Patents

Literature

79 results about "Hexachlorobutadiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexachlorobutadiene, Cl₂C=C(Cl)C(Cl)=CCl₂, is a colorless liquid at room temperature that has an odor similar to that of turpentine. It is a chlorinated aliphatic diene with niche applications but is most commonly used as a solvent for other chlorine-containing compounds.

Separation and purification method of mixed waste gas containing chlorine and hydrogen chloride

InactiveCN1865127ARealize recycling of resourcesHigh recovery rateChlorine/hydrogen-chloride purificationPurification methodsGas phase

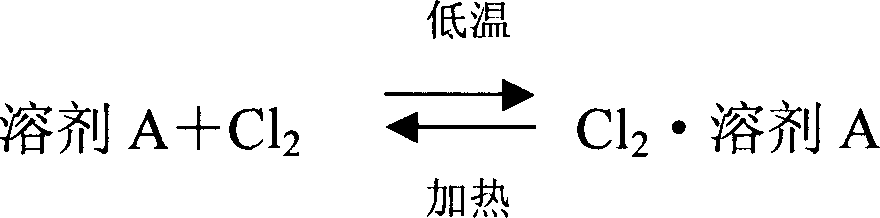

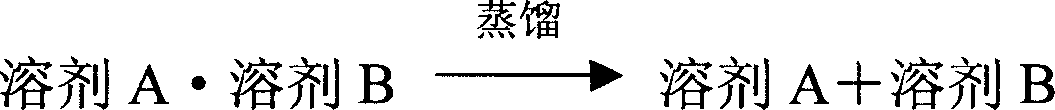

This invention relates to a method for separating and purifying mixing exhaust gas of chlorine and hydrochloride, comprising: absorb the chlorine in the mixing exhaust gas using solvent A to separate from gas phase hydrochloride, the chlorine can be obtained after solvent A desorption, the hydrochloride can be obtained by removing solvent A in the gas phage hydrochloride using solvent B, wherein: solvent A is one of benzene, silicon tetrachloride, nonyl hydride, sulfur monochloride, carbon tetrachloride and chlorosulfonic acid, and solvent B is one of cyclopentadiene and hexachlorobutadiene. By washing with concentrated hydrochloric acid to remove trace amount of organic compounds, and chemical washing to remove heavy metal elements, the hydrochloride is absorbed by water to make hydrochloric acid. This invention is characterized of efficient separation of chlorine and hydrochloride, high efficiency of separation, low cost, high-usage of resources, high purity of chlorine up to 99%, recycling use, and the purity of hydrochloride meets the requirement of producing industrial hydrochloride and hydrochloride regent .

Owner:ZHEJIANG WEIHUA CHEMICAL CO LTD

Method for preparing hexachlorobutadiene

InactiveCN101525267ASimple processLow equipment requirementsHalogenated hydrocarbon preparationZinc bromideHexachlorobutadiene

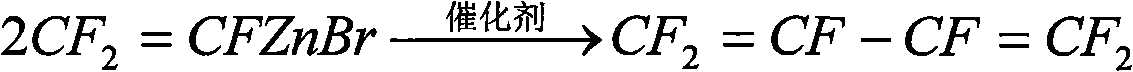

The invention provides a method for preparing hexachlorobutadiene by using 1, 1- dibromo-tetrafluoroethane, comprising: zinc powder and aprotic polar solvent are added into a reactor I protected by inert gas to lead the temperature to reach 50-90 DEG C; the 1, 1- dibromo-tetrafluoroethane is added into the reactor I within 0.5-3.5h and then reacts for 1.5-5h at the temperature of 50-120 DEG C; after that, the zinc powder reacts with the 1, 1- dibromo-tetrafluoroethane to produce trifluoro-ethylene zinc bromide; the reactor I is cooled to be room temperature, and the solution in the reactor I is added into a reactor II containing catalyst and solvent at the temperature below 1-40 DEG C within 0.5-3h and then reacts for 1-7h at the temperature of 0-60 DEG C; after the reaction, the obtained product is collected by a liquid nitrogen cold trap. The invention has the advantages of short synthetic route, simple technique, high raw material conversion rate, high yield of product and high purity of crude product, so that the product is simple to separate and purify, and the environmental pollution is reduced.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

