Method for rectifying thionyl chloride

A technology of thionyl chloride and rectification, which is applied in the rectification field of thionyl chloride, can solve the problems of inability to realize large-scale production, low degree of automation, limited product purity, etc., and achieves high energy utilization rate and improved degree of automation. , the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

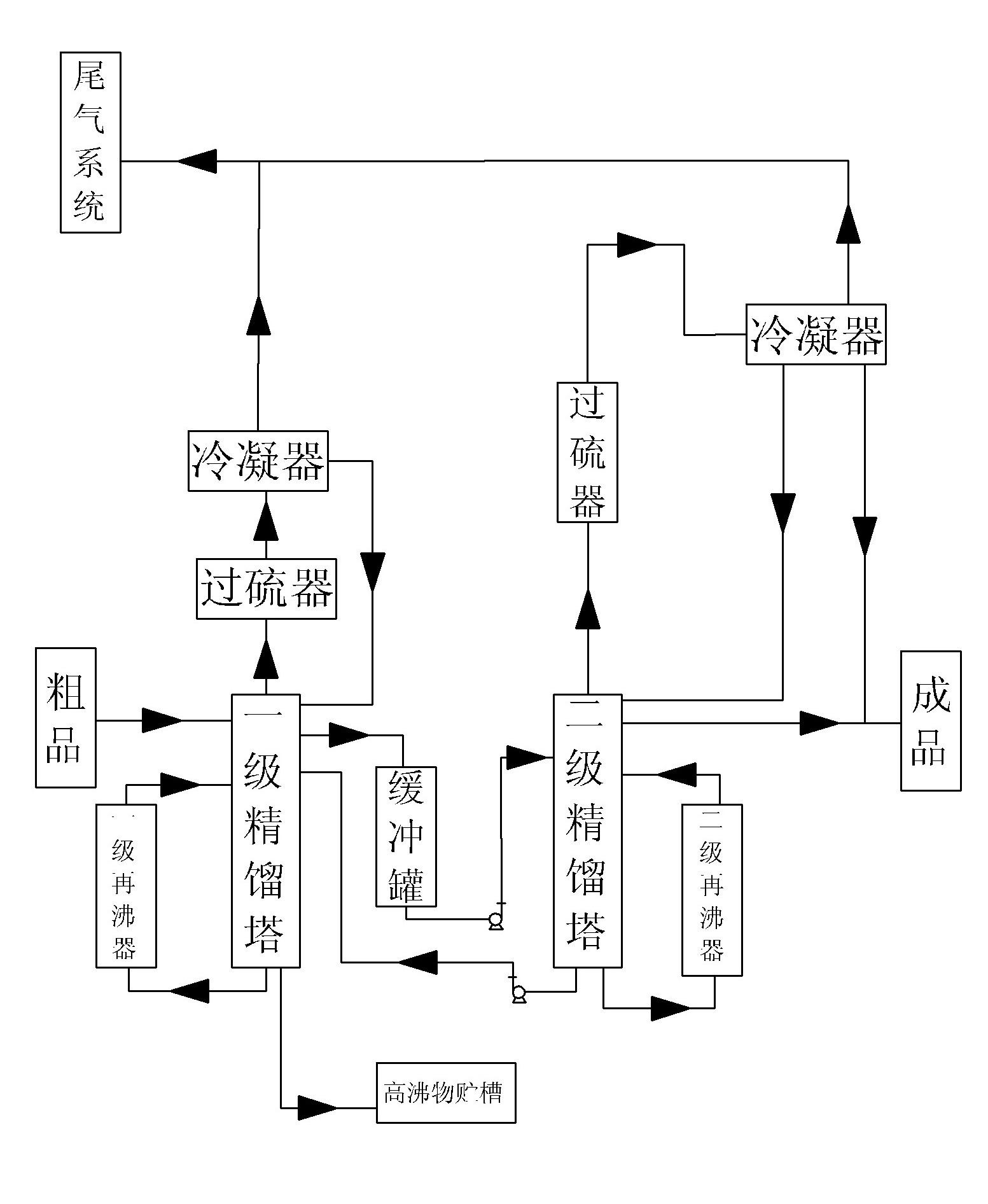

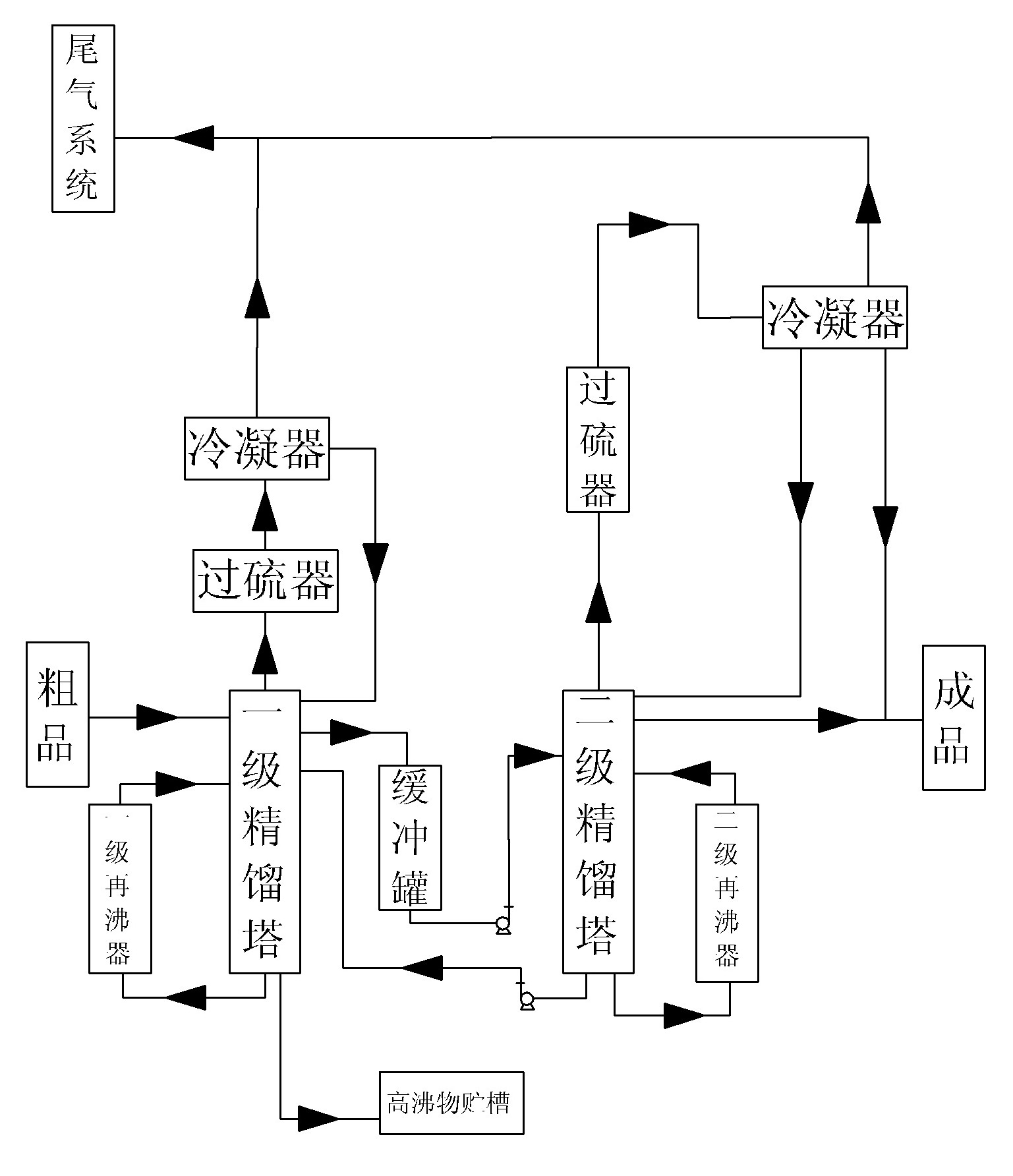

[0015] The rectification method of thionyl chloride adopts two-stage continuous rectification process, and its process flow chart is as follows figure 1 As shown, it includes primary rectification and secondary rectification, correspondingly adopts primary rectification tower and secondary rectification tower, and the sulfur oxychloride crude product with volume percentage concentration of 60% after sulfur supplementation is pumped to Feed the high-level tank, and then rely on the liquid level difference to continuously enter the first-stage rectification tower for rectification. The high boiler sulfur monochloride is continuously extracted from the bottom of the tower, and the sulfur monochloride is introduced into the high boiler storage tank, and the low boiler distilled from the top of the first-stage rectification column is removed through the sulfur oversulfurizer continuously. The side line of the primary rectification tower continuously extracts the semi-finished produ...

Embodiment 2

[0017] The rectification method of thionyl chloride adopts two-stage continuous rectification process, and its process flow chart is as follows figure 1 As shown, which includes primary rectification and secondary rectification, the primary rectification tower and