Patents

Literature

35results about How to "Less industrial waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of nano Ru/C supported catalyst

ActiveCN105498761AIncrease temperatureExtended service lifeCarboxylic preparation by ozone oxidationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonRuthenium

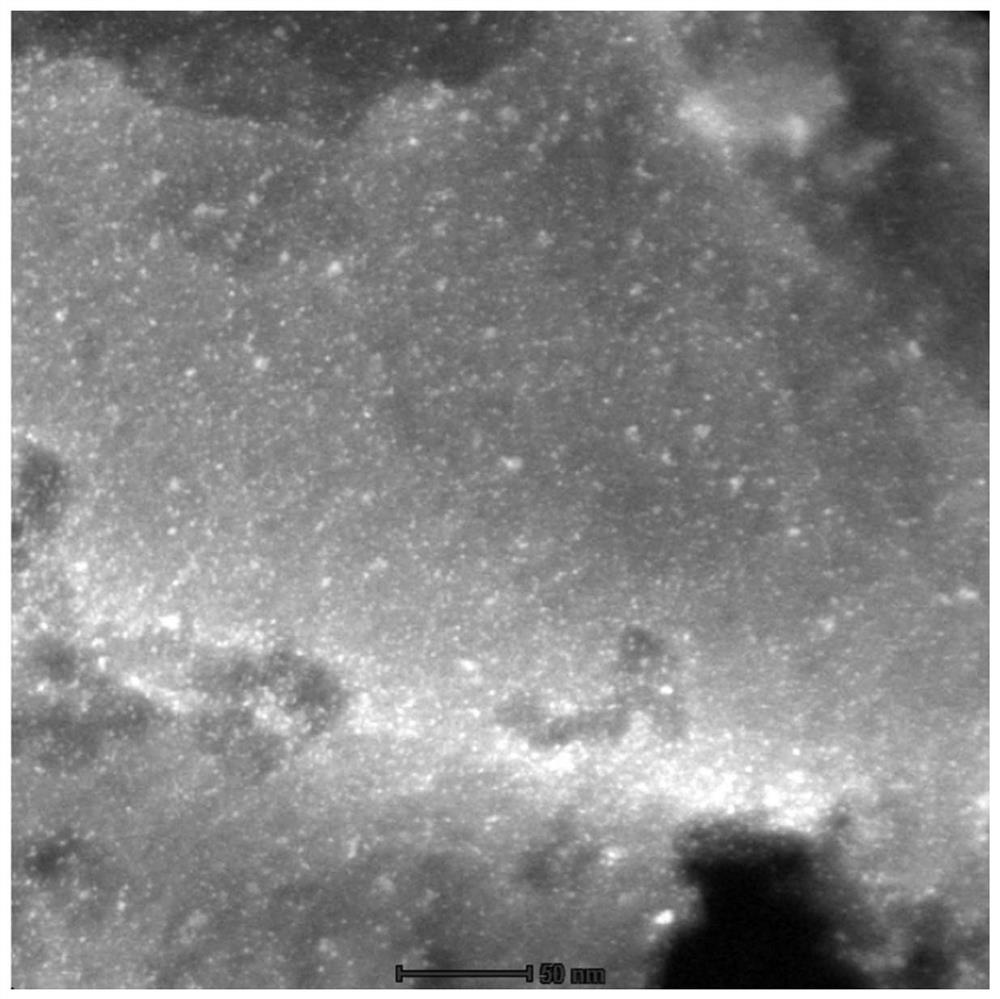

The invention discloses a preparation method of a nano Ru / C supported catalyst. The method comprises steps as follows: treated activated carbon is added to a ruthenium slat aqueous solution, stirring and dipping are performed for 0.5-4 h, then an alkaline compound aqueous solution is used for adjusting the pH of mixed slurry of activated carbon and ruthenium salt to 7-12, the mixed slurry is stirred continuously for 1-6 h, left to stand for 2-4 h and filtered, a filter cake is washed with water to be neutral and free of chloride ions and dried at the temperature of 80-120 DEG C for 4-12 h, and a treated Ru / C precursor is obtained; the treated Ru / C precursor is subjected to sectioned calcination in the inert atmosphere; a product after calcination is reduced, and then the nano Ru / C supported catalyst with high dispersion is obtained. The particle size of ruthenium particles of the catalyst is 1-4 nm. The method is low in production cost, has mild preparation conditions and causes few three industrial wastes, and the catalyst has advantages of long service life and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hexafluoropropylene-2-butyne synthesizing method

ActiveCN105348034AHigh yieldConvenient sourcePreparation by halogen replacementHexachlorobutadieneHexafluoropropylene

The invention discloses a hexafluoropropylene-2-butyne synthesizing method. Hexachlorobutadiene (CCl2=CCl-CCl=CCl2) is taken as the raw material to generate hexafluoropropylene-2-butyne under the action of a catalyst, the raw material hexachlorobutadiene is easy to obtain and low in cost. The gaseous-phase circulating fluorination method is adopted, the discharge level of three industrial wastes is low, the yield of products is high, and production cost is reduced greatly; the gaseous-phase circulating fluorination method is conducted at normal temperature, the traditional high-pressure telomerization process route is avoided, and risks in industrial safety production are reduced greatly; meanwhile, the method has the advantage that operation is easy and is totally suitable for industrial production.

Owner:TIANJIN MEDICAL UNIV

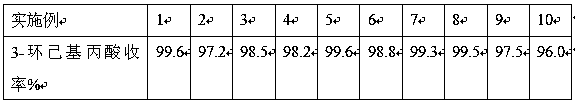

Oxymatrine emulsifiable concentrate pesticide

The invention relates to an emulsifiable concentrate pesticide containing 2.4% of oxymatrine, which belongs to the field of botanical pesticides. The pesticide mainly comprises 20% of sophora flavescens, 20% of castanopsis sclerophylla, 10% of tobacco, 5% of derris, 5% of tripterygium wilfordii, 20% of pterocarya stenoptera, 6% of hops, 4% of humulus scandens, and 10% of zanthoxylum schinifollum. The pesticide is able to kill the pests mainly in a contact killing manner and has characteristics of high decomposition speed, no residual, no pollution to the family environment and the like. The pesticide has obvious preventing and killing effect on multi-species of pests, such as Lepidoptera, Hemiptera, Coleoptera, Homoptera, Diptera and the like, in vegetables, fruit trees, flowers, forest trees, and field crops.

Owner:青岛罗素生物技术有限公司 +1

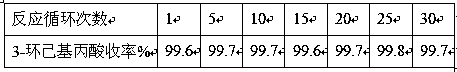

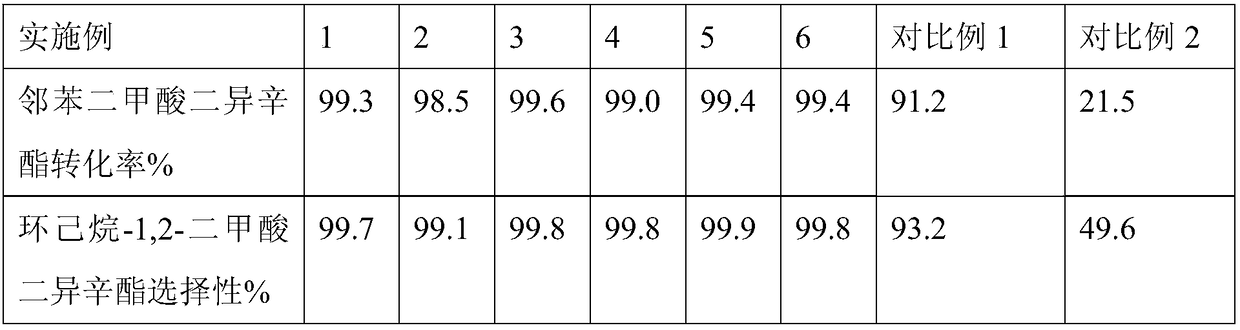

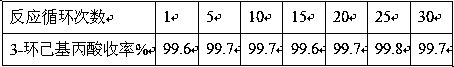

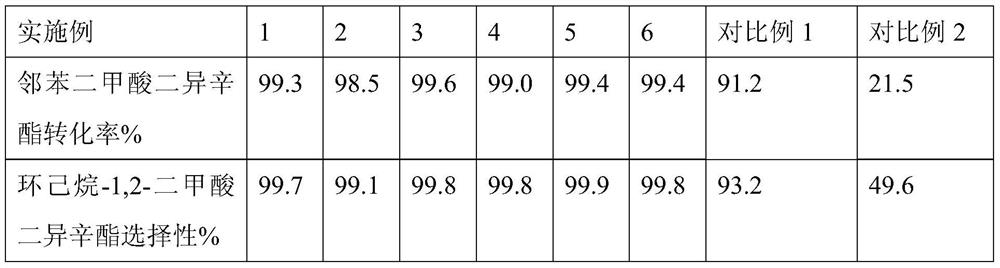

Nano-ruthenium carbon catalyst and preparation method and application thereof

ActiveCN108993497AAvoid desorptionInhibit migrationOrganic compound preparationCatalyst activation/preparationActivated carbonReduction treatment