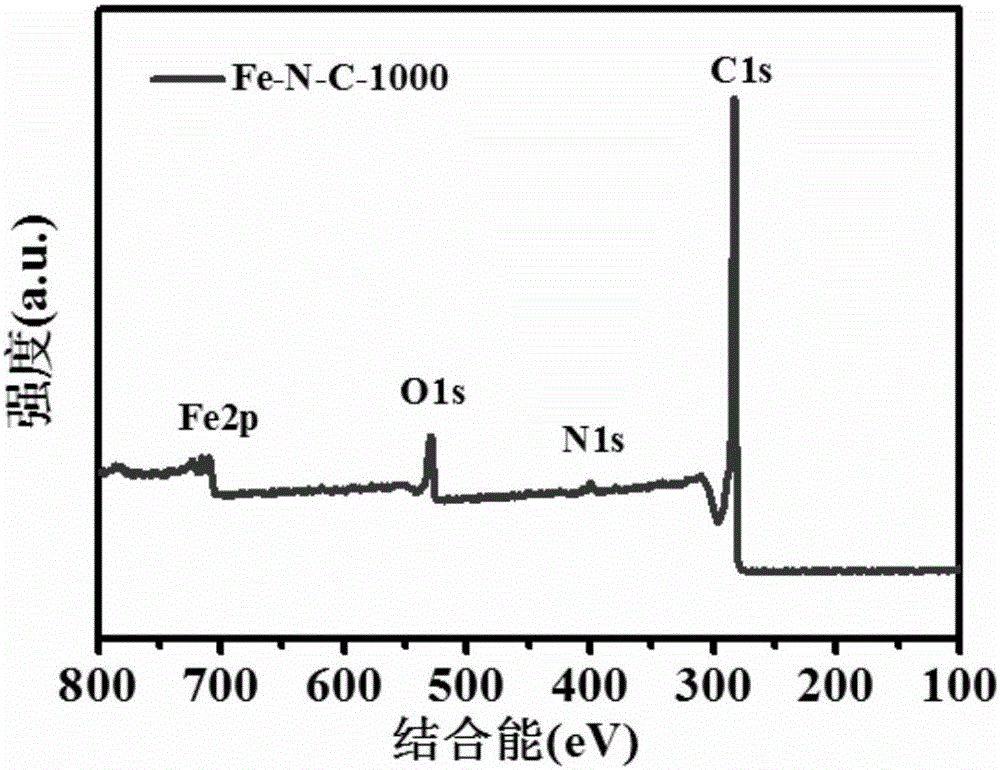

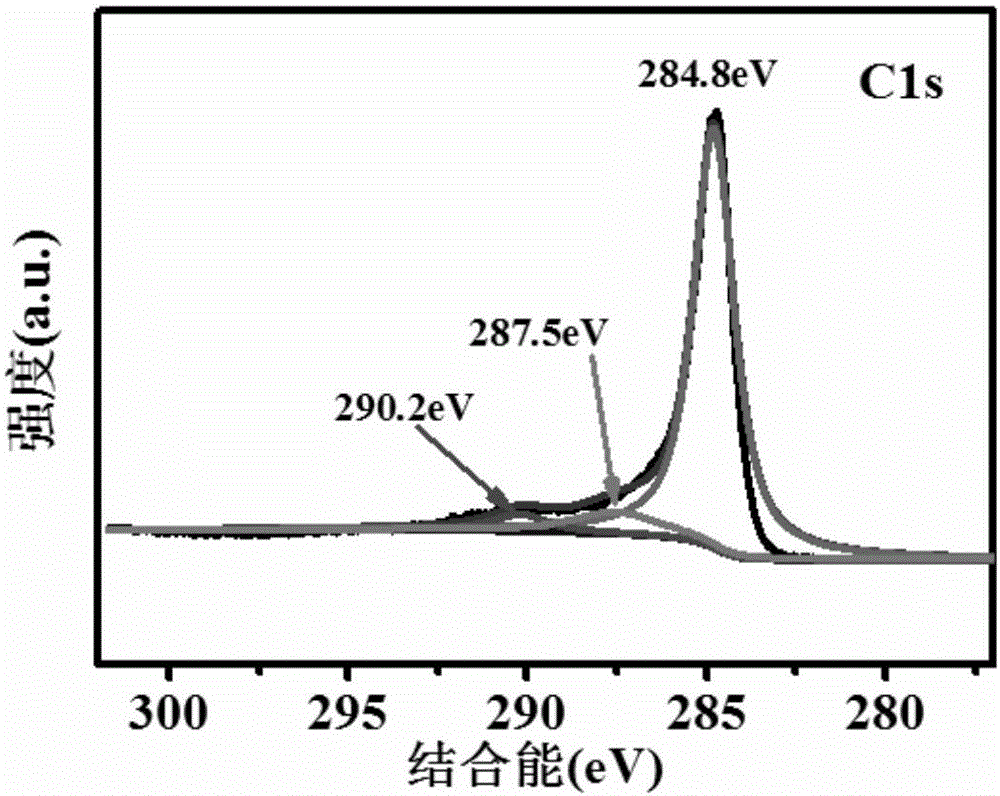

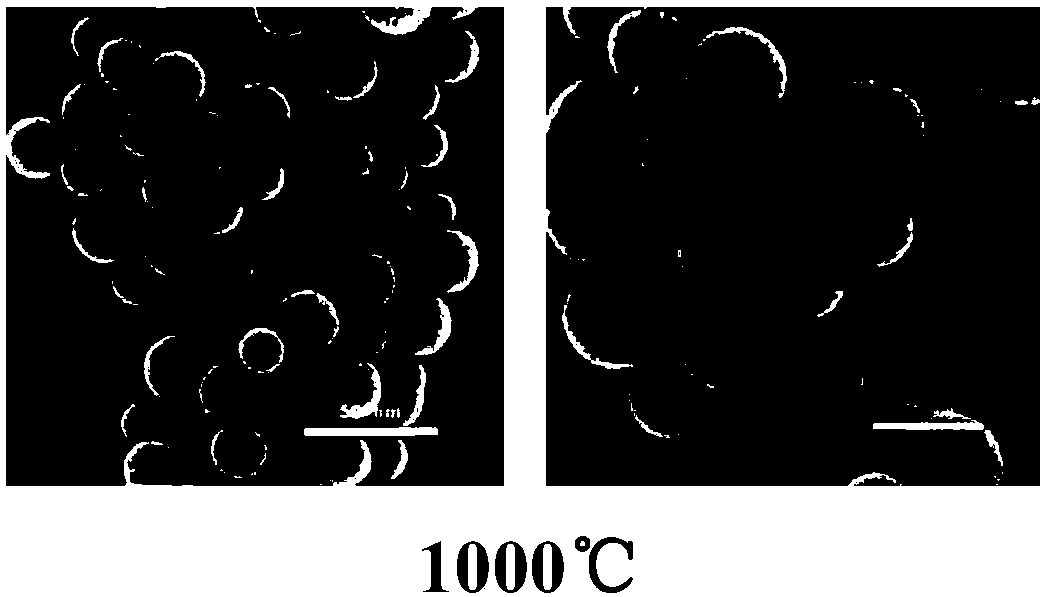

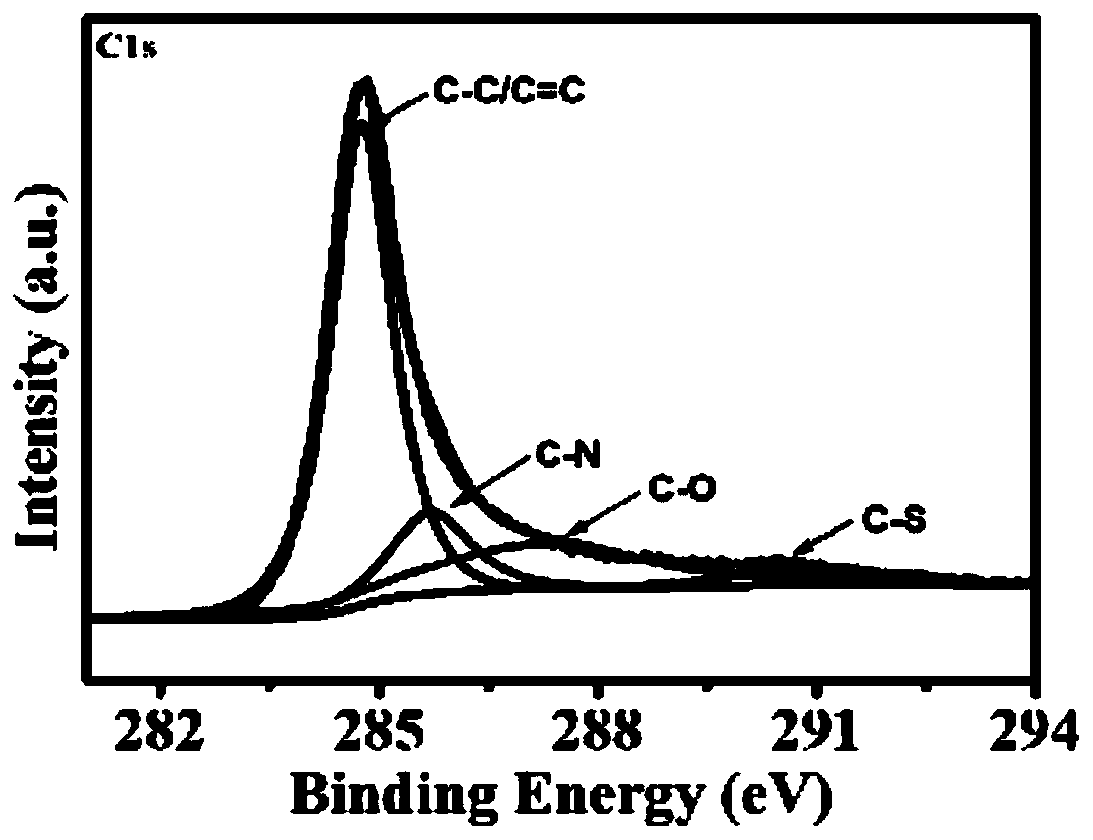

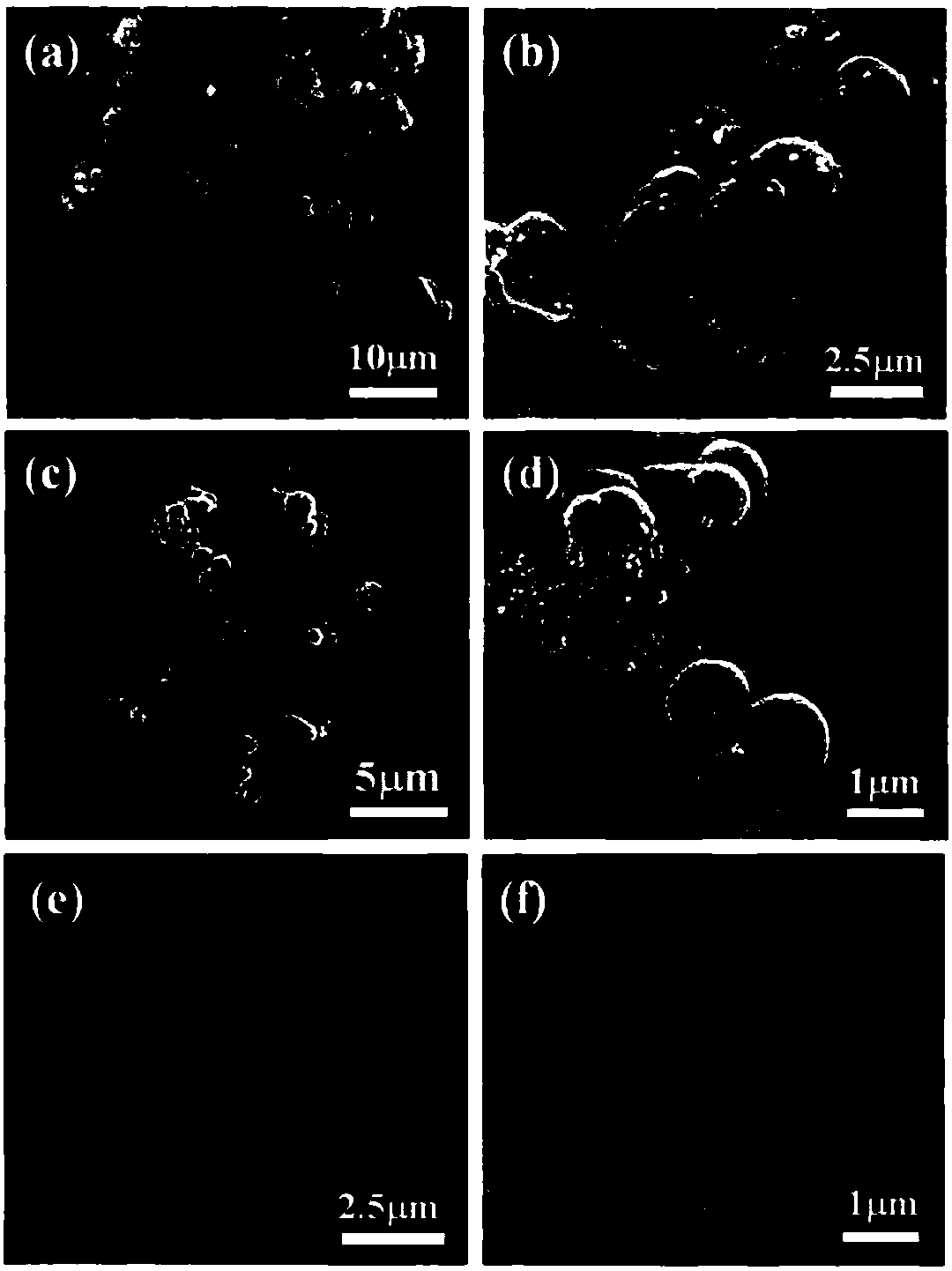

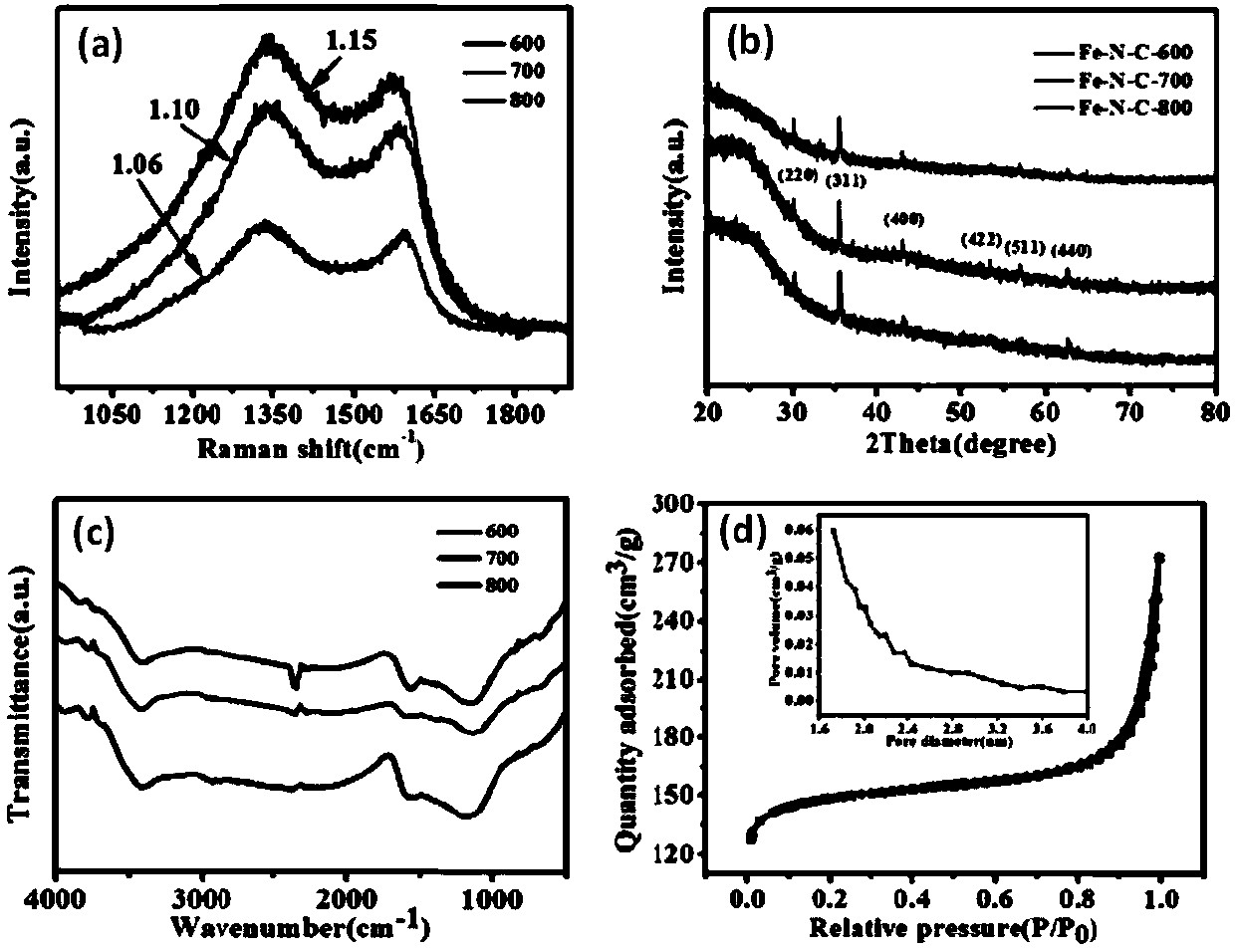

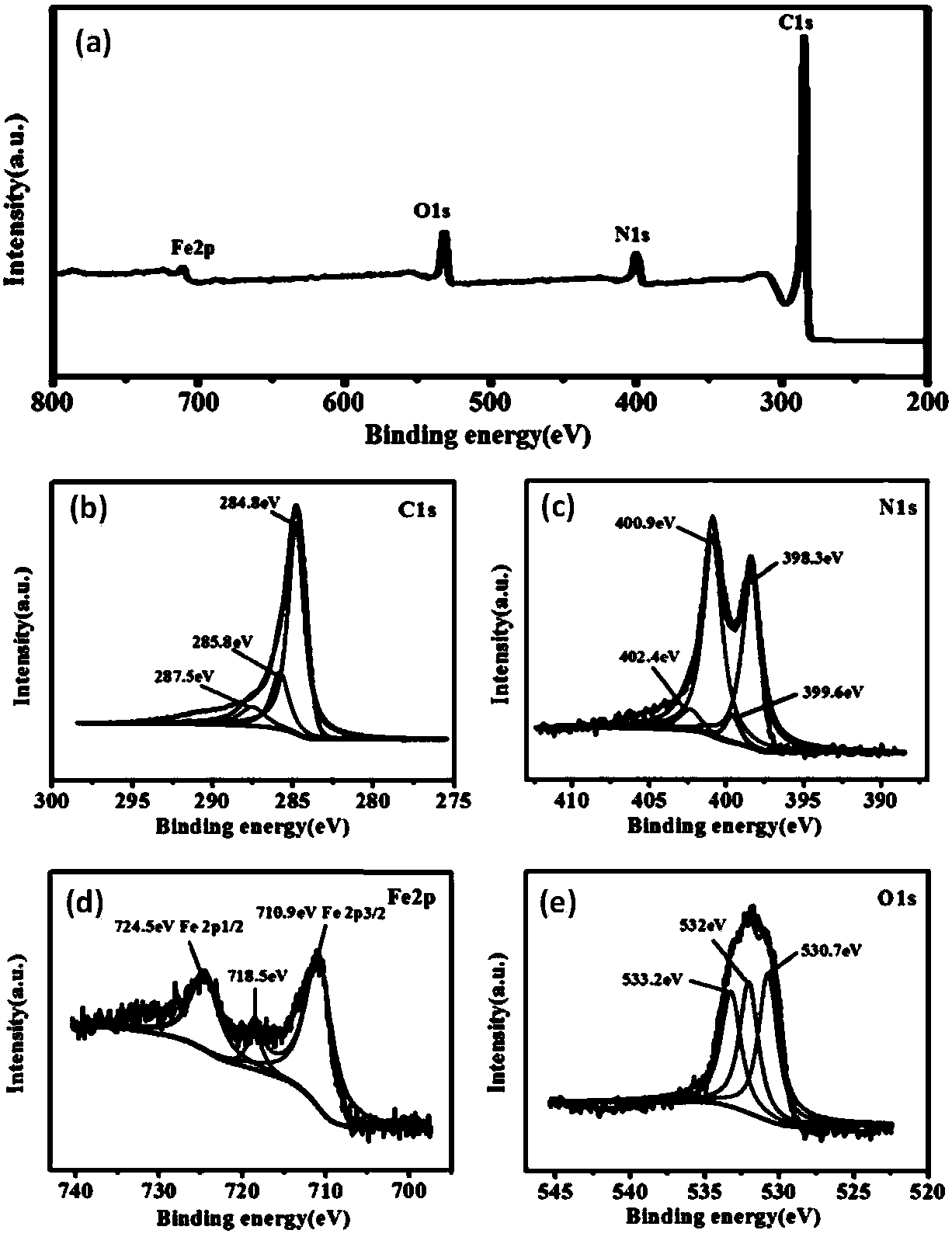

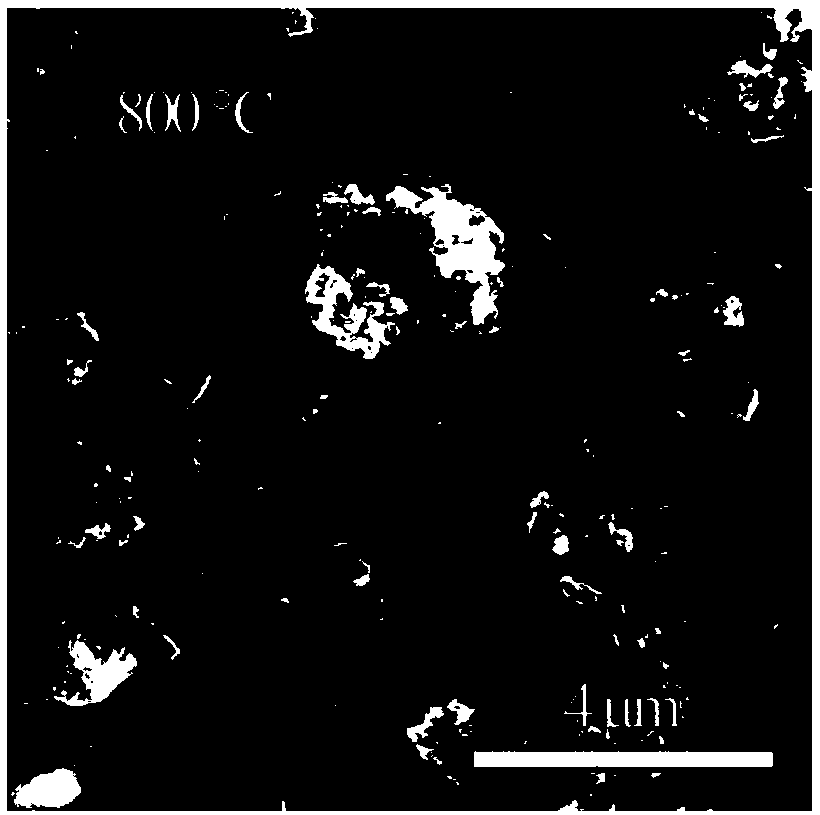

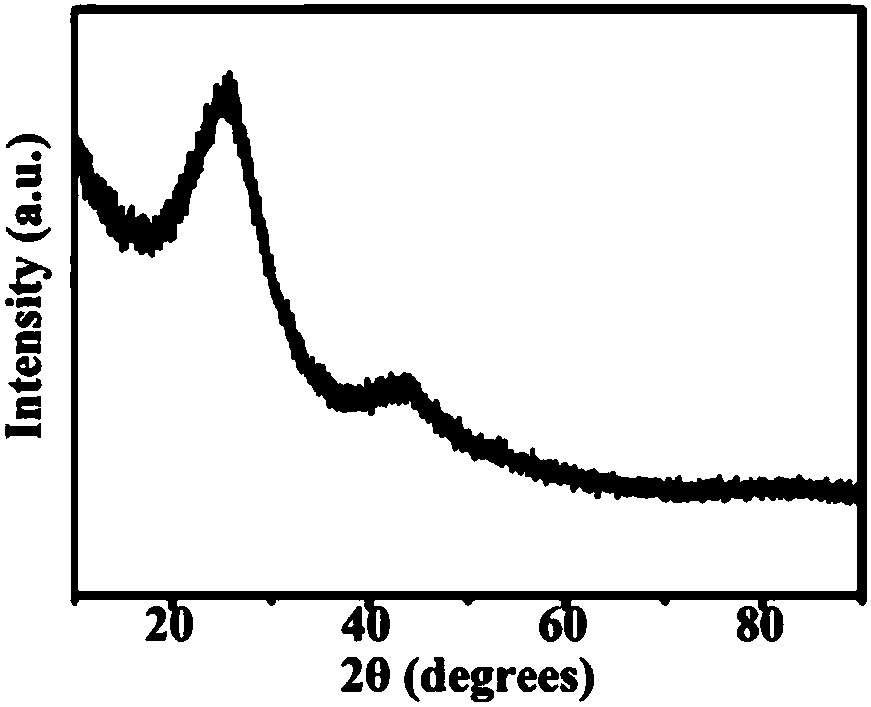

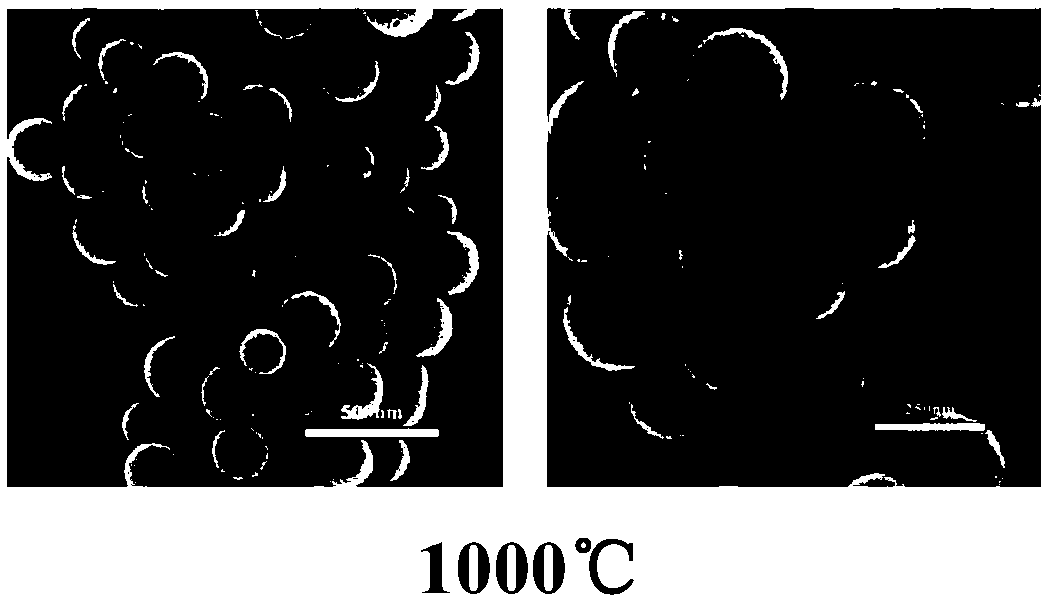

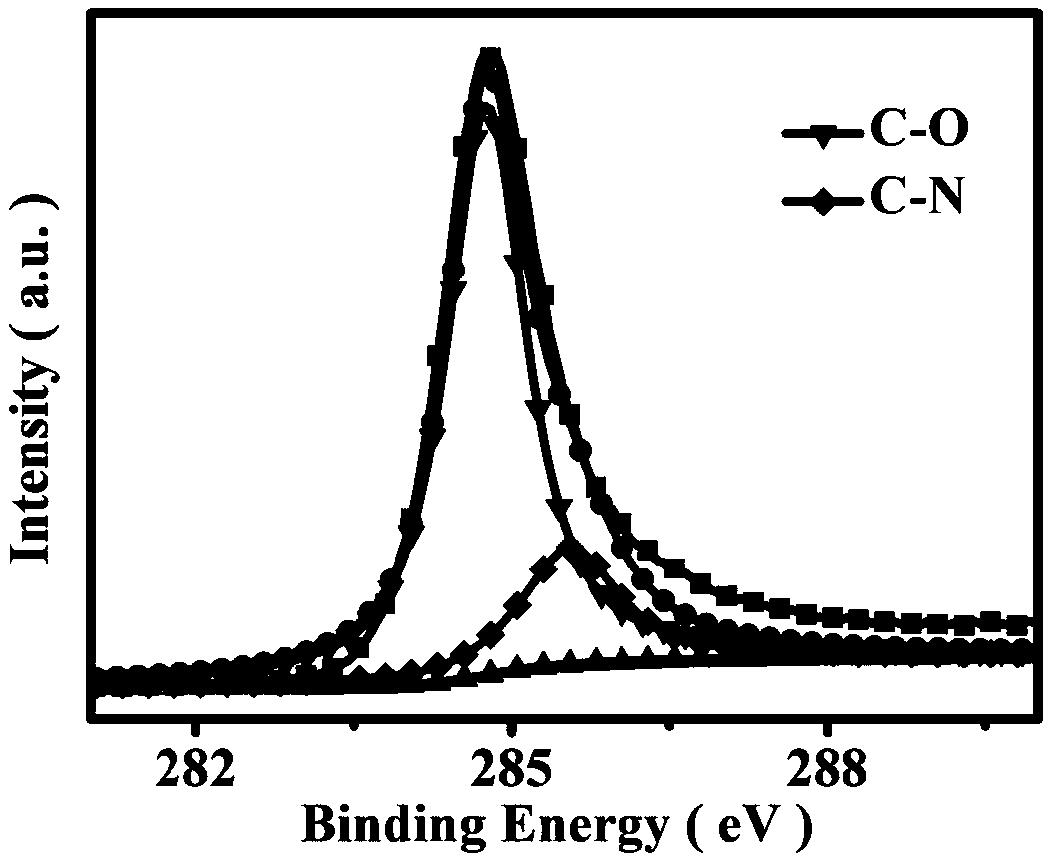

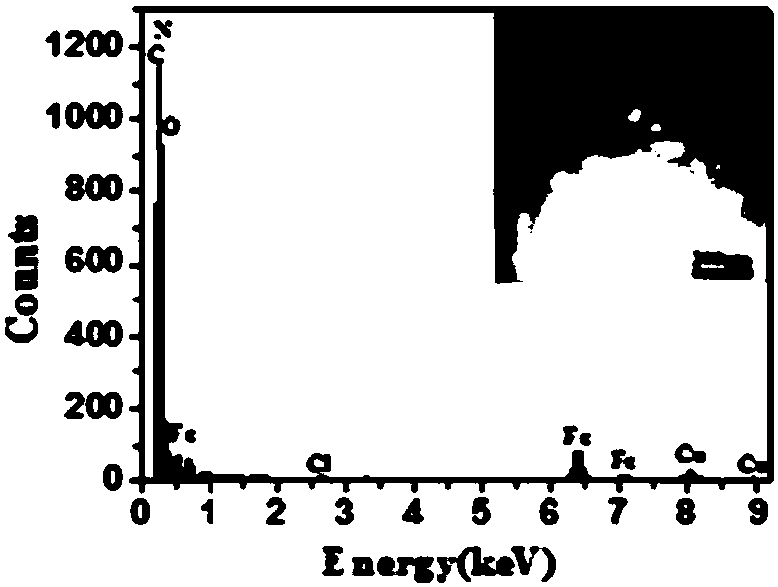

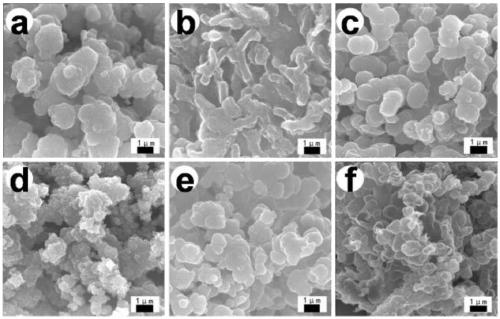

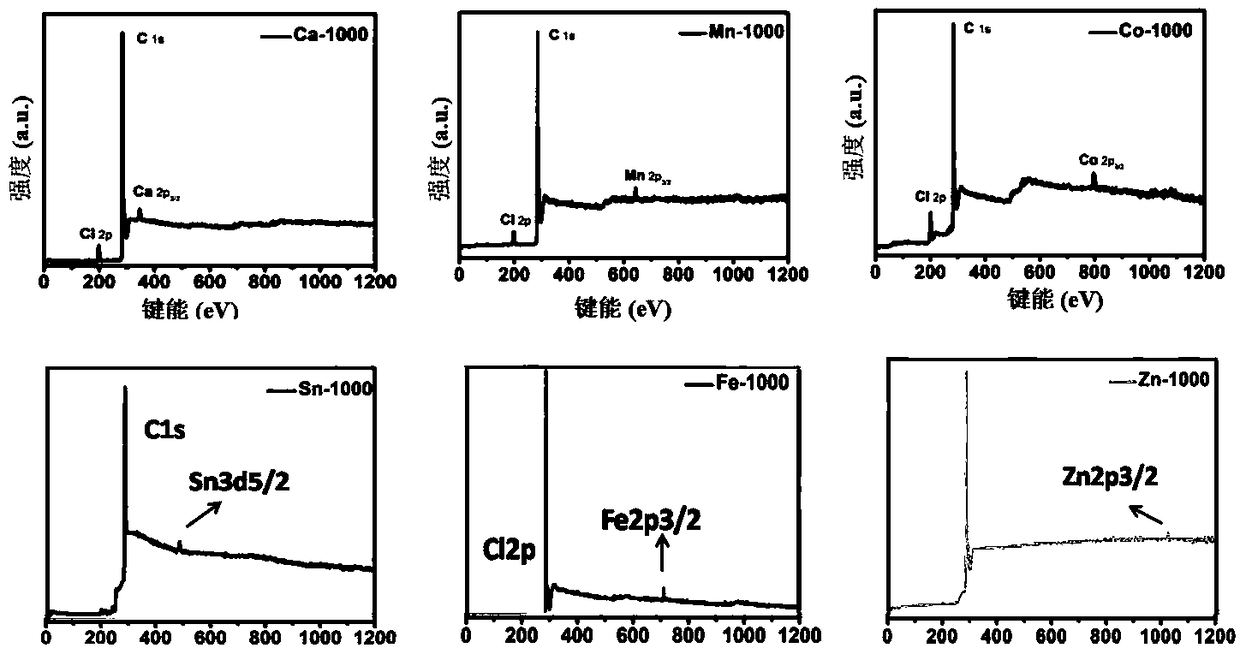

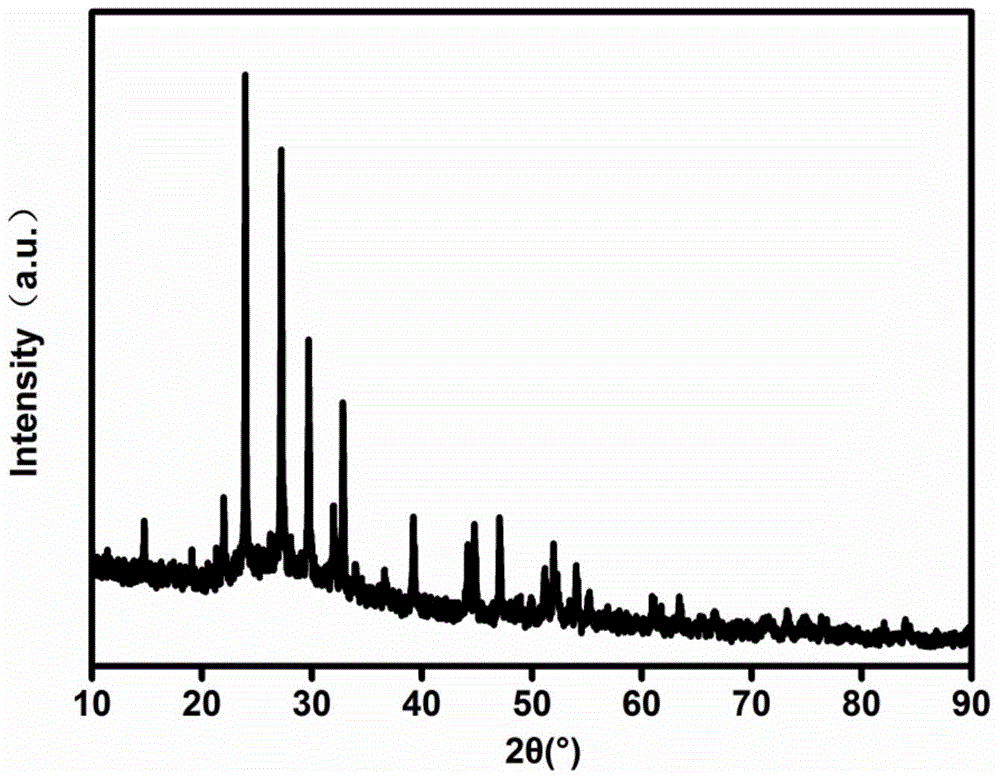

Iron-nitrogen codope carbon microspheres as well as preparation method, application and oxygen reduction electrode

