmol) anhydrous aluminum trichloride and 13ml (165mmol) sulfur monochloride successively in 250ml three-neck round bottom flask, then add dropwise 100ml anhydrous acetonitrile, then slowly heat, Continue to stir and reflux for 10h. After the reaction is completed, filter, extract with carbon disulfide ladder for 10 hours, wash 30ml×20 times with 1mol / L hydrochloric acid solution, soak in 0.1mol / L ammonia water (pH=8~9) overnight, wash 20ml×15 times with 0.1mol / L ammonia water , and finally vacuum-dried at 60° C. for 24 hours to obtain 6.0 g of black powdery solid chlorinated polyaniline with a yield of 93%. The elemental analysis results (wt%) are: C 37.64, N 7.66, H1.10, S 3.18, Cl 50.32. FT-IR (KBr, cm -1 ): 3375, 3057, 1671, 1582, 1474, 1359, 1223, 1127, 1080, 1036, 866, 819, 574. The scanning electron microscope spectrum of chlorinated polyaniline is shown in the accompanying drawing.

Embodiment 2

[0014] Add 4.50g (49.5mmol) of polyaniline, 36.5g (272mmol) of anhydrous aluminum trichloride and 24ml (165mmol) of sulfur monochloride successively into a 250ml three-neck round bottom flask, then add 150ml of anhydrous DMF dropwise, and then slowly heat , Continue stirring and reflux reaction for 12h. After the reaction is complete, filter, wash with ether 100ml×5 times, carbon disulfide 50ml×8 times, deionized distilled water 50ml×10 times, then soak with 250ml 1mol / L ammonia water (pH=8~9) overnight, and then wash with 0.1mol / L ammonia water washing 50ml×10 times, and finally vacuum drying at 80° C. for 48 hours to obtain 9.3 g of black powdery solid chlorinated polyaniline with a yield of 97%. The elemental analysis results (wt%) are: C 33.83, N6.86, H 0.92, S 5.20, Cl 48.36. FT-IR (KBr, cm -1 ): 3380, 1586, 1477, 1230, 1128, 1079, 1037, 945, 825, 707, 481.

Embodiment 3

[0016] Add 3.5g of polyaniline, 3.8ml of phenylhydrazine, and 100ml of anhydrous ether into a 150ml round bottom flask, and react at room temperature for 8h. After the reaction, filter, wash with ether 30ml x 6 times, and then vacuum-dry at 80°C for 6h to obtain 3.5g black powdery solid reduced polyaniline.

[0017] Add 0.50 g of reduced polyaniline, 3.30 g of anhydrous aluminum trichloride and 2.2 ml of sulfur monochloride to a 100 ml single-necked round-bottom flask in sequence, then add dropwise 30 ml of anhydrous acetonitrile, and then continue stirring and heating under reflux for 10 h. After the reaction is completed, filter, extract with carbon disulfide ladder for 10 hours, wash 30ml×20 times with 1mol / L hydrochloric acid, soak in 150ml 0.1mol / L ammonia water for 24h, then wash 30ml×15 times with 0.1mol / L ammonia water, and finally vacuum-dry at 60°C After 24 hours, 1.0 g of black powdery solid chlorinated polyaniline was obtained with a yield of 95%. The elemental an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com