secondary rectification tower are adopted accordingly, and the sulfur oxychloride crude product with a volume percentage concentration of 70% after sulfur supplementation is pumped to Feed the high-level tank, and then rely on the liquid level difference to continuously enter the first-stage rectification tower for rectification. The high boiler sulfur monochloride is continuously extracted from the bottom of the tower, and the sulfur monochloride is introduced into the high boiler storage tank, and the low boiler distilled from the top of the first-stage rectification column is removed through the sulfur oversulfurizer continuously. The side line of the primary rectification tower continuously extracts the semi-fini...

Embodiment 3

[0019] The rectification method of thionyl chloride adopts two-stage continuous rectification process, and its process flow chart is as follows figure 1 As shown, it includes primary rectification and secondary rectification, correspondingly adopts primary rectification tower and secondary rectification tower, and the sulfur oxychloride crude product that the volume percent concentration after sulfur supplementation is 65% is pumped to Feed the high-level tank, and then rely on the liquid level difference to continuously enter the first-stage rectification tower for rectification. The high boiler sulfur monochloride is continuously extracted from the bottom of the tower, and the sulfur monochloride is introduced into the high boiler storage tank, and the low boiler distilled from the top of the first-stage rectification column is removed through the sulfur oversulfurizer continuously. The side line of the primary rectification tower continuously extracts the semi-finished prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com