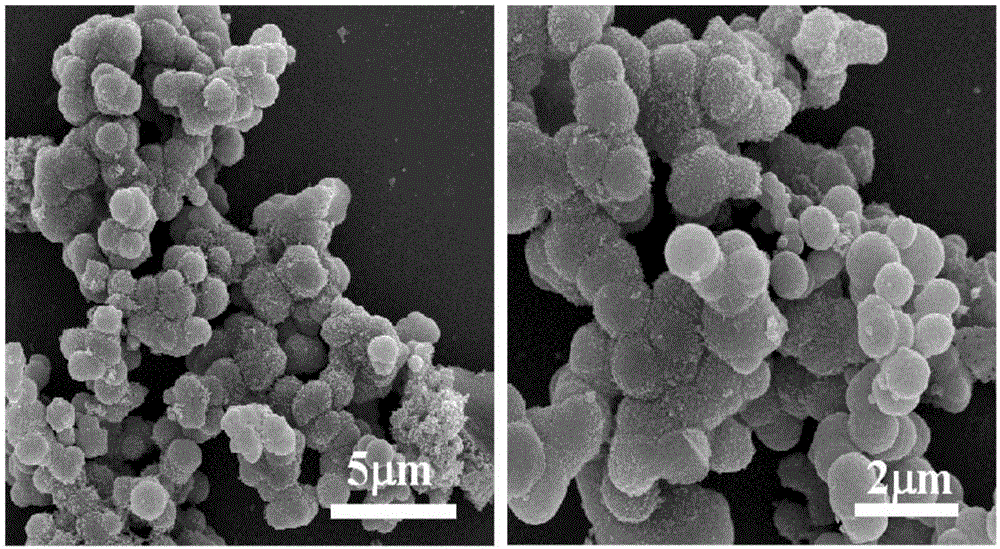

ActiveCN106784865AImprove performanceImprove electrochemical performanceCell electrodesMicrosphereHigh pressure

The invention relates to a preparation method of an iron-nitrogen codope carbon microsphere composite material. The preparation method comprises the following steps: S1, performing sealed reaction on hexachlorobutadiene, an iron source compound and a nitrogen-containing compound at high temperature and high pressure; S2, after the reaction is completed, releasing the pressure to normal pressure, naturally cooling to the room temperature, and drying obtained solids so as to obtain a dried sample; S3, performing high-temperature roasting treatment on the dried sample in the presence of an inert gas, thereby obtaining the iron-nitrogen codope carbon microsphere composite material. The invention further relates to a composite material, application of the composite material, and an oxygen reduction electrode with the composite material. The iron-nitrogen codope carbon microsphere composite material is excellent in property, can be used for preparing the oxygen reduction electrode of a fuel battery, thus can be used in fuel batteries, is good in electrochemical property, and has great application potential and industrial values in the electrochemical field.

Owner:温州邦欣源科技有限公司

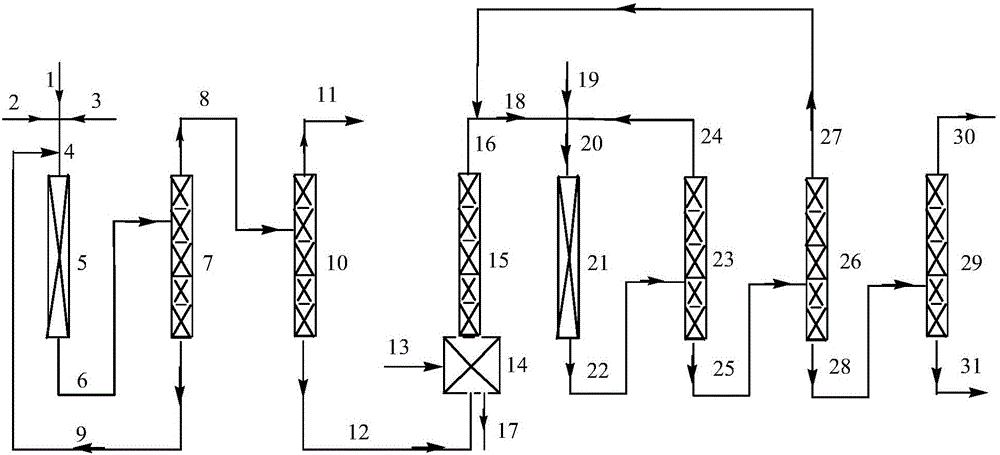

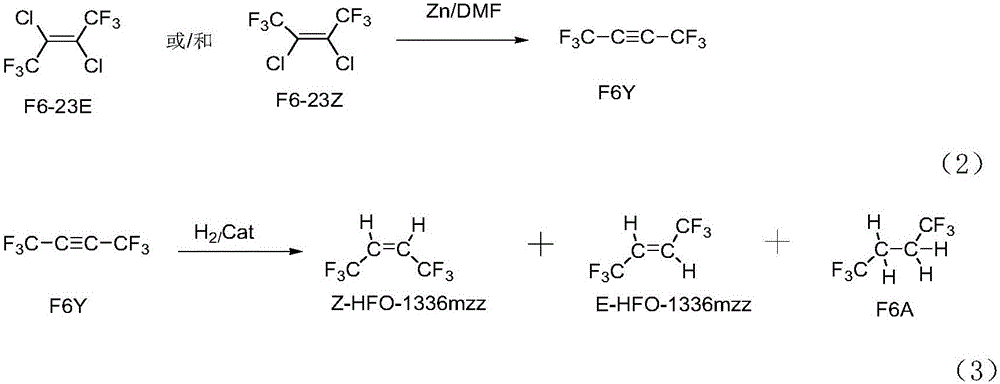

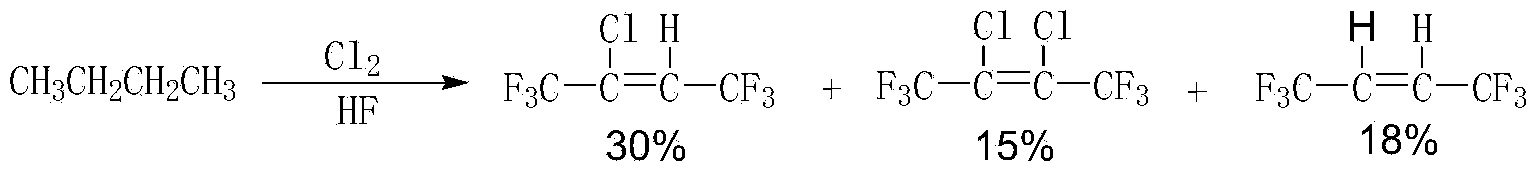

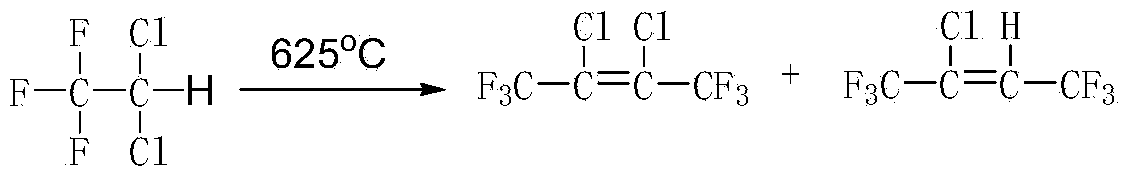

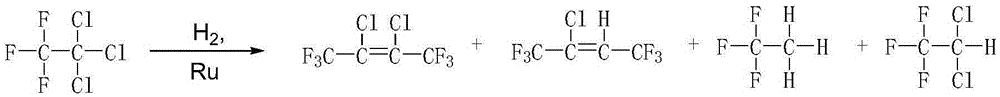

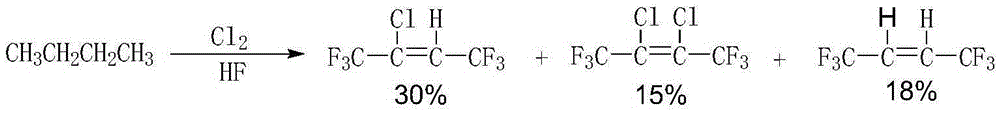

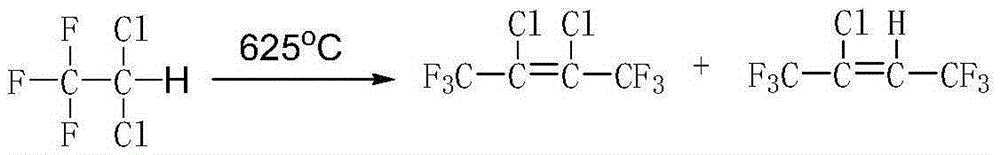

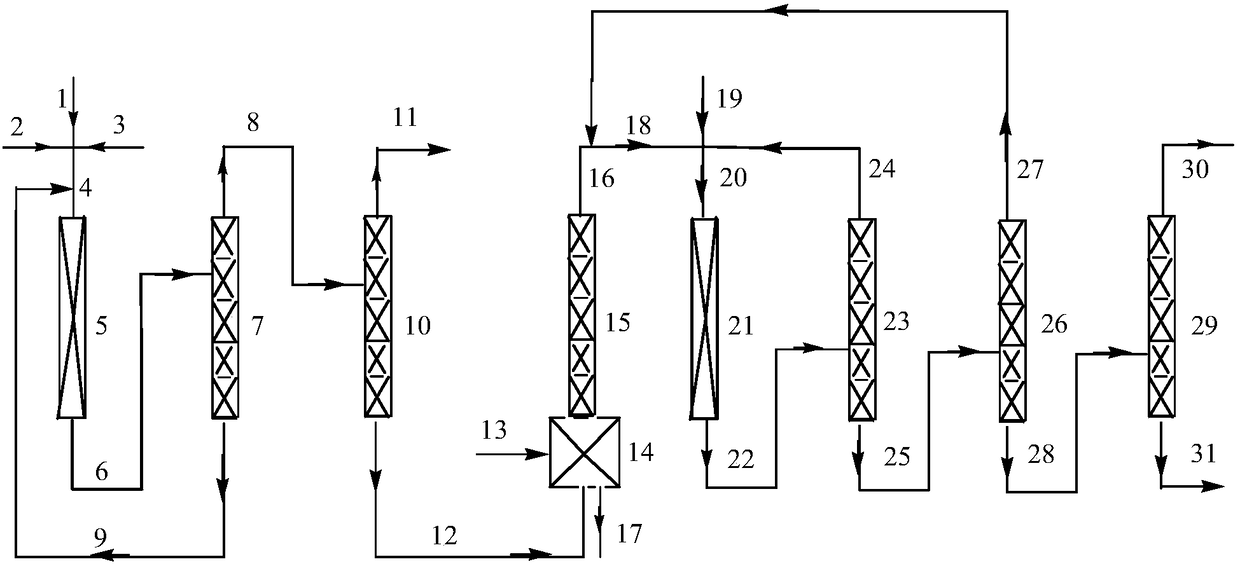

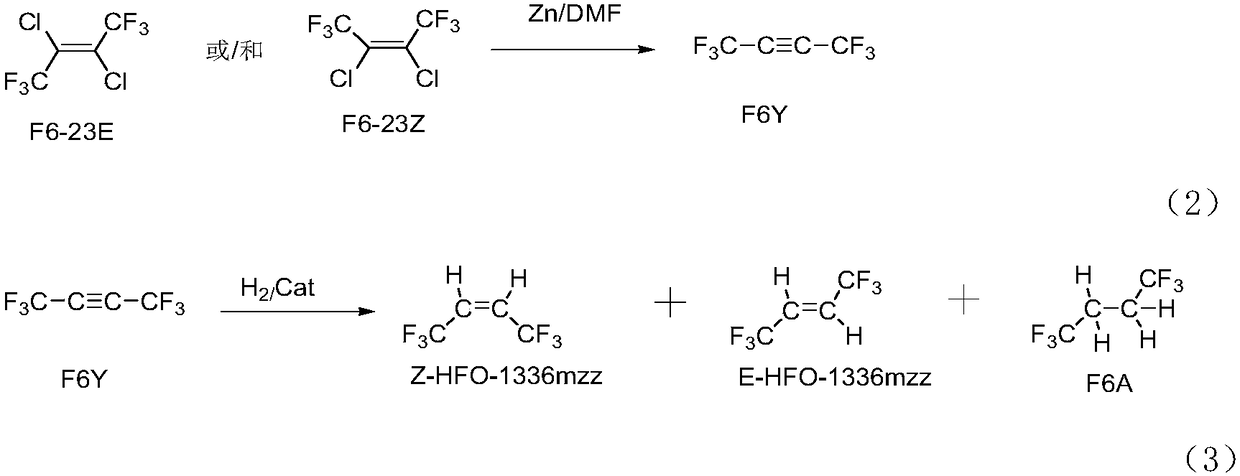

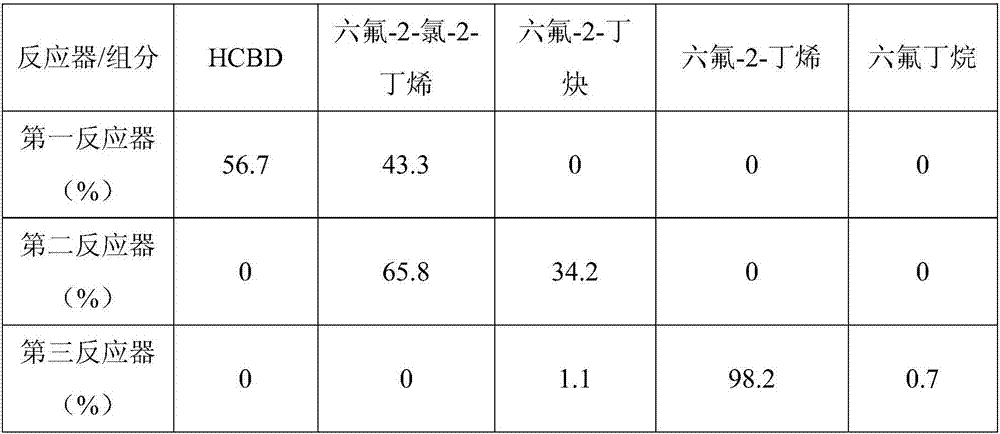

Preparation method of Z-1,1,1,4,4,4-hexafluoro-2-butene

ActiveCN106008147ALow priceHigh activityPreparation by dehalogenationPreparation by halogen replacementChemical synthesisGas phase

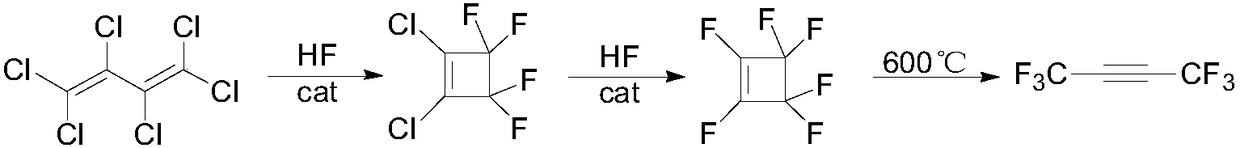

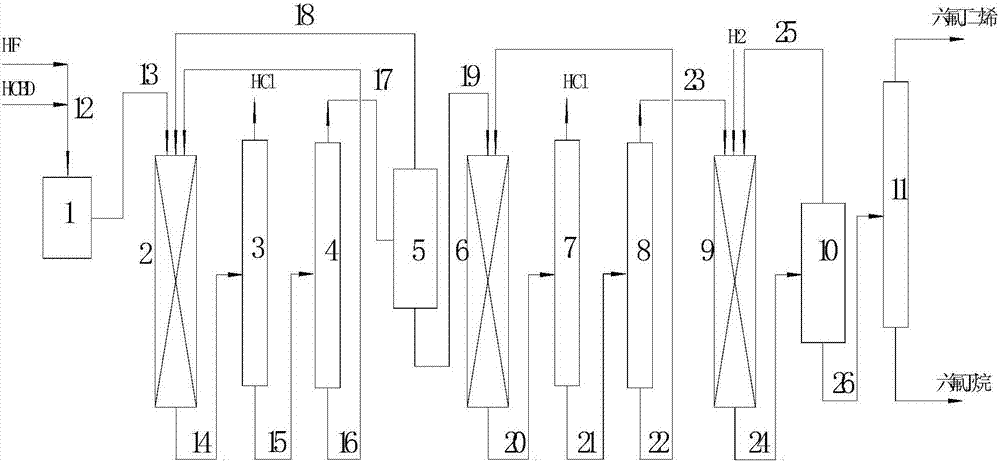

The invention relates to a preparation method of Z-1,1,1,4,4,4-hexafluoro-2-butene, belonging to the field of chemical synthesis. The method comprises the following steps of taking hexachlorobutadiene (HCBD) as a raw material, performing gas-phase catalytic chlorination-fluoridation separation to obtain 2,3-dichlorohexafluoro-2-butene, performing liquid-phase dechlorination to obtain hexafluoro-2-butyne, and preparing the Z-1,1,1,4,4,4-hexafluoro-2-butene (Z-HFO-1336mzz) by means of performing gas-phase catalytic hydrogenation, wherein three reactions are included totally. The Z-1,1,1,4,4,4-hexafluoro-2-butene with high selectivity is obtained by means of performing catalytic hydrogenation by adopting the hexafluoro-2-butyne, and meanwhile the product is easily separated from side products and the raw material. The method disclosed by the invention has the advantages that the original raw material is easily obtained, the activity of a catalyst is high, the service life of the catalyst is long, the raw material can be recycled, and the standard of zero emissions is reached.