The present invention discloses a nano-ruthenium carbon catalyst and a preparation method and an application thereof. The catalyst comprises activated carbon, and active ruthenium particles and auxiliary components loaded thereon; and the auxiliary components comprise zinc, copper, nickel, etc. The preparation method comprises the following steps: activated carbon is soaked in an aqueous solutionof ruthenium salt; a basic compound is added; stirring, putting still, filtering, drying and calcination are conducted to obtain a first ruthenium carbon precursor; then the first ruthenium carbon precursor is soaked in an auxiliary aqueous solution; then the basic compound is added; stirring, putting still, filtering and drying are conducted to obtain a second ruthenium carbon precursor; under aprotective atmosphere, the second ruthenium carbon precursor is subjected to a staged calcination treatment to obtain a third ruthenium carbon precursor; and then a reduction treatment is conducted toobtain the catalyst. The catalyst can be reused 100 times or more in a reaction of hydrogenating aromatic ring compounds to prepare cyclohexyl derivatives, and has advantages of long service life, low production cost, mild reaction conditions, high product purity, less three industrial wastes, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

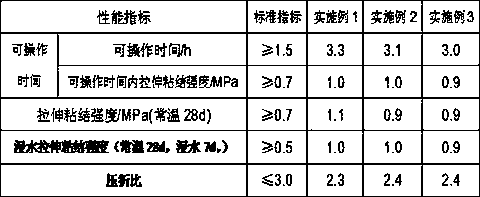

Cement-based composite anti-crack binding dry mortar and preparation and application methods thereof

The invention discloses cement-based composite anti-crack binding dry mortar and preparation and application methods thereof. The cement-based composite anti-crack binding dry mortar comprises, by mass, 300-400 parts of ordinary Portland cement, 600-700 parts of quartz sand, 0.3-0.6 part of anti-crack fiber, 2-3 parts of cellulose ether, 20-30 parts of latex powder and 20-25 parts of fly ash. Thepreparation method includes the steps of firstly, weighing the raw materials according to the mass; secondly, evenly mixing the weighed raw materials in an agitator to obtain the cement-based composite anti-crack binding dry mortar. The application method includes the steps of firstly, weighing the cement-based composite anti-crack binding dry mortar and water of corresponding mass, wherein the mass ratio of the cement-based composite anti-crack binding dry mortar to the water is (100-200):100; secondly, evenly mixing for use. The cement-based composite anti-crack binding dry mortar is convenient to operate, easy to control, capable of being used after being sufficiently mixed with an appropriate amount of water, high in binding force, good in water resistance, good in crack resistance, good in permeability resistance and the like.

Owner:山东天汇防水股份有限公司

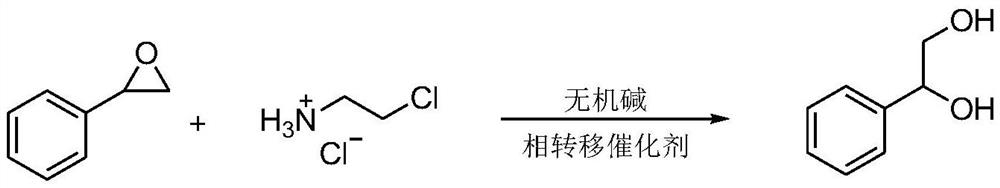

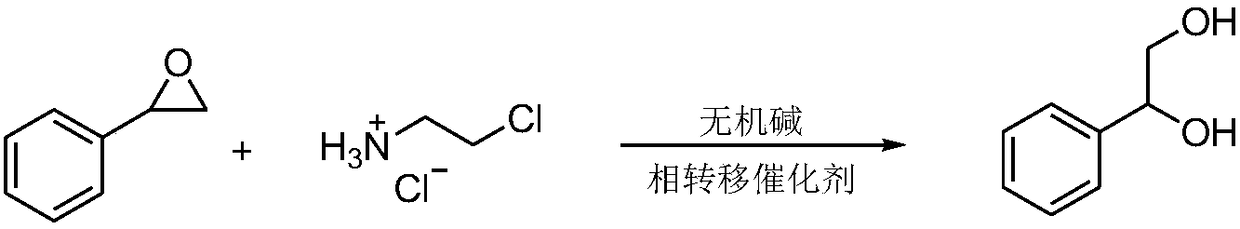

Synthetic method for 1-phenyl-1,2-ethanediol

ActiveCN108129260AHigh purityHigh yieldOrganic compound preparationPreparation by hydrolysisStyrene oxideOrganic layer

The invention provides a synthetic method for 1-phenyl-1,2-ethanediol. The synthetic method comprises the following steps: (1) performing a reaction: adding styrene oxide, a phase transfer catalyst, 2-chloroethylaminehydrochloride, an inorganic alkali and water into a flask with a thermometer and a reflux condenser pipe, performing stirring, and performing a heating reflux reaction; (2) performingend point monitoring: performing monitoring on the reaction of the step (1) by adopting an HPLC, and determining the reaction end point when the raw material styrene oxide disappears; and (3) performing extraction: when the reaction of the step (1) reaches the reaction end point, stopping heating, cooling the system to room temperature, performing extraction by using an organic solvent, separating and taking an organic layer, and performing decompression exsolution to obtain a white solid. The prepared product provided by the invention has high purity, a high yield and reduced three industrial waste (waste water, waste gas and solid waste), is friendly to the environment, and meets the requirements of the green chemistry process.

