Patents

Literature

80 results about "Glucaric Acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

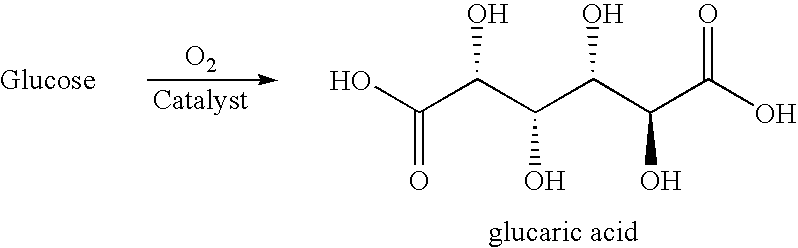

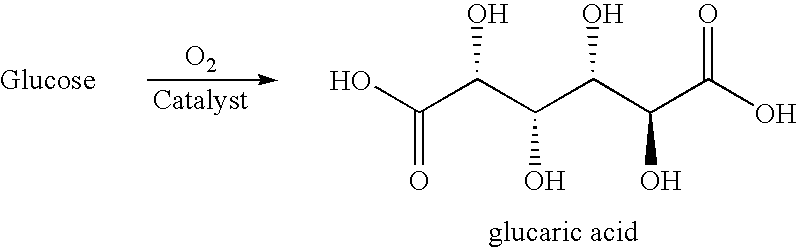

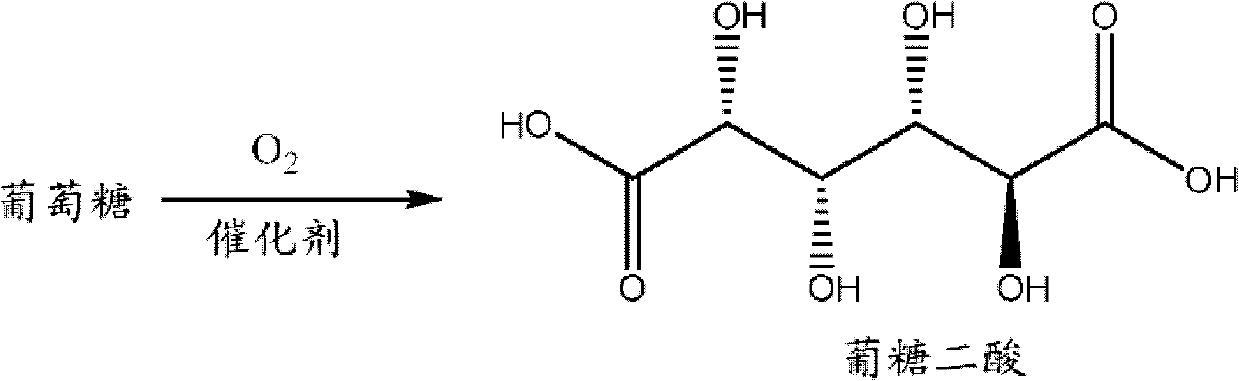

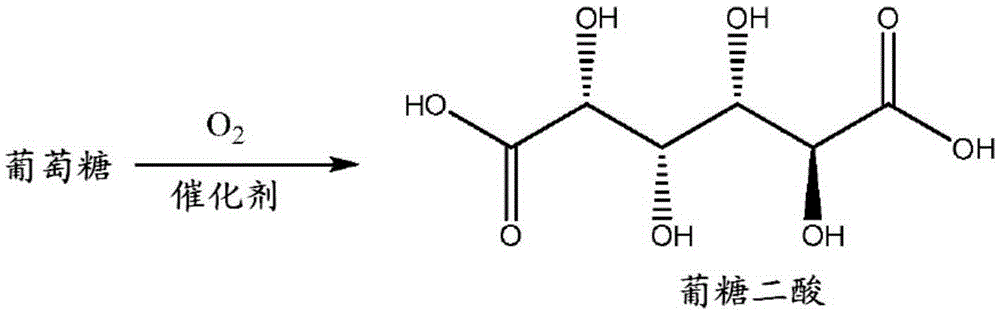

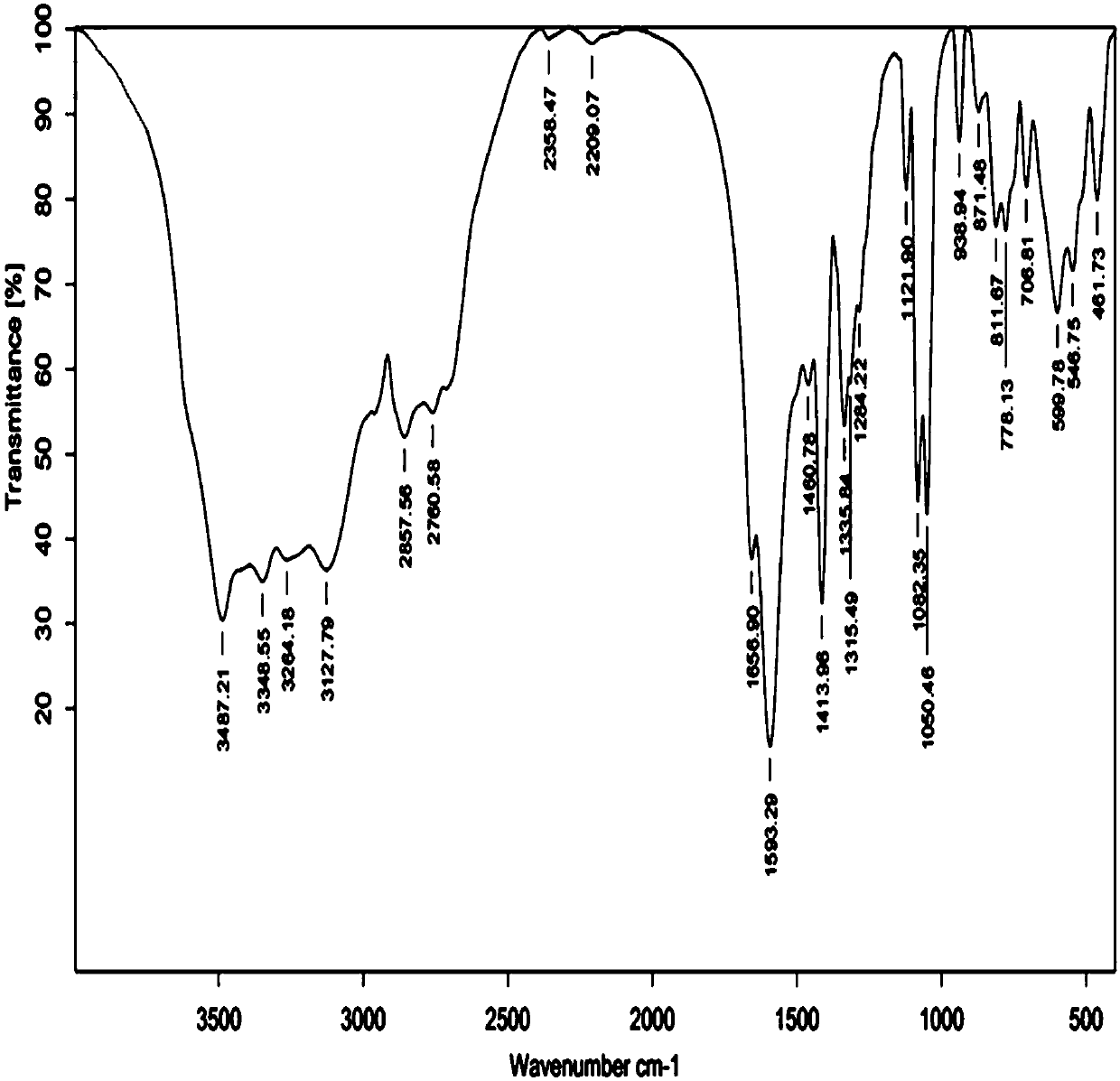

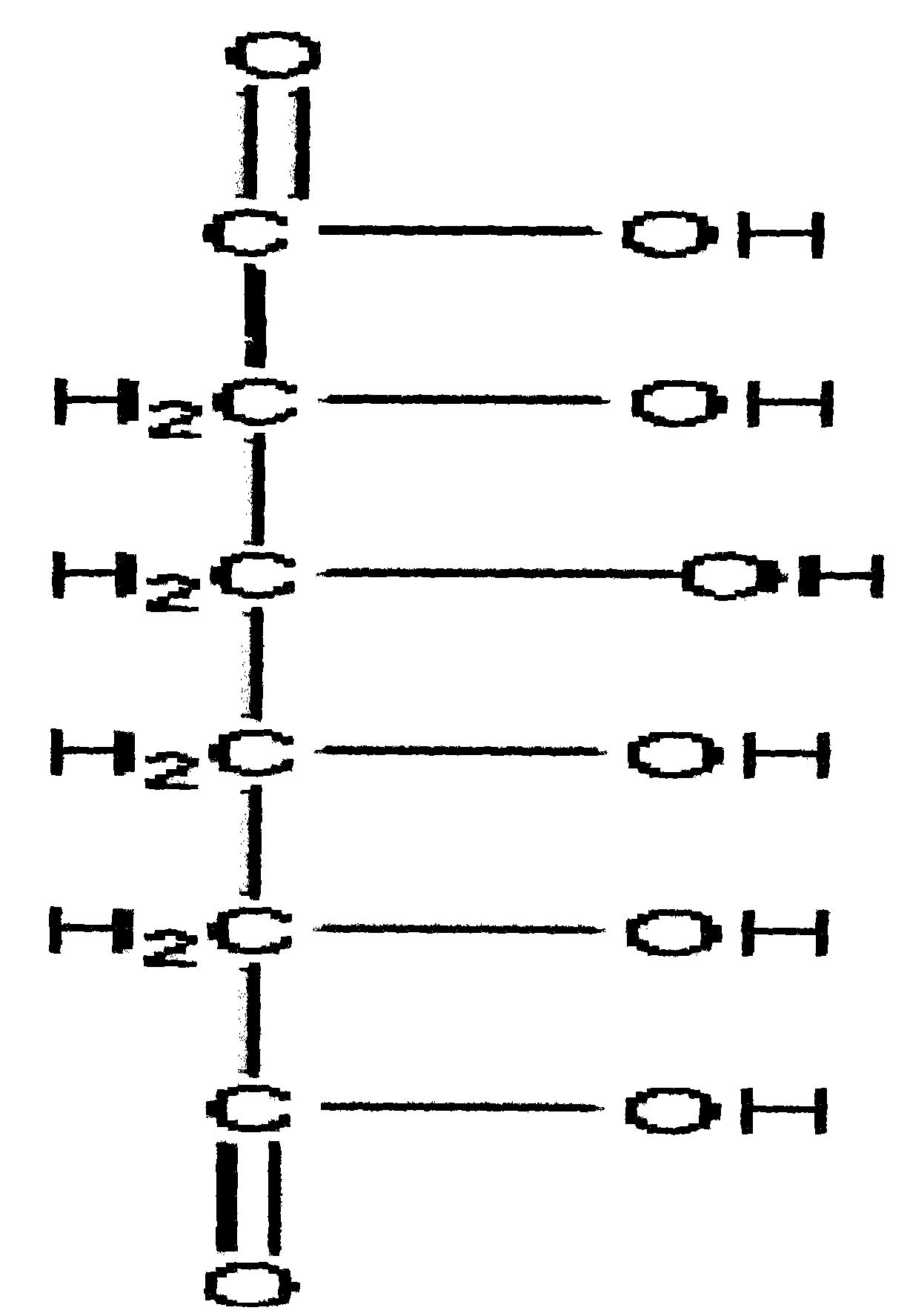

A sugar acid derived from D-glucose in which both the aldehydic carbon atom and the carbon atom bearing the primary hydroxyl group are oxidized to carboxylic acid groups.

Production of adipic acid and derivatives from carbohydrate-containing materials

ActiveUS8669397B2Low costLactams preparationCarboxylic acid nitrile preparationCatalytic oxidationHydrodeoxygenation

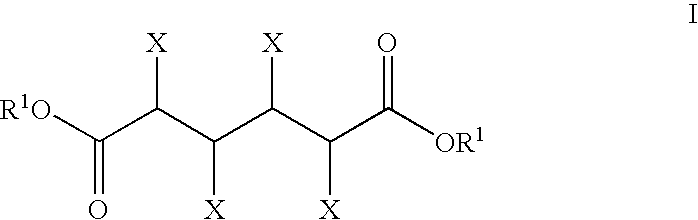

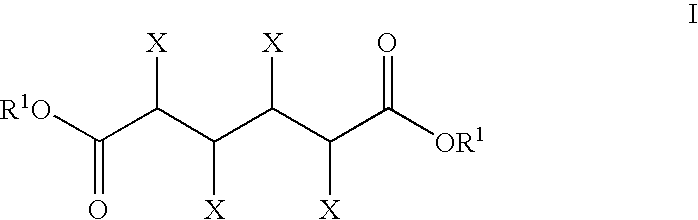

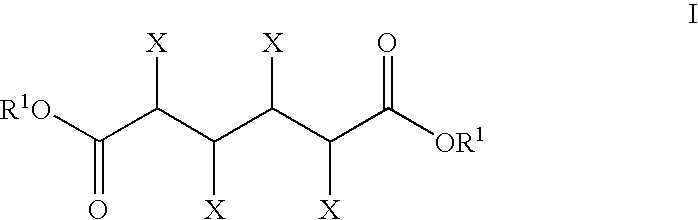

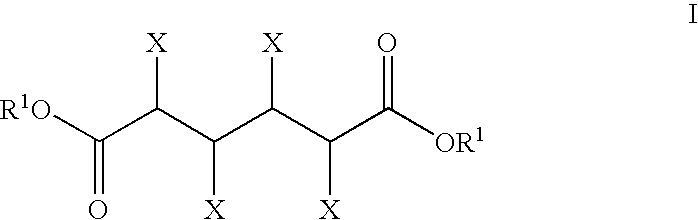

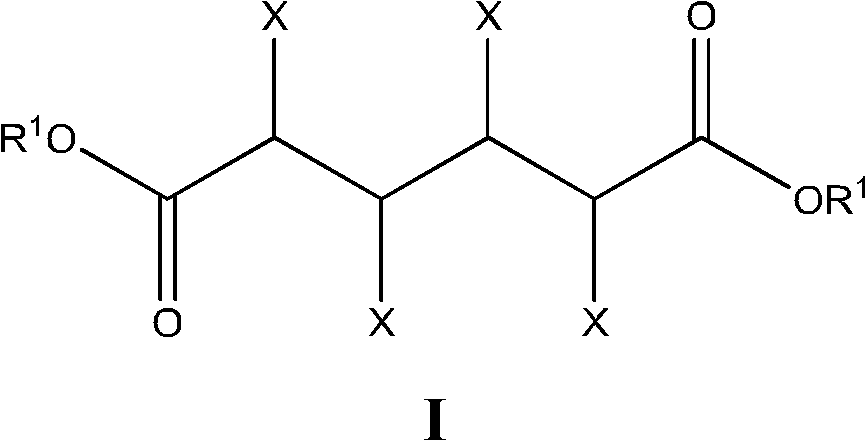

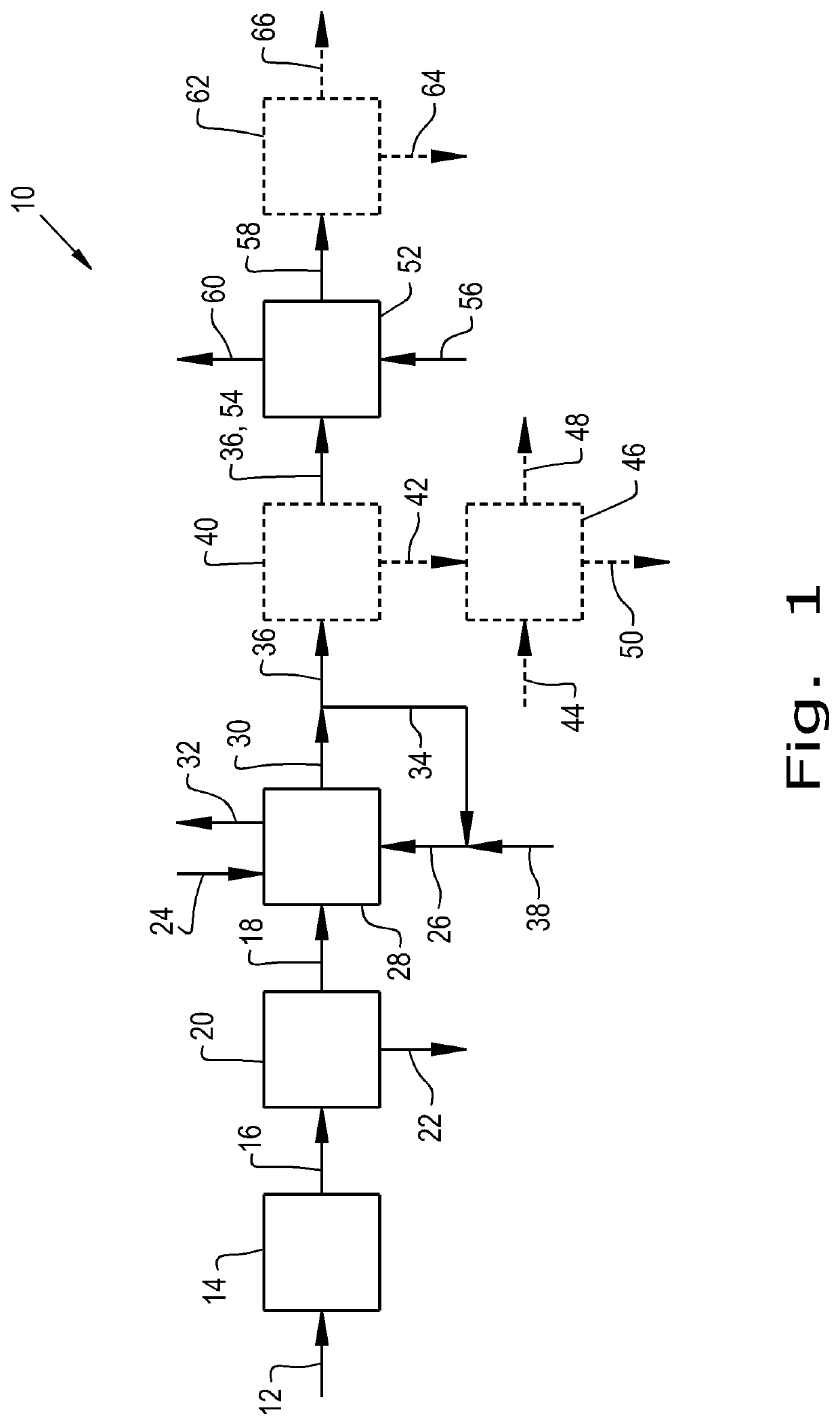

The present invention generally relates to processes for the chemocatalytic conversion of a glucose source to an adipic acid product. The present invention includes processes for the conversion of glucose to an adipic acid product via glucaric acid or derivatives thereof. The present invention also includes processes comprising catalytic oxidation of glucose to glucaric acid or derivative thereof and processes comprising the catalytic hydrodeoxygenation of glucaric acid or derivatives thereof to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