Owner:泉州宇极新材料科技有限公司

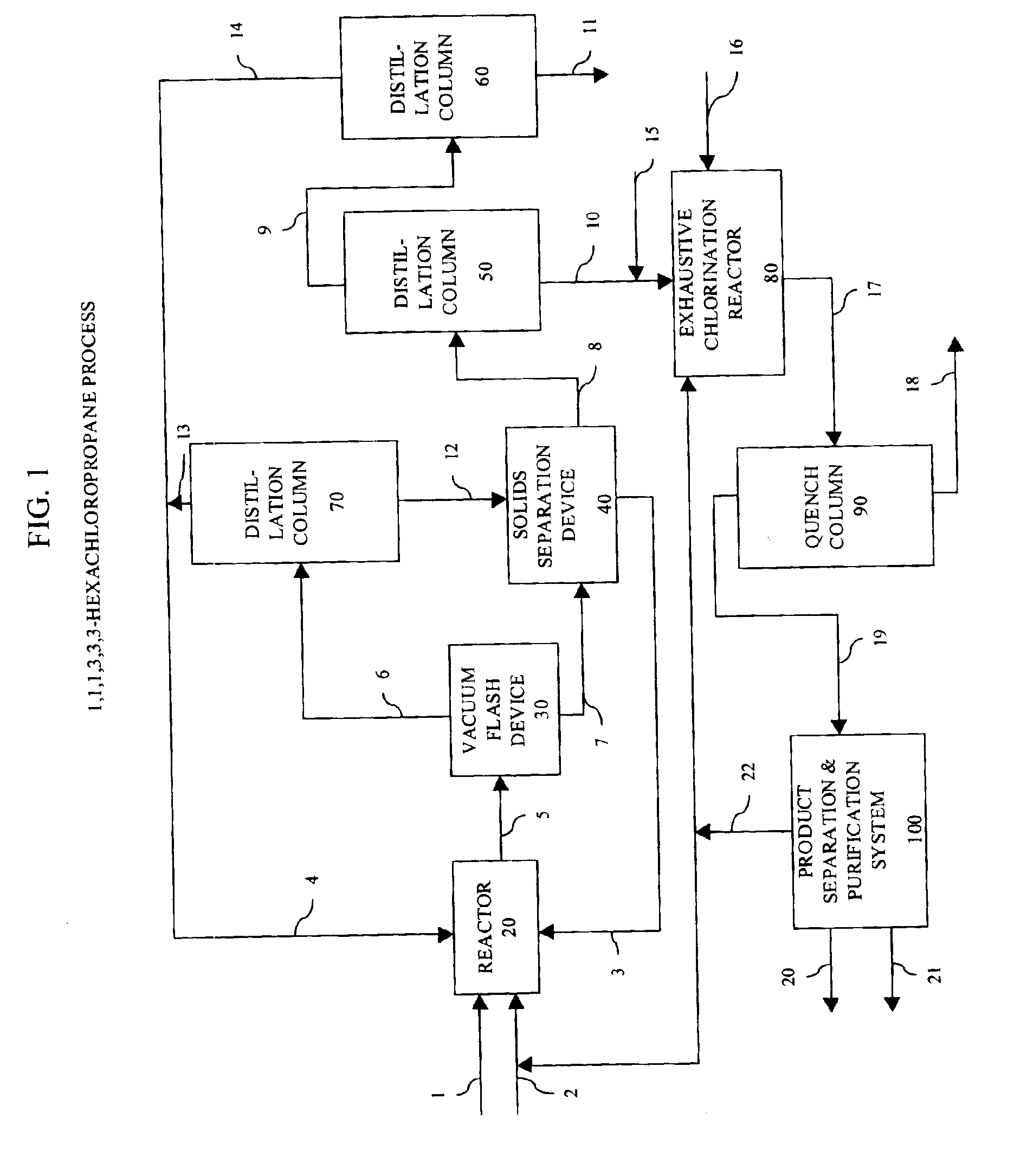

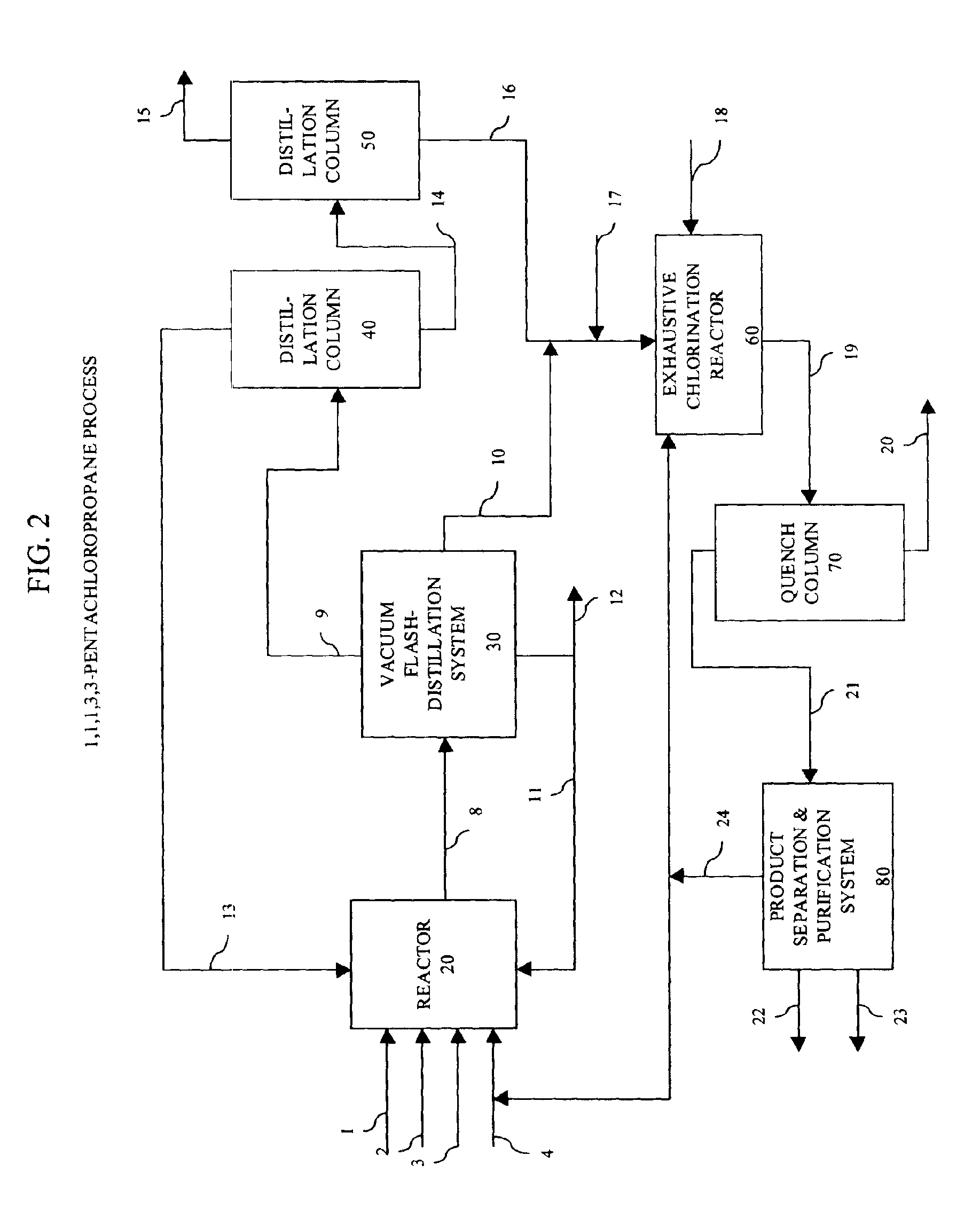

Method for reusing heavy end by-products in the manufacture of polychlorinated alkanes

ActiveUS7112709B2Efficient productionReduce the number of materialsHalogenated hydrocarbon separation/purificationPreparation by halogen additionAlkaneHexachlorobutadiene

A method for recovering much of the carbon and chlorine value in the heavy ends and other undesired by-products formed during the production of a C3 or higher polychlorinated alkane through the reaction of carbon tetrachloride with an olefine or chlorinated olefine, the improvement comprising the step of first separating the heavy ends and any other higher or lower boiling chlorohydrocarbon impurities from most of the desired product, and subjecting the separated heavy ends and impurities therewith to a high temperature exhaustive chlorination to produce carbon tetrachloride, tetrachloroethene, and minor amounts of hexachlorobutadiene and hexachlorobenzene by-products.

Owner:OCCIDENTAL CHEM CORP

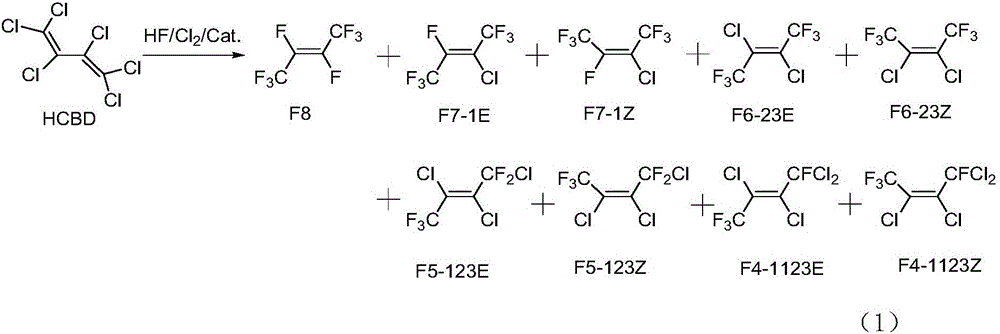

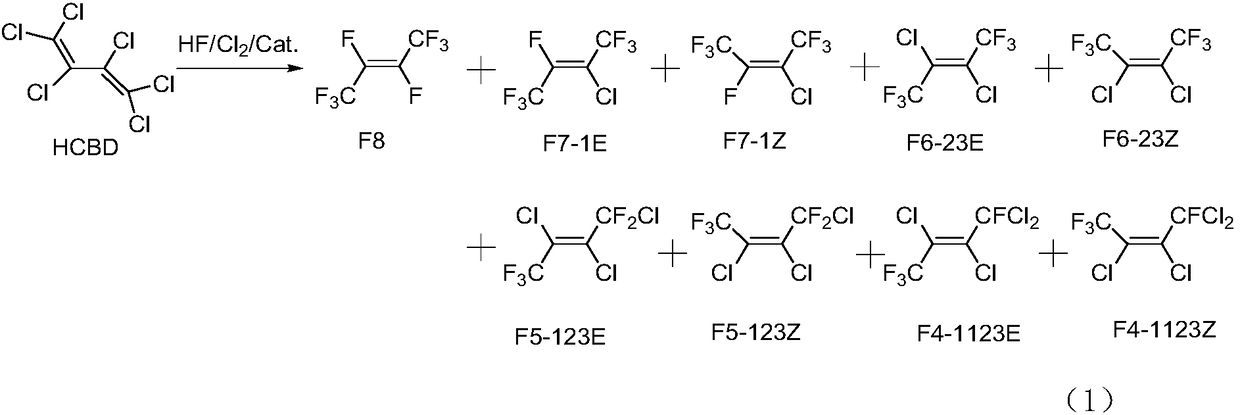

Preparation method for 2-chloro-1,1,1,4,4,4-hexafluoro-2-butene

ActiveCN104072333AHigh yieldRaw materials are easy to getHalogenated hydrocarbon preparationHydrogen fluorideButene

The invention discloses a preparation method for 2-chloro-1,1,1,4,4,4-hexafluoro-2-butene. The preparation method is as follows: mixing a catalyst, hydrogen fluoride and hexachlorobutadiene in a molar ratio of (0.01-0.3):(5-50):1, then, heating to 30-250 DEG C for reacting for 3-12 hours while controlling the reaction pressure to 0.1-3.0Mpa, and cooling, layering, washing, alkaline-washing and rectifying to obtain a product after the reaction is ended. The preparation method disclosed by the invention has the advantages of being simple in process, high in yield, easy in obtaining of materials and gentle in reaction condition.