Owner:CHANGZHOU HIGH TECH RES INST OF NANJING UNIV

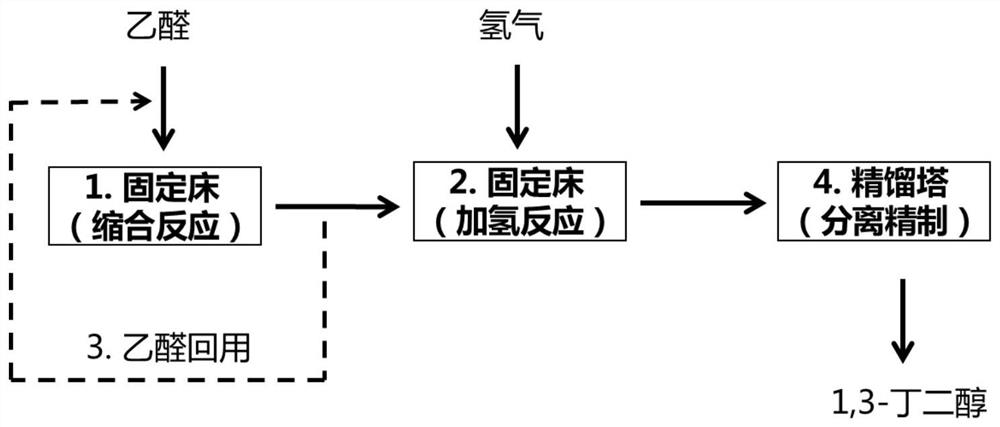

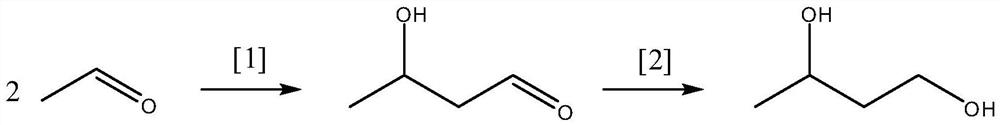

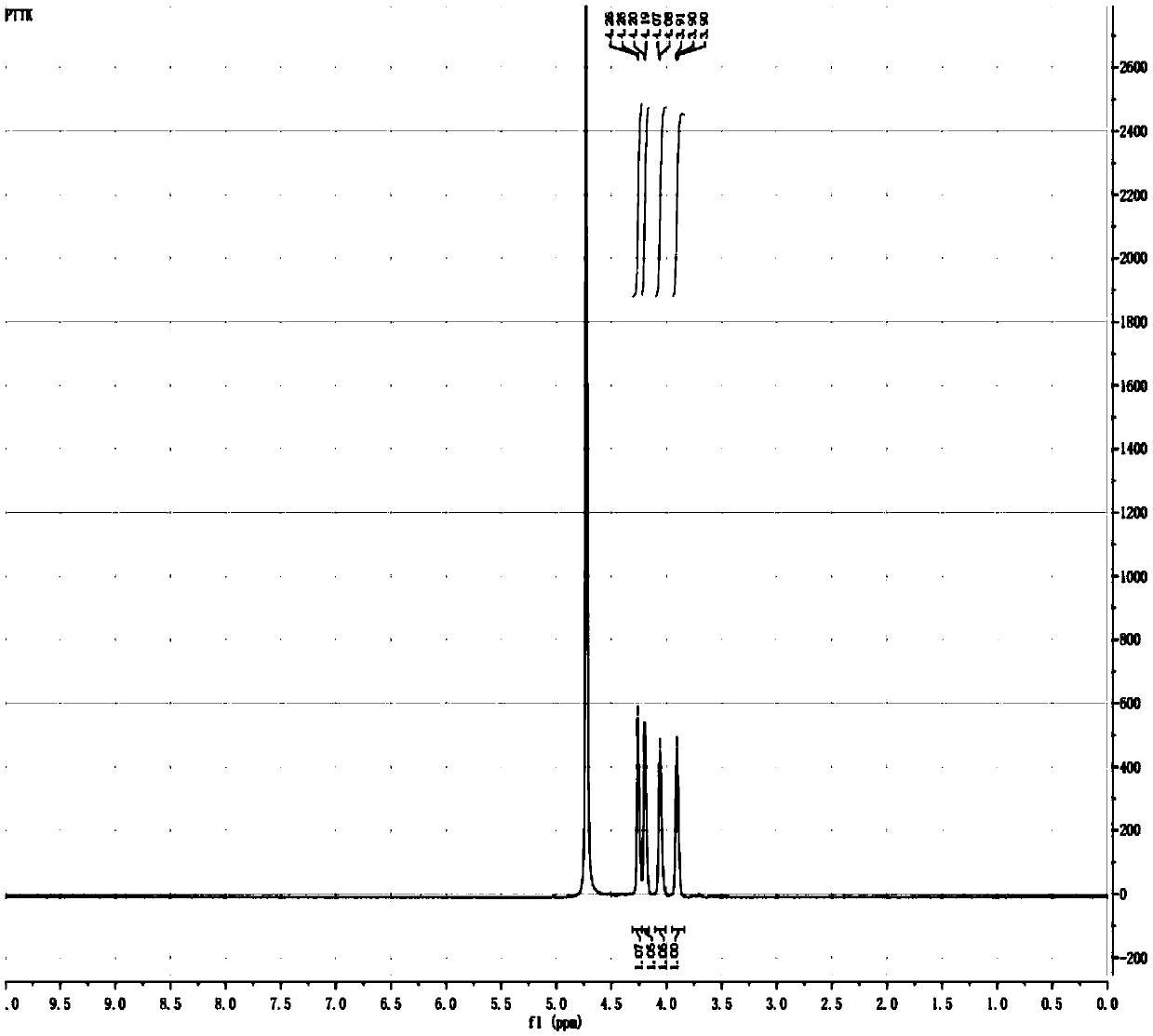

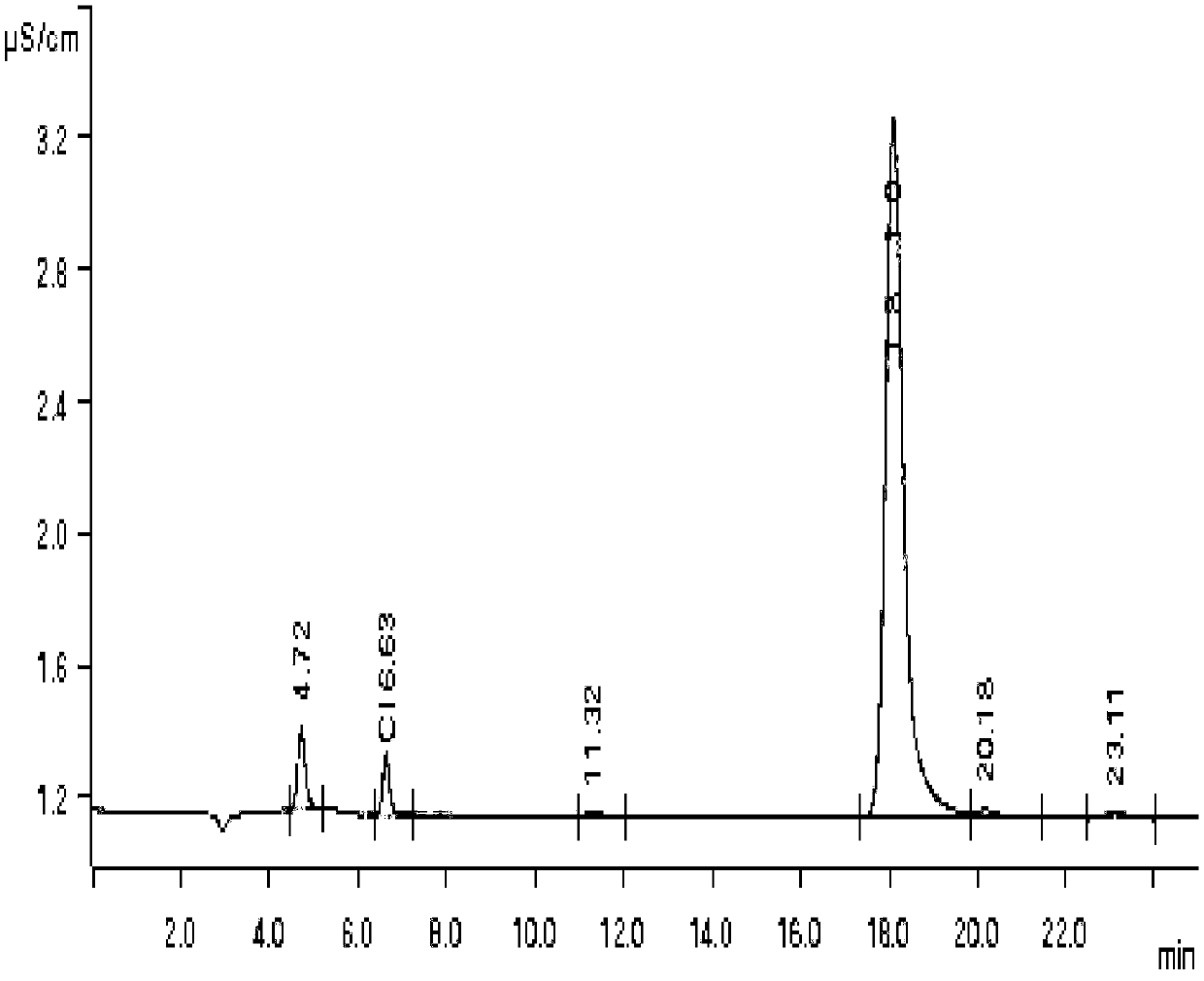

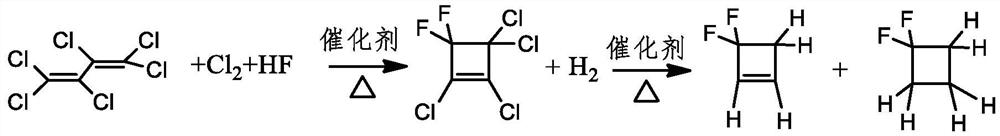

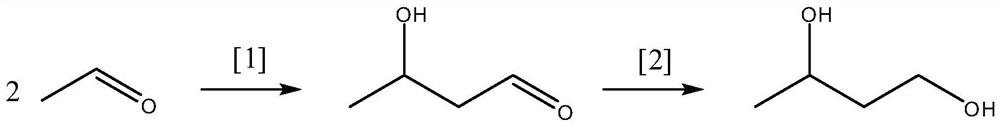

Method for preparing 1, 3-butylene glycol by adopting fixed bed continuous reaction

ActiveCN112390712AEfficient condensation reactionSimple methodOrganic compound preparationHydroxy compound preparationPtru catalystFixed bed

The invention discloses a method for preparing 1, 3-butylene glycol by adopting a fixed bed continuous reaction, and the preparation method comprises the following steps of: 1) feeding an acetaldehydeaqueous solution into a condensation reaction fixed bed reactor filled with a solid base catalyst by using carrier gas to obtain a condensation reaction product; 2) feeding the reaction material flowfrom which acetaldehyde is separated and a hydrogen flow into a hydrogenation reactor together, and carrying out hydrogenation reaction on 3-hydroxy butyraldehyde in the presence of a hydrogenation catalyst to generate 1, 3-butylene glycol; and 3) finally acquiring the 1, 3-butylene glycol product by separation and purification methods like vacuum rectification. According to the preparation method disclosed by the invention, a specific solid base catalyst is adopted, so that efficient condensation reaction of acetaldehyde is realized, and further the 1, 3-butylene glycol is prepared. The method is simple and efficient, particularly, the fixed bed reactor is combined with the specific catalyst, and the method is simple and convenient to operate, green, environment-friendly and few in industrial three wastes, and is a sustainable green synthesis route.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparation method of calcium glucarate

ActiveCN109678695ANo pollution in the processEasy to operateOrganic compound preparationCarboxylic acid salt preparationCatalytic oxidationGluconic acid

The invention relates to a preparation method of calcium glucarate, and belongs to the field of pharmacy. The invention provides a preparation method of the calcium glucarate. The preparation method comprises the following steps: (1) putting glucose, oxygen and a metal catalyst palladium vanadium ammonium into a high-pressure reactor for catalytic oxidation reaction to obtain glucaric acid; (2) after the oxidation reaction, adding potassium-containing alkali to convert the glucaric acid into potassium gluconate; (3) enabling the potassium gluconate to react with an acid to release the glucaricacid; (4) enabling the glucaric acid to react with the calcium-containing alkali to obtain the calcium glucarate. The preparation method disclosed by the invention is pollution-free to the environment, and meanwhile, the total yield is increased; the catalyst can be repeatedly used; the cost is reduced; the calcium content is 98 to 102 percent; a small amount of industrial wastewater, waste residues and waste gas are generated; the preparation method is suitable for industrial production.

Owner:江苏东南纳米材料有限公司

Preparation method of 1,1,1,2,4,4,4-heptafluoro-2-butene

ActiveCN108911947ALess industrial wasteReduce manufacturing costPreparation by halogen replacementCatalyst activation/preparationHexachlorobutadieneHydrogen fluoride

The invention discloses a preparation method of 1,1,1,2,4,4,4-heptafluoro-2-butene. The method uses hexachlorobutadiene and hydrogen fluoride as raw materials and uses a chromium-based catalyst as a fluorine-chlorine exchange catalyst to form the 1,1,1,2,4,4,4-heptafluoro-2-butene under gas phase conditions through a plurality of gas-phase catalytic reactions. Compared with the prior art, the preparation method of the 1,1,1,2,4,4,4-heptafluoro-2-butene provided by the invention has the following advantages: 1, the gas phase fluorination method adopted in the method is a cycle fluorination method, has less three industrial wastes (waste water, waste gases and solid waste), and greatly reduces the production costs; 2, the method can realize rapid and multiple-cycle fluorination, improve a product yield, and have simple separation and purification of the product; and 3, the method has the advantages of cheap raw materials, convenient sources and simple operation, and is suitable for industrialized production.