Production of Adipic Acid and Derivatives from Carbohydrate-Containing Materials

ActiveUS20100317823A1Increase costLow costCarboxylic acid nitrile preparationOrganic chemistry methodsCatalytic transformationCatalytic oxidation

The present invention generally relates to processes for the chemocatalytic conversion of a glucose source to an adipic acid product. The present invention includes processes for the conversion of glucose to an adipic acid product via glucaric acid or derivatives thereof. The present invention also includes processes comprising catalytic oxidation of glucose to glucaric acid or derivative thereof and processes comprising the catalytic hydrodeoxygenation of glucaric acid or derivatives thereof to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

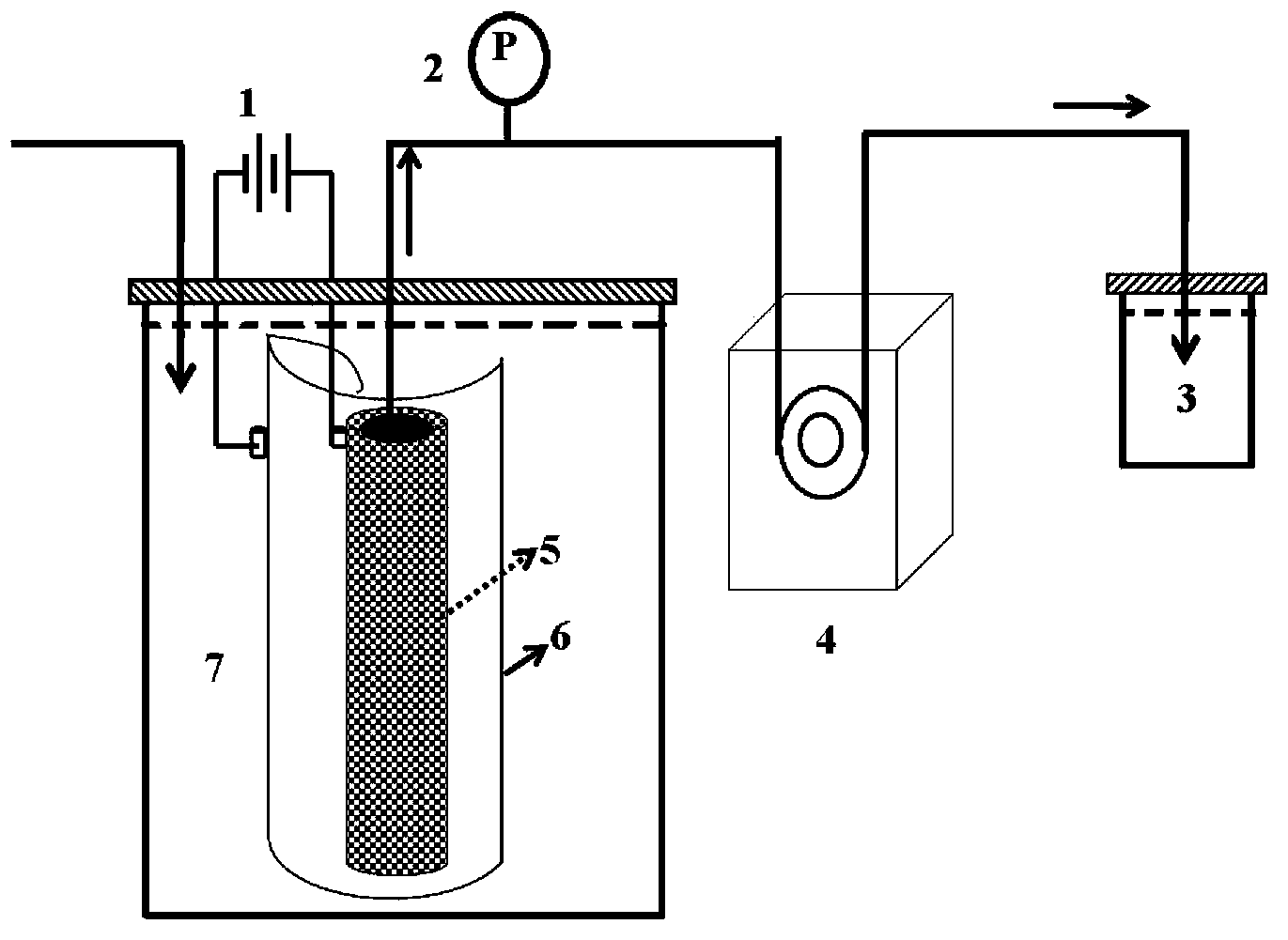

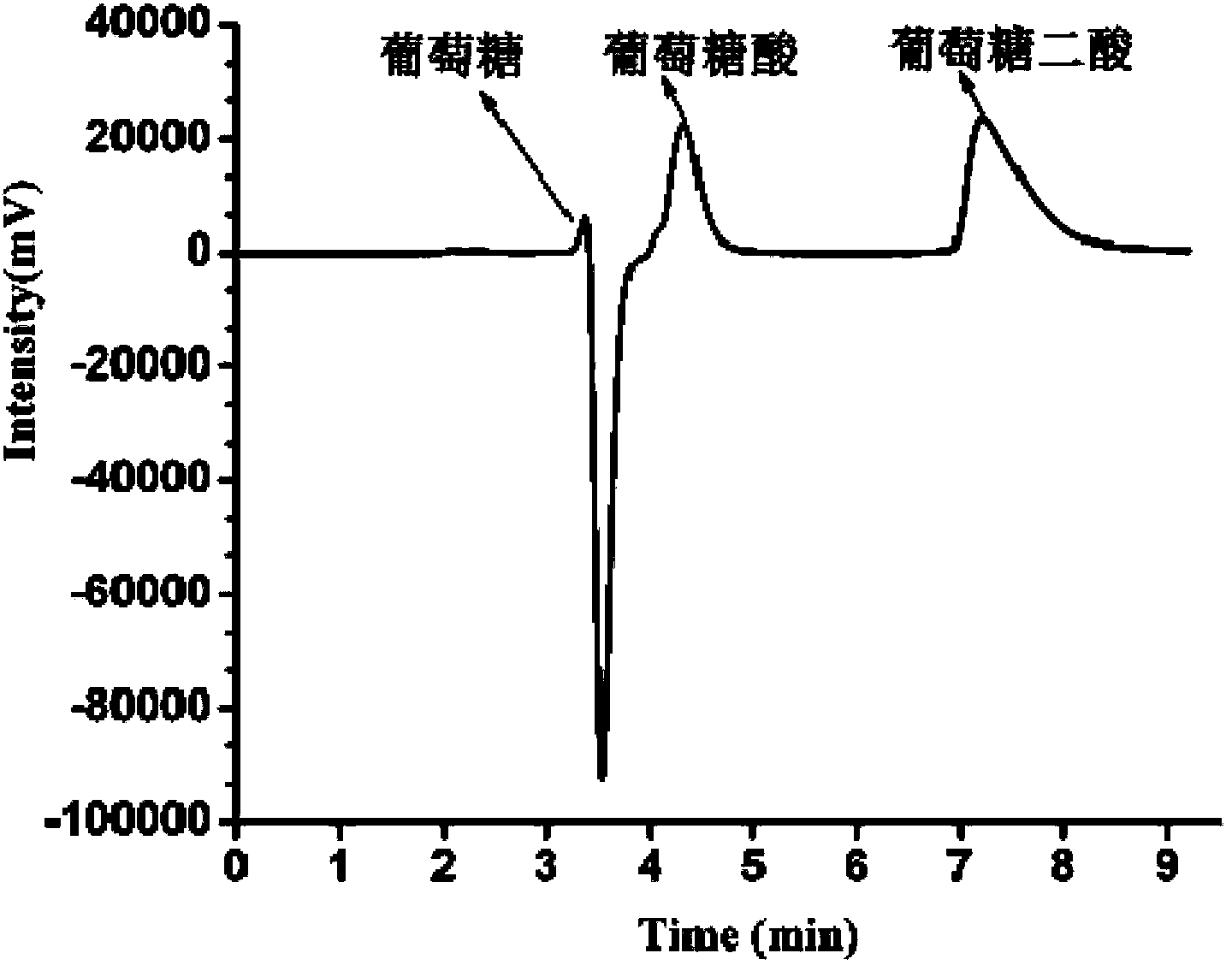

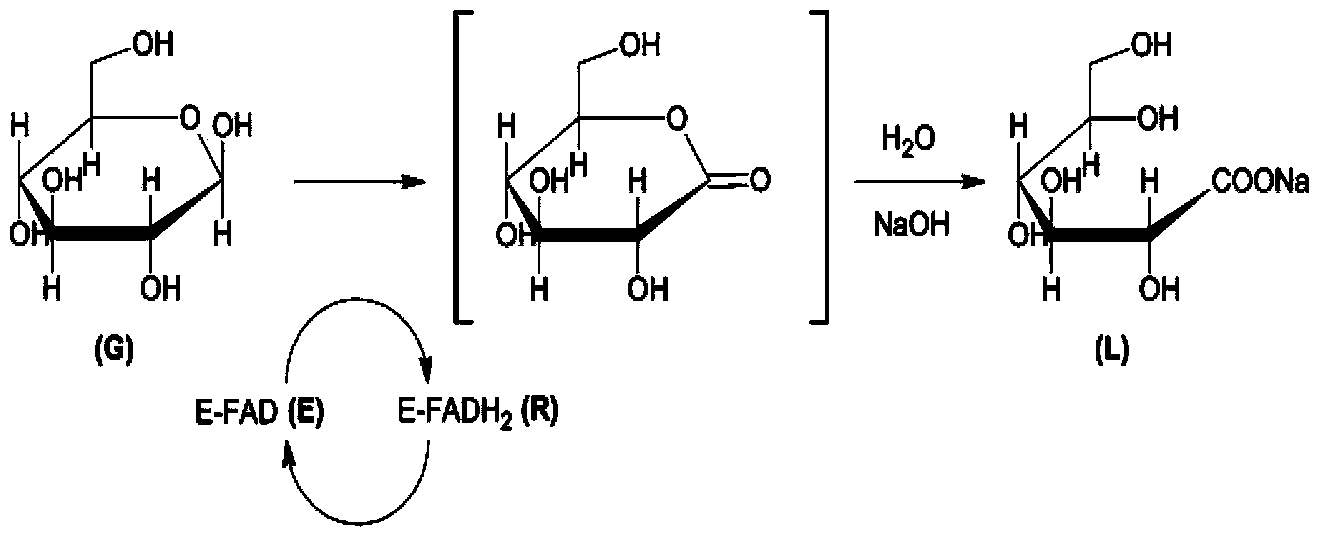

Preparation method of gluconic acid and glucaric acid

InactiveCN103436910AMaintain continuous efficiencySeparation in timeElectrolysis componentsElectrolytic organic productionPeristaltic pumpCatalytic oxidation

The invention discloses a preparation method of gluconic acid and glucaric acid in the technical field of organic electrochemistry synthesis. The preparation method comprises the steps that an electro-catalytic membrane serving as an anode and an auxiliary electrode serving as a cathode are connected with a voltage-stabilized source by wires to form an electro-catalytic membrane reactor; by taking a glucose aqueous solution as a reactant, and an inorganic substance as an electrolyte, gluconic acid and glucaric acid are prepared by catalytic oxidation of glucose with the electro-catalytic membrane under the action of an electric field; membrane penetration liquid is collected by suction of a peristaltic pump; obtained target products are separated from reaction liquid in real time by permeation of the membrane; the membrane penetration liquid is separated and purified to form gluconic acid and glucaric acid products; and yields of gluconic acid and glucaric acid are adjusted and controlled by adjusting and controlling current density and membrane flux. The preparation method integrates catalytic oxidation and separation functions, and can separate the obtained target products from the reaction liquid timely, so that the continuous high efficiency of the electro-catalytic membrane is maintained effectively; a side reaction is avoided; and the selectivity of the target products is improved.

Owner:TIANJIN POLYTECHNIC UNIV

Novel method for synthesizing mixed glucose derivative

InactiveCN101486639ALess investmentExtended service lifeCarboxylic preparation by oxidationPolyesterPolyamide

The invention relates to a novel synthetic method of mixed glucose derivatives. According to the weight proportion of glucose, solvent, weak acidic nitrate oxidant and catalyst of 0.1 percent to 98 percent : 0.1 percent to 98 percent : 0.1 percent to 98 percent : 0.001 percent to 60 percent, the glucose, solvent, weak acidic nitrate oxidant and catalyst are mixed, stirred and heated until the temperature rises to 40 DEG C to 100 DEG C; air (or oxygen) is filled into the reaction system at a speed of 0.001 percent to 100 percent of reaction solution volume per minute, reaction lasts for 0.1h to 20h and crude products are obtained; and mixed glucose derivatives composed of glucaric acid, glucaric acid-1,4-lactone and glucaric acid -1,4:3,6 dilactone are obtained through the separation and purification of the crude products. The products can be applied to the synthesis of polyester, polyamide and other high polymer materials and also can be taken as a medical intermediate and used for medicament synthesis.

Owner:NANJING FORESTRY UNIV

Oxidation of carbohydrates by means of peroxidases and nitroxy radicals

A method of oxidising carbohydrates and / or carbohydrate derivatives having primary alcohol groups comprising contacting a reaction medium containing said carbohydrates and / or carbohydrate derivatives with a nitroxy radical mediator and a peroxidase enzyme, characterized in that the initial reaction medium contains at least 10% by weight carbohydrates and / or carbohydrate derivatives, in that the peroxidase enzyme is an oilseed peroxidase and in that a hydroperoxide and an alkali compound are gradually added to the reaction medium such that its pH is maintained at between 3.5 and 10.0 (pH-Stat); use of said method in a process for producing gluconic acid, glucaric acid and / or D-glucuronolactone.