Owner:JUHUA GROUP TECH CENT

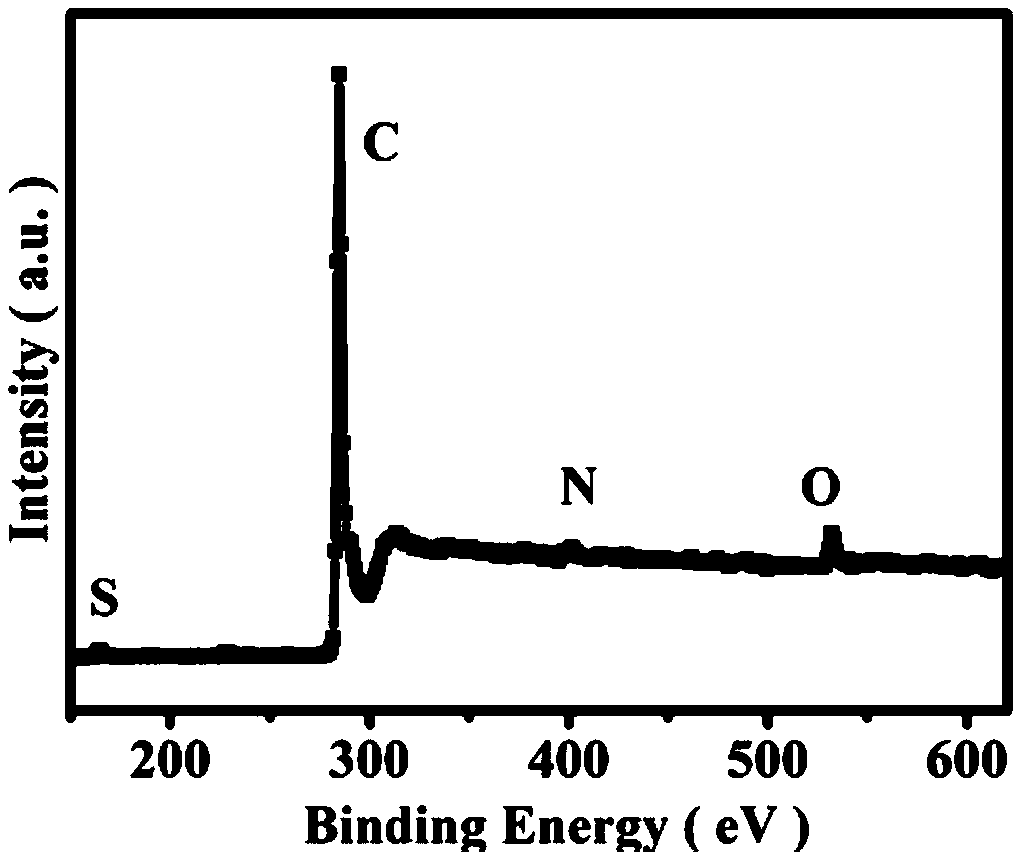

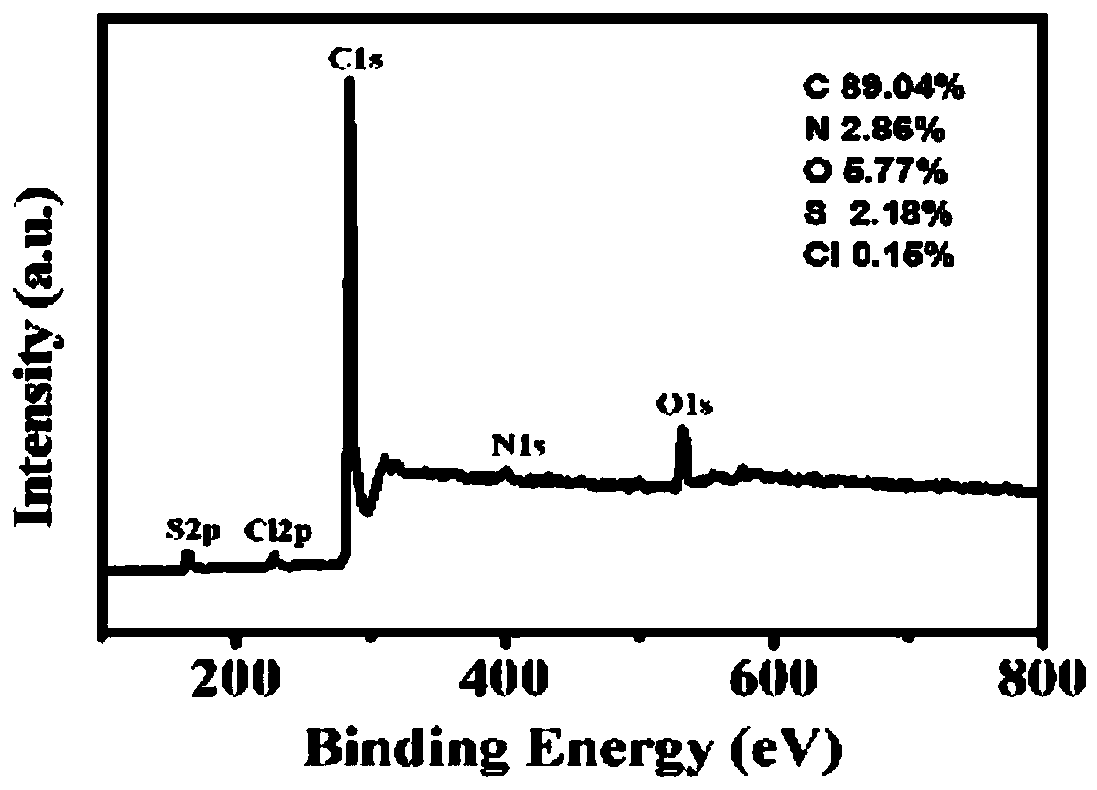

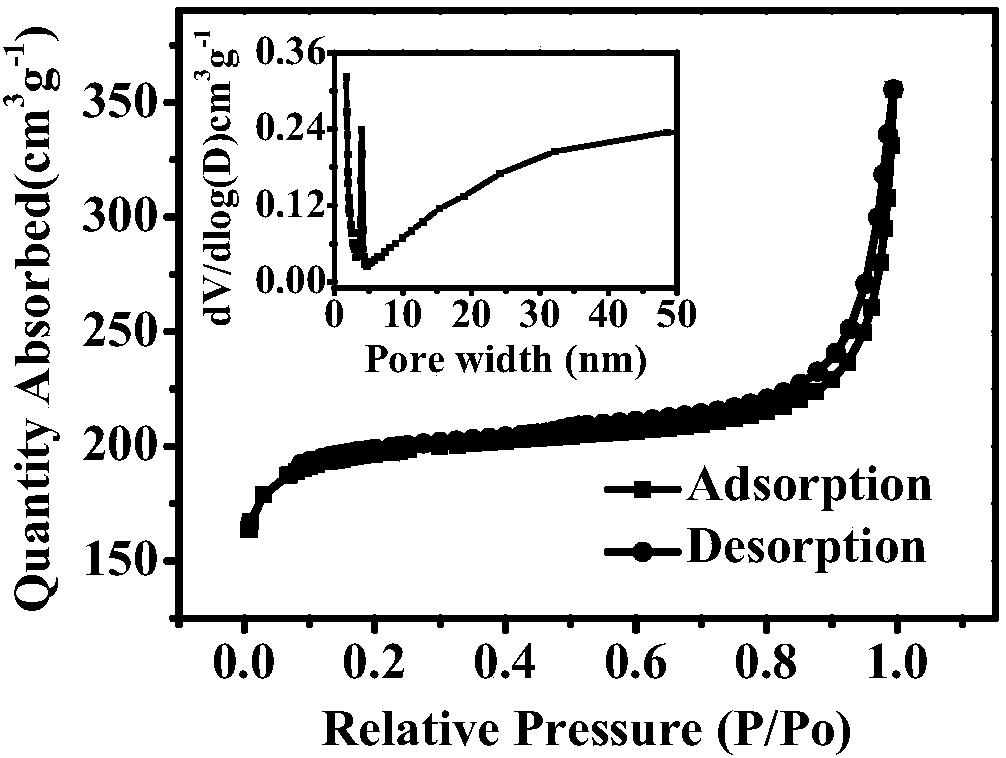

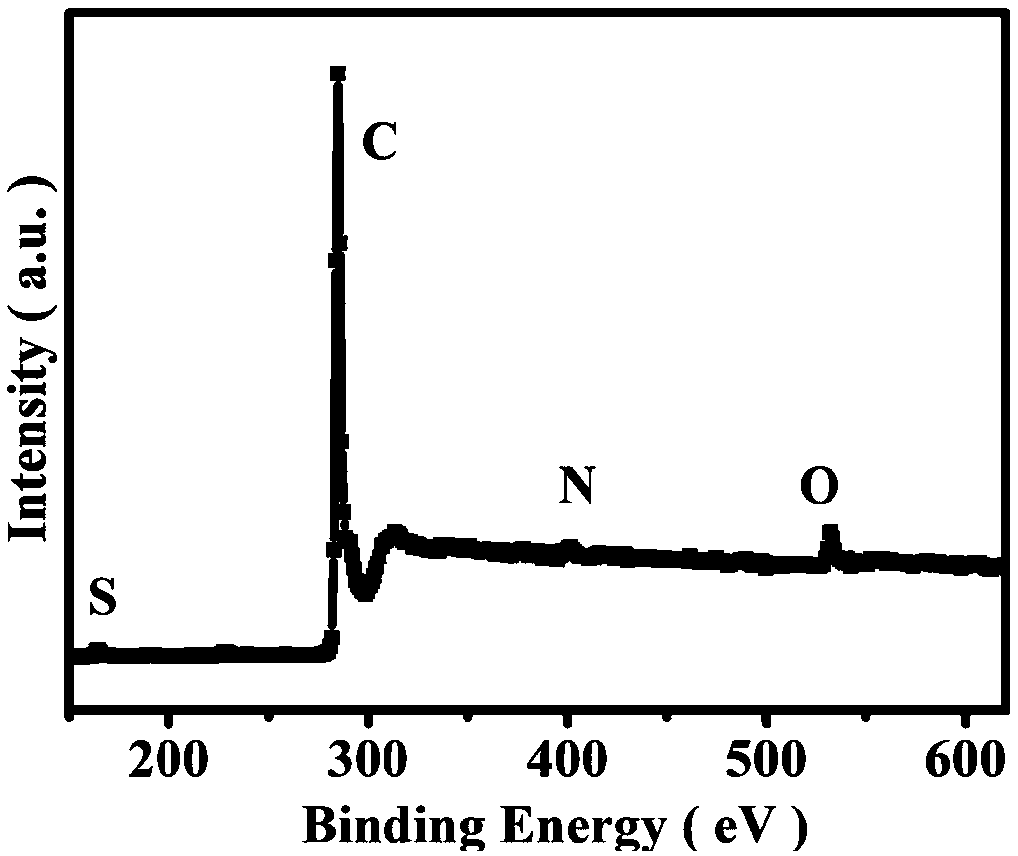

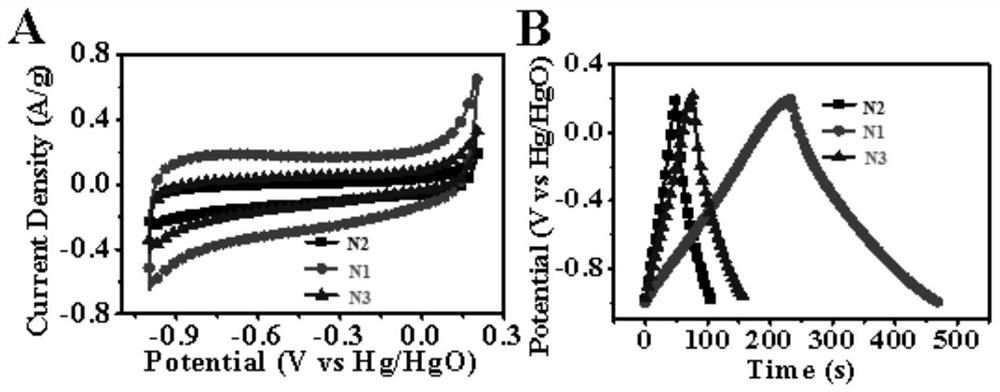

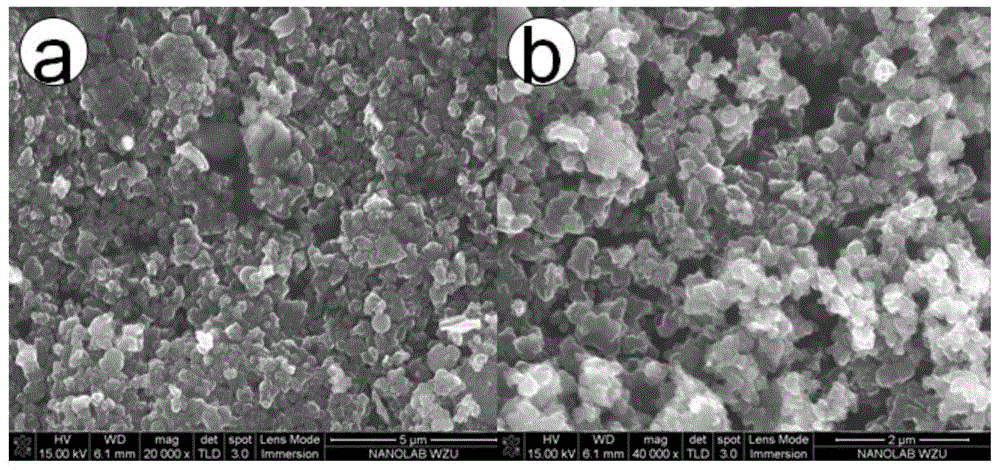

Nitrogen and sulfur co-doped porous carbon microsphere, preparation method and application thereof and oxidization-reduction electrode

ActiveCN107658474AImprove performanceImprove electrochemical performanceCell electrodesPorous carbonMicrosphere

The invention relates to a preparation method of a nitrogen and sulfur co-doped porous carbon microsphere composite material. The method comprises the following steps of S1, performing closed reactionon hexachlorobutadiene, tellurium diethyl dithiocarbamate (TDEC) and a solvent under high temperature and high pressure; S2, relieving pressure to normal pressure after reaction is completed, naturally cooling to a room temperature, and drying the obtained solid to obtain a dried sample; and S3, performing high-temperature roasting processing on the dried sample under protection of inert gas so as to obtain the nitrogen and sulfur co-doped porous carbon microsphere composite material. The invention also relates to the composite material, application thereof and oxidization-reduction performance comprising the composite material. The nitrogen and sulfur co-doped porous carbon microsphere composite material has excellent performance and can be used for preparing an oxidization-reduction electrode of a fuel cell, so that the nitrogen and sulfur co-doped porous carbon microsphere composite material can be used in the fuel cell, shows excellent electrochemical performance and has huge application potential and industrial value in the field of electrochemistry.

Owner:INST OF NEW MATERIALS & IND TECH WENZHOU UNIV

Hexafluoropropylene-2-butyne synthesizing method

ActiveCN105348034AHigh yieldConvenient sourcePreparation by halogen replacementHexachlorobutadieneHexafluoropropylene

The invention discloses a hexafluoropropylene-2-butyne synthesizing method. Hexachlorobutadiene (CCl2=CCl-CCl=CCl2) is taken as the raw material to generate hexafluoropropylene-2-butyne under the action of a catalyst, the raw material hexachlorobutadiene is easy to obtain and low in cost. The gaseous-phase circulating fluorination method is adopted, the discharge level of three industrial wastes is low, the yield of products is high, and production cost is reduced greatly; the gaseous-phase circulating fluorination method is conducted at normal temperature, the traditional high-pressure telomerization process route is avoided, and risks in industrial safety production are reduced greatly; meanwhile, the method has the advantage that operation is easy and is totally suitable for industrial production.

Owner:TIANJIN MEDICAL UNIV

Three-dimensional nitrogen-sulfur-co-doped porous carbon material as well as preparation method and application thereof

ActiveCN107758641AImprove electrochemical performanceSimple preparation processHybrid capacitor electrodesCarbon preparation/purificationHexachlorobutadienePorous carbon

The invention discloses a three-dimensional nitrogen-sulfur-co-doped porous carbon material as well as a preparation method and application thereof. The method comprises the following steps: carryingout a closed reaction among pyridine, hexachlorobutadiene and thiocyanuric acid under a reaction pressure higher than a barometric pressure, relieving the pressure to a normal pressure after the reaction is ended, drying the sample, and performing high-temperature treatment on the sample under inert gas shielding, thereby obtaining the three-dimensional nitrogen-sulfur-co-doped porous carbon material. The three-dimensional nitrogen-sulfur-co-doped porous carbon material disclosed by the invention has excellent electrochemical performance, so that the porous carbon material can be applied to the field of chemical energy storage, particularly the field of supercapacitors, and has excellent industrialization value.

Owner:WENZHOU UNIVERSITY

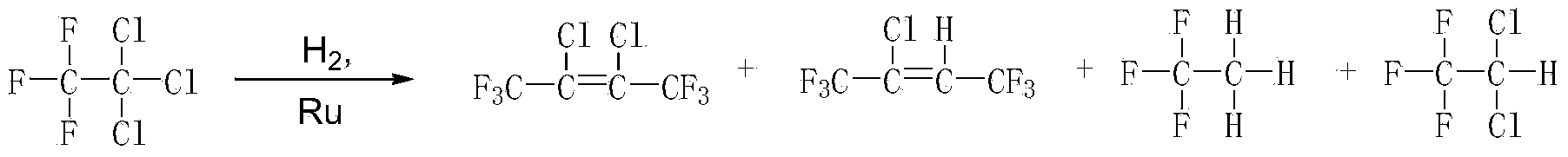

Synthetic method of 1,1,1,4,4,4-hexafluoro-2-butene

ActiveCN103193586BSimple processShort stepsPreparation by dehalogenationHexachlorobutadieneTetrachloroethylene