Owner:CIVIL AVIATION UNIV OF CHINA

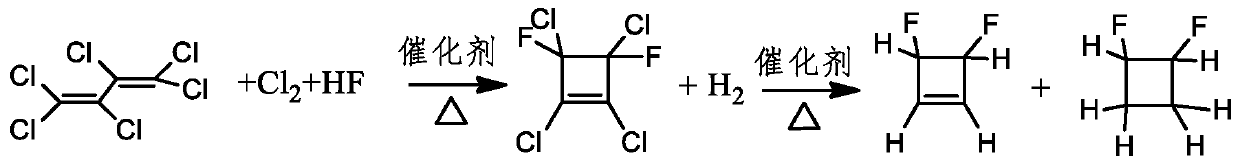

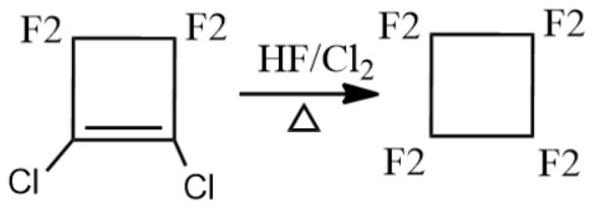

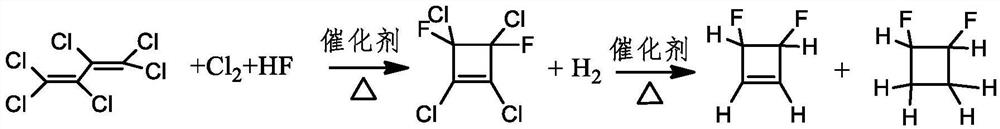

A method for synthesizing fire extinguishing agent octafluorocyclobutane

ActiveCN107721810BSave raw materialsConvenient sourcePreparation by halogen replacementCatalyst activation/preparationChemical synthesisPtru catalyst

The invention relates to a method for synthesizing a fire extinguishing agent octafluorocyclobutane, and belongs to the field of organic chemical synthesis. The method for synthesizing octafluorocyclobutane is characterized in that the octafluorocyclobutane is generated from dichlorotetrafluorocyclobutene, hydrogen fluoride and chlorine gas in the presence of a fluorination catalyst. FORMULA is shown in the description. According to the method, raw materials are cheap, the raw material source is convenient, product separating and purifying is simple, industrial production is easy, and a littlethree industrial wastes (waste solid, waste water and waste gas) is generated.

Owner:天津航大翼安科技发展有限公司

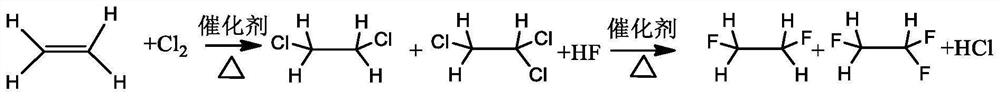

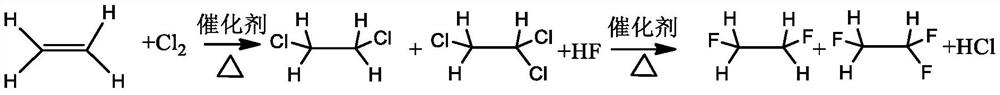

A method for synthesizing 1,2-difluoroethane and 1,1,2-trifluoroethane

ActiveCN111116304BConvenient sourceLow pricePreparation by halogen replacementPreparation by halogen additionChemical synthesisHydrogen fluoride

The invention relates to "a method for synthesizing 1,2 difluoroethane and 1,1,2 trifluoroethane", which belongs to the field of organic chemical synthesis. This method for synthesizing 1,2-difluoroethane and 1,1,2-trifluoroethane is characterized in that ethylene (molecular formula CH 2 =CH 2 ) and chlorine gas (molecular formula Cl 2 ) is heated under the action of a catalyst to generate a mixture of 1,2-dichloroethane and 1,1,2-trichloroethane, which is heated with hydrogen fluoride (molecular formula HF) under the action of a fluorination catalyst to generate 1,2 ‑Difluoroethane and 1,1,2‑trifluoroethane. The invention has cheap raw materials and convenient sources; simple separation and purification of products; easy industrial production; and less industrial waste.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

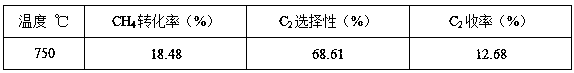

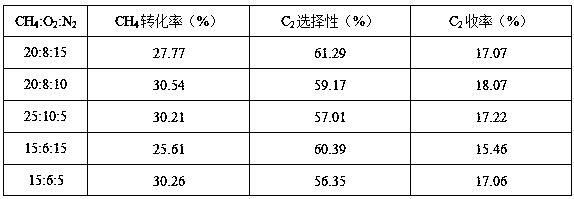

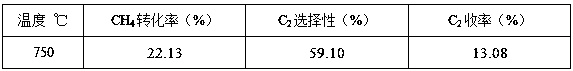

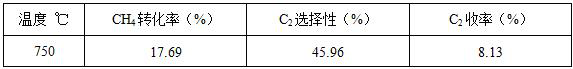

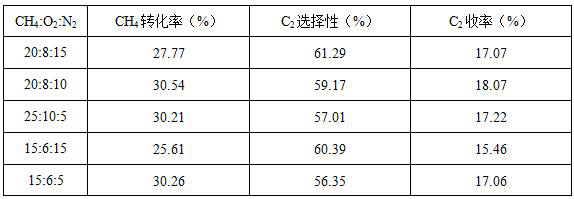

A kind of preparation method of solid acid catalyst for producing ethylene by oxidative coupling of methane

ActiveCN109289833BImprove response resultsInhibit deep oxidationCatalystsHydrocarbon preparation catalystsPtru catalystSolid acid

The present invention relates to a kind of preparation method of methane oxidative coupling ethylene solid acid catalyst, the method comprises the following steps: (1) TiO 2 Fully grind to 6000~7000 mesh, add it to the tungsten salt solution, impregnate with ultrasonic, stir and evaporate to dryness in a water bath to obtain the tungsten-titanium solid acid precursor; the tungsten-titanium solid acid precursor is roasted and ground into powder to obtain WO 3 Solid acid WO with a content of 5 wt%~15 wt% 3 / TiO 2 Carrier; (2) Add LiNO sequentially in ionized water 3 , Mn(NO 3 ) 2 , and make it completely dissolved, and then impregnate the solid acid WO with excess impregnation method 3 / TiO 2 carrier to obtain impregnation; (3) stirring and evaporating the impregnation in a water bath, grinding it into powder and roasting to obtain a solid acid catalyst. The preparation method of the invention is simple, the preparation conditions are mild, and the three industrial wastes are less, and the obtained catalyst has the advantages of good performance, long service life and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

