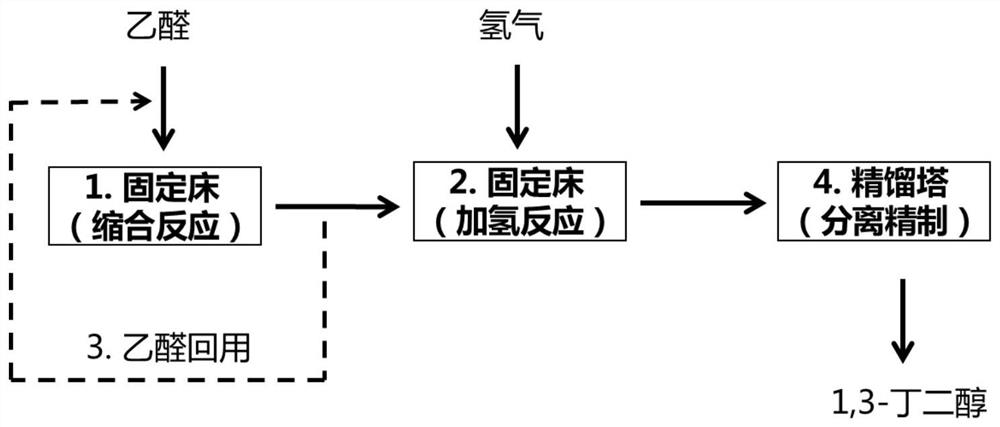

Method for preparing 1, 3-butylene glycol by adopting fixed bed continuous reaction

A fixed-bed reactor and butanediol technology, which is applied to the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of hydroxyl compounds, can solve problems such as inability to recycle, difficult separation, and smaller particle size of Raney nickel. Achieve the effect of simple operation, good stability and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

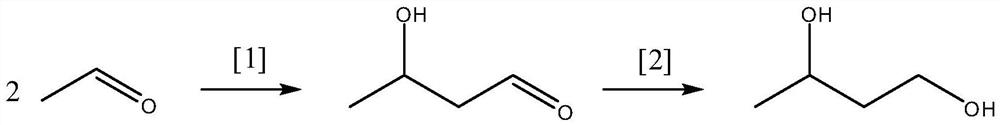

[0054] The solid base catalyst used in the step 1) of the preparation method according to the present invention is packed in a fixed-bed reactor, and the catalyst is stable under reaction conditions, for example, the very important properties of the reaction process include stability to moisture and air , and the impact resistance of reactive materials are very stable. The catalyst can efficiently promote the condensation reaction of acetaldehyde, the reaction mainly generates 3-hydroxybutyraldehyde, and the by-product is crotonaldehyde (also known as crotonaldehyde). The total selectivity of the products 3-hydroxybutyraldehyde and crotonaldehyde of this step reaction is generally above 80%, and under preferred conditions, the total selectivity can exceed 90%, even exceed 95%. The by-product crotonaldehyde of this step reaction is generated by dehydration of 3-hydroxybutyraldehyde. Using the technology developed by the patent of the present invention, the ratio of 3-hydroxybut...

preparation Embodiment 1

[0058] 130g Mg(NO 3 ) 2 ·6H 2 0, 8g of silica gel, 1g of zinc oxide and 1g of activated carbon were mixed in a flask, added 150g of water, stirred at 80°C for 5 hours, evaporated to dryness, then roasted at a high temperature at 900°C in a nitrogen atmosphere, then crushed and sieved, 10 -20 mesh sieve to obtain gray black catalyst particles.

Embodiment 1 to 6

[0059] Embodiment 1 to 6: the condensation reaction of the acetaldehyde reaction raw material of different concentration in fixed-bed reactor

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com