Owner:JUHUA GROUP TECH CENT

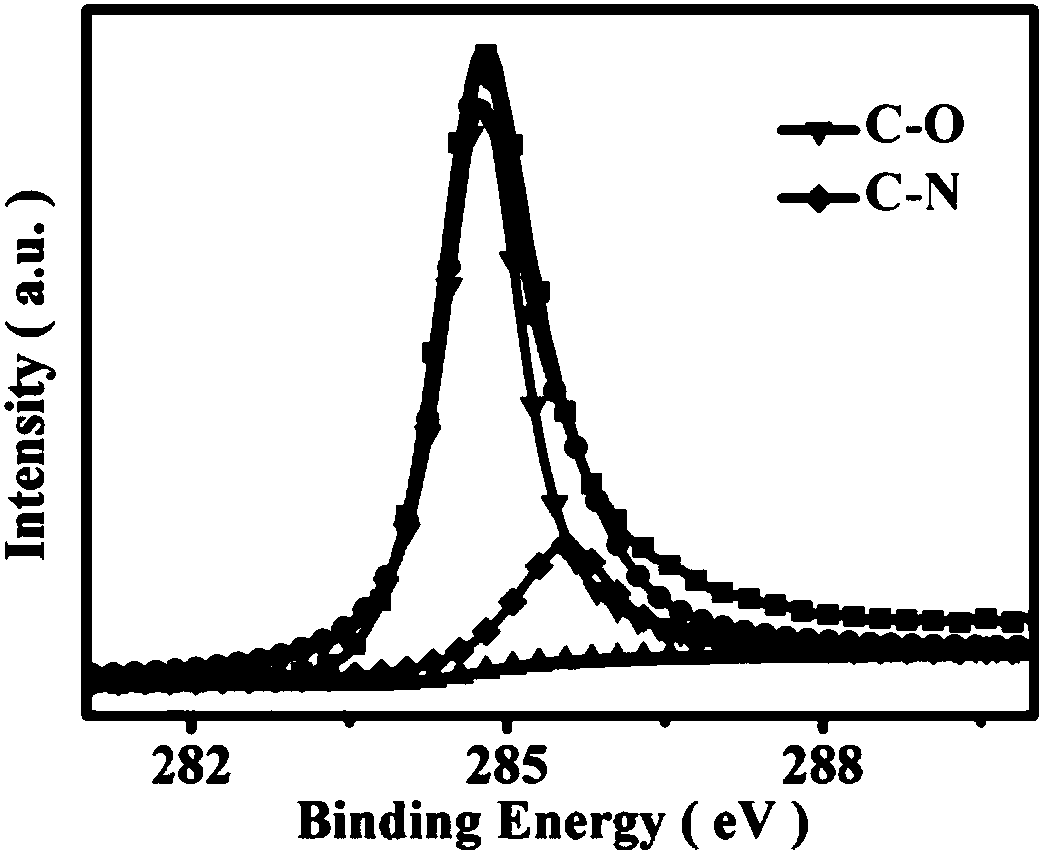

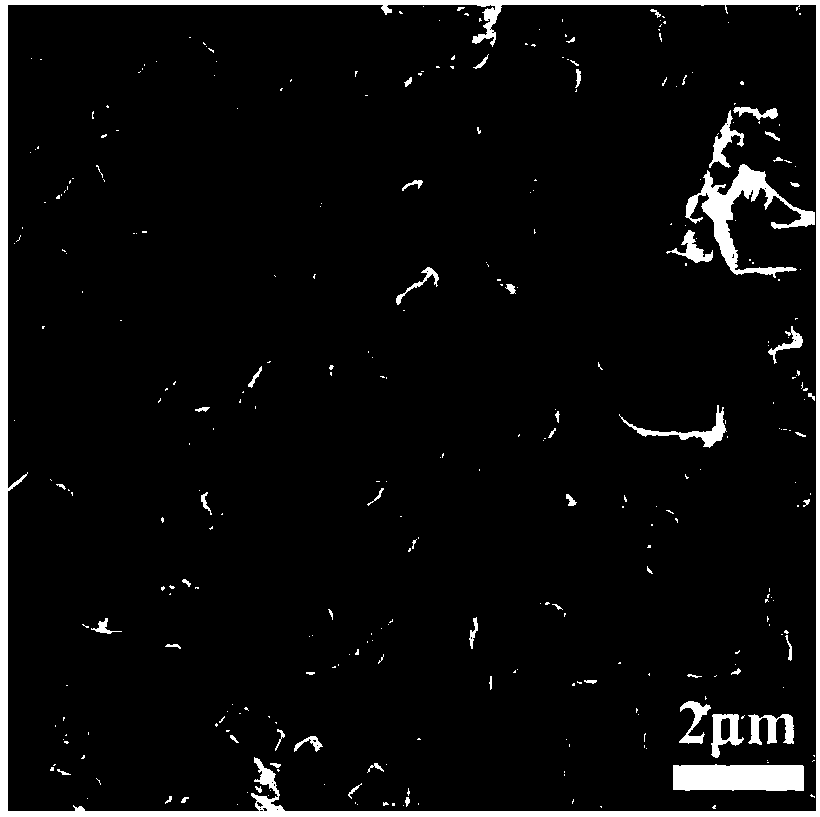

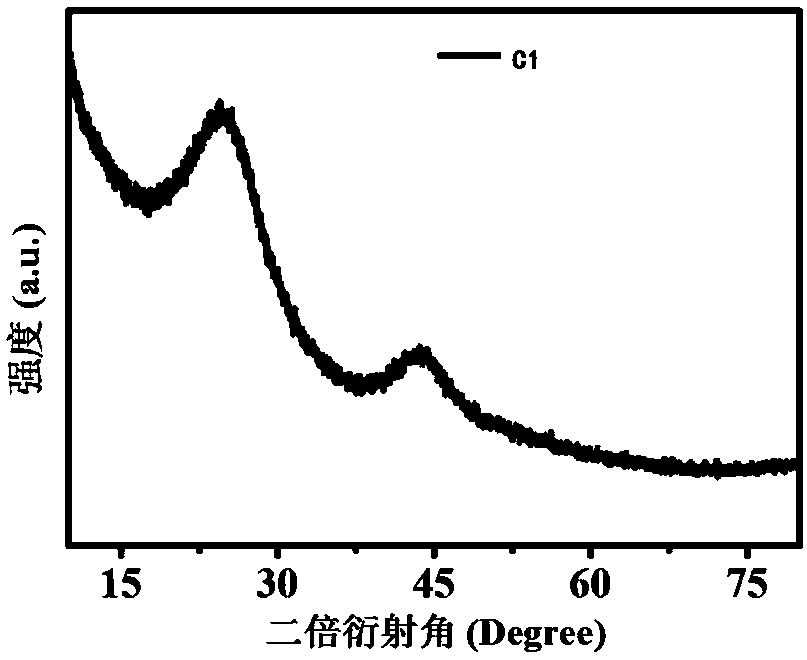

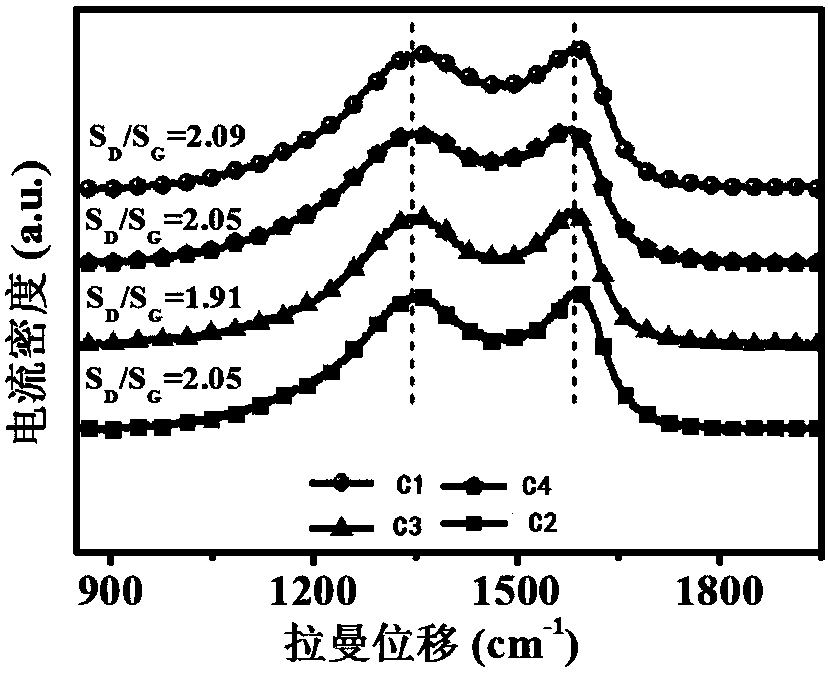

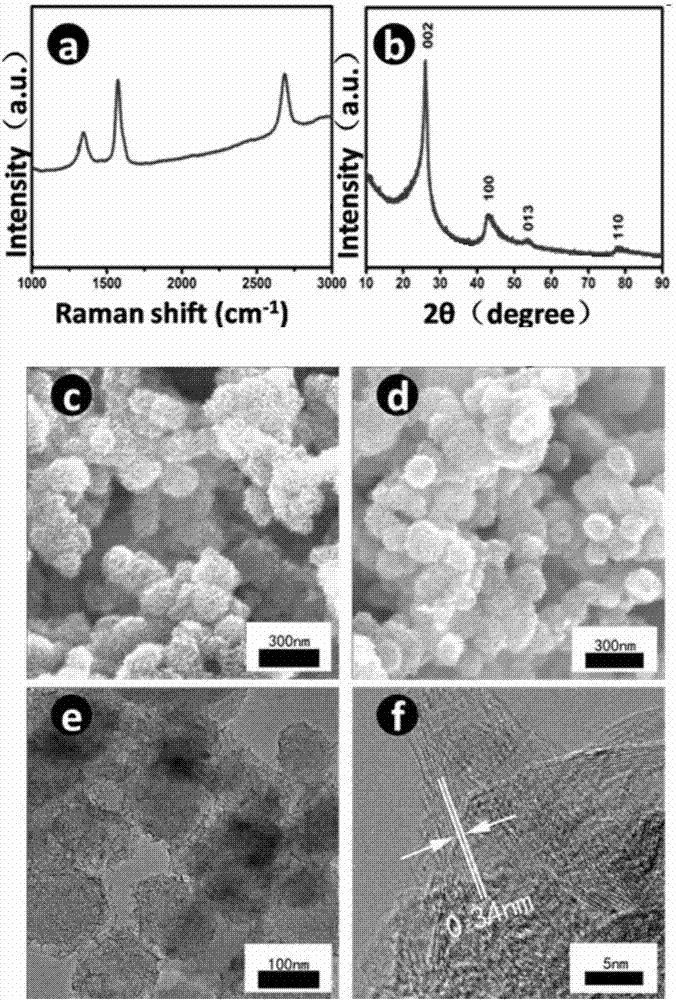

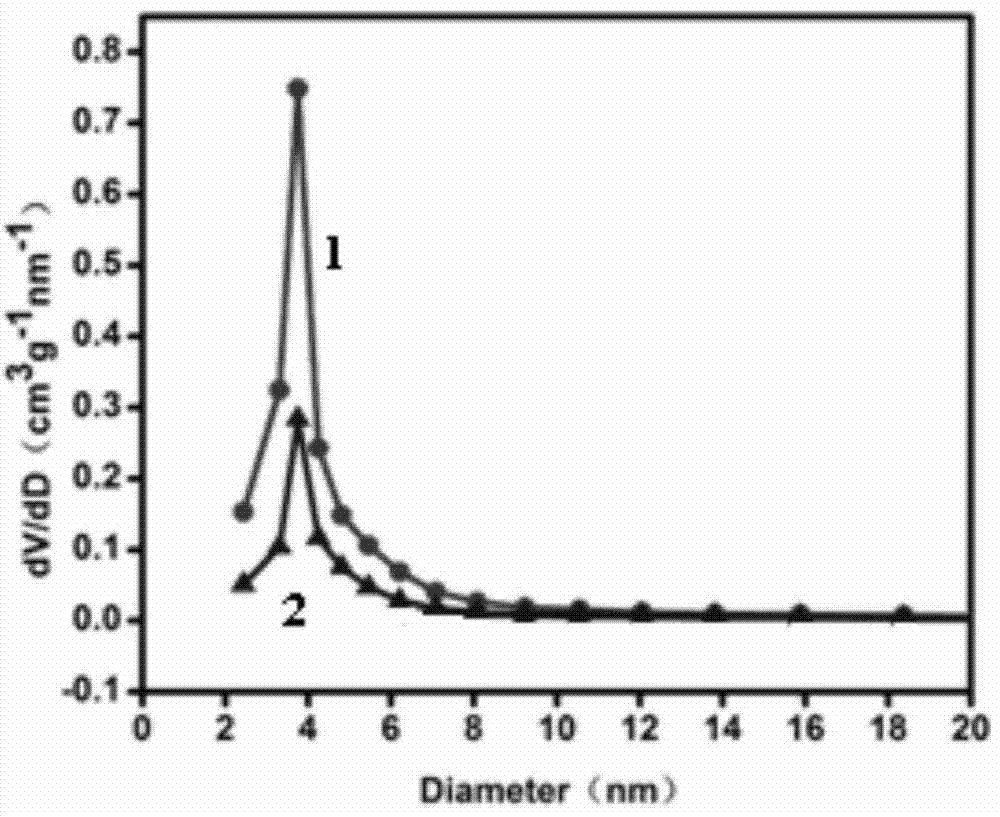

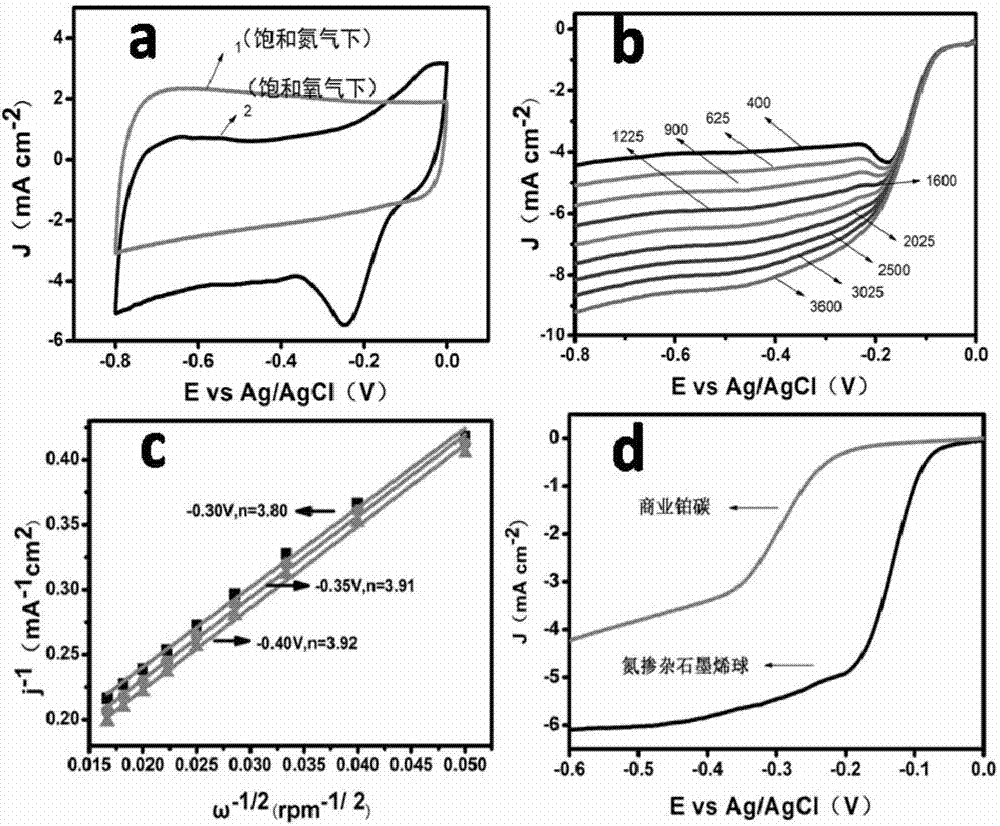

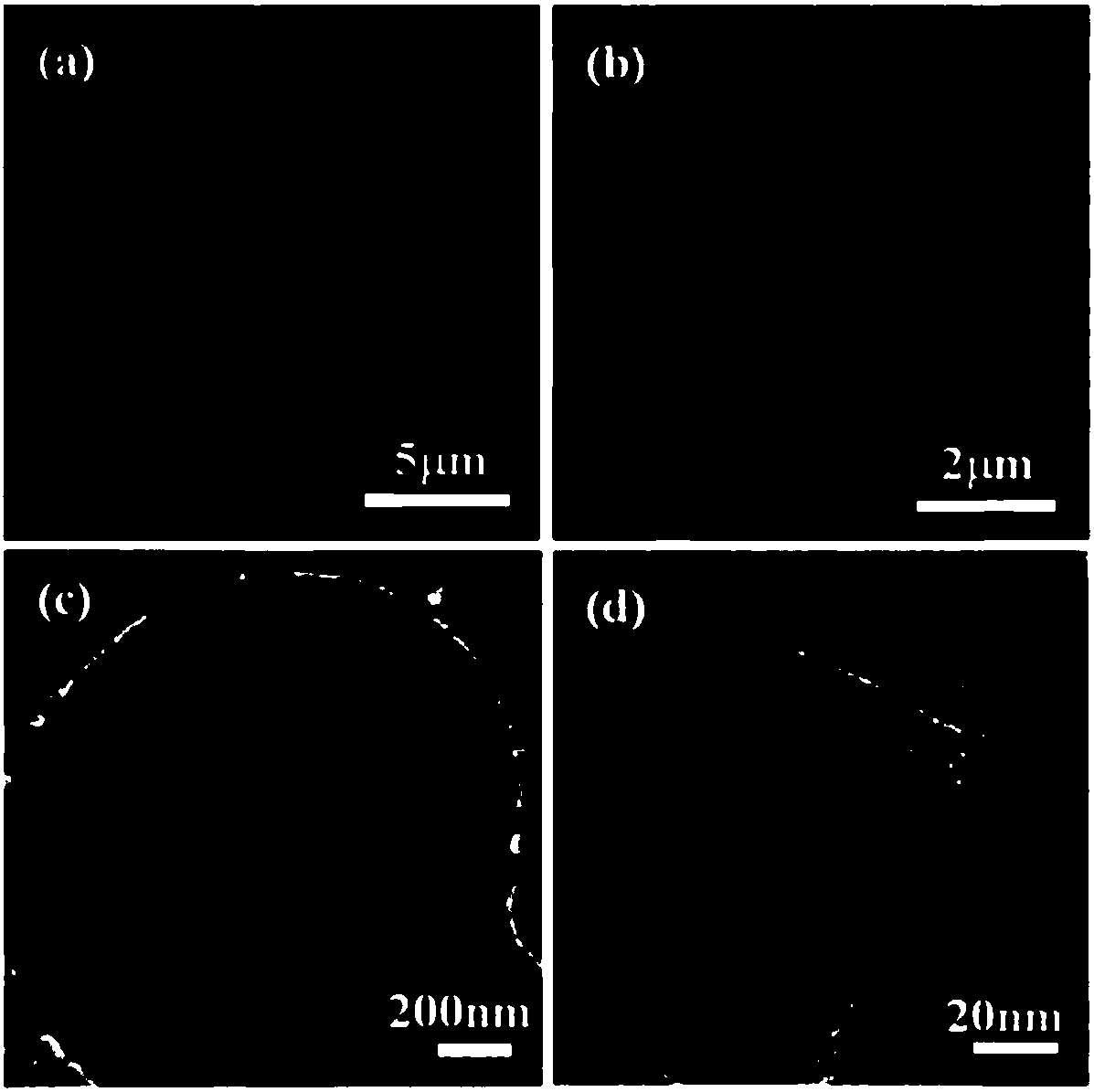

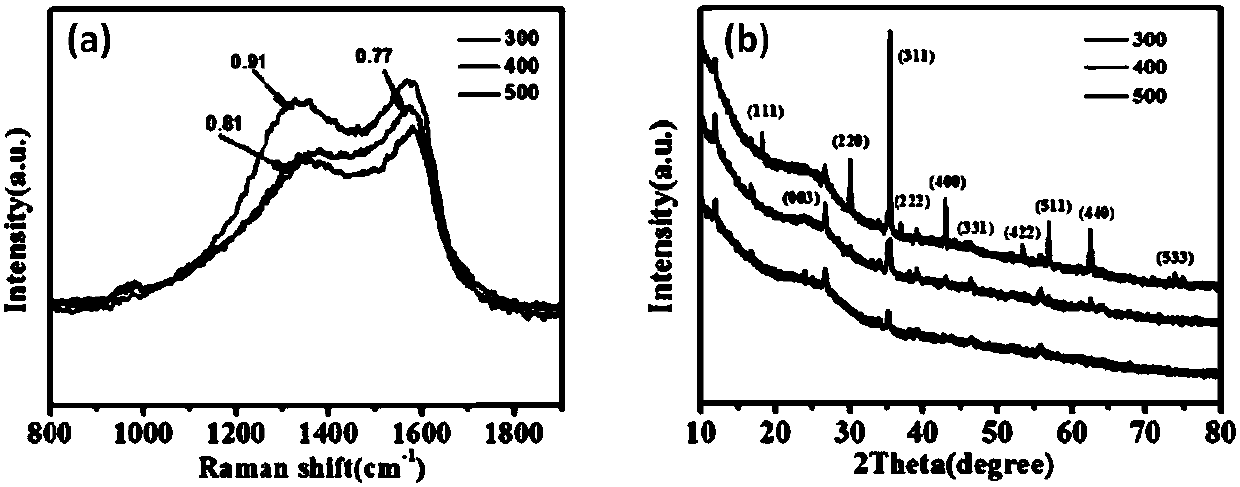

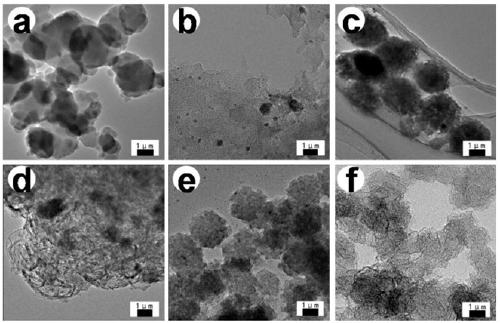

Nitrogen-doped mesoporous graphene microspheres, and preparation method and application thereof

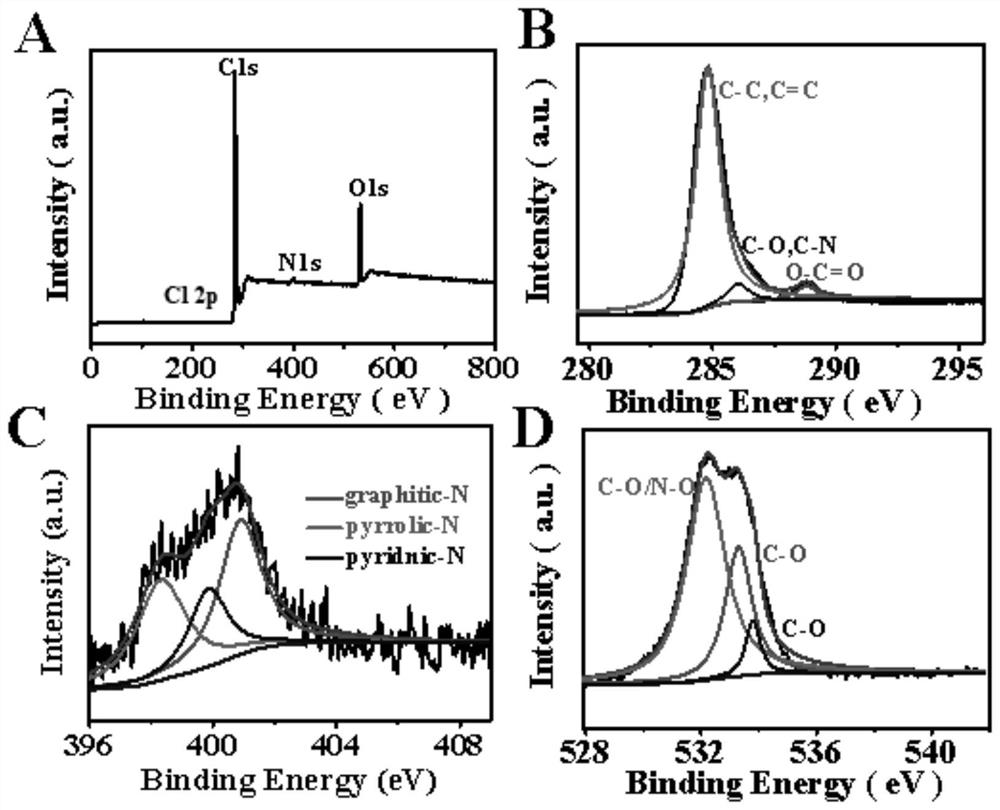

ActiveCN103831121ALarge specific surface areaUniform pore sizePhysical/chemical process catalystsCell electrodesMicrosphereOxygen

The invention discloses nitrogen-doped mesoporous graphene microspheres, and a preparation method and an application thereof. The method comprises the steps of adding metal sodium into hexachlorobutadiene, carrying out a sealed reaction for 10-40 h at a temperature of 200-300 DEG C and under a pressure of 1-15 MPa, carrying out aftertreatment on a reaction product after the reaction is finished, thus obtaining mesoporous graphene microspheres; mixing the mesoporous graphene microspheres with urea or carrying out ammonia purge on the mesoporous graphene microspheres under the protection of an inert gas, then carrying out a sealed reaction for 0.5-4 h at a temperature of 700-1,200 DEG C; and after the reaction is finished, subjecting a reaction product to centrifugation and washing precipitate with water to obtain the nitrogen-doped mesoporous graphene microspheres. The specific surface area of the nitrogen-doped mesoporous graphene microspheres is 900-1,000 m<2> / g; pore volume is 0.1-1.8 cm<3> / g; and average aperture is 3.5-4.2 nm. The nitrogen-doped mesoporous graphene microspheres can be used as a platinum- and oxygen-free reduction catalyst which has high activity, low cost and long service life, for the field of fuel cells.

Owner:WENZHOU UNIVERSITY

A kind of preparation method of 2-chloro-1,1,1,4,4,4-hexafluoro-2-butene

ActiveCN104072333BHigh yieldSimple processHalogenated hydrocarbon preparationHexachlorobutadieneButene

Owner:JUHUA GROUP TECH CENT

Carbon material with oxygen reduction activity and nitrogen-sulfur co-doped cauliflower-like structure, oxygen reduction electrode, preparation method and fuel cell

ActiveCN110556548AImprove performanceImprove electrochemical performanceCell electrodesCarbon preparation/purificationHigh pressureOxygen

The invention relates to a carbon material with oxygen reduction activity and a nitrogen-sulfur co-doped cauliflower-like structure. The preparation method comprises steps that S1, hexachlorobutadieneand nitrogen-sulfur co-source compound are added into solvent, and closed reaction under high temperature and high pressure is carried out; S2, after the reaction is finished, the pressure relieved to normal pressure, naturally cooling to room temperature is performed, and centrifuging, washing and drying of the obtained solid are performed to obtain a dried sample; and S3, high-temperature roasting treatment of the dried sample under the protection of inert gas is carried out so as to obtain the nitrogen-sulfur co-doped cauliflower-like structure carbon material. The invention further relates to the composite material, application and an oxygen reduction electrode comprising the composite material. The nitrogen-sulfur co-doped cauliflower-like structure carbon material has excellent performance, can be used for preparing an oxygen reduction electrode of a fuel cell, can be used in the fuel cell, shows good electrochemical performance and has huge application potential and industrialvalues in the field of electrochemistry.

Owner:WENZHOU UNIVERSITY

Synthetic method of 1,1,1,4,4,4-hexafluoro-2-butene

ActiveCN103193586AShort stepsMild reaction conditionsPreparation by dehalogenationHexachlorobutadieneTetrachloroethylene

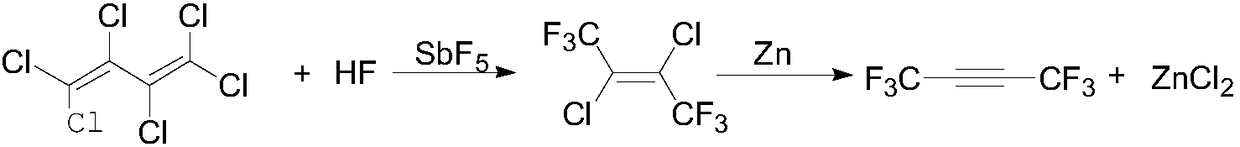

The invention discloses a synthetic method of 1,1,1,4,4,4-hexafluoro-2-butene, and the synthetic method comprises the steps of carrying out a reaction between hexachlorobutadiene and hydrogen fluoride in the presence of a catalyst to generate 1,1,1,4,4,4-hexafluoro-2,3-dichlorobutane, and carrying out a reductive dechlorination reaction on the 1,1,1,4,4,4-hexafluoro-2,3-dichlorobutane in a solvent by using zinc powder to generate the 1,1,1,4,4,4-hexafluoro-2-butene. According to the synthetic method, the process is simple, the steps are short, the reaction conditions are mild and the product can be obtained through two steps of reaction; and the raw materials are easy to get, the cost is low, and the byproduct hexachlorobutadiene obtained by reducing tetrachloroethylene by carbon tetrachloride at high temperature can be used as a raw material, so that the cost is further reduced.

