A kind of synthetic method of phenyl glycol

A technology of phenylethylene glycol and synthesis method, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems that do not meet the requirements of green chemistry development, the catalytic reaction efficiency is not high, and the catalyst is difficult to obtain and other problems, to achieve the effect of easy availability of catalyst, reduction of industrial three wastes, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

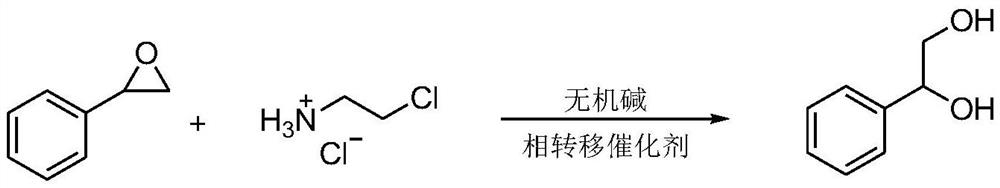

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: preparation of phenyl glycol

[0019] (1) Reaction: Add styrene oxide 5g (41.67mmol), tetrabutylammonium bromide 5mg, 2-chloroethylamine hydrochloride 0.48g (4.17mmol), carbonic acid Sodium hydrogen 0.34g (4.17mmol), water 50mL, stirring, heating to reflux, the reaction temperature is 40°C;

[0020] (2) End point monitoring: the reaction of step (1) is monitored by HPLC, and when the raw material styrene oxide disappears, it is the end point of the reaction;

[0021] (3) Extraction: When the reaction in step (1) reaches the end point, stop heating, cool the system to room temperature, extract with 80 mL of ethyl acetate, separate the ethyl acetate layer, and precipitate under reduced pressure to obtain a white solid.

[0022] The yield of phenylethylene glycol was 99%, the purity was 98.5% (as determined by HPLC), the melting point was 63-65° C., and the MS m / z was 161.05 (M+Na, 100).

Embodiment 2

[0023] Embodiment 2: preparation of phenyl glycol

[0024] (1) Reaction: Add styrene oxide 10g (83.34mmol), tetrabutylammonium bromide 12mg, 2-chloroethylamine hydrochloride 0.7g (6.03mmol), carbonic acid Sodium hydrogen 0.506g (6.03mmol), water 120mL, stirring, heating to reflux, the reaction temperature is 45°C;

[0025] (2) End point monitoring: the reaction of step (1) is monitored by HPLC, and when the raw material styrene oxide disappears, it is the end point of the reaction;

[0026] (3) Extraction: When the reaction in step (1) reaches the end point, stop heating, cool the system to room temperature, extract with 120 mL of ethyl acetate, separate the ethyl acetate layer, and precipitate under reduced pressure to obtain a white solid.

[0027] The yield of phenylethylene glycol was 97%, the purity was 96% (as determined by HPLC), the melting point was 63-65° C., and the MS m / z was 161.05 (M+Na, 100).

Embodiment 3

[0028] Embodiment 3: preparation of phenyl glycol

[0029] (1) Reaction: Add styrene oxide 3g (25mmol), tetrabutylammonium bromide 24mg, 2-chloroethylamine hydrochloride 0.29g (2.5mmol), bicarbonate Sodium 0.21g (2.5mmol), water 60mL, stirred, heated to reflux, the reaction temperature is 37°C;

[0030] (2) End point monitoring: the reaction of step (1) is monitored by HPLC, and when the raw material styrene oxide disappears, it is the end point of the reaction;

[0031] (3) Extraction: When the reaction in step (1) reaches the end of the reaction, stop heating, cool the system to room temperature, extract with 60 mL of ethyl acetate, separate the ethyl acetate layer, and precipitate under reduced pressure to obtain a white solid.

[0032] The yield of phenylethylene glycol was 96%, the purity was 98% (as determined by HPLC), the melting point: 63-65° C., MS m / z: 161.05 (M+Na, 100).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com