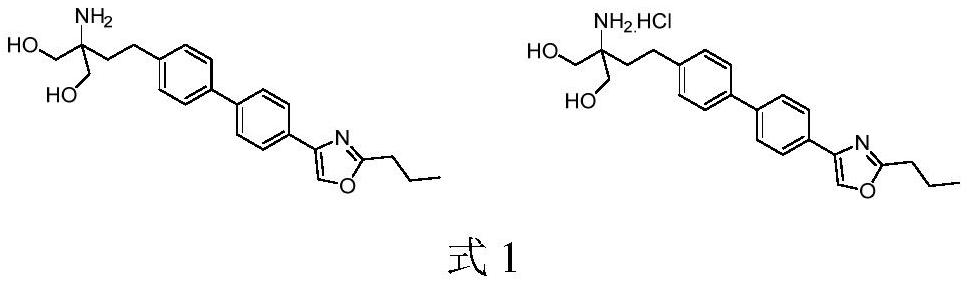

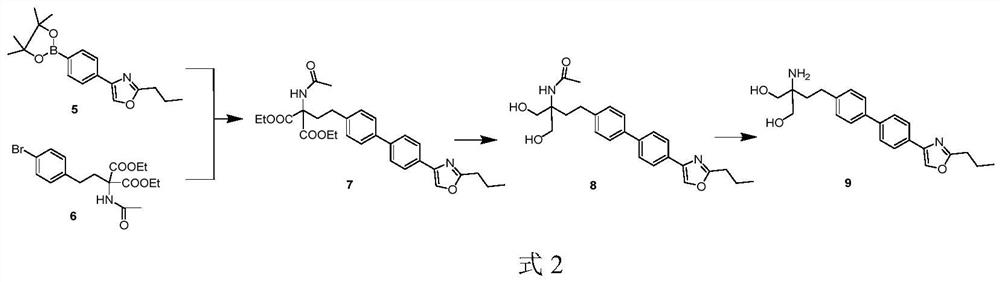

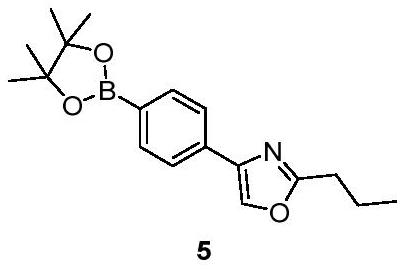

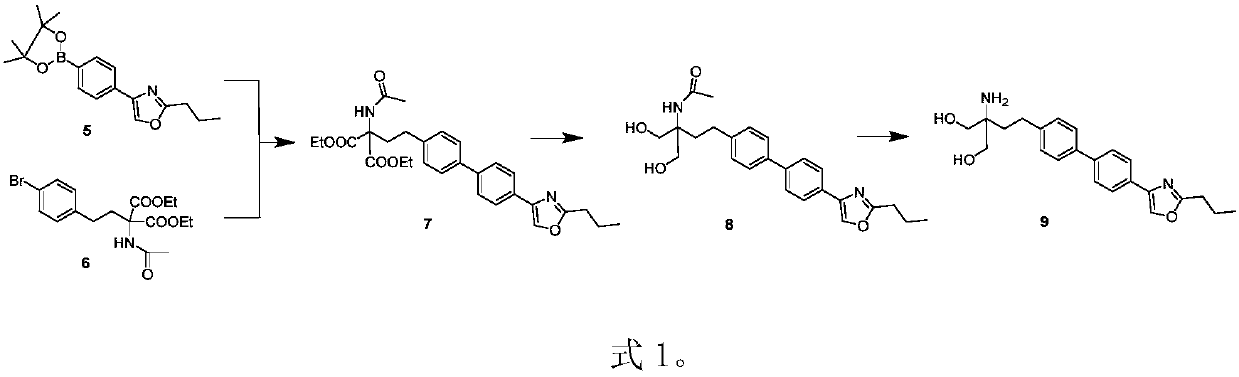

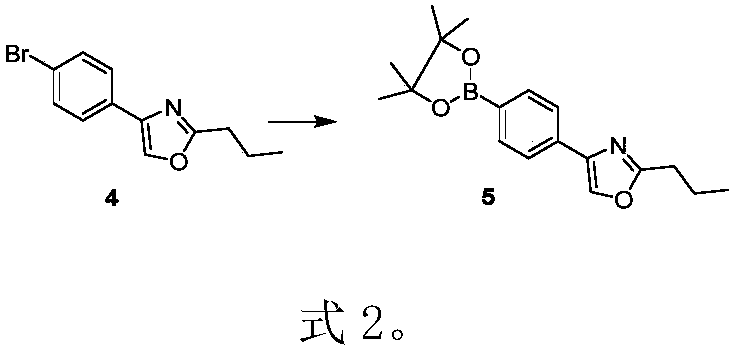

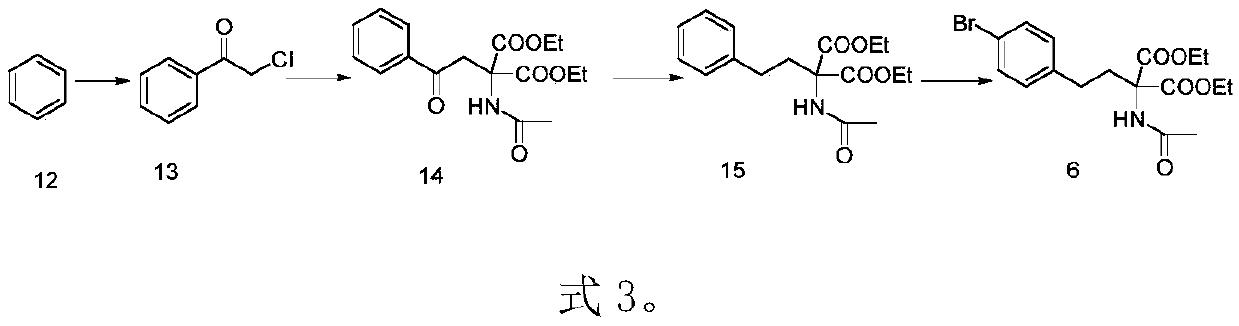

The preparation method of Prosymod

ActiveCN111087358BHigh yieldHigh purityGroup 3/13 element organic compoundsBiochemical engineeringBromobenzenes

The invention discloses a preparation method of prosamod, which uses bromobenzene and benzene as starting materials to prepare prosamod by adopting a convergent synthesis route. The method has high yield, low cost, less pollution of three wastes, and is easy to operate. It has high application value.

Owner:渐宽(苏州)生物科技有限公司 +1

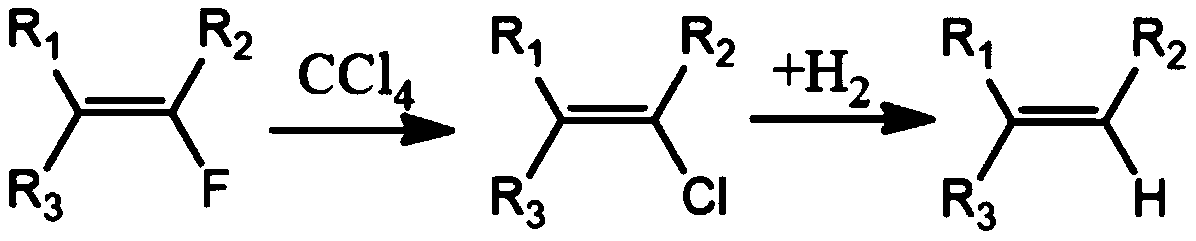

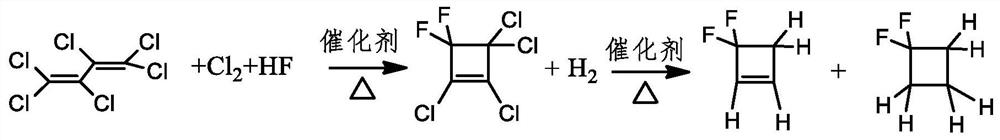

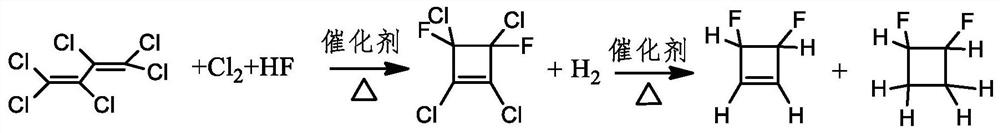

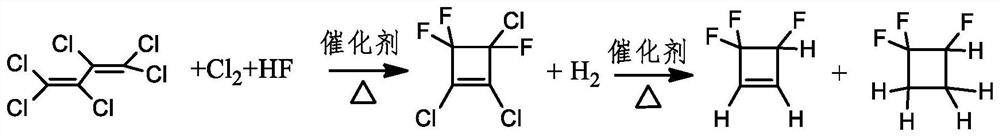

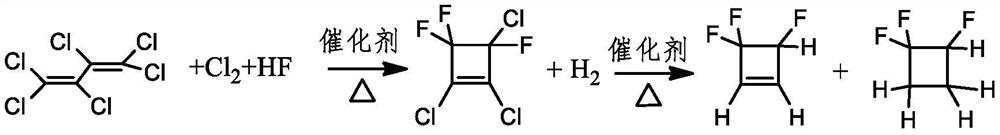

A kind of gas-phase catalytic synthesis method of 4,4-difluorocyclobutene

ActiveCN111039746BConvenient sourceLow pricePreparation by dehalogenationPreparation by halogen replacementChemical synthesisHydrogen fluoride

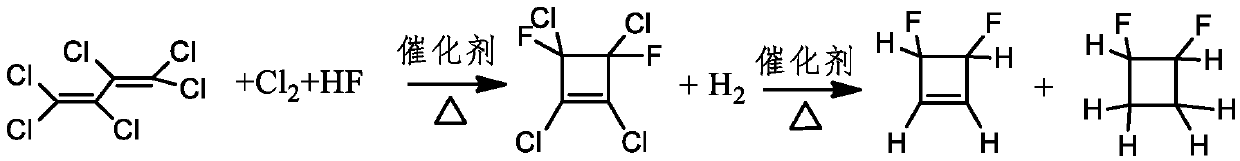

The invention relates to a method for synthesizing 4,4-difluorocyclobutene through gas phase catalysis, and belongs to the field of organic chemical synthesis. The method is characterized in that: hexachlorobutadiene (the molecular formula is CCl2=CCl-CCl=CCl2), chlorine (the molecular formula is Cl2) and anhydrous hydrogen fluoride (the molecular formula is HF) generate 1,2,3,3-tetrachloro-4,4-difluorocyclobutene (the molecular formula is Cyclo-CF2-CCl2-CCl=CCl-) in a gas phase manner under the action of a cyclofluorination catalyst. Then, under the action of a hydrodechlorination catalyst, the 1,2,3,3-tetrachloro-4,4-difluorocyclobutene and hydrogen are subjected to a gas phase reaction to generate the 4,4-difluorocyclobutene (the molecular formula is Cyclo-CF2-CH2-CH=CH-). The raw materials are cheap and convenient to obtain; the product separation and purification are simple; the industrial production is easy; industrial three wastes are reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A kind of method for preparing 1,3-butanediol by using fixed bed continuous reaction

ActiveCN112390712BEfficient condensation reactionSimple methodOrganic compound preparationHydroxy compound preparationPtru catalystFixed bed

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparation method of pusaimode (Chinese name)

ActiveCN111087358AHigh yieldHigh purityGroup 3/13 element organic compoundsBenzeneEnvironmental engineering

The invention discloses a preparation method of pusaimode. Bromo-benzene and benzene are used as initial raw materials to prepare pusaimode by adopting a convergent synthesis route. The yield of the preparation method is high, the cost is low, the amount of generated waste water, waste gas, and waste solids is low, the operation is convenient, and the application value is high.