Owner:JUHUA GROUP TECH CENT

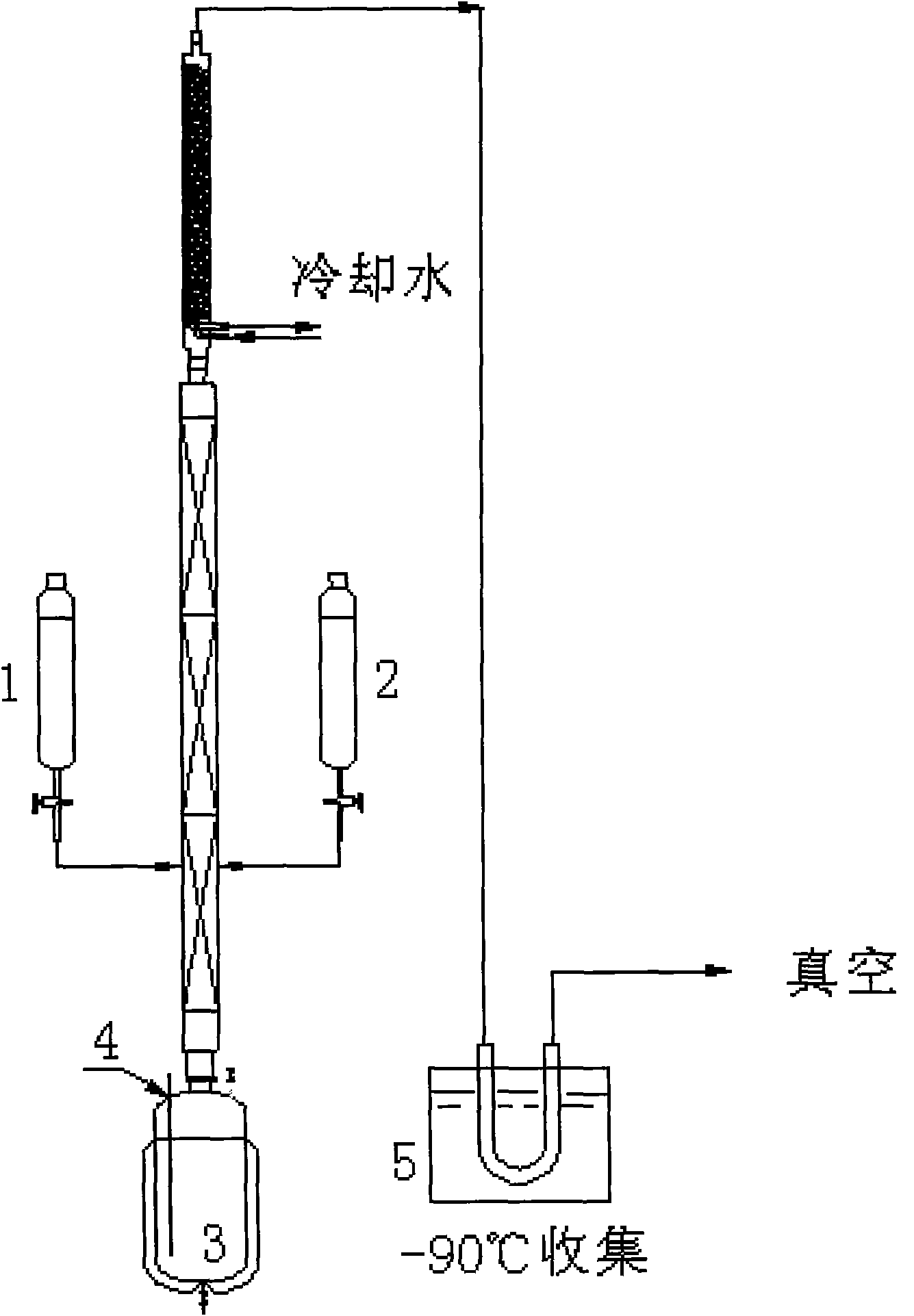

Preparation method of hexachlorobutadiene

ActiveCN101774884BAccelerated disengagementPromote enrichmentPreparation by dehalogenationGrignard reagentDistillation

The invention relates to a preparation method of hexachlorobutadiene. Under the existence of a polar solvent, I-CF2-CF2-CF2-CF2-I and a Grignard reagent synthetized by metals of Mg, Zn or Li and the like and aromatic organic compounds react in a rectifying column in manner of reaction distillation, wherein the reaction temperature is the boiling temperature of the corresponding solvent under the reaction condition, and the reaction is carried out in vacuum, or the reaction is carried out at ordinary pressure, and meanwhile, nitrogen purging is utilized in the reaction process. In the invention, the reaction is carried out in manner of reaction distillation; in the reaction process, the maximal steam quantity of steam in a reaction area can be ensured, and meanwhile, under the assistance of the vacuum or nitrogen purging, reaction products are rapidly separated from the solvent, thereby reducing the occurrence of side reaction and effectively increasing the yield and selectivity of the reaction, wherein the highest reaction yield can reach 97.6 percent, and the selectivity can reach 97.78 percent. Meanwhile, after the reaction is ended, the solvent can be recovered in the same device, thereby reducing the equipment investments and reducing the operating steps.

Owner:TIANJIN UNIV

The preparation method of z-1,1,1,4,4,4-hexafluoro-2-butene

ActiveCN106008147BLow priceHigh activityPreparation by dehalogenationPreparation by halogen replacementChemical synthesisGas phase

The invention relates to a preparation method of Z-1,1,1,4,4,4-hexafluoro-2-butene, belonging to the field of chemical synthesis. The method comprises the following steps of taking hexachlorobutadiene (HCBD) as a raw material, performing gas-phase catalytic chlorination-fluoridation separation to obtain 2,3-dichlorohexafluoro-2-butene, performing liquid-phase dechlorination to obtain hexafluoro-2-butyne, and preparing the Z-1,1,1,4,4,4-hexafluoro-2-butene (Z-HFO-1336mzz) by means of performing gas-phase catalytic hydrogenation, wherein three reactions are included totally. The Z-1,1,1,4,4,4-hexafluoro-2-butene with high selectivity is obtained by means of performing catalytic hydrogenation by adopting the hexafluoro-2-butyne, and meanwhile the product is easily separated from side products and the raw material. The method disclosed by the invention has the advantages that the original raw material is easily obtained, the activity of a catalyst is high, the service life of the catalyst is long, the raw material can be recycled, and the standard of zero emissions is reached.

Owner:泉州宇极新材料科技有限公司

Method for synthesizing fluorochloro succinic acid

InactiveCN107721845ALess industrial wasteEasy to separate and purifyHalogenated hydrocarbon preparationCarboxylic preparation by oxidationChemical synthesisHexachlorobutadiene

The invention relates to a method for synthesizing fluorochloro succinic acid, and belongs to the field of organic chemical synthesis. The method for synthesizing fluorochloro succinic acid is characterized in that hexachlorobutadiene (the molecular formula is as follow: CCl2 being equal to CCl-CCl being equal to CCl2) generates fluorochloro cyclobutene (the molecular formula is as follow: Cyclo-C2FxCly-CCl being equal to CCl-, wherein the sum of the x and y is 4) under the effect of cyclo-fluorinated catalysts; then, the fluorochloro succinic acid (the molecular formula is HOOC-C2FxCly-COOH)is generated under the effect of oxidizing agents. CCl2 is equal to CCl-CCl being equal to CCl2 arrow Cyclo-C2FxCly-CCl being equal to CCl- arrow HOOC-C2FxCly-COOH. The method has the advantages thatthe raw materials are cheap; the resources can be conveniently obtained; the product separation and purification are simple; the industrial production is easy; three industrial wastes (waste water, waste solid and waste water) are few.

Owner:CIVIL AVIATION UNIV OF CHINA

Preparation method of codoping electrode nitrogen with porous carbon/ferriferrous oxide composite material for super capacitor, and application thereof

ActiveCN107731557AGood electrical propertiesHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceCooking & baking

The invention relates to a preparation method of codoping electrode nitrogen with porous carbon / ferriferrous oxide composite material for super capacitor, and application thereof. The method comprisesthe steps of adding cyclopentadienyl iron, iron powder, hexachlorobutadiene, pyridine into the inner container of a reaction vessel having 50 ml polytetrafluoroethylene for mixing; sealing the mixture and putting in a high temperature reaction vessel and placing the reaction vessel in a baking oven for reaction; drying the product at the temperature of 120 D for six hours; taking out a proper amount of the sample, and adding urea solution in the sample, and placing the sample in a high temperature reaction vessel and placing the high temperature reaction vessel in the baking oven under the temperature of 200 D for 12-hour reaction, and cooling the sample to room temperature and conducting separation, and placing the sample in a vacuum drying box for drying under the temperature of 90 D; taking out the sample in a quartz tube of a tubular furnace and putting argon in the quartz tube; slowly heating the tubular furnace with the heating rate of 10 D / min for 90 minutes, and conducting automatic cooling on the tubular furnace, and obtaining the sample. The invention is advantageous in that the electrode capacitance produced by the composite material has quite large capacitance value; stability is good, and producing cost is low; massive potential is provided in the electrochemistry field.

Owner:温州邦欣源科技有限公司

Nitrogen-enriched doped multistage porous carbon material based on in-situ polymerization and preparation method and application thereof

ActiveCN108039283AGood electrical propertiesGood application prospectHybrid capacitor electrodesHybrid/EDL manufactureHexachlorobutadieneIn situ polymerization

The invention discloses nitrogen-enriched doped multistage porous carbon material based on in-situ polymerization and a preparation method and application thereof. The material is prepared according to the following method: an imidazole derivative and hexachlorobutadiene are mixed under the ultrasonic environment for 1h and react for 4h-12h in a sealed way under the temperature condition of 180-220 DEG C, then the pressure is released to the normal pressure and the mixture is dried so that a solid substance is obtained; and high temperature processing is performed on the obtained solid substance under the temperature of 700-900 DEG C under the protection of inert gas so that the finished product can be obtained. The nitrogen-enriched doped multistage porous carbon material based on in-situpolymerization has excellent electrochemical performance and can be used for preparing the capacitor electrode and especially the supercapacitor electrode so that the material can be used for the capacitor and especially the supercapacitor and has great application potential and industrial value in the field of energy storage.

Owner:WENZHOU UNIVERSITY

Method for preparing 2-chlorine-1,1,1,4,4,4-hexafluoro-2-butene by adopting micro-channel reactor

InactiveCN109851470AHigh activityShort reaction timePreparation by halogen halide additionPreparation by halogen replacement2-ButeneHigh activity

The invention discloses a method for preparing 2-chlorine-1,1,1,4,4,4-hexafluoro-2-butene by adopting a micro-channel reactor. The method comprises the following steps: (1) activating the catalyst: introducing a liquid fluorination catalyst and anhydrous HF into a micro-channel reactor to obtain an activated catalyst-HF mixture; and (2) carrying out a fluorination reaction: returning the activatedcatalyst-HF mixture prepared in the step (1) into the micro-channel reactor in the step (1), meanwhile, respectively introducing anhydrous HF and hexachlorobutadiene into the micro-channel reactor from a second path and a third path, conveying a mixture obtained after a reaction to a rectifying tower through a pump, extracting a mixture of 2-chlorine-1,1,1,4,4,4-hexafluoro-2-butene and HF from the top of the rectifying tower, and carrying out layering, wherein the lower layer is 2-chlorine-1,1,1,4,4,4-hexafluoro-2-butene, and the upper layer is HF. The method for preparing 2-chlorine-1,1,1,4,4,4-hexafluoro-2-butene has a high conversion rate, high selectivity and few impurities, and activity of the catalyst is greatly prolonged. The silicon carbide micro-channel reactor is adopted, so that the reaction time is short, superacid corrosion resistance is achieved, reaction mass transfer and heat transfer performance is excellent, and therefore, high activity of the catalyst can be kept for a long time.

Owner:JUHUA GROUP TECH CENT

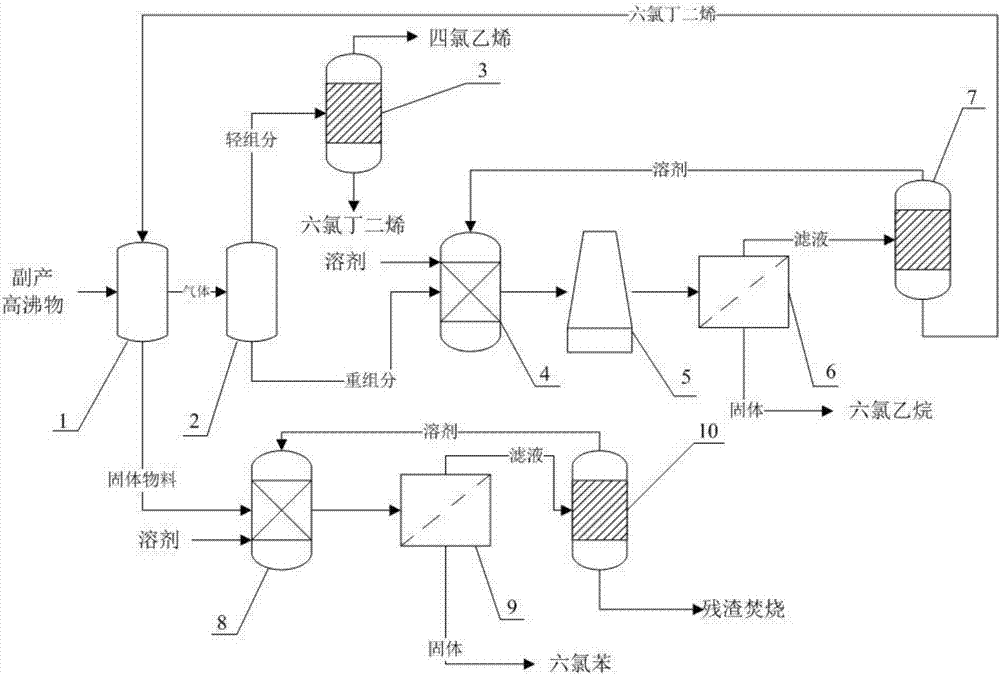

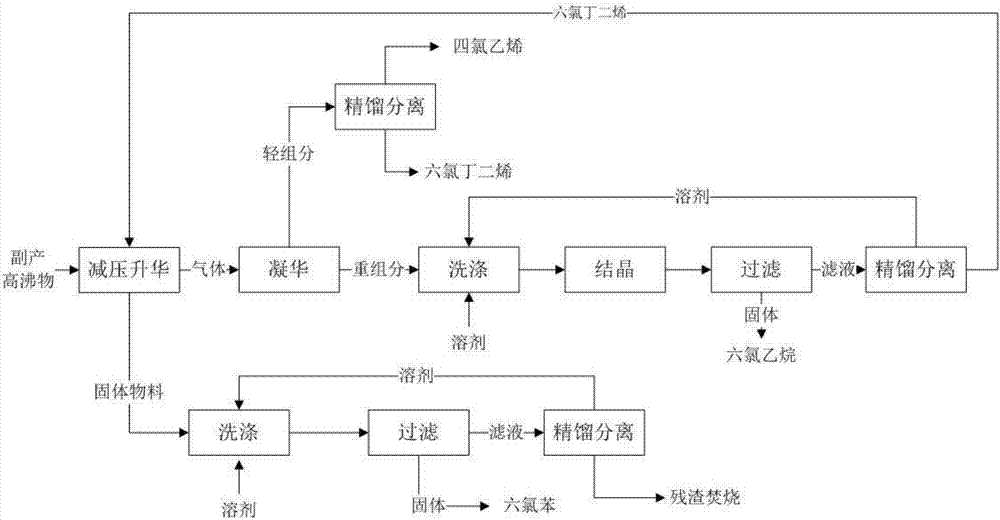

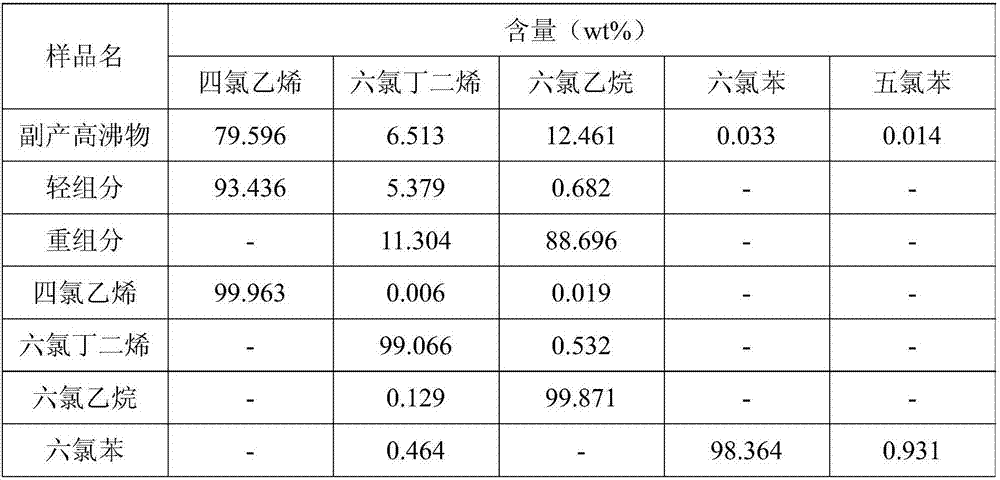

Separation system for by-product high-boiling matter in tetrachloroethylene production and separation method

InactiveCN107573210AEfficient separationLow sublimation temperatureHalogenated hydrocarbon separation/purificationSolventHexachloroethane

The invention provides a separation system for by-product high-boiling matter in tetrachloroethylene production and a separation method. The system comprises a decompression sublimation device, a desublimation device, a first rectifying tower, a hexachloroethane separation system and a hexachlorobenzene separation system, wherein a gas material outlet of the decompression sublimation device is connected with a feeding port of the desublimation device, a light-component material outlet of the desublimation device is connected with a feeding port of the first rectifying tower, a heavy-componentmaterial outlet of the desublimation device is connected with a feeding port of the hexachloroethane separation system, and a solid material outlet of the decompression sublimation device is connectedwith the hexachlorobenzene separation system. According to the method, the byproduct high-boiling matter in the tetrachloroethylene production is separated and purified one by one through processes such as decompression sublimation, washing by using a solvent, recrystallization and rectification, and high-efficiency separation of hexachloroethane, hexachlorobutadiene and hexachlorobenzene is realized; and by adopting a mode of the decompression sublimation, a sublimation temperature of the product is reduced, energy consumption of the whole technological process is effectively reduced, and production costs are greatly reduced.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Capacitor electrode and preparation method based on nitrogen-sulfur co-doped porous carbon microsphere material

ActiveCN107689303BGood electrical propertiesGreat application potentialHybrid capacitor electrodesHybrid/EDL manufactureHexachlorobutadienePorous carbon

The invention relates to a capacitor electrode based on a nitrogen-sulfur co-doped porous carbon microsphere composite material and a preparation method of the capacitor electrode. The method comprises the following steps: S1: subjecting hexachlorobutadiene, tellurium diethyldithiocarbamate (TDEC) and a solvent to an airtight reaction under a high temperature and pressure; S2: after the reaction is finished, releasing the pressure to normal pressure and naturally cooling to room temperature, and drying the resulting solid to obtain a dried sample; S3: performing high-temperature roasting treatment on the dried sample under the protection of inert gas to obtain the nitrogen-sulfur co-doped porous carbon microsphere composite material. The nitrogen-sulfur co-doped porous carbon microsphere composite material has excellent electrical properties and thus can be applied in the field of capacitors, especially in the field of super capacitors, and has a good application prospect and industrialization potential.