Owner:CERESTAR HLDG

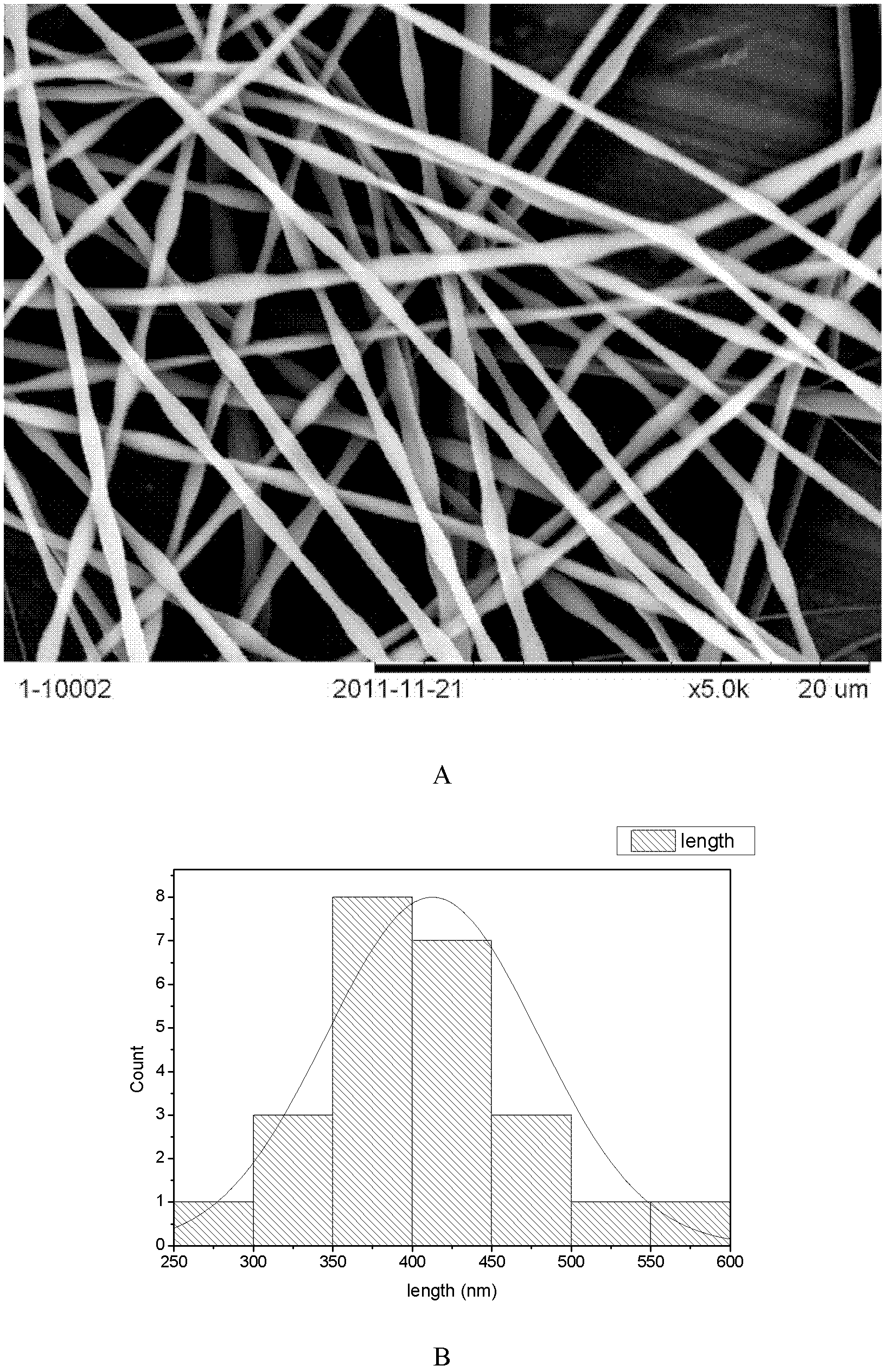

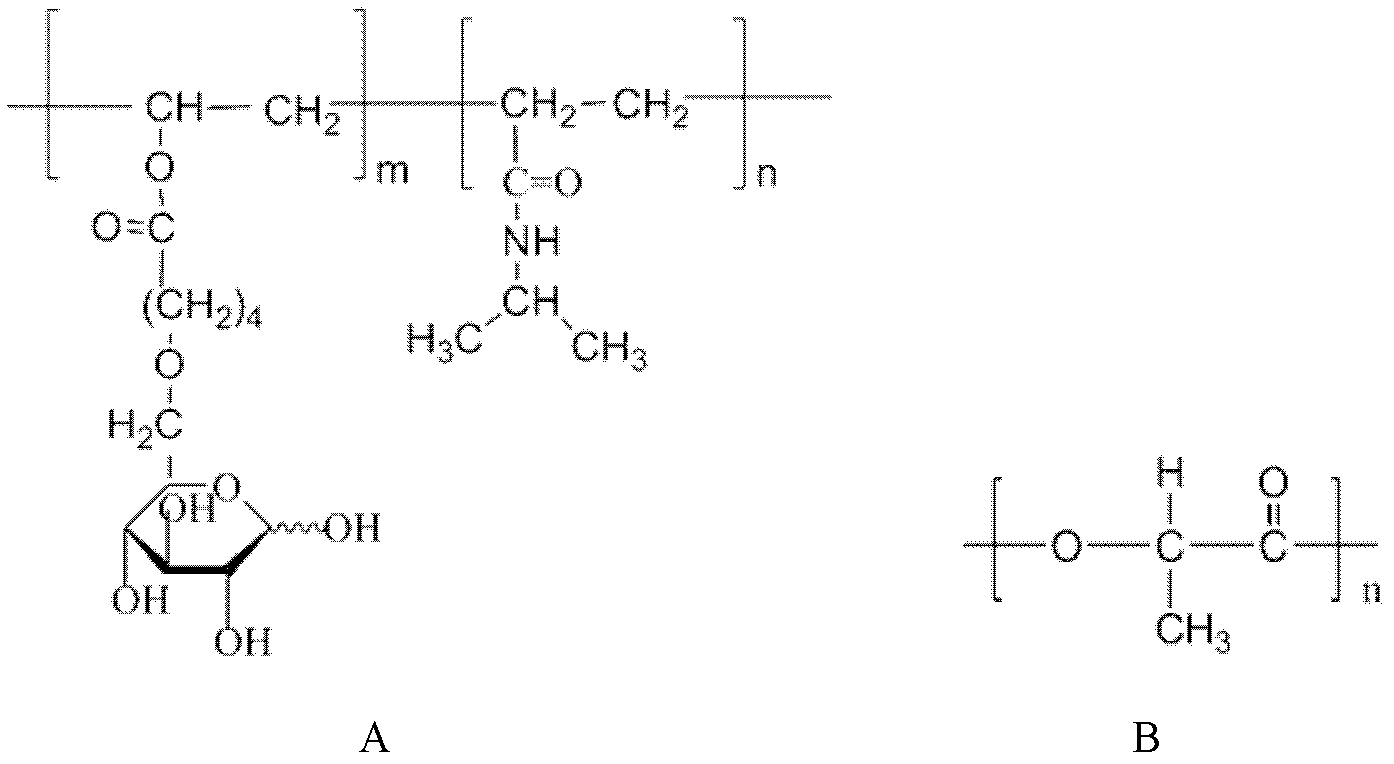

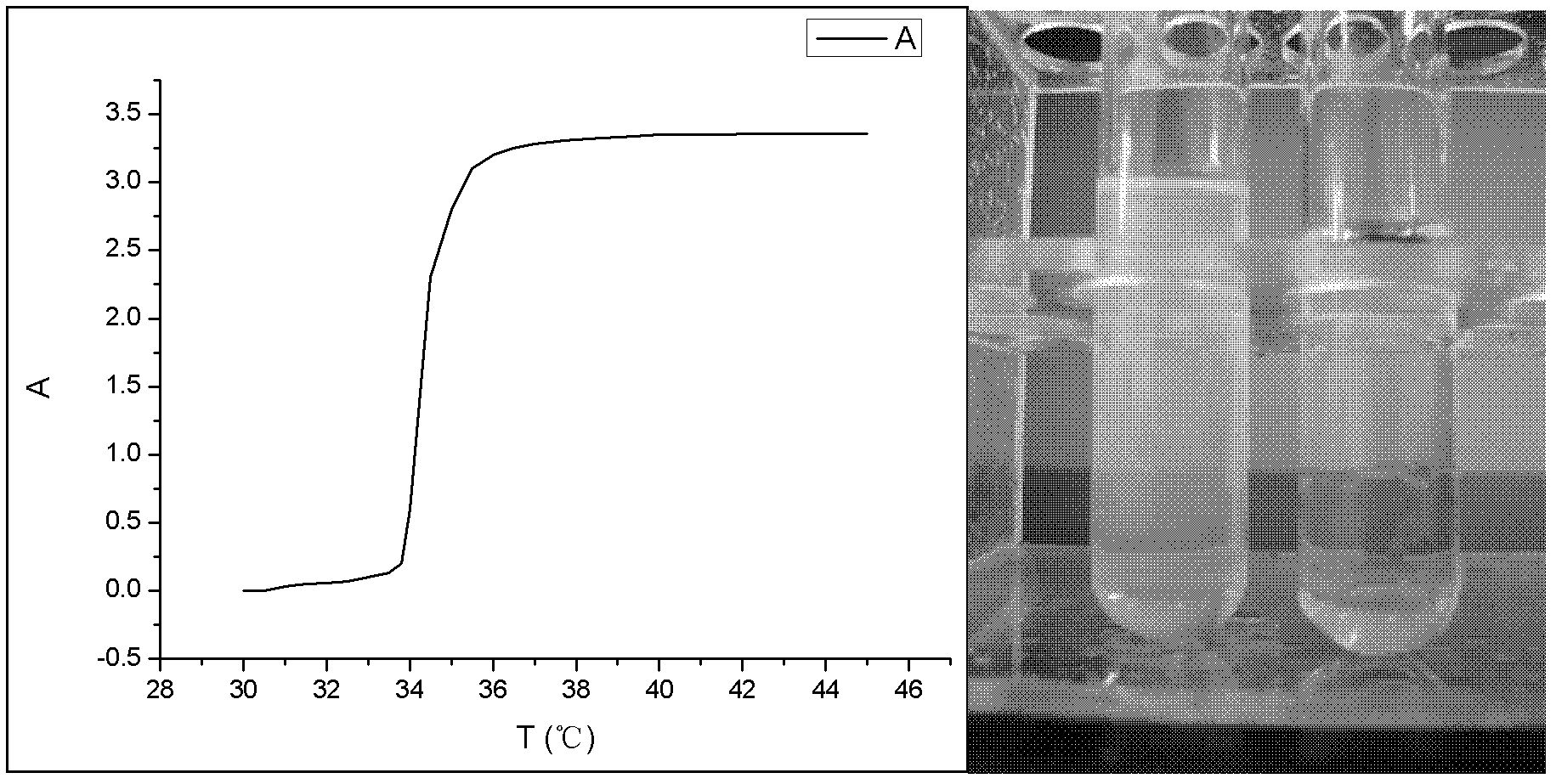

Dual-hydrophilic thermo-sensitive polymer/lactic acid polymer composite nanofiber felt and preparation method thereof

InactiveCN102660841ARich sourcesLow priceNon-woven fabricsSpinning solutions preparationPolymer scienceSolvent

The invention relates to a dual-hydrophilic thermo-sensitive polymer / lactic acid polymer composite nanofiber felt and a preparation method thereof. The nanofiber felt comprises the following components: dual-hydrophilic thermo-sensitive polymer and lactic acid polymer with the mass ratio of 10:1. The preparation method comprises the following steps: (1) carrying out free radical polymerization reaction on glucaric acid divinyl ester and N-isopropyl acrylamide to obtain the dual-hydrophilic thermo-sensitive polymer; (2) dissolving the high polymer in a solvent, stirring for 1-4 hours, and carrying out ultrasonic degassing to obtain a spinning solution A; (3) dissolving the lactic acid polymer in the solvent, stirring for 1-8 hours, carrying out ultrasonic degassing to obtain a spinning solution B; and (4) mixing the spinning solution A with the spinning solution B, and carrying out electrostatic spinning to obtain the dual-hydrophilic thermo-sensitive polymer / lactic acid polymer composite nanofiber felt. According to the invention, the method is continuously feasible, the operation is simple and easy, industrialization is easy to realize, and the obtained nanofiber felt can be used for carrying medicines and control the release of the medicine; and the nanofiber felt can also be implanted into a release system and can be used in the fields of tissue engineering scaffold and the like.