Owner:渐宽(苏州)生物科技有限公司 +1

A kind of preparation method of nano ruthenium carbon supported catalyst

ActiveCN105498761BIncrease temperatureExtended service lifeCarboxylic preparation by ozone oxidationMetal/metal-oxides/metal-hydroxide catalystsCeriumSlurry

The invention discloses a method for preparing a nanometer ruthenium carbon-supported catalyst. The method includes the following steps: adding treated activated carbon to a ruthenium salt solution, stirring and impregnating it for 0.5-4 h, and then using an aqueous alkaline compound solution to adjust the activated carbon and ruthenium. The pH of the salt mixed slurry reaches 7-12, continue stirring for 1-6 hours, let it stand for 2-4 hours, and filter. After the filter cake is washed with water until neutral and free of chloride ions, the filter cake is heated at a temperature of 80-120°C. The treated ruthenium carbon precursor is obtained by drying for 4-12 hours under low temperature; the treated ruthenium carbon precursor is roasted in sections under inert atmosphere conditions; the roasted product is reduced to obtain highly dispersed nano-ruthenium carbon-loaded type Catalyst, the particle size of the ruthenium particles of the catalyst is 1‑4 nm. The method of the present invention has the advantages of low production cost, mild preparation conditions, less industrial waste, and long service life of the catalyst obtained.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of preparation method of 1,1,1,2,4,4,4-heptafluoro-2-butene

ActiveCN108911947BLess industrial wasteReduce manufacturing costPreparation by halogen replacementCatalyst activation/preparationHydrogen fluorideHexachlorobutadiene

The invention discloses a preparation method of 1,1,1,2,4,4,4-heptafluoro-2-butene. In the method, hexachlorobutadiene and hydrogen fluoride are used as raw materials, and under gas-phase conditions, a chromium-based catalyst is used as a fluorine-chlorine exchange catalyst, and 1, 1, 1, 2, 4, 4, 4- Heptafluoro-2-butene. Compared with the prior art, the preparation method of 1,1,1,2,4,4,4-heptafluoro-2-butene provided by the present invention has the following advantages: 1. The gas-phase fluorination method adopted in the present invention is Cyclic fluorination has fewer industrial three wastes and greatly reduces production costs; 2. The present invention can realize rapid multiple cycle fluorination, improve product yield, and simple product separation and purification; 3. It has cheap raw materials, convenient sources and simple operation. Advantages, suitable for industrial production.

Owner:CIVIL AVIATION UNIV OF CHINA

A kind of gas-phase catalytic synthesis method of 3,4-difluorocyclobutene

ActiveCN110981689BConvenient sourceLow pricePreparation by dehalogenationChemical synthesisHexachlorobutadiene

The invention relates to a method for synthesizing 3,4-difluorocyclobutene through gas phase catalysis, and belongs to the field of organic chemical synthesis. According to the method, hexachlorobutadiene (the molecular formula is CCl2=CCl-CCl=CCl2), chlorine gas (the molecular formula is Cl2) and anhydrous hydrogen fluoride (the molecular formula is HF) generate 1,2,3,4-tetrachloro-3,4-difluorocyclobutene (the molecular formula is Cyclo-CFCl-CFCl-CCl=CCl-) in a gas phase manner under the action of a cyclofluorination catalyst; and under the action of a hydrodechlorination catalyst, the 1,2,3,4-tetrachloro-3, 4-difluorocyclobutene and hydrogen generate 3,4-difluorocyclobutene (the molecular formula is Cyclo-CFH-CFH-CH=CH-) in a gas phase manner. According to the invention, the method has characteristics of cheap and easily-available raw materials, simple separation and purification of the product and less industrial three-waste, and is suitable for industrial production.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