Owner:WENZHOU UNIV

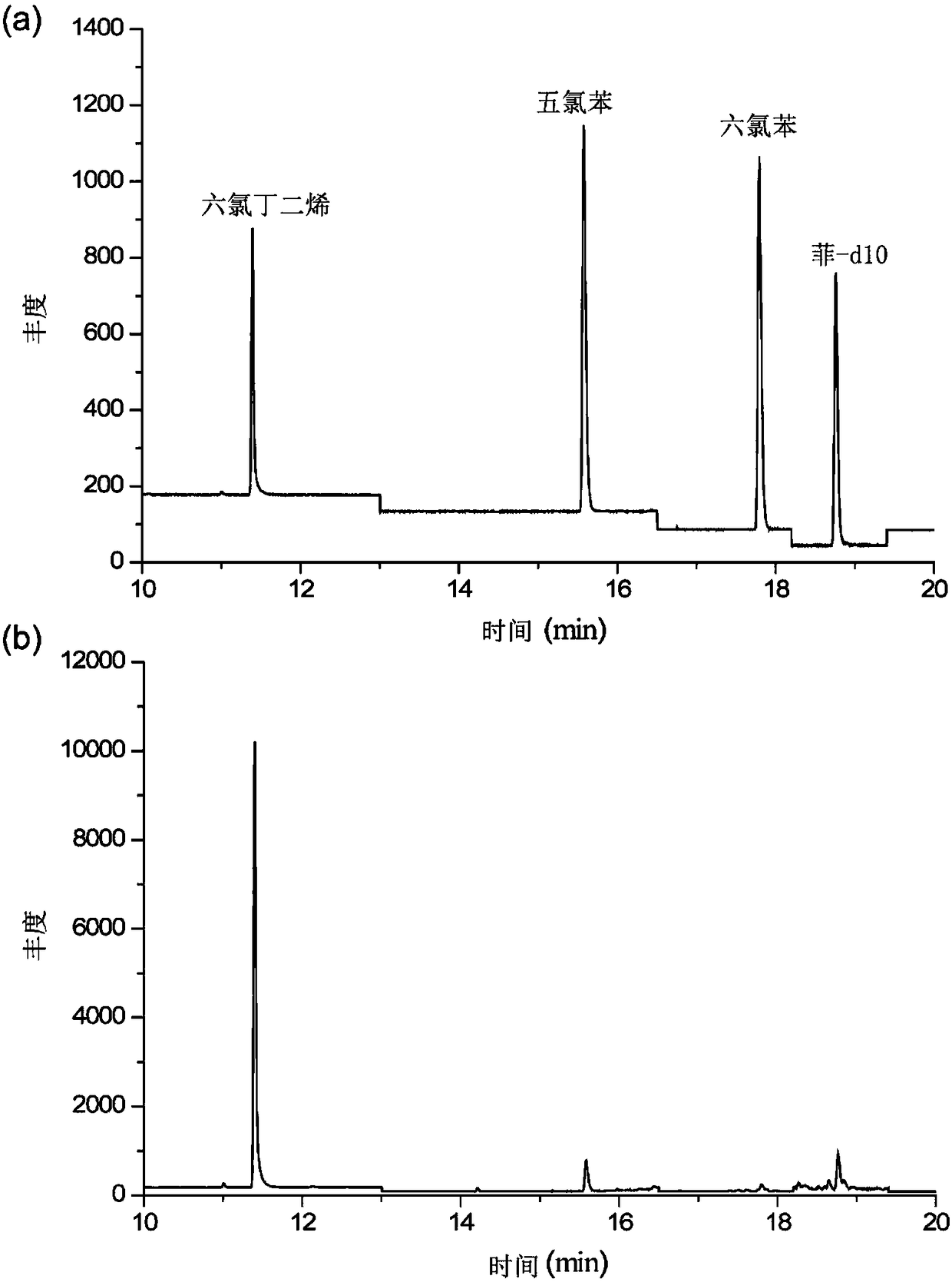

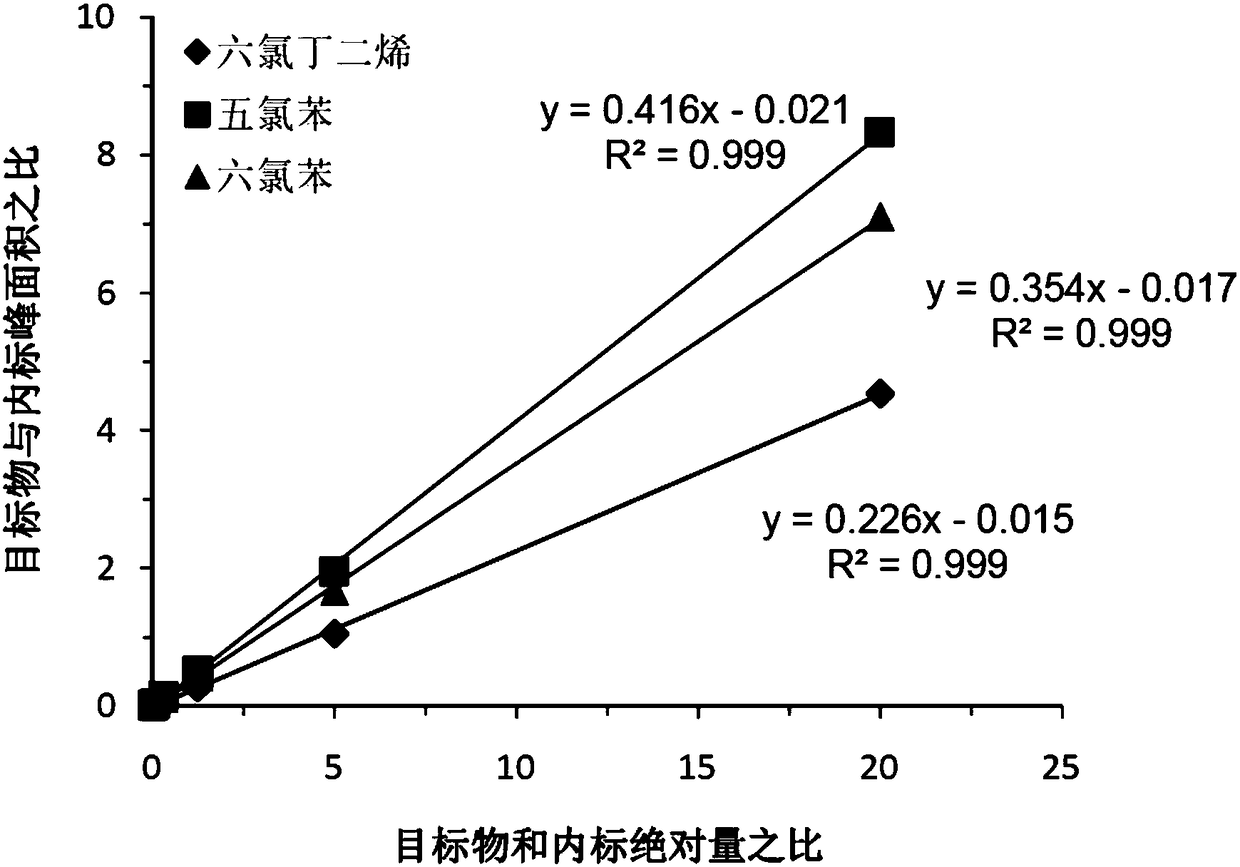

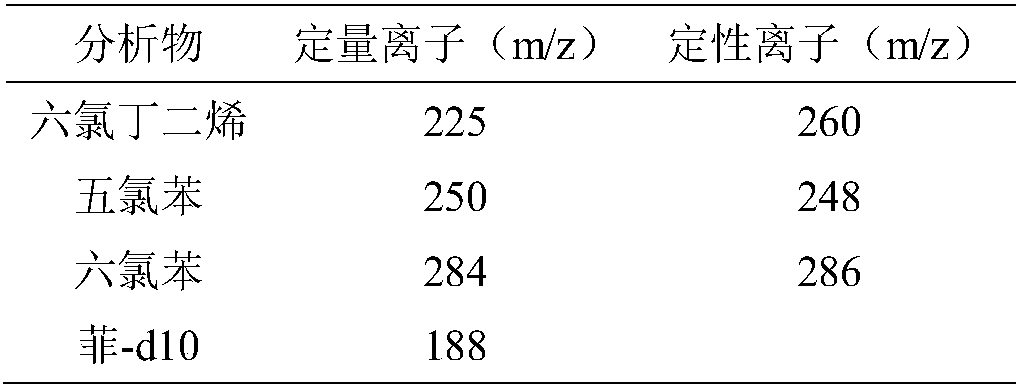

Method for simultaneously detecting hexachlorobutadiene, pentachlorobenzene and hexachlorobenzene in waste incineration fly ash

InactiveCN108152397AEasy to operateHigh sensitivityComponent separationHexachlorobutadieneGas chromatography–mass spectrometry

The invention discloses a method for simultaneously detecting hexachlorobutadiene, pentachlorobenzene and hexachlorobenzene in waste incineration fly ash. The method comprises the following steps: sample pretreatment, ultrasonic extraction, purification, gas chromatography-mass spectrometry joint detection, establishment of a standard curve and acquisition of a quantifying result. The method disclosed by the invention has the advantages of easiness in operation, high sensitivity and relatively high recovery rate at the time of impurity removal, and fills in the blank of athe method appears forthe first time for analyzing and detecting hexachlorobutadiene in fly ash.

Owner:ZHEJIANG UNIV OF TECH

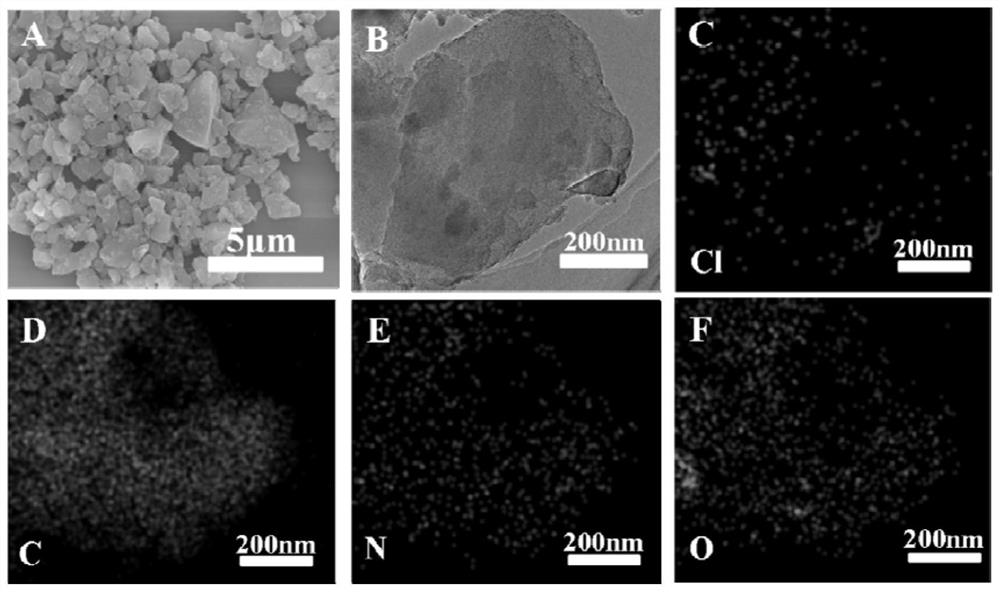

Preparation method of nitrogen-oxygen co-doped porous carbon/ferroferric oxide composite material and application of nitrogen-oxygen co-doped porous carbon/ferroferric oxide composite material in supercapacitor electrode

ActiveCN107658142AGood electrical propertiesExcellent specific capacitanceHybrid capacitor electrodesHybrid/EDL manufacturePorous carbonOxide composite

The invention relates to a preparation method of a nitrogen-oxygen co-doped porous carbon / ferroferric oxide composite material. The method comprises the following steps of (1) weighing certain parts by weight of cyclopentadienyl iron, hexachlorobutadiene and pyridine, adding the cyclopentadienyl iron, the hexachlorobutadiene and the pyridine to a polytetrafluoroethylene reactor tank and mixing; (2) sealing the polytetrafluoroethylene reactor tank, putting the polytetrafluoroethylene reactor tank into a high temperature reactor, tightening a reactor cover, and putting the reactor into an oven to react at 180-220 DEG C for 6-24h; (3) cooling to a room temperature, opening the reactor, putting a product into the oven and drying at 120 DEG C for 6h; and (4) putting a moderate amount of sampleinto the middle part of a quartz tube of a tube furnace, introducing argon, evacuating the air in the tube, slowly heating the tube furnace at a heating rate of 10 DEG C / min, maintaining the temperature for 60-120min, automatically cooling an instrument, cooling and closing the gas to obtain the nitrogen-oxygen co-doped porous carbon / ferroferric oxide composite material. The nitrogen-oxygen co-doped porous carbon / ferroferric oxide composite material has excellent electrical property, is used for preparing a supercapacitor electrode, and has great potential in the field of electrochemistry.

Owner:WENZHOU UNIVERSITY

High-density nitrogen-oxygen-chlorine co-doped carbon particle material as well as preparation method and application thereof

ActiveCN112357900AImprove electrochemical performanceIncrease capacitanceHybrid capacitor electrodesCarbon preparation/purificationAnilineCalcination

The invention relates to a high-density nitrogen-oxygen-chlorine co-doped carbon particle material, and a preparation method and application thereof. The method comprises the following steps: S1, uniformly mixing hexachlorobutadiene and aniline, and carrying out a heating closed reaction in a hydrothermal kettle; S2, after the reaction is finished, naturally cooling to normal temperature and normal pressure, and washing and drying the obtained solid to obtain a dried sample; and S3, carrying out high-temperature calcination treatment on the dried material under the protection of inert gas, soas to obtain the high-density nitrogen-oxygen-chlorine co-doped carbon particles, and the invention also relates to the composite material, application and a super capacitor working electrode comprising the composite material. The high-density nitrogen-oxygen-chlorine co-doped carbon particles have excellent performance, can be used for preparing a working electrode of a super capacitor, can be used in the super capacitor, show good electrochemical energy storage characteristics, and have huge application potential and industrial value in the field of electrochemical energy storage.

Owner:INST OF NEW MATERIALS & IND TECH WENZHOU UNIV

Production and application method of porous carbon material with high specific surface area

InactiveCN109279593ALarge specific surface areaHigh resistivityCell electrodesCarbon preparation/purificationPorous carbonVacuum drying

The invention discloses a production and application method of a porous carbon material with a high specific surface area. The method comprises two specific steps. The step one comprises the followingsteps: S1, adding 0.05-0.4 g of metal and 10-80 ml of hexachlorobutadiene into a stainless steel reaction kettle with a polytetrafluoroethylene liner, covering the reaction kettle with a reaction kettle cover, and placing the reaction kettle in a drying oven for carrying out a reaction at a temperature of 210-230 DEG C for 8-50 hours; S2, centrifuging and washing the product obtained after the reaction of the step S1 is completed, carrying out vacuum drying, carrying out heating for 0.5-4 hours under the protection of inert gas, carrying out cooling to room temperature, and collecting and storing the product in a drying utensil for later use; and S3, carrying out heat treatment on the product obtained in the step S2 under the protection of inert gas. The step two comprises applying the porous carbon material with a high specific surface area prepared in the step one to an oxygen reduction process. An oxygen reduction electrode prepared from the porous carbon material with a high specific surface area can also be applied to fuel cells.

Owner:INST OF NEW MATERIALS & IND TECH WENZHOU UNIV

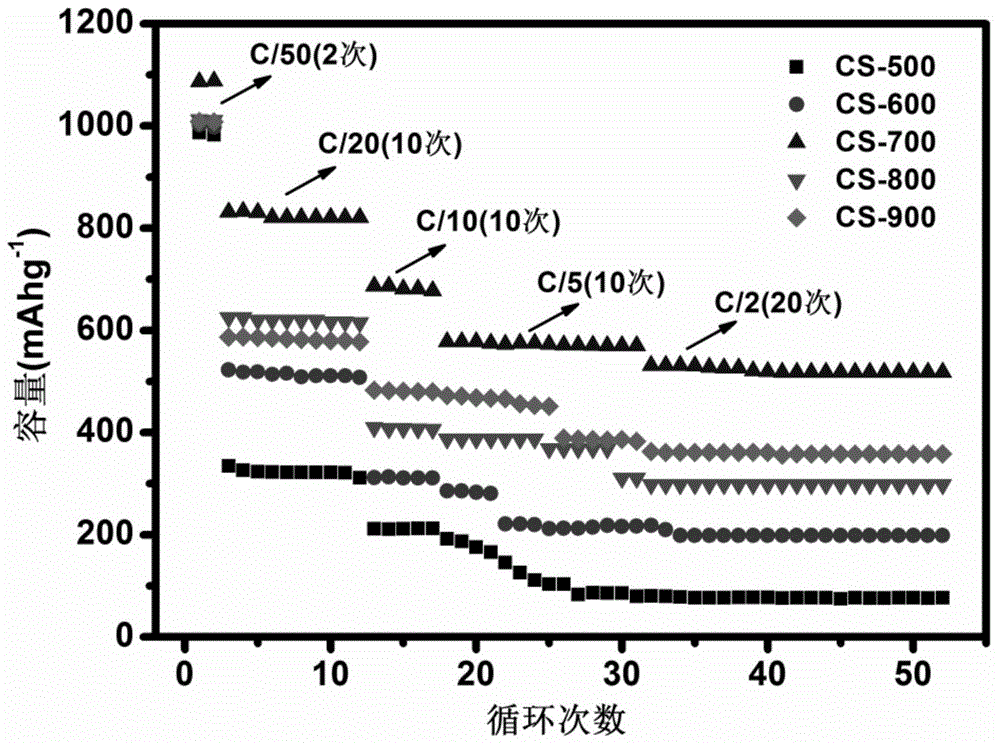

Preparation method and application of high-sulfur content carbon and sulfur lithium ion battery material

ActiveCN104617295AReduce Shuttle EffectImprove cycle stabilityCell electrodesSecondary cellsHexachlorobutadieneElectrical battery

The invention discloses a preparation method and application of a high-sulfur content carbon and sulfur lithium ion battery material. The method comprises the following steps: adding elemental sulfur into a reaction vessel, injecting hexachlorobutadiene to perform closed reaction under the conditions that the temperature is 100-300 DEG C, and the pressure is 0-15 MPa, centrifuging after post-treatment, precipitating and washing, and drying to obtain a primary product; performing heat treatment in a tube furnace for 30 minutes-4 hours under the inert gas protection. The invention provides the application of a novel high-sulfur content carbon and sulfur material to a lithium ion battery. The method is extremely simple, the raw material source is rich, carbon atoms and sulfur atoms of the prepared novel high-sulfur content carbon and sulfur material are combined in a way of a chemical bond, and the mass percentage occupied by the content of sulfur elements in the material can reach 10-80 percent. The carbon and the sulfur atoms are mutually combined through the chemical bond, the sulfur atoms are uniformly dispersed in the material so as to be in full contact and react with lithium ions in the charging and discharging processes, therefore the specific capacity and the cycling performance of the lithium ion battery are greatly improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Hexafluoro-2-butyne preparation method

ActiveCN108530259ASimple processEase of industrial productionPreparation by halogen replacementHexachlorobutadieneSolvent

The invention discloses a hexafluoro-2-butyne preparation method which is characterized by subjecting hexachlorobutadiene and fluoride salt to reaction in solvents. The hexafluoro-2-butyne preparationmethod is simple in processing, low in cost, green and environmentally friendly and easy to achieve industrialization.

Owner:JUHUA GROUP TECH CENT

Preparation method 1,1,1,4,4,4-hexafluoro-2-butene

ActiveCN106966856ARaw materials are easy to getLow costPreparation by hydrogen halide split-offHydrogen fluorideHexachlorobutadiene

The invention discloses a preparation method of 1,1,1,4,4,4-hexafluoro-2-butene. According to the preparation method, raw materials hexachlorobutadiene and hydrogen fluoride are subjected to preheating, and are delivered into a first reactor; reaction is carried out in the presence of zinc, magnesium, gallium-loaded chromic oxide catalyst so as to obtain a mixture containing 1,1,1,4,4,4-hexafluoro-2-chloro-2-butene; separation is carried out, and obtained 1,1,1,4,4,4-hexafluoro-2-chloro-2-butene is delivered into a second reactor; reaction is carried out in the presence of zinc chloride-loaded aluminium oxide catalyst so as to obtain a mixture containing hexafluoro-2-butyne; separation is carried out, and obtained hexafluoro-2-butyne and hydrogen are delivered into a third reactor; reaction is carried out in the presence of Pd / BaSO4 catalyst so as to obtain a mixture containing 1,1,1,4,4,4-hexafluoro-2-butene, and 1,1,1,4,4,4-hexafluoro-2-butene is obtained via separation. The preparation method is simple; the raw materials are easily available; cost is low; and yield is high.

Owner:ZHEJIANG QUHUA FLUOR CHEM

Preparation method of 1,1,1,2,4,4,4-heptafluoro-2-butene

ActiveCN108911947ALess industrial wasteReduce manufacturing costPreparation by halogen replacementCatalyst activation/preparationHexachlorobutadieneHydrogen fluoride

The invention discloses a preparation method of 1,1,1,2,4,4,4-heptafluoro-2-butene. The method uses hexachlorobutadiene and hydrogen fluoride as raw materials and uses a chromium-based catalyst as a fluorine-chlorine exchange catalyst to form the 1,1,1,2,4,4,4-heptafluoro-2-butene under gas phase conditions through a plurality of gas-phase catalytic reactions. Compared with the prior art, the preparation method of the 1,1,1,2,4,4,4-heptafluoro-2-butene provided by the invention has the following advantages: 1, the gas phase fluorination method adopted in the method is a cycle fluorination method, has less three industrial wastes (waste water, waste gases and solid waste), and greatly reduces the production costs; 2, the method can realize rapid and multiple-cycle fluorination, improve a product yield, and have simple separation and purification of the product; and 3, the method has the advantages of cheap raw materials, convenient sources and simple operation, and is suitable for industrialized production.

Owner:CIVIL AVIATION UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com