Owner:DONGHUA UNIV

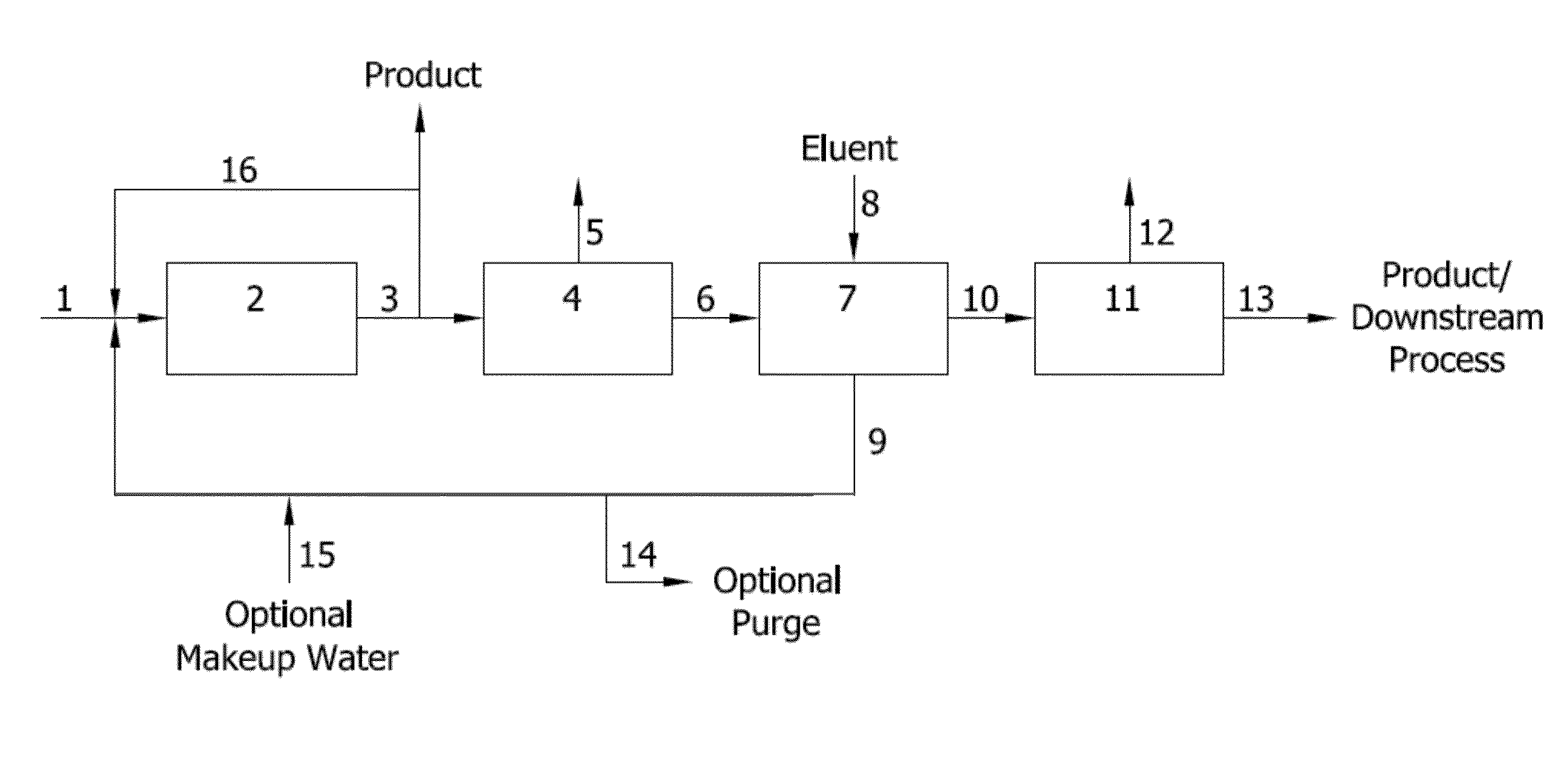

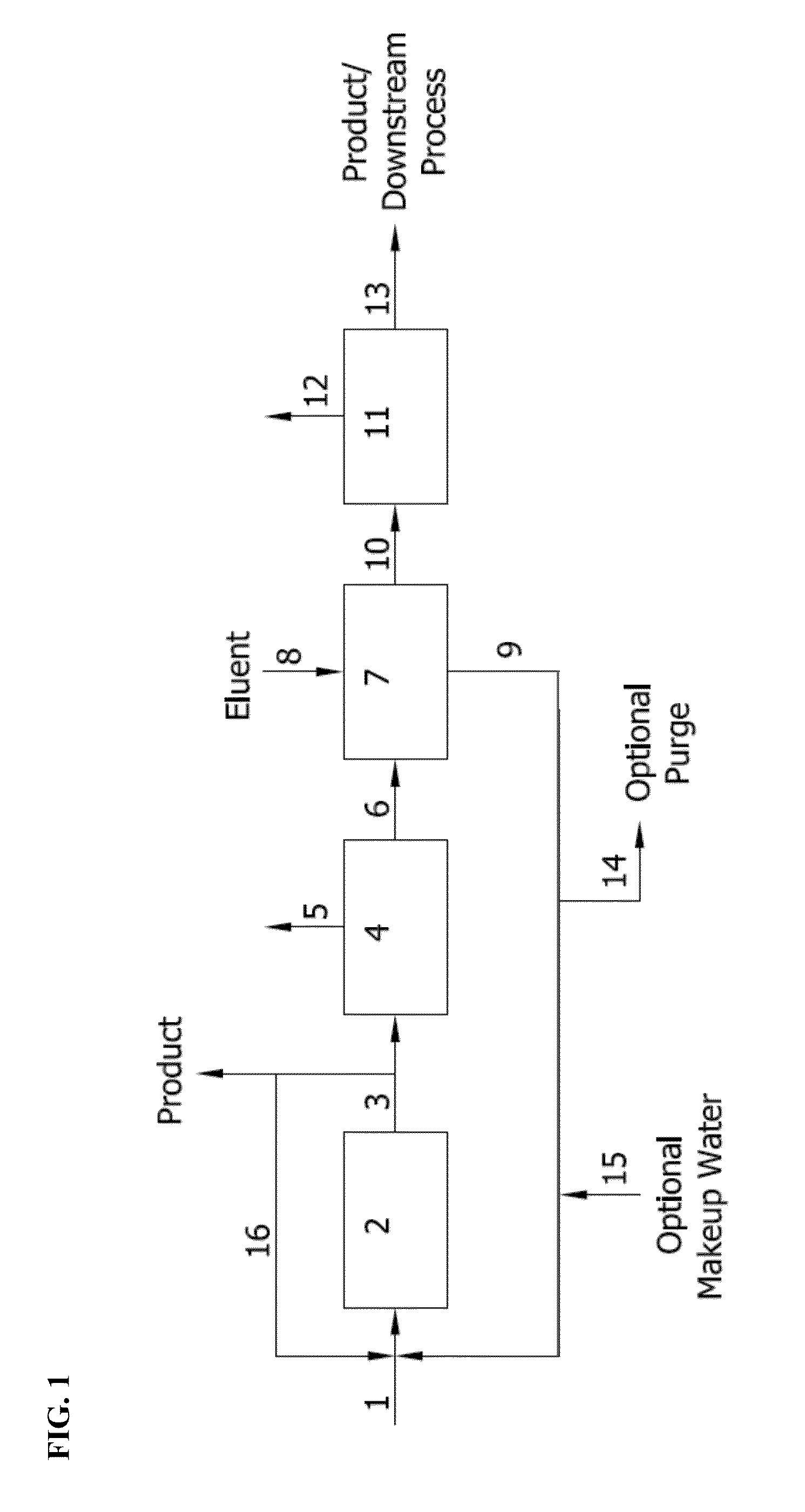

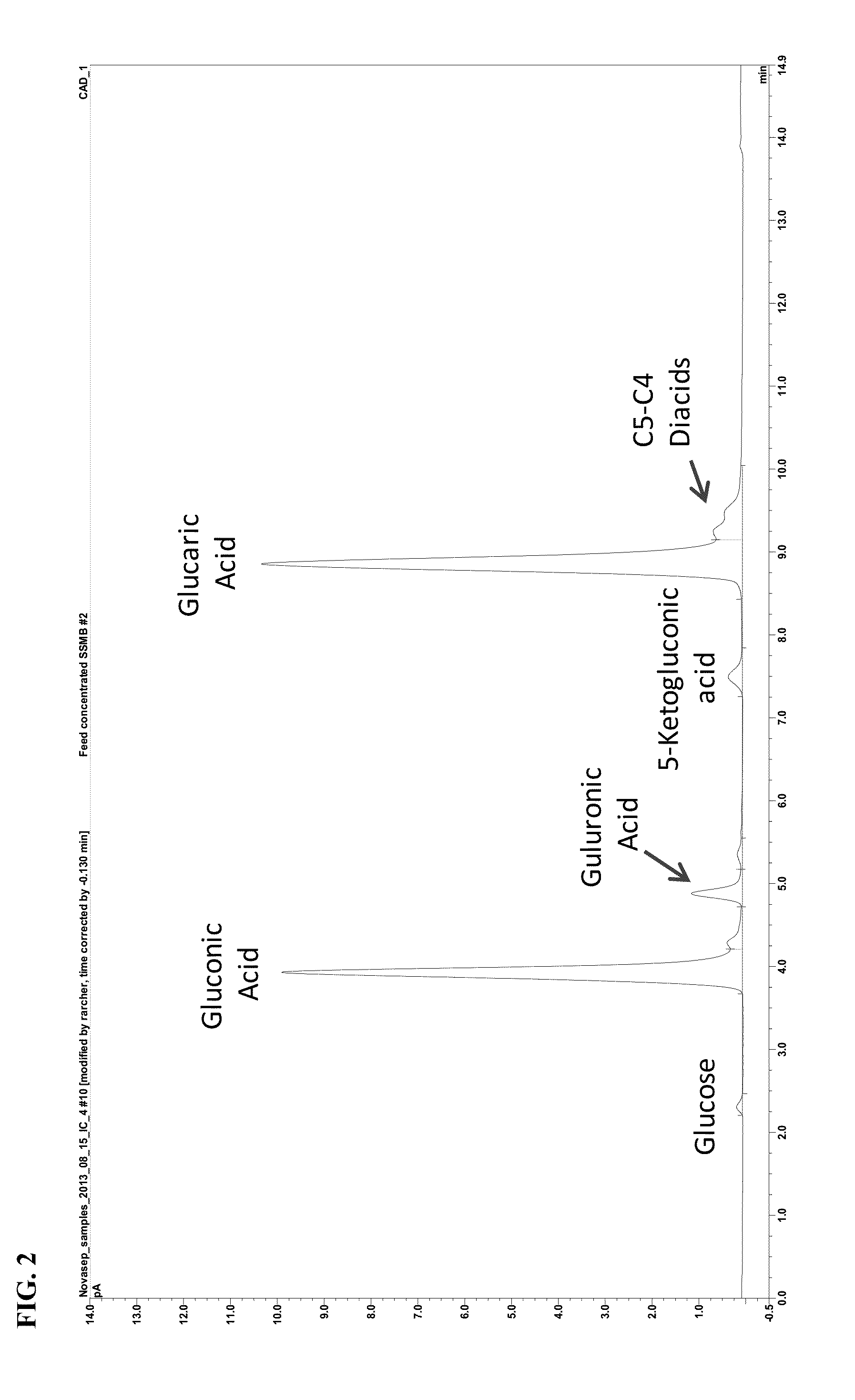

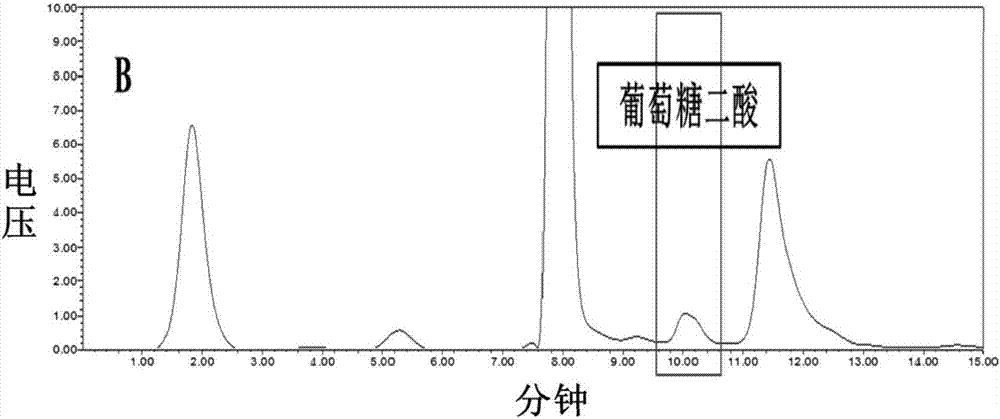

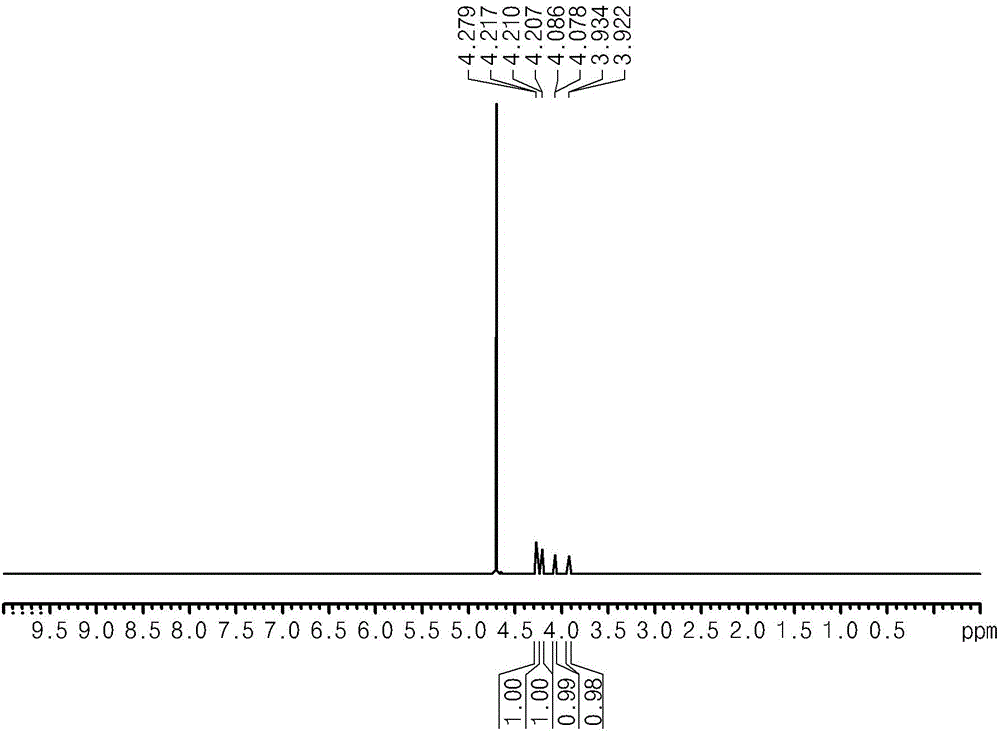

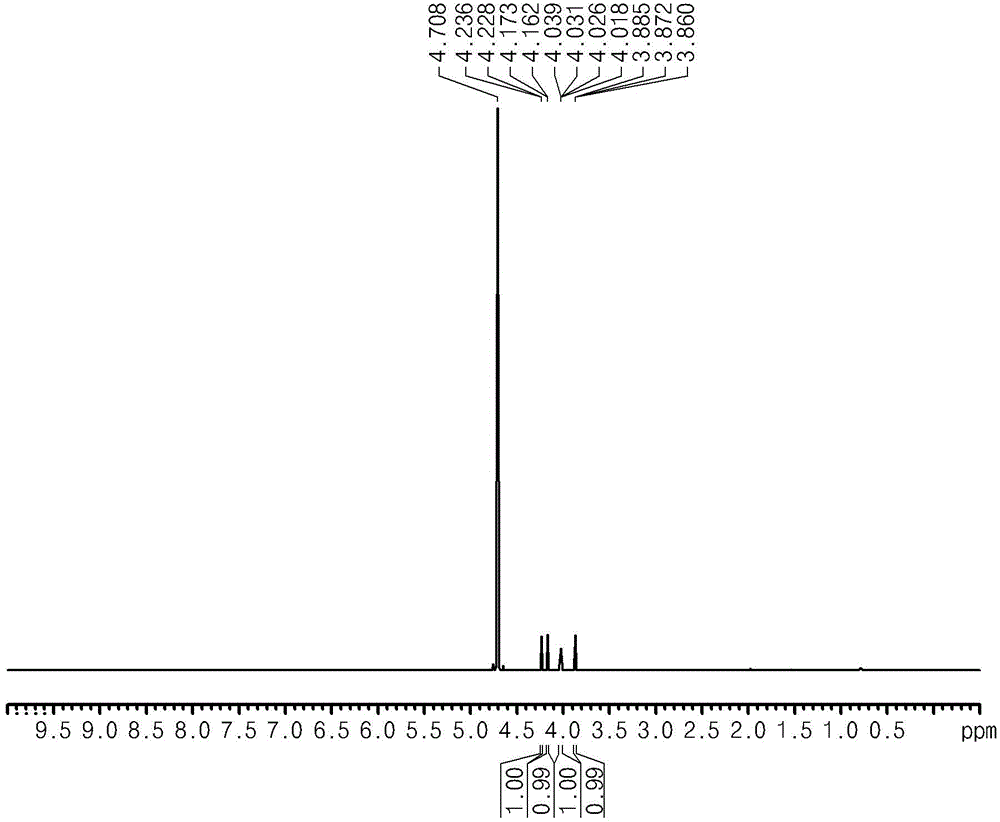

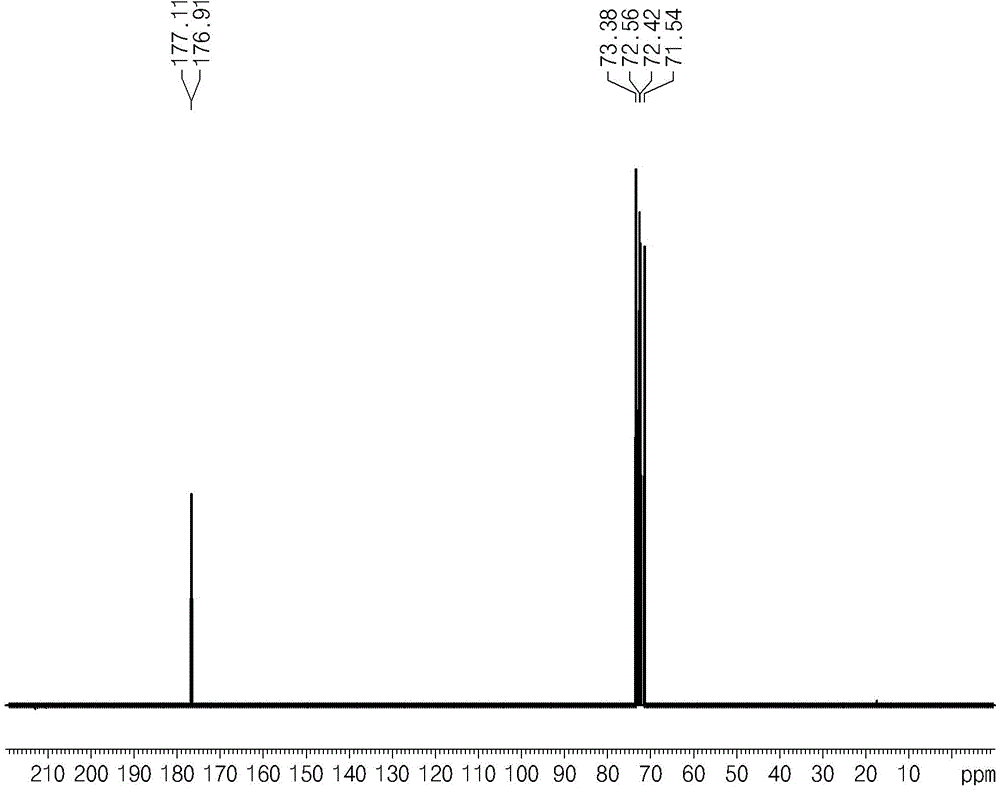

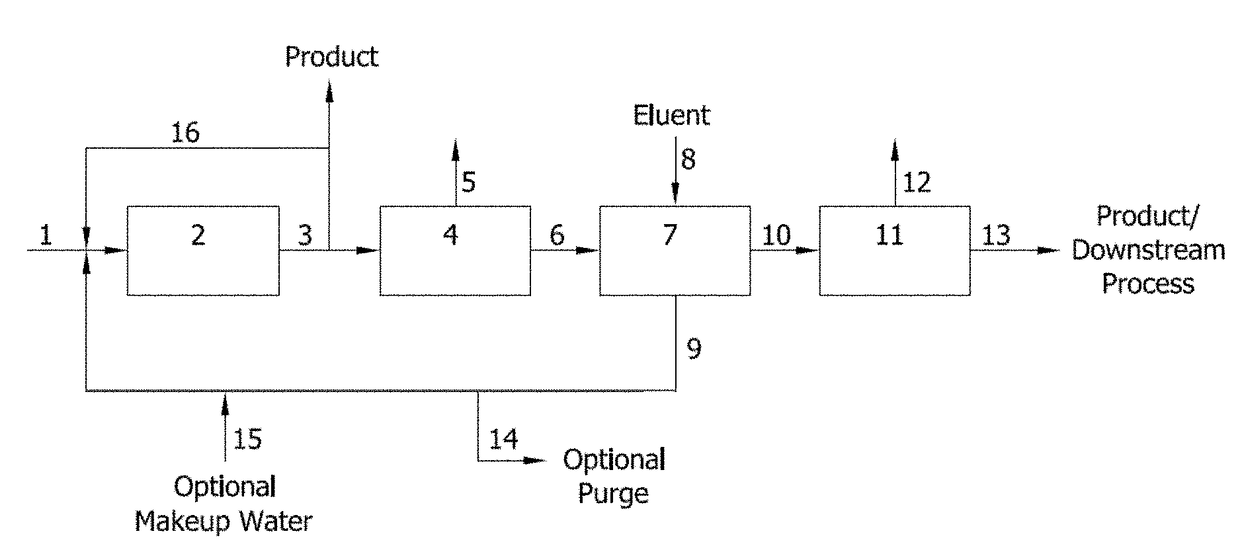

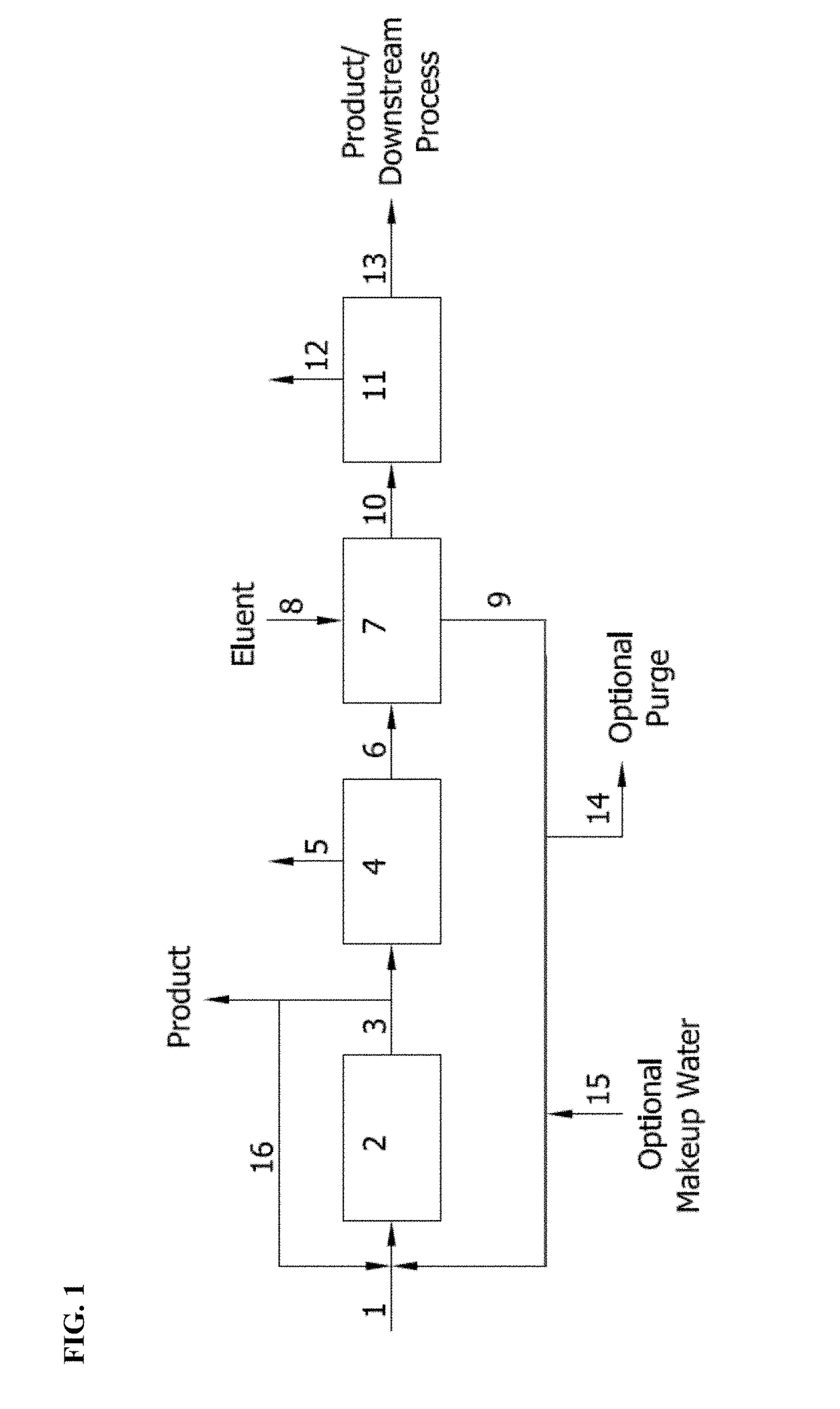

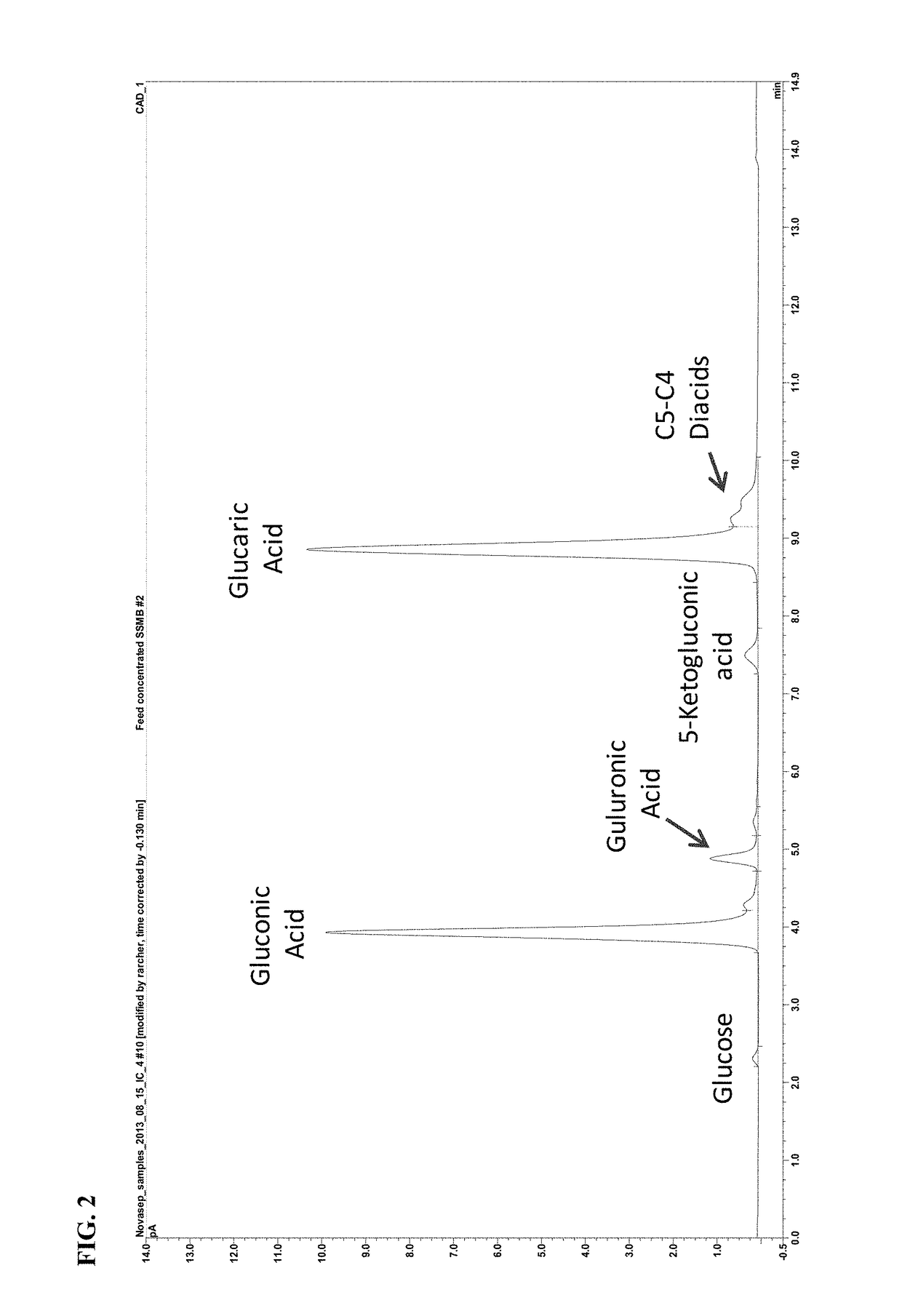

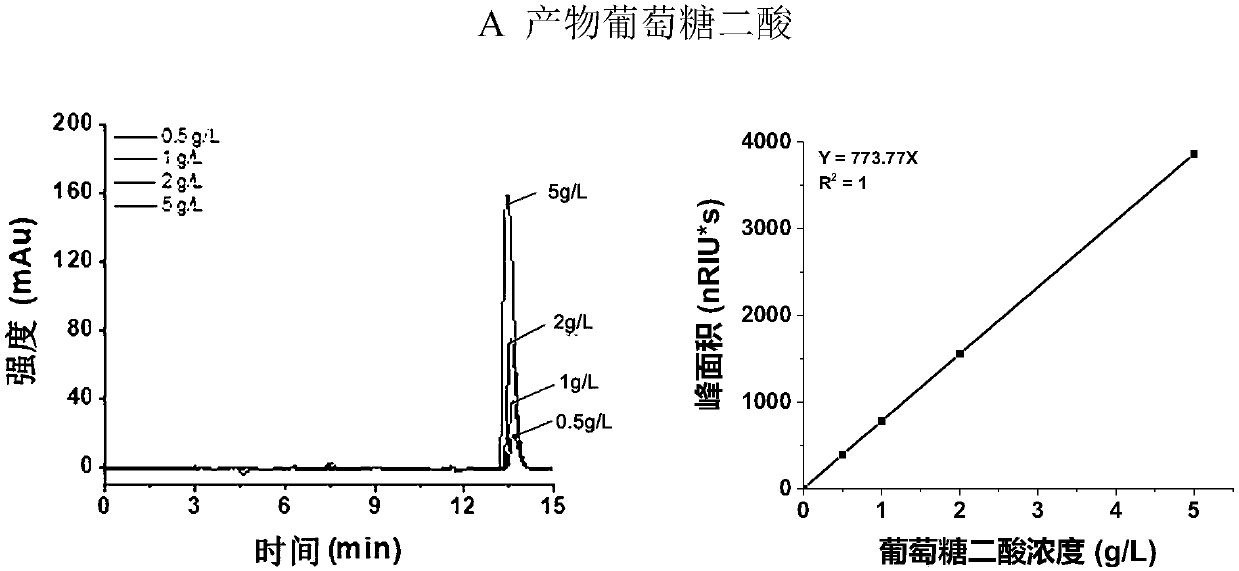

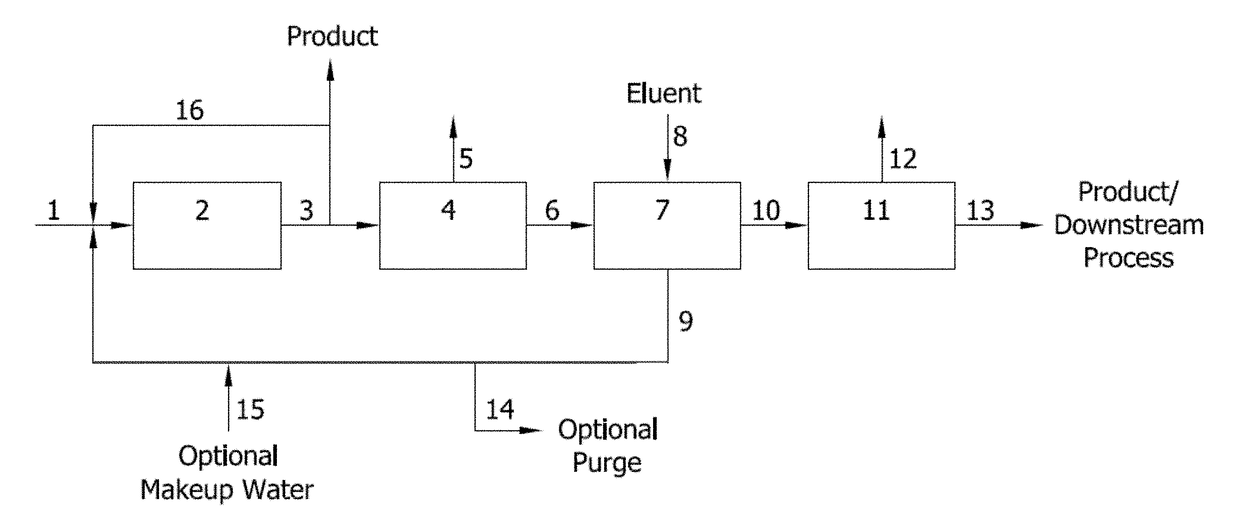

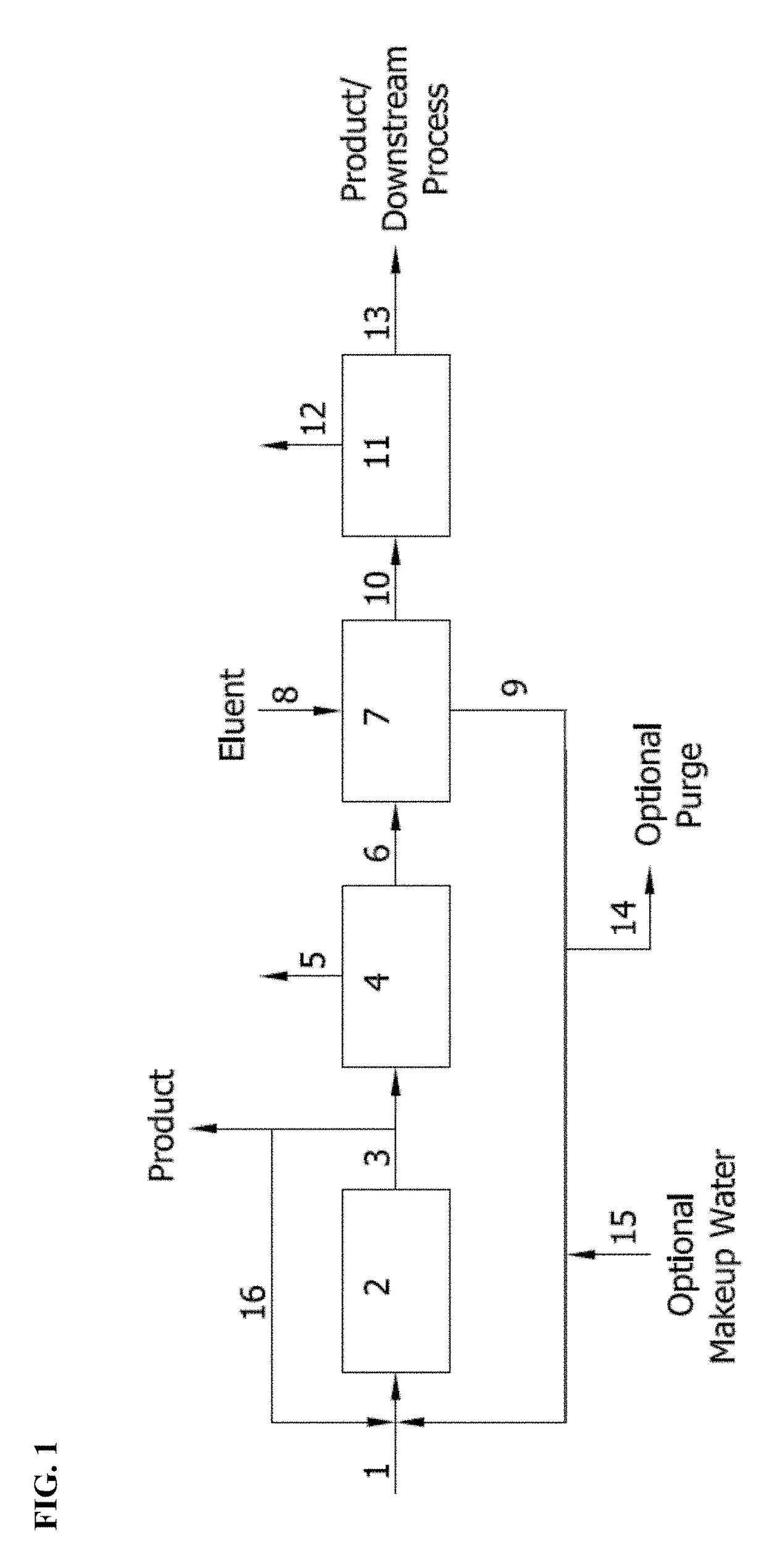

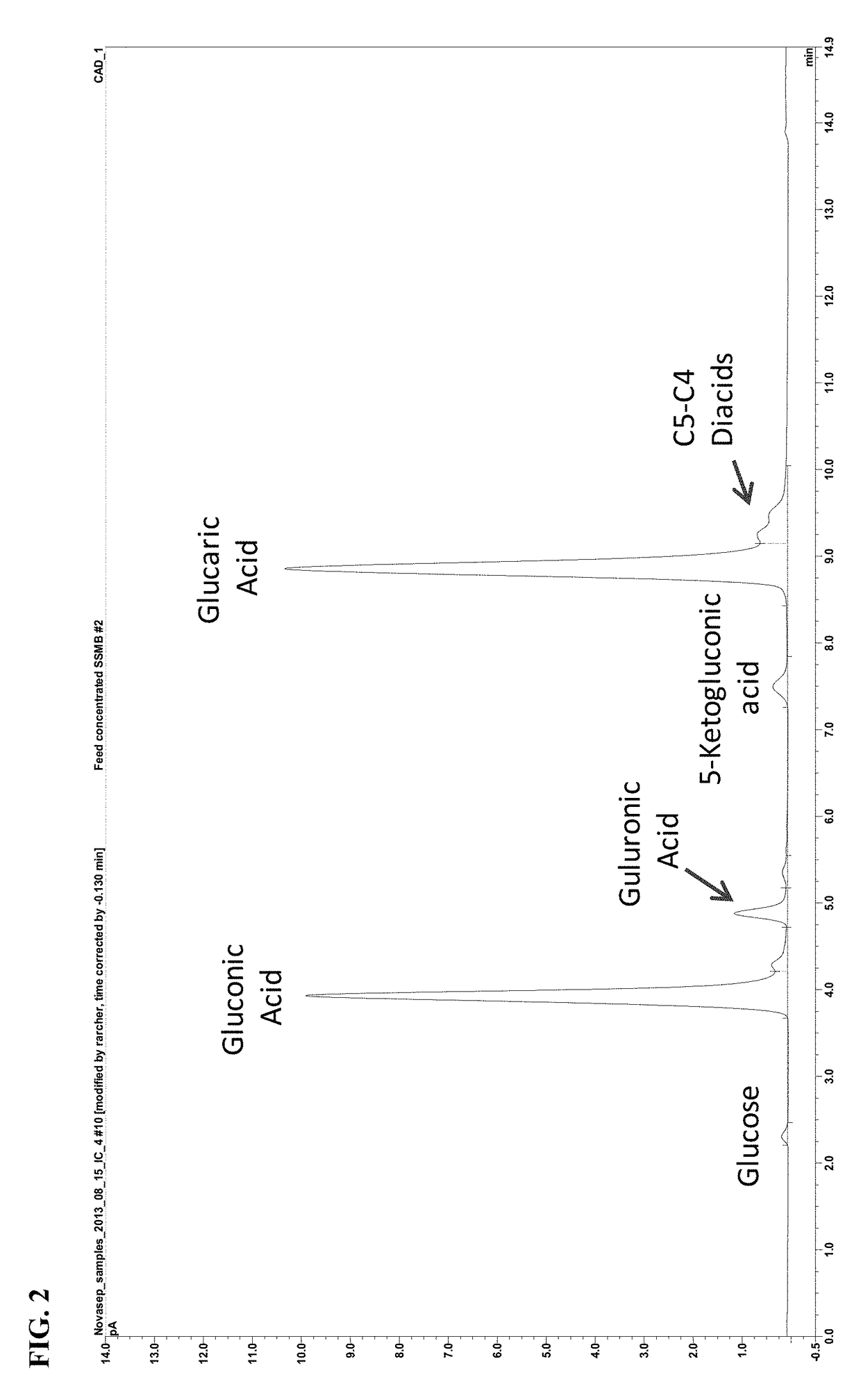

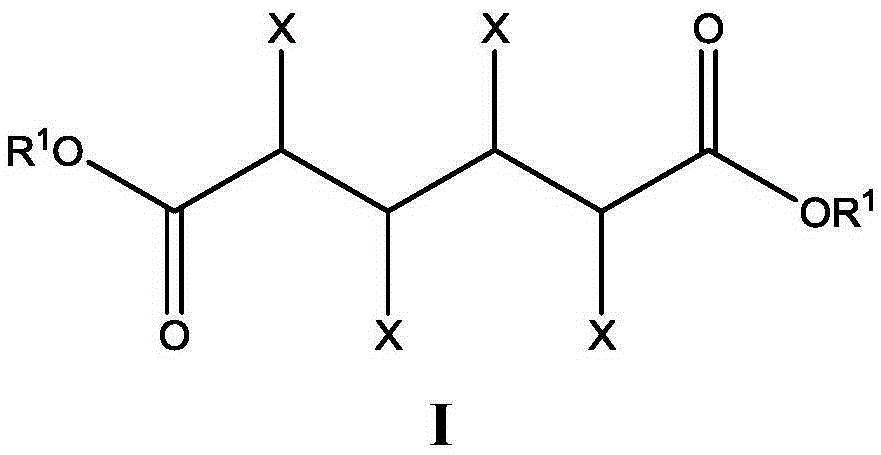

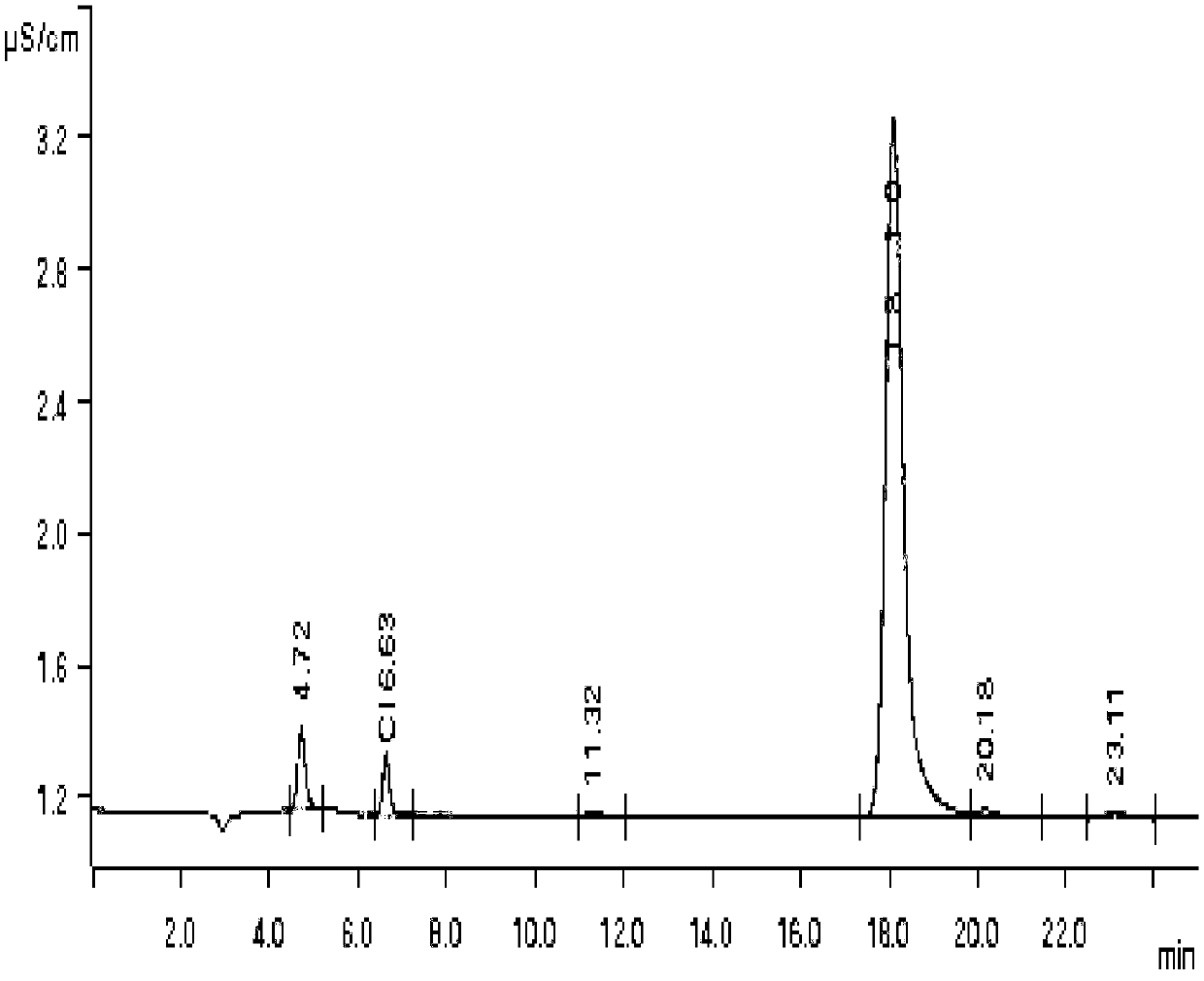

Preparation and separation of a di-carboxylic acid-containing mixture

ActiveUS20160090346A1Organic compound preparationSolid sorbent liquid separationD-GlucoseCarboxylic acid

Processes for separating a di-carboxylic acid or salt thereof from a mixture containing the di-carboxylic acid or salt thereof and one or more other components are provided. Also separation media useful for these separation processes is provided. In particular, processes for preparing an aldaric acid are described, such as glucaric acid from glucose, which includes separating the aldaric acid from the reaction product. Also, various glucaric acid products are described.

