Preparation method of solid acid catalyst for oxidative coupling of methane to ethylene

A technology of solid acid catalyst and oxidative coupling, which is applied in the direction of carbon compound catalyst, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., and can solve the problem of low methane conversion rate, existence safety, and yield Low-level problems, to achieve the effect of good catalytic performance, enhanced activity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

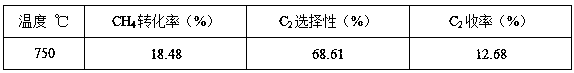

Embodiment 1

[0024] Example 1 A method for preparing a solid acid catalyst for oxidative coupling of methane to ethylene, comprising the following steps:

[0025] (1) Add 2 g of anatase TiO 2 Fully ground to 6000~7000 mesh, added to 0.112 g / 5 mL ammonium metatungstate solution, ultrasonically impregnated for 20 minutes under the condition of ultrasonic frequency of 45KHz and temperature of 20°C, and then stirred and evaporated to dryness in 80°C water bath to obtain Tungsten-titanium solid acid precursor; the tungsten-titanium solid acid precursor is heated to 800°C at a heating rate of 4°C / min in a muffle furnace, roasted for 3 hours, and then ground into powder to obtain WO 3 5 wt% solid acid WO 3 / TiO 2 carrier.

[0026] (2) Add 0.138 g LiNO to 10 mL ionized water in sequence 3 , 0.358 g Mn(NO 3 ) 2 (50%), and make it dissolve completely, then add 1.448 g solid acid WO 3 / TiO 2 The carrier is impregnated by an excessive impregnation method to obtain an impregnation;

[0027] (3...

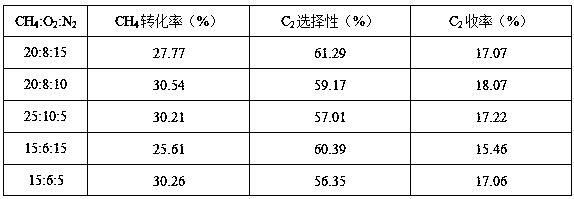

Embodiment 2

[0031] Example 2 A method for preparing a solid acid catalyst for oxidative coupling of methane to ethylene, comprising the following steps:

[0032] (1) Add 2 g of anatase TiO 2 After being fully ground to 6000~7000 mesh, it was added to 0.185 g / 5 mL ammonium metatungstate solution, ultrasonically impregnated for 20 minutes under the conditions of ultrasonic frequency of 200KHz and temperature of 60°C, and then stirred and evaporated to dryness in a water bath of 80°C to obtain Tungsten-titanium solid acid precursor; the tungsten-titanium solid acid precursor is heated to 800°C at a heating rate of 4°C / min in a muffle furnace, roasted for 3 hours, and then ground into powder to obtain WO 3 8 wt% solid acid WO 3 / TiO 2 carrier.

[0033] (2) Add 0.138 g LiNO to 10 mL ionized water in sequence 3 , 0.358 g Mn(NO 3 ) 2 (50%), and make it dissolve completely, then add 1.493 g solid acid WO 3 / TiO 2 The carrier is impregnated by an excessive impregnation method to obtain an ...

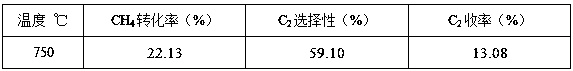

Embodiment 3

[0038] Example 3 A method for preparing a solid acid catalyst for oxidative coupling of methane to ethylene, comprising the following steps:

[0039] (1) Add 2 g of anatase TiO 2 Fully ground to 6000~7000 mesh, added to 0.112 g / 5 mL ammonium metatungstate solution, ultrasonically impregnated for 20 minutes under the condition of ultrasonic frequency of 45KHz and temperature of 20°C, and then stirred and evaporated to dryness in 80°C water bath to obtain Tungsten-titanium solid acid precursor; the tungsten-titanium solid acid precursor is heated to 800°C at a heating rate of 4°C / min in a muffle furnace, roasted for 2 hours, and then ground into powder to obtain WO 3 5 wt% solid acid WO 3 / TiO 2 carrier.

[0040] (2) Add 0.138 g LiNO to 10 mL ionized water in sequence 3 , 0.358 g Mn(NO 3 ) 2 (50%), and make it dissolve completely, then add 1.448 g solid acid WO 3 / TiO 2 The carrier is impregnated by an excessive impregnation method to obtain an impregnation;

[0041] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com