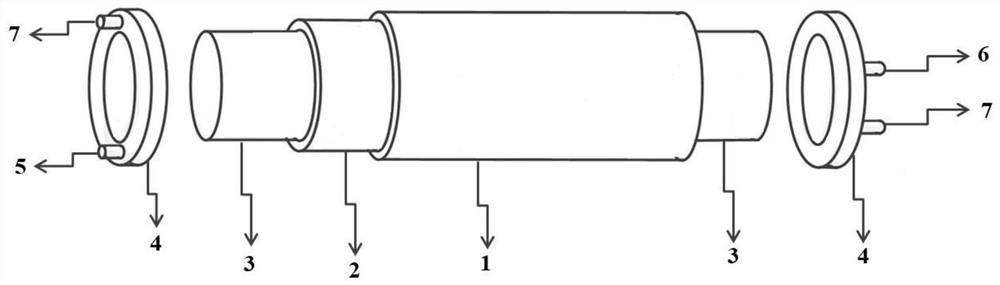

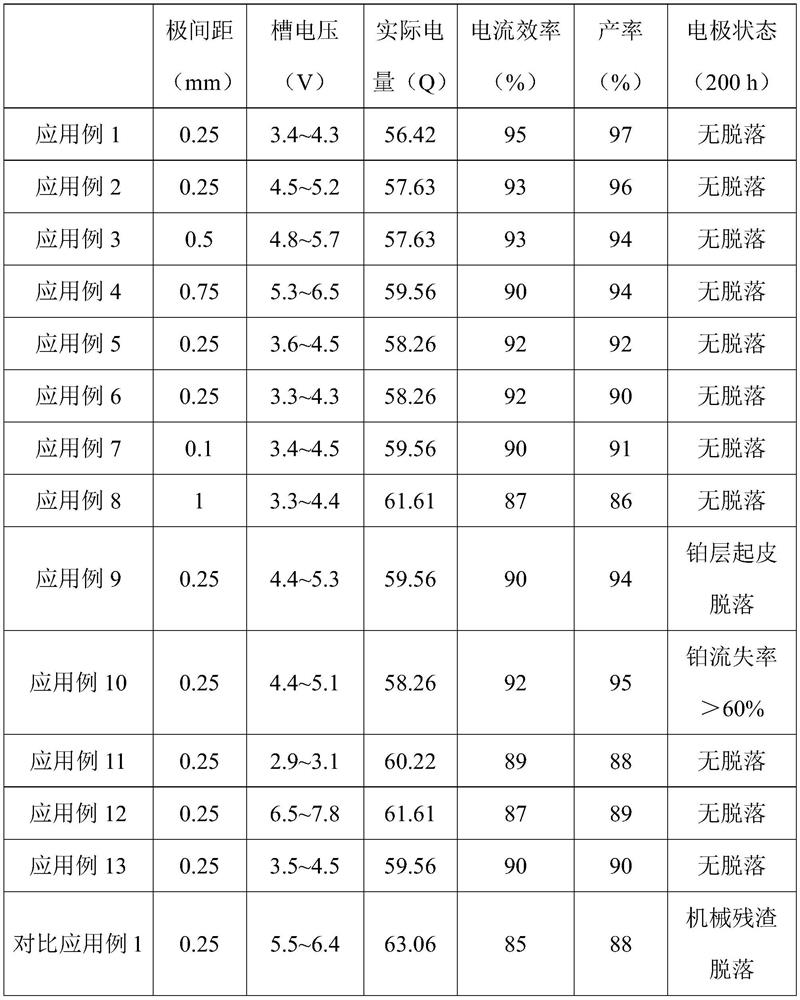

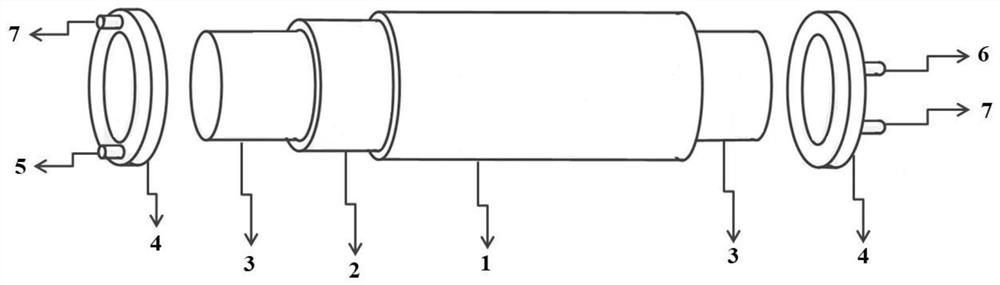

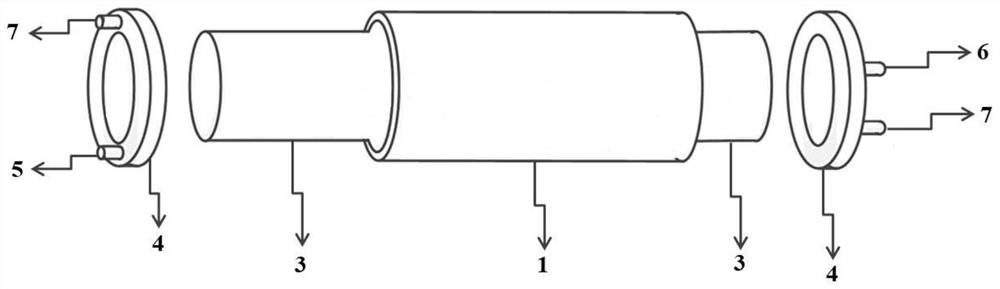

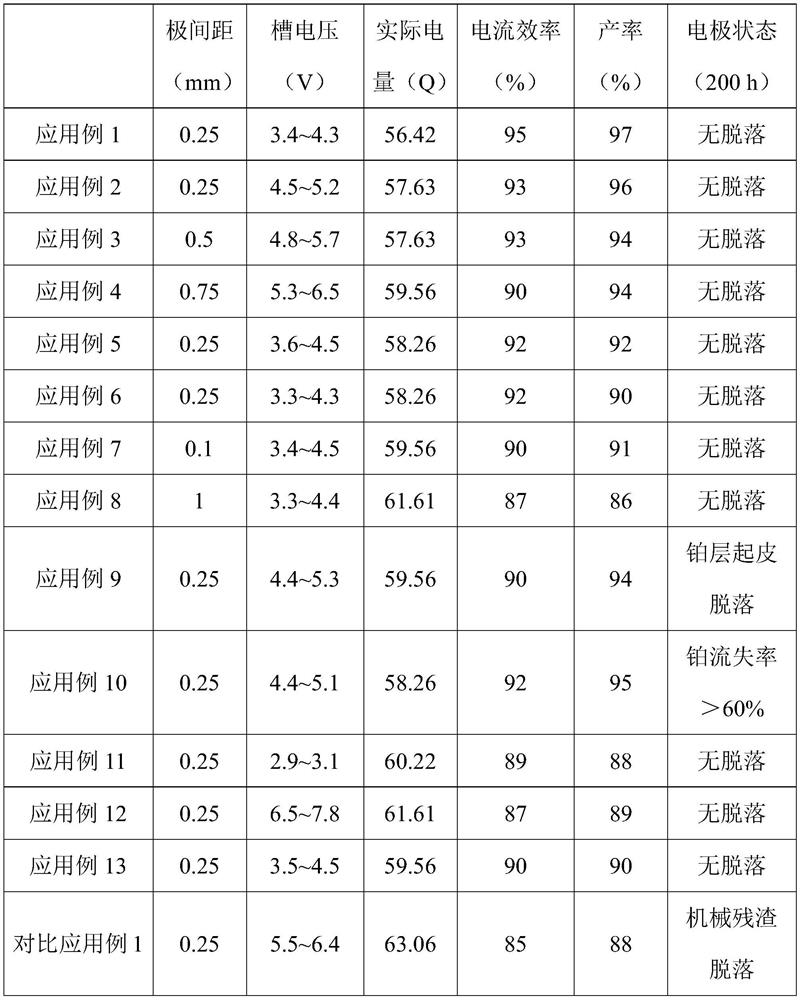

A sleeve-type microchannel electrolytic reaction device and its application

The present invention provides a casing type microchannel electrolysis reaction device and its application. The casing type microchannel electrolysis reaction device includes electrodes, feed pipes, discharge pipes and wiring piles; For the inner electrode in the outer tube electrode, the distance between the outer tube electrode and the inner electrode is 0.1-1mm; the outer tube electrode and the inner electrode are each independently selected from metal electrodes, carbon electrodes or conductive polymer electrodes , and at least one of them is a platinum-plated titanium electrode. The special design of the sleeve-type electrode realizes the fine and flexible adjustment of the electrode spacing, improves the current efficiency under the premise of ensuring the reaction conversion rate, makes the reaction conditions more mild and controllable, the reaction time is shorter, and reduces the waste of industrial waste. The production can fully meet the requirements of high efficiency, low energy consumption and environmental protection in the synthesis of organic compounds, and is especially suitable for the electrolytic preparation of substituted furan compounds or substituted pyrrole compounds.

Owner:WANHUA CHEM GRP CO LTD

Sleeve type micro-channel electrolytic reaction device and application thereof

The invention provides a sleeve type micro-channel electrolytic reaction device and an application thereof. The sleeve type micro-channel electrolytic reaction device comprises an electrode, a feedingpipe, a discharging pipe and a wiring pile; the electrode comprises an outer tube electrode and an inner electrode arranged in the outer tube electrode in a penetrating mode, and the distance betweenthe outer tube electrode and the inner electrode ranges from 0.1 mm to 1 mm. The outer tube electrode and the inner electrode are respectively and independently selected from a metal electrode, a carbon electrode or a conductive polymer electrode, and at least one of the outer tube electrode and the inner electrode is a titanium-plated platinum electrode. Due to the special design of the sleeve type electrode, fine, flexible and adjustable electrode spacing is realized, the current efficiency is improved on the premise of ensuring the reaction conversion rate, the reaction conditions are milder and more controllable, the reaction time is shorter, and the generation of industrial three wastes is reduced. The device can fully meet the requirements of high efficiency, low energy consumptionand environmental protection in organic compound synthesis, and is especially suitable for electrolytic preparation of substituted furan compounds or substituted pyrrole compounds.

Owner:WANHUA CHEM GRP CO LTD

A kind of method for synthesizing hexafluoro-2-butyne

ActiveCN105348034BHigh yieldConvenient sourcePreparation by halogen replacementHexachlorobutadieneCCL2

The invention discloses a hexafluoropropylene-2-butyne synthesizing method. Hexachlorobutadiene (CCl2=CCl-CCl=CCl2) is taken as the raw material to generate hexafluoropropylene-2-butyne under the action of a catalyst, the raw material hexachlorobutadiene is easy to obtain and low in cost. The gaseous-phase circulating fluorination method is adopted, the discharge level of three industrial wastes is low, the yield of products is high, and production cost is reduced greatly; the gaseous-phase circulating fluorination method is conducted at normal temperature, the traditional high-pressure telomerization process route is avoided, and risks in industrial safety production are reduced greatly; meanwhile, the method has the advantage that operation is easy and is totally suitable for industrial production.

Owner:TIANJIN MEDICAL UNIV

A kind of nano ruthenium carbon catalyst and its preparation method and application

ActiveCN108993497BAvoid desorptionInhibit migrationOrganic compound preparationCatalyst activation/preparationActivated carbonPtru catalyst

The invention discloses a nano-ruthenium carbon catalyst as well as a preparation method and application thereof. The catalyst includes active carbon, active ruthenium particles supported thereon and auxiliary components, and the auxiliary components include zinc, copper, nickel and the like. The preparation method comprises: immersing activated carbon in an aqueous solution of ruthenium salt, adding a basic compound, stirring and standing still, filtering and drying, and roasting to obtain the first ruthenium carbon precursor, then immersing in an aqueous solution of an auxiliary agent, and then adding a basic compound , after stirring and standing still, filter and dry to obtain the second ruthenium carbon precursor; in a protective atmosphere, the second ruthenium carbon precursor is subjected to segmental roasting treatment to obtain the third ruthenium carbon precursor, followed by reduction treatment, obtain the catalyst. The catalyst of the invention can be reused more than one hundred times in the hydrogenation reaction of aromatic ring compounds to prepare cyclohexyl derivatives, and has the advantages of long service life, low production cost, mild reaction conditions, high product purity and less industrial waste.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of method of gas phase catalytic synthesis 3,4,4-trifluorocyclobutene

ActiveCN110981688BConvenient sourceLow pricePreparation by dehalogenationMetal/metal-oxides/metal-hydroxide catalystsHydrogen fluorideHexachlorobutadiene

The invention relates to "a method for gas phase catalytic synthesis of 3,4,4-trifluorocyclobutene" and belongs to the field of organic chemical synthesis. This method for synthesizing 3,4,4-trifluorocyclobutene is characterized by: hexachlorobutadiene (molecular formula CCl 2 =CCl‑CCl=CCl 2 ), chlorine (molecular formula Cl 2 ), anhydrous hydrogen fluoride (molecular formula HF) generates 1,2,3-trichloro-3,4,4-trifluorocyclobutene (molecular formula Cyclo-CF) in the gas phase under the action of the ring fluorination catalyst 2 -CFCl-CCl=CCl-). Then, 1,2,3-trichloro-3,4,4-trifluorocyclobutene and hydrogen generate 3,4,4-trifluorocyclobutene (molecular formula Cyclo- CF 2 ‑CFH‑CH=CH‑). The invention has cheap raw materials and convenient sources; the product is simple to separate and purify; easy for industrial production; and has less industrial waste.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