Owner:ARCHER DANIELS MIDLAND CO

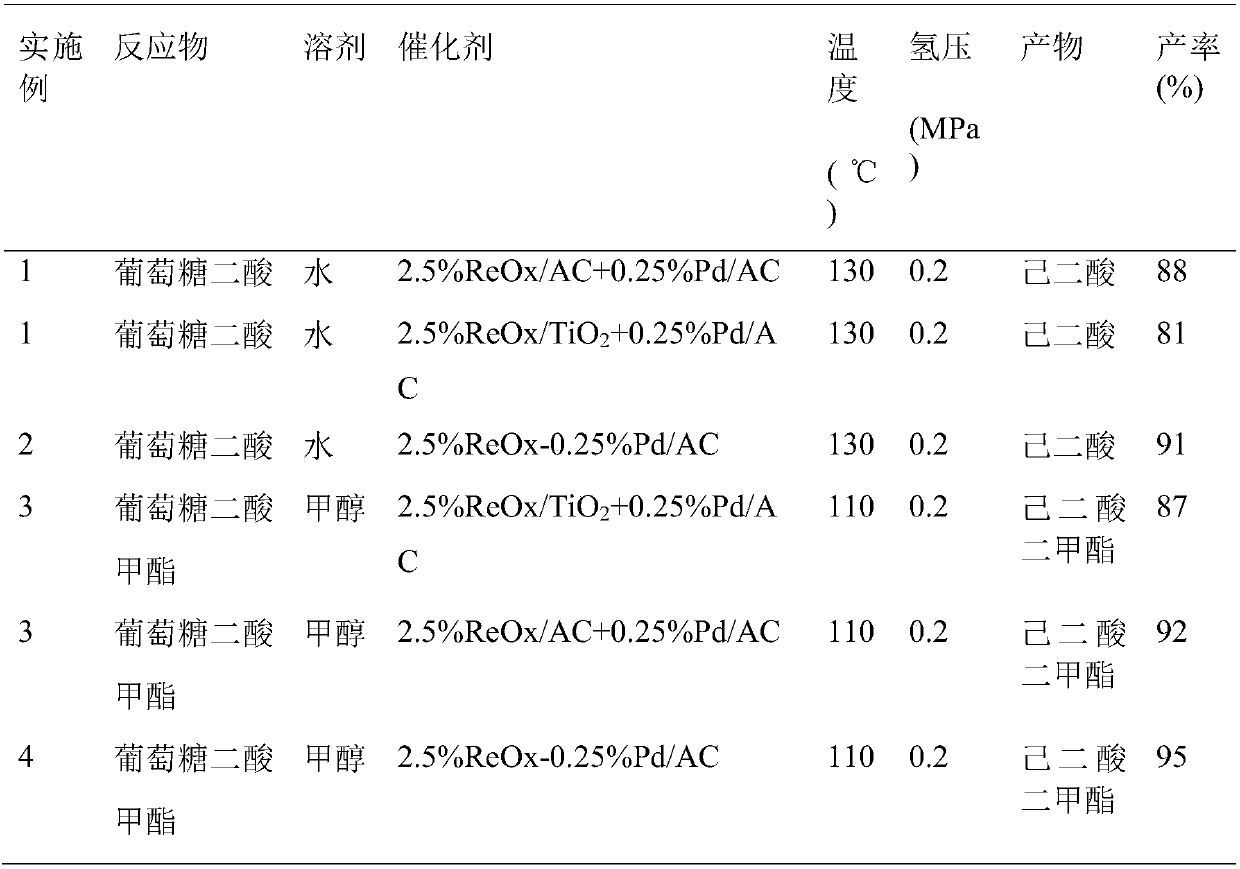

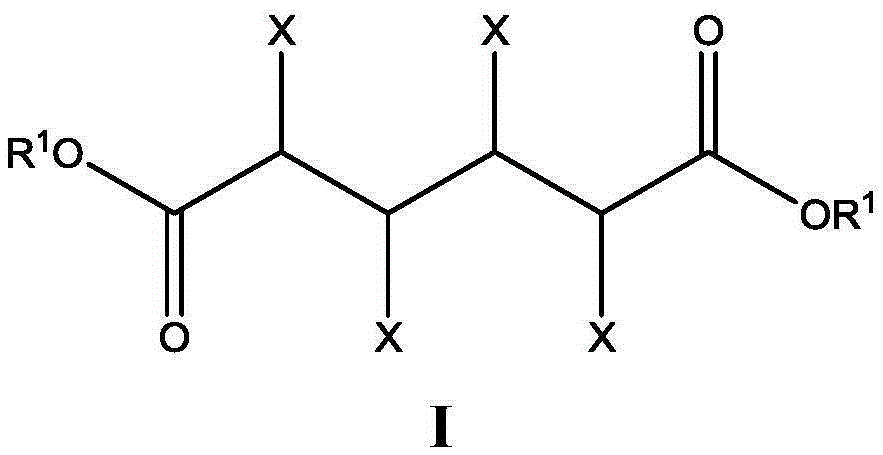

Method for preparing adipic acid from glucaric acid

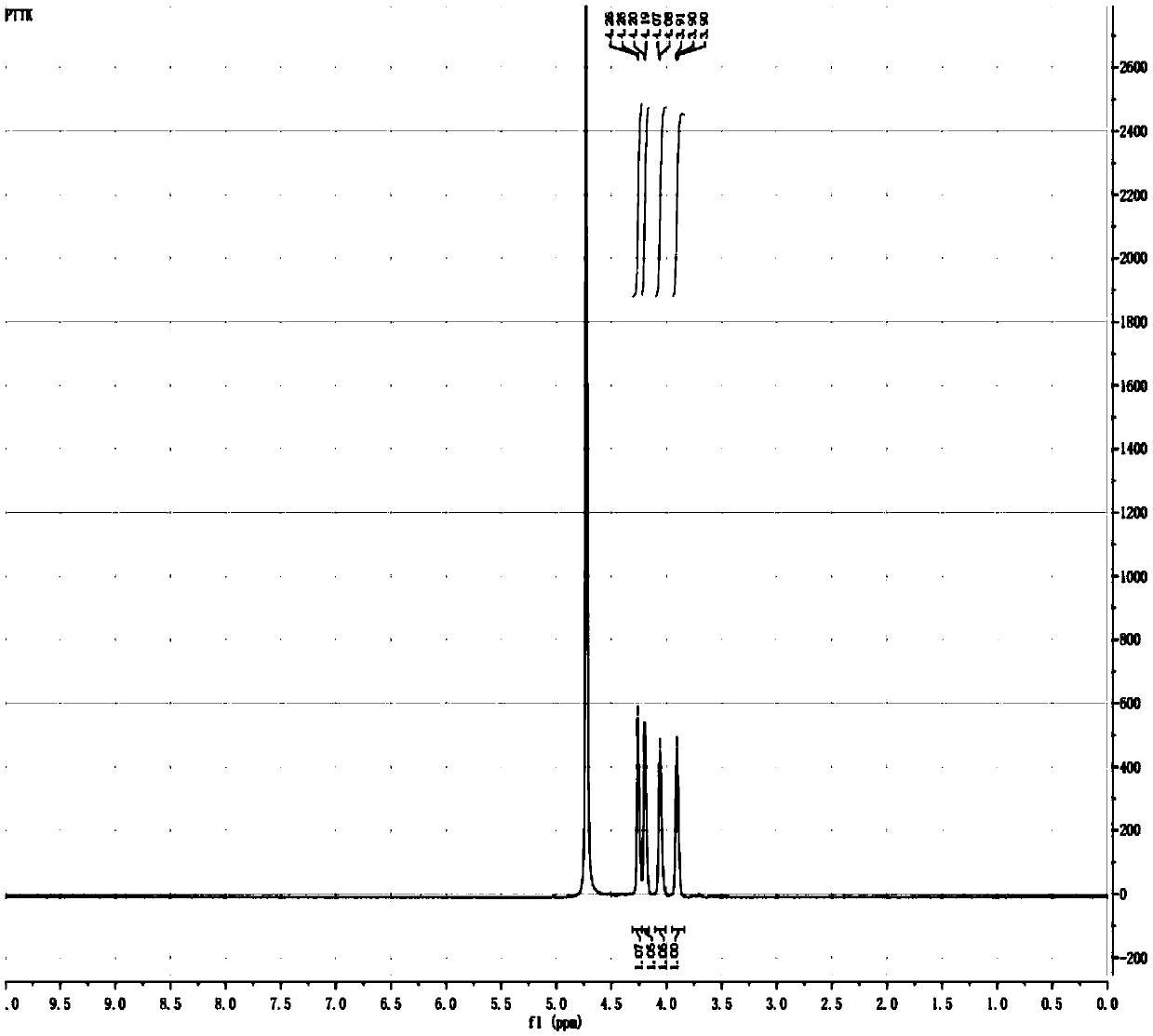

ActiveCN107556186AImprove catalytic performanceReaction process greenOrganic compound preparationCarboxylic acid esters preparationHydrogenAlcohol

The invention discloses a method for preparing adipic acid from glucaric acid. The method comprises the following steps: making glucaric acid react with hydrogen in a water solution or an alcoholic solution to obtain the adipic acid. When the glucaric acid reacts with the hydrogen in the water solution, a system utilizes a hydrodeoxygenation catalyst to perform hydrodeoxygenation reaction; when the glucaric acid reacts with the hydrogen in the alcoholic solution, an esterification catalyst, the hydrodeoxygenation catalyst and a hydrolysis catalyst are sequentially added into the system to respectively perform esterification reaction, the hydrodeoxygenation reaction and hydrolysis reaction. The method disclosed by the invention has the advantages of green and pollution-free reaction processand environmental friendliness; furthermore, production cost is reduced.

Owner:PEKING UNIV

Method for producing glucaric acid

ActiveUS9227904B1Low costLow cost productionOrganic compound preparationCarboxylic preparation by oxidationPotassium hydroxideCatalytic oxidation

The present disclosure relates to a method for producing glucaric acid, and more particularly, to a method for producing glucaric acid including the steps of: (1) inputting aldohexose and potassium hydroxide to an aqueous solution; and (2) deriving a catalytic oxidation reaction after adding a supported noble metal catalyst to the aqueous solution under the presence of oxygen gas.

Owner:HYUNDAI MOTOR CO LTD +1

Compositions and methods for producing chemicals and derivatives thereof

Owner:SYNTHETIC GENOMICS INC

Production of adipic acid and derivatives from carbohydrate-containing materials

ActiveCN102803195ALactams preparationCarboxylic acid nitrile preparationHydrodeoxygenationCatalytic oxidation

The present invention generally relates to processes for the chemocatalytic conversion of a glucose source to an adipic acid product. The present invention includes processes for the conversion of glucose to an adipic acid product via glucaric acid or derivatives thereof. The present invention also includes processes comprising catalytic oxidation of glucose to glucaric acid or derivative thereof and processes comprising the catalytic hydrodeoxygenation of glucaric acid or derivatives thereof to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

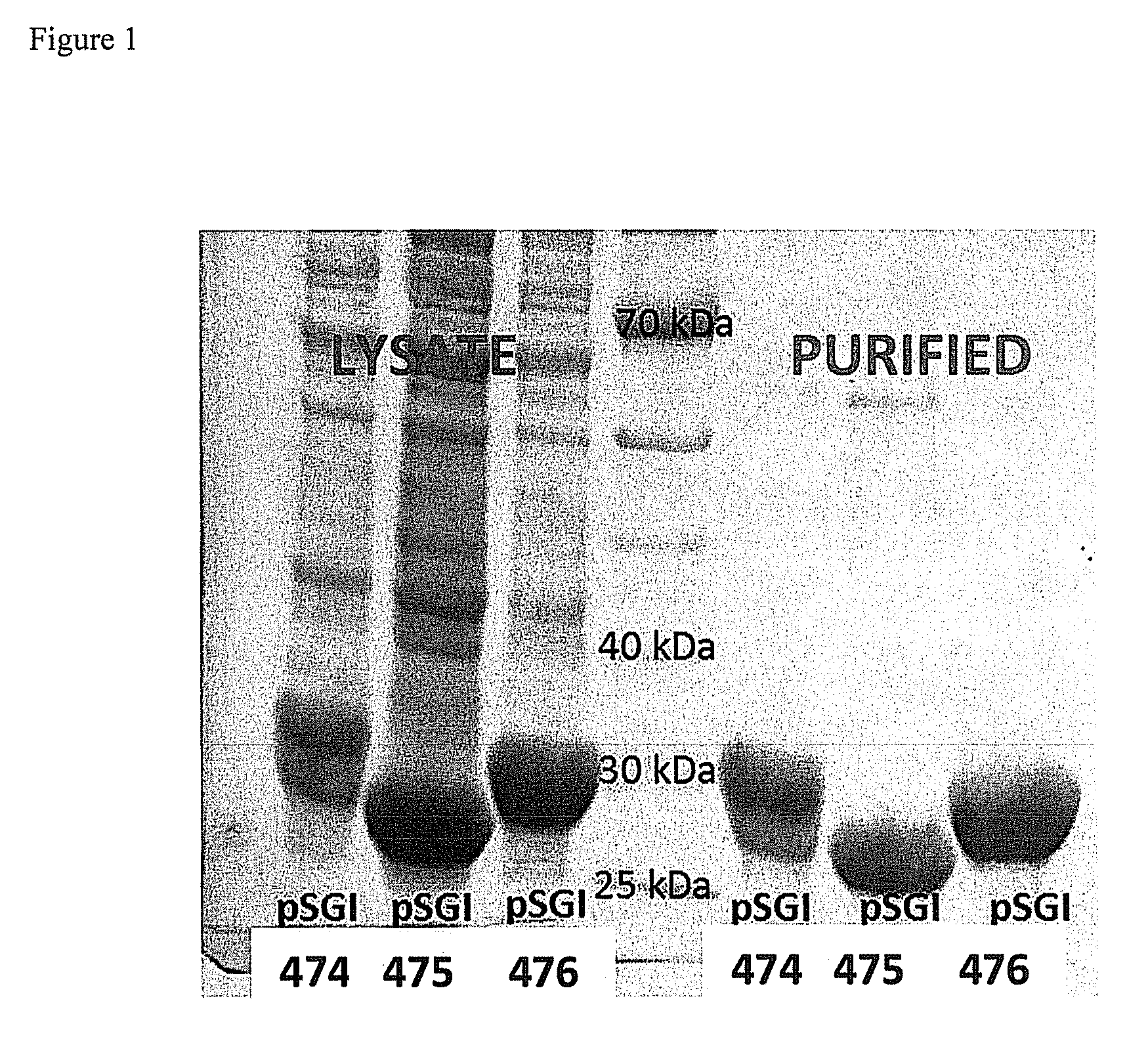

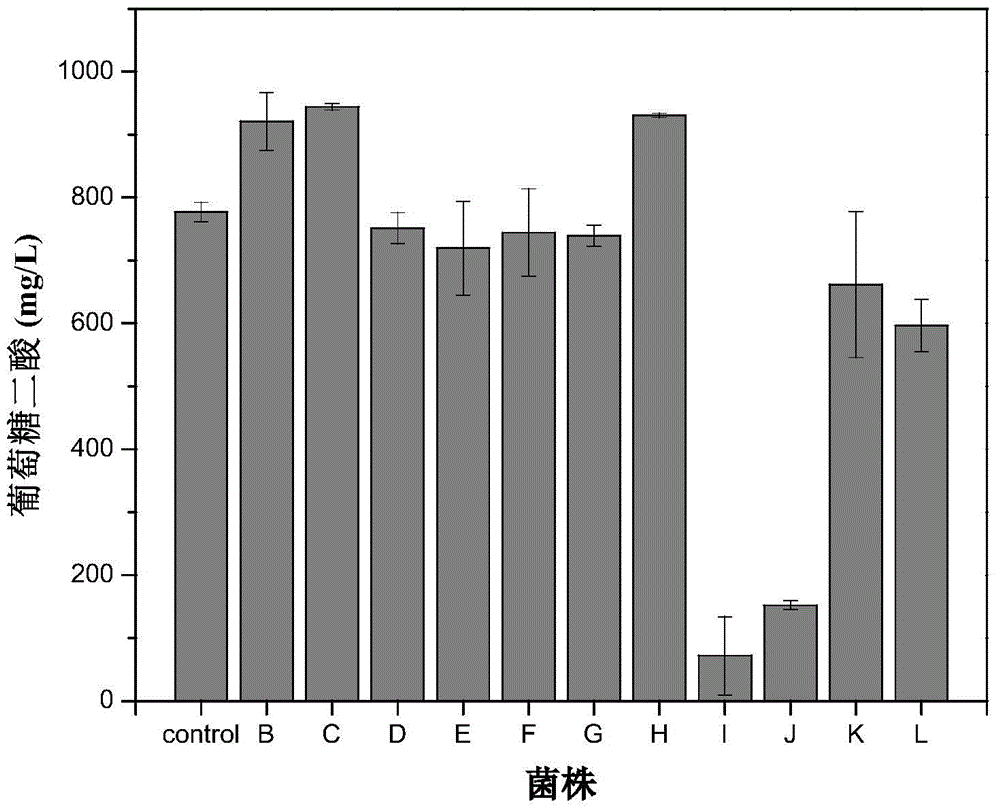

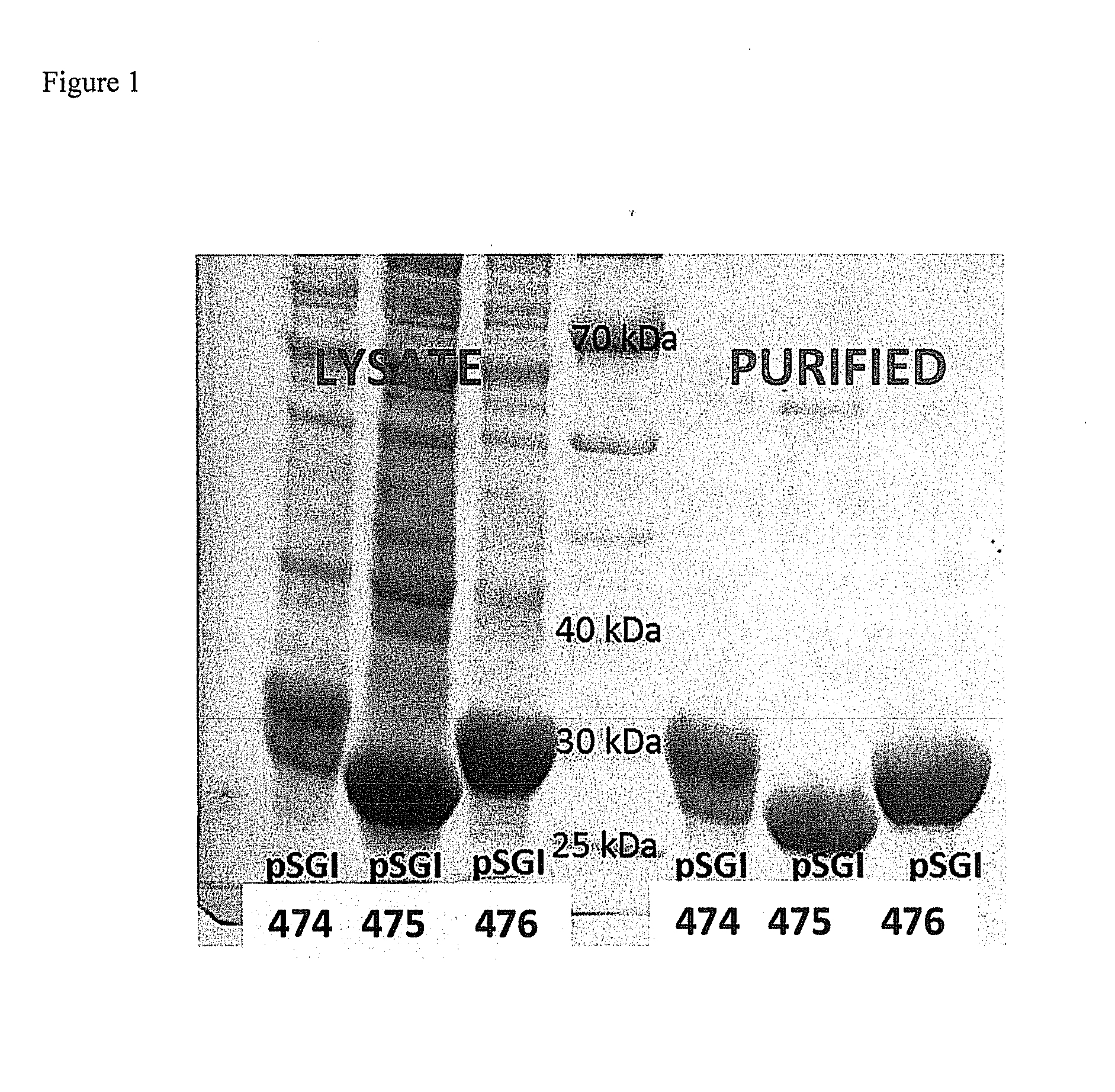

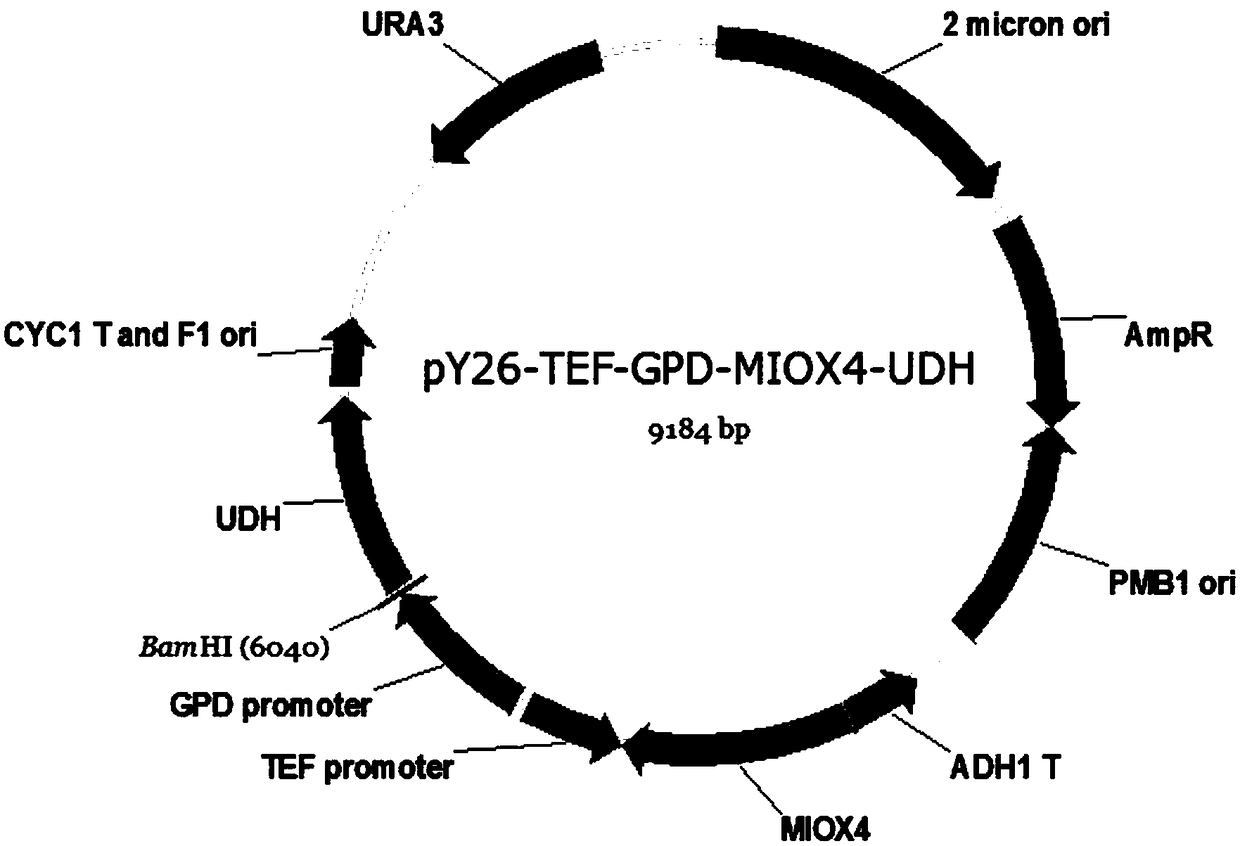

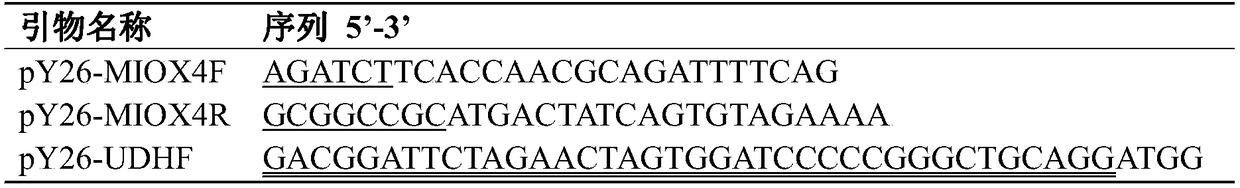

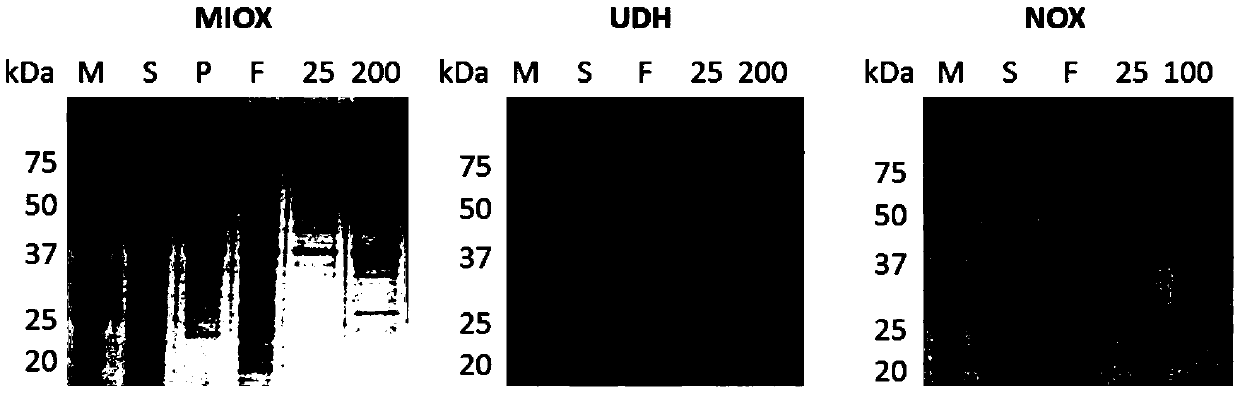

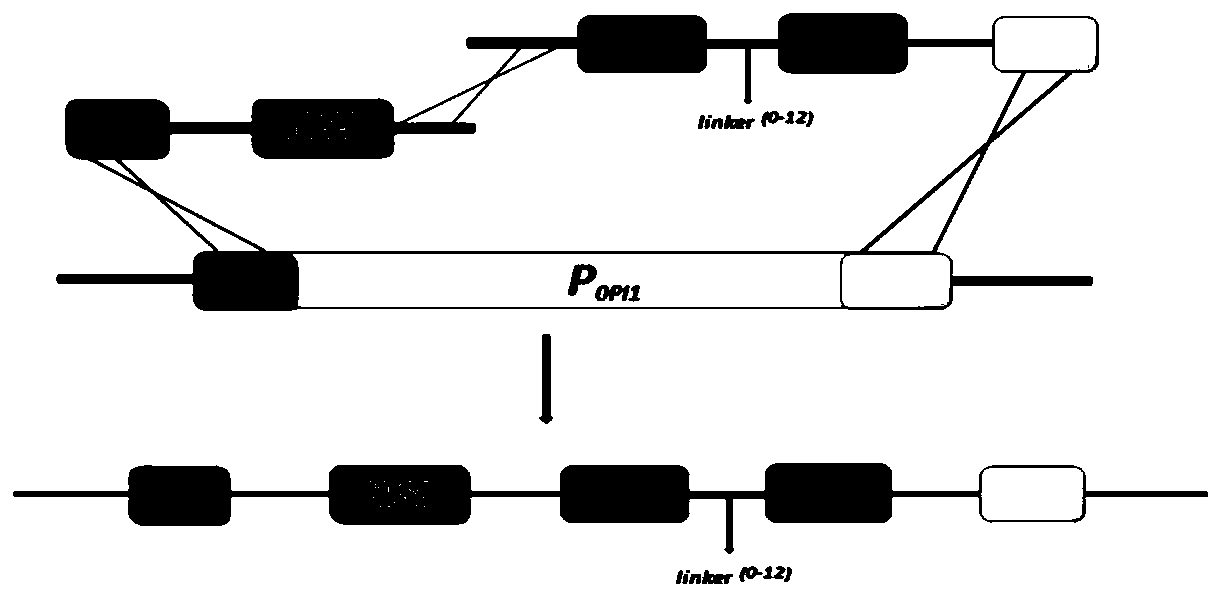

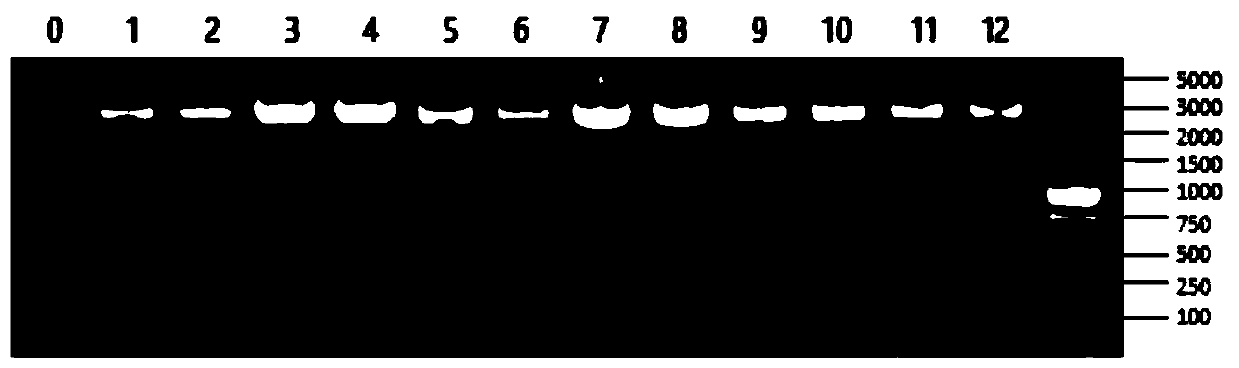

Method for producing glucaric acid by improving yeast fermentation by use of fusion expression

InactiveCN104911117AIncreased glucaric acid productionIncrease productionFungiMicroorganism based processesPichia pastorisGlucaric Acid

Owner:JIANGNAN UNIV

Compositions and methods for producing chemicals and derivatives thereof

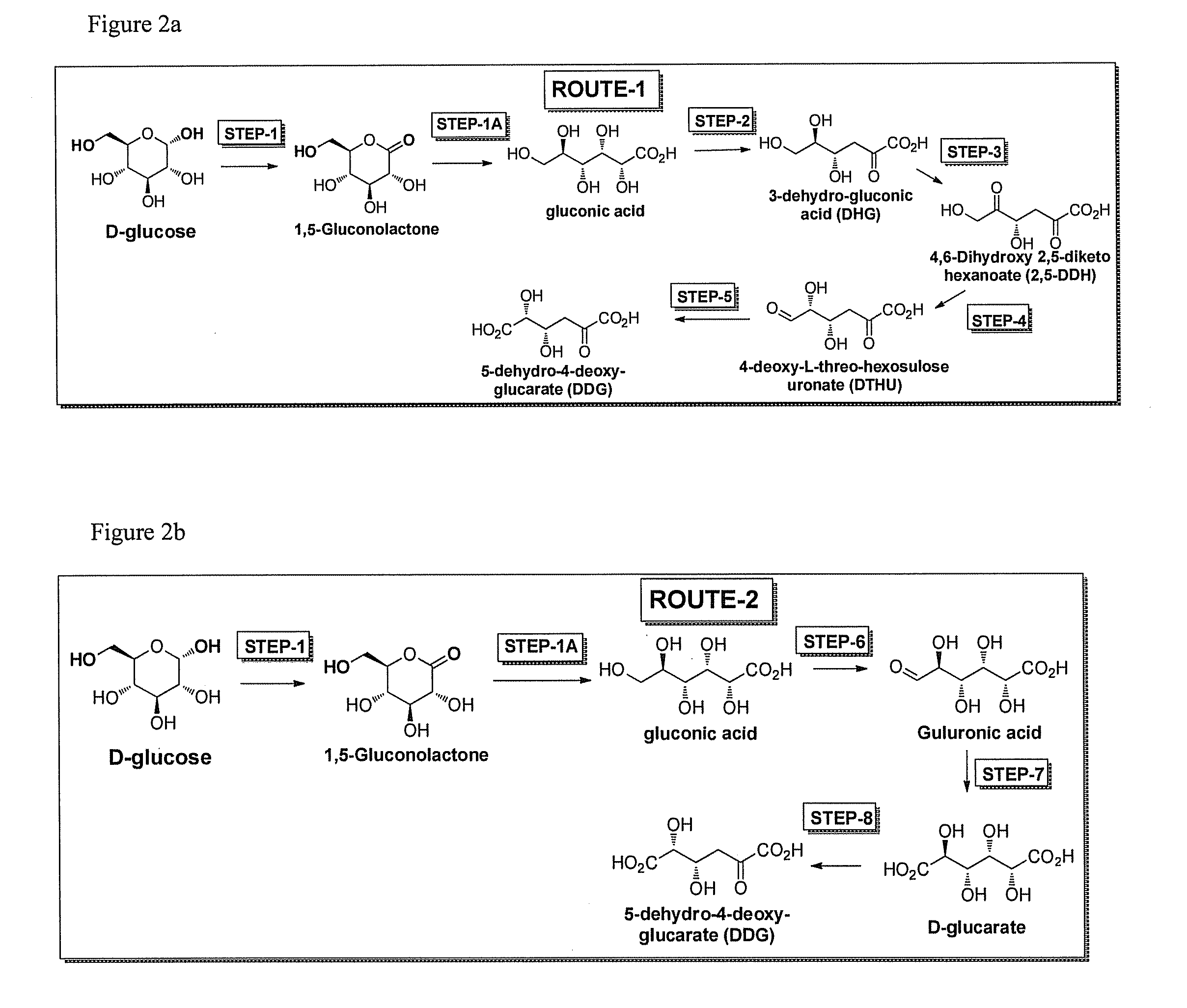

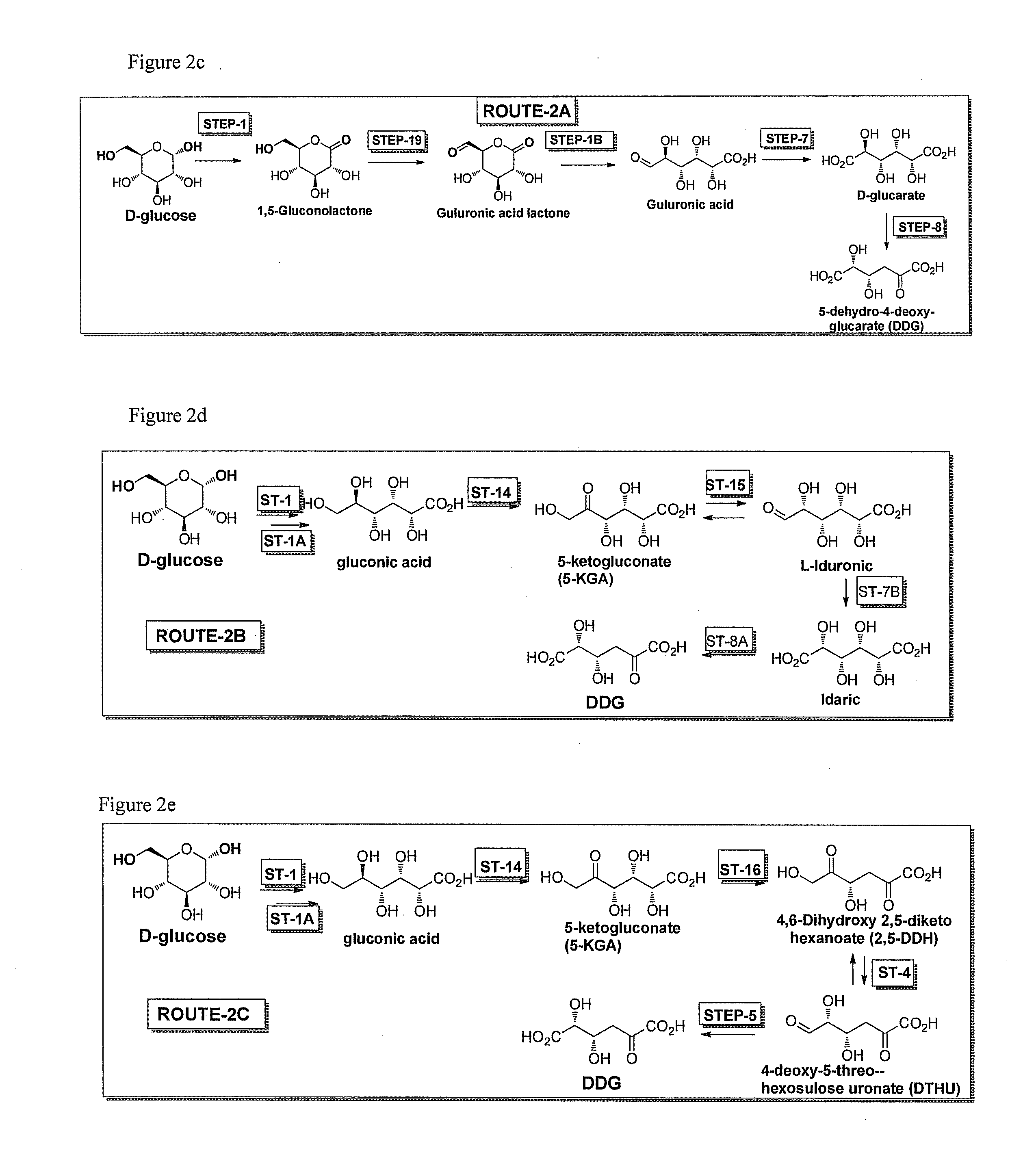

InactiveUS20140206047A1Strong specificityImprove efficiencyOrganic chemistryFermentationMetaboliteD-Glucose

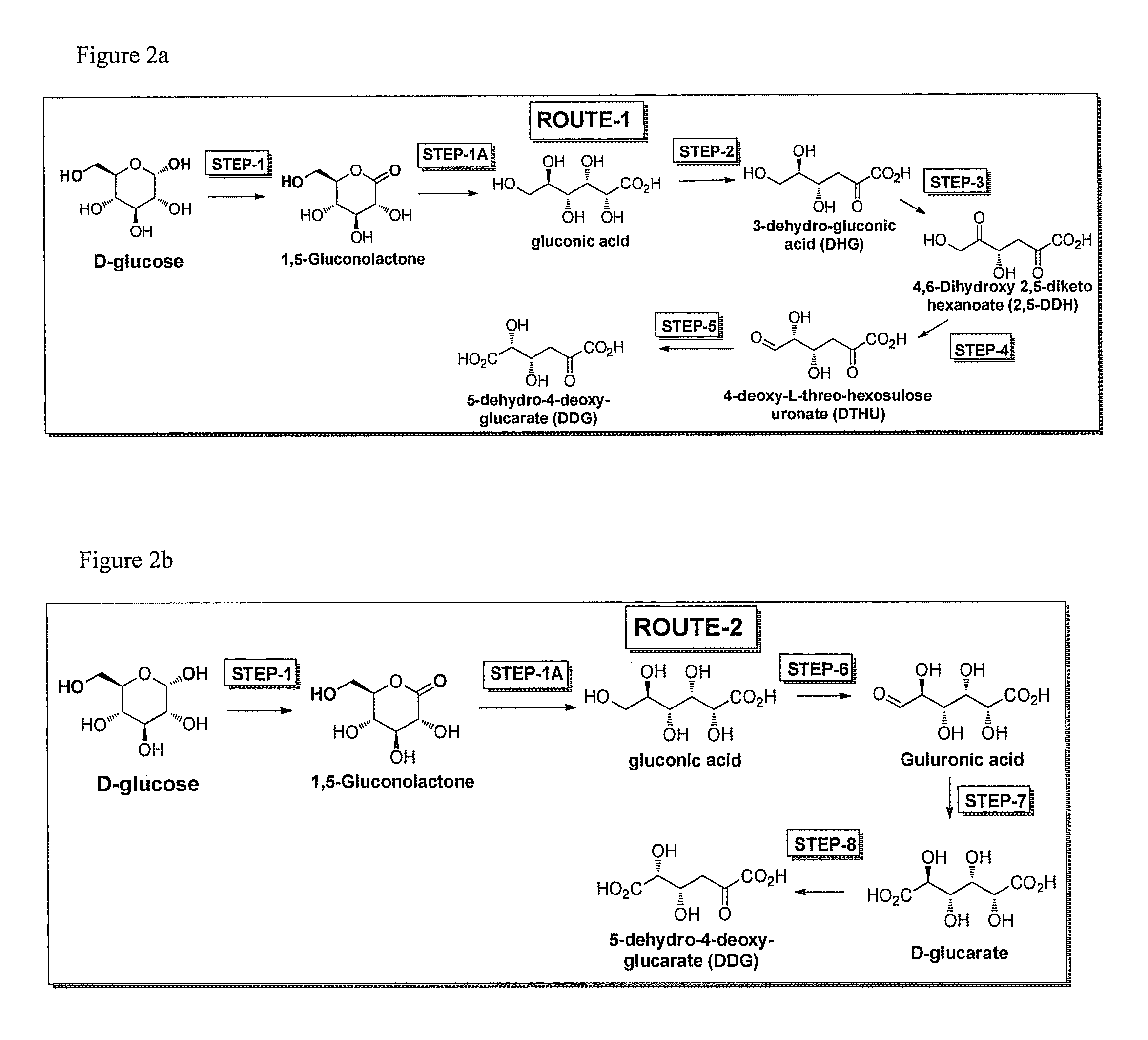

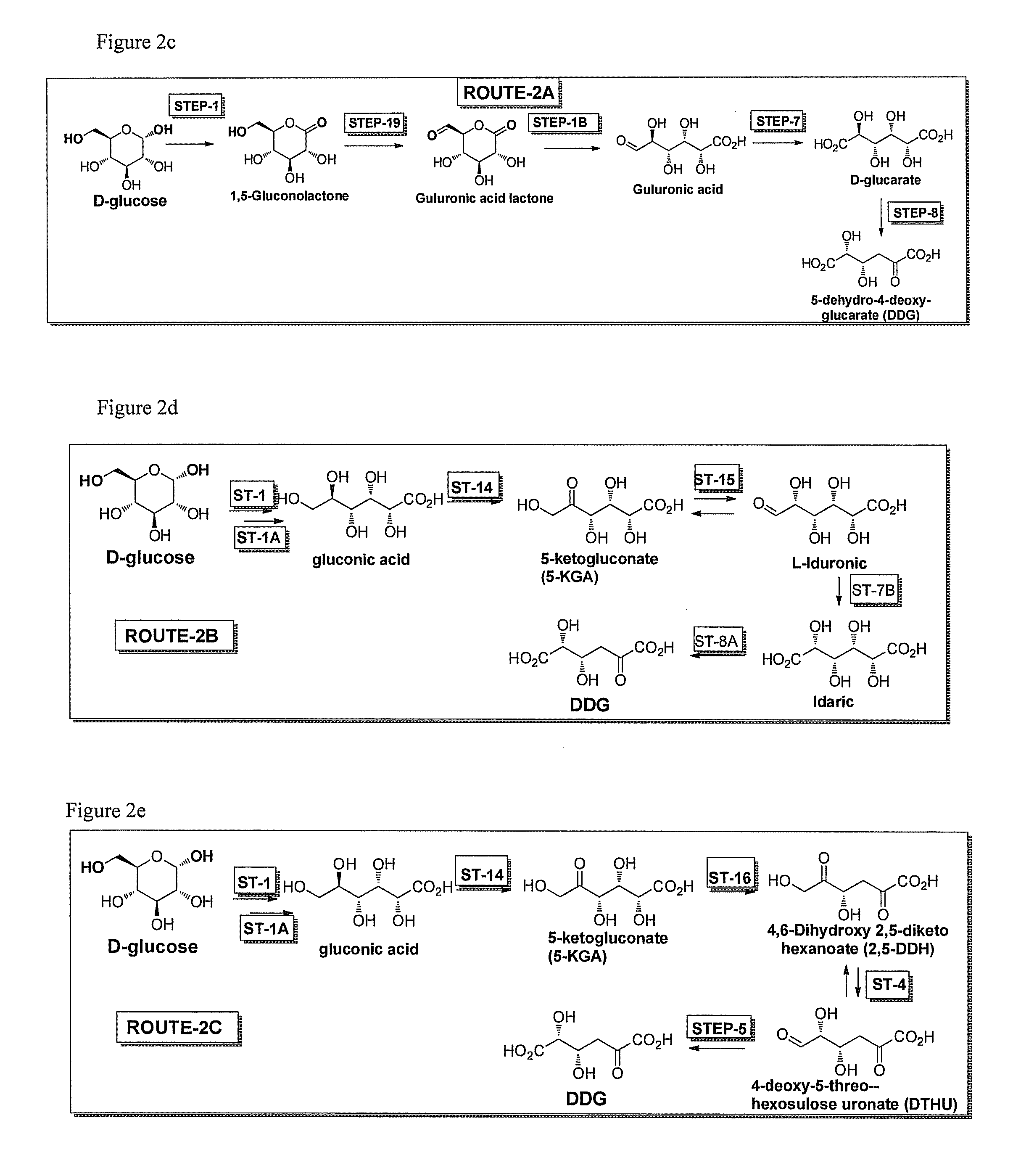

The present invention provides methods for producing a product of one or more enzymatic pathways. The pathways used in the methods of the invention involve one or more conversion steps such as, for example, an enzymatic conversion of guluronic acid into D-glucarate (Step 7); an enzymatic conversion of 5-ketogluconate (5-KGA) into L-Iduronic acid (Step 15); an enzymatic conversion of L-Iduronic acid into Idaric acid Step 7b); and an enzymatic conversion of 5-ketocluconate into 4,6-dihydroxy 2,5-diketo hexanoate (2,5-DDH) (Step 16). In some embodiments the methods of the invention produce 2,5-furandicarboxylic acid (FDCA) as a product. The methods include both enzymatic and chemical conversions as steps. Various pathways are also provided for converting glucose into 5-dehdyro-4-deoxy-glucarate (DDG), and for converting glucose into 2,5-furandicarboxylic acid (FDCA). The methods also involve the use of engineered enzymes that perform reactions with high specificity and efficiency. Additional products that can be produce include metabolic products such as, but not limited to, guluronic acid, L-iduronic acid, idaric acid, glucaric acid. Any of the products can be produced using glucose as a substrate or using any intermediate in any of the methods or pathways of the invention.

Owner:SYNTHETIC GENOMICS INC

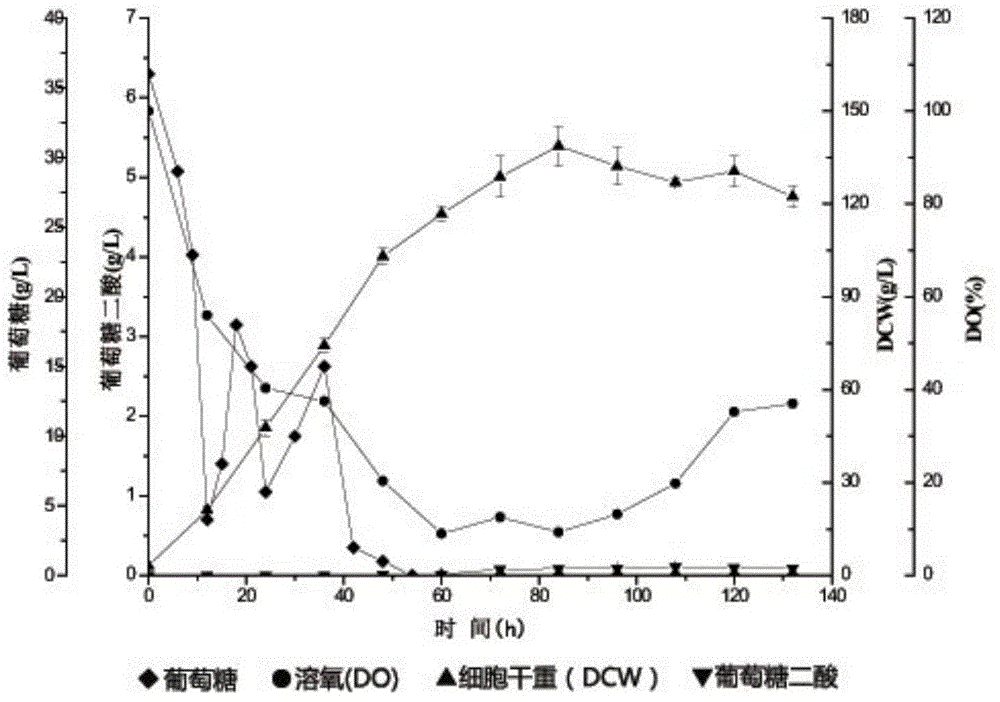

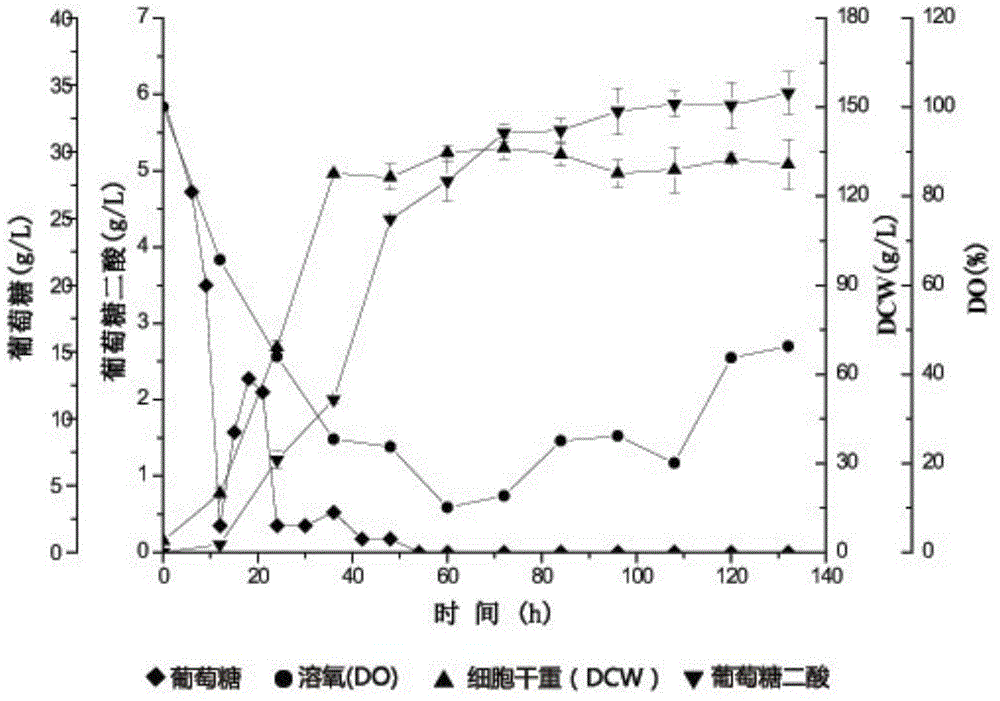

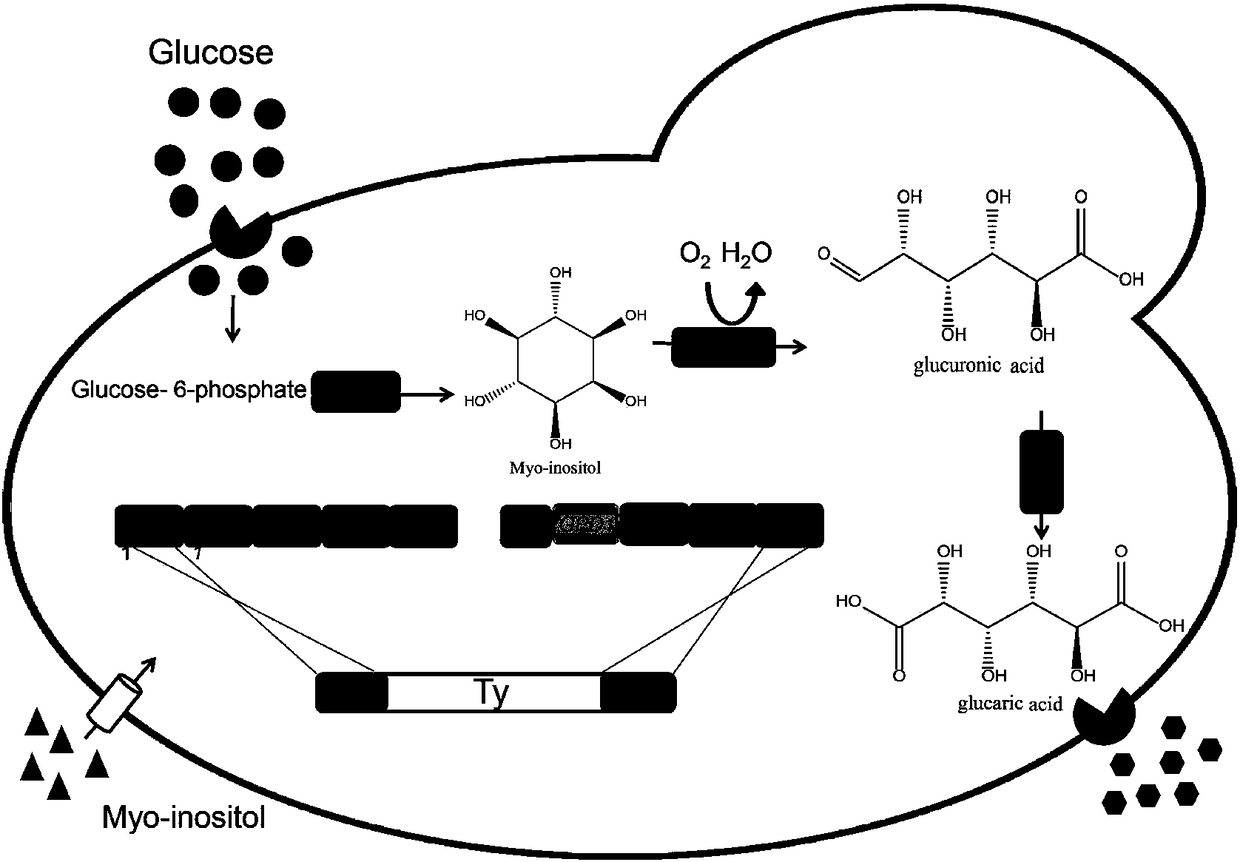