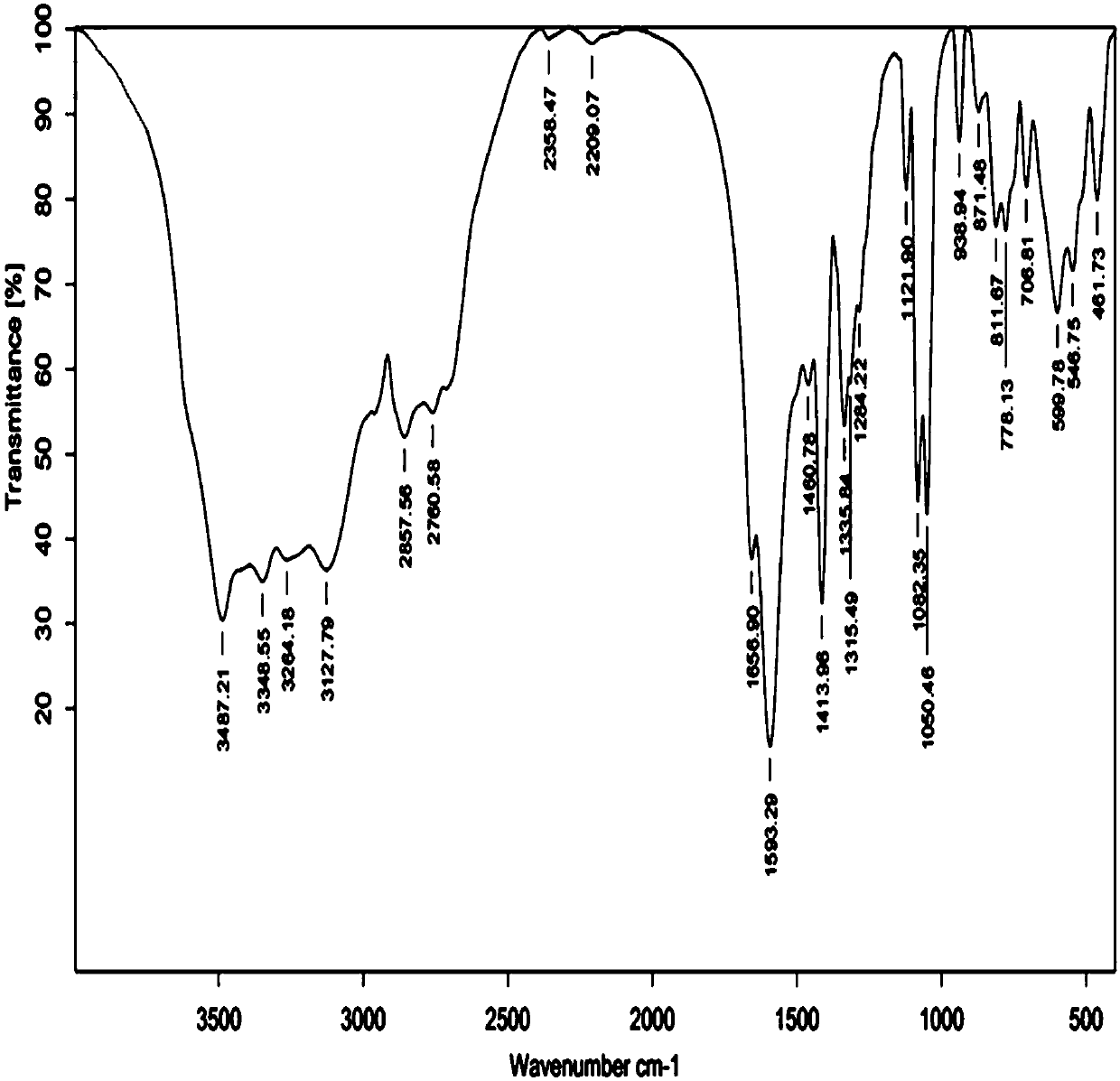

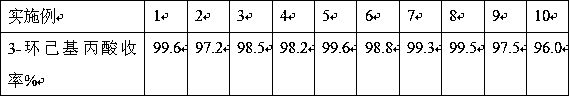

n-[(3,4,5-trifluoro)phenyl]acrylamide and its preparation method

ActiveCN110372529BLow priceWeak priceOrganic compound preparationCarboxylic acid amides preparationSodium bicarbonatePtru catalyst

The invention belongs to the technical field of organic synthesis, and specifically relates to N-[(3,4,5-trifluoro)phenyl]acrylamide and a preparation method thereof. The specific steps of the preparation method of N-[(3,4,5-trifluoro)phenyl]acrylamide are as follows: (1) 3,4,5-trifluoroaniline, reaction solvent and catalyst are added to the reaction vessel, stirred and mixed Then add acryloyl chloride and react at -10°C to 30°C for 1 to 7 hours; (2) Add water to the reaction solution obtained in step (1), stir and mix, filter, separate the precipitate, and dry the precipitate , to obtain N‑[(3,4,5‑trifluoro)phenyl]acrylamide. The preparation method of the present invention has simple and easy-to-obtain raw materials, low cost, simple operation, high yield and high purity of N-[(3,4,5-trifluoro)phenyl]acrylamide; weakly basic catalyst—sodium bicarbonate The reaction amplification process is simple and feasible, the three wastes produced by the reaction are less, and the reaction is green and environmentally friendly.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

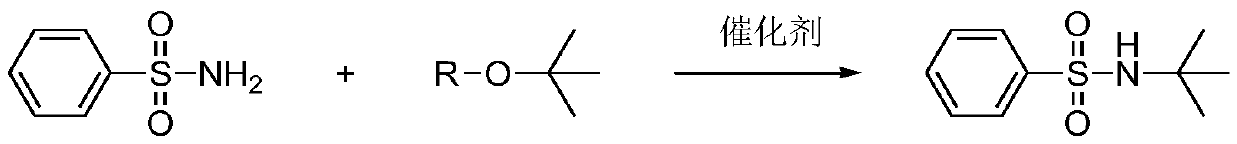

A kind of synthetic method of n-tert-butylbenzenesulfonamide

ActiveCN107459471BInexpensive and easy to obtain activityLow costSulfonic acid amide preparationDesolvationTert-butylbenzene

The invention discloses a synthesis method of N-tert-butylbenzenesulfonamide. The method comprises the following steps: putting benzenesulfonamide, materials, a catalyst and a solvent into a four-necked flask and stirring; heating and carrying out reflowing reaction; when the raw material benzenesulfonamide disappears, reaching a reaction end point to obtain a reactant; cooling the reactant to room temperature; filtering to remove an insoluble substance; carrying out decompression and desolvation to obtain the N-tert-butylbenzenesulfonamide.

Owner:CHANGZHOU HIGH TECH RES INST OF NANJING UNIV

A kind of method for replacing fluorine on double bond of fluorine-containing olefin into hydrogen

ActiveCN107759440BSave raw materialsConvenient sourcePreparation by dehalogenationPreparation by halogen replacementChemical synthesisPtru catalyst

Owner:天津航大翼安科技发展有限公司

A kind of synthetic method of phenyl glycol

ActiveCN108129260BHigh purityHigh yieldOrganic compound preparationPreparation by hydrolysisStyrene oxidePtru catalyst

The invention provides a kind of synthetic method of phenylethylene glycol, and this synthetic method comprises the following steps: (1) reaction: add styrene oxide, phase transfer catalyst, 2-chloroethyl in the flask with thermometer, reflux condenser Amine hydrochloride, inorganic alkali, water, stirring, heating and reflux reaction; (2) End point monitoring: the reaction of step (1) is monitored by HPLC, when the raw material styrene oxide disappears, it is the end point of the reaction; (3) Extraction: When the reaction in step (1) reaches the end of the reaction, stop heating, cool the system to room temperature, extract with an organic solvent, separate the organic layer, and precipitate under reduced pressure to obtain a white solid. The prepared product has high purity and yield, reduces three industrial wastes, is environmentally friendly, and meets the requirements of green chemical technology.

Owner:CHANGZHOU HIGH TECH RES INST OF NANJING UNIV

Method for gas phase catalytic synthesis of 3,4-difluorocyclobutene

ActiveCN110981689AConvenient sourceLow pricePreparation by dehalogenationChemical synthesisHydrogen fluoride

The invention relates to a method for synthesizing 3,4-difluorocyclobutene through gas phase catalysis, and belongs to the field of organic chemical synthesis. According to the method, hexachlorobutadiene (the molecular formula is CCl2=CCl-CCl=CCl2), chlorine gas (the molecular formula is Cl2) and anhydrous hydrogen fluoride (the molecular formula is HF) generate 1,2,3,4-tetrachloro-3,4-difluorocyclobutene (the molecular formula is Cyclo-CFCl-CFCl-CCl=CCl-) in a gas phase manner under the action of a cyclofluorination catalyst; and under the action of a hydrodechlorination catalyst, the 1,2,3,4-tetrachloro-3, 4-difluorocyclobutene and hydrogen generate 3,4-difluorocyclobutene (the molecular formula is Cyclo-CFH-CFH-CH=CH-) in a gas phase manner. According to the invention, the method has characteristics of cheap and easily-available raw materials, simple separation and purification of the product and less industrial three-waste, and is suitable for industrial production.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Preparation method of solid acid catalyst for oxidative coupling of methane to ethylene

ActiveCN109289833AImprove response resultsInhibit deep oxidationCatalystsHydrocarbon preparation catalystsWater bathsSolid acid

The invention relates to a preparation method of a solid acid catalyst for oxidative coupling of methane to ethylene. The method comprises the steps of: (1) fully grinding TiO2 to 6000-7000 meshes, then adding the ground TiO2 into a tungsten salt solution, conducting ultrasonic impregnation, stirring and evaporation to dryness in water bath to obtain a tungsten-titanium solid acid precursor; roasting and grinding the tungsten-titanium solid acid precursor into powder, thus obtaining a WO3 / TiO2 carrier with a WO3 content of 5wt%-15wt%; (2) adding LiNO3 and Mn(NO3)2 into ionized water in order for complete dissolution, and then impregnating the solid acid WO3 / TiO2 carrier by excessive impregnation process to obtain an impregnated substance; and (3) subjecting the impregnated substance to stirring and evaporation to dryness in water bath, performing grinding into powder, and then conducting roasting to obtain the solid acid catalyst. The preparation method provided by the invention has the characteristics of simplicity, mild preparation conditions and few industrial three wastes, and the obtained catalyst has the advantages of good performance, long service life and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![n-[(3,4,5-trifluoro)phenyl]acrylamide and its preparation method n-[(3,4,5-trifluoro)phenyl]acrylamide and its preparation method](https://images-eureka.patsnap.com/patent_img/7053b107-5097-4e79-b39a-61f3df9f2282/190808172508.png)

![n-[(3,4,5-trifluoro)phenyl]acrylamide and its preparation method n-[(3,4,5-trifluoro)phenyl]acrylamide and its preparation method](https://images-eureka.patsnap.com/patent_img/7053b107-5097-4e79-b39a-61f3df9f2282/190808172512.png)

![n-[(3,4,5-trifluoro)phenyl]acrylamide and its preparation method n-[(3,4,5-trifluoro)phenyl]acrylamide and its preparation method](https://images-eureka.patsnap.com/patent_img/7053b107-5097-4e79-b39a-61f3df9f2282/190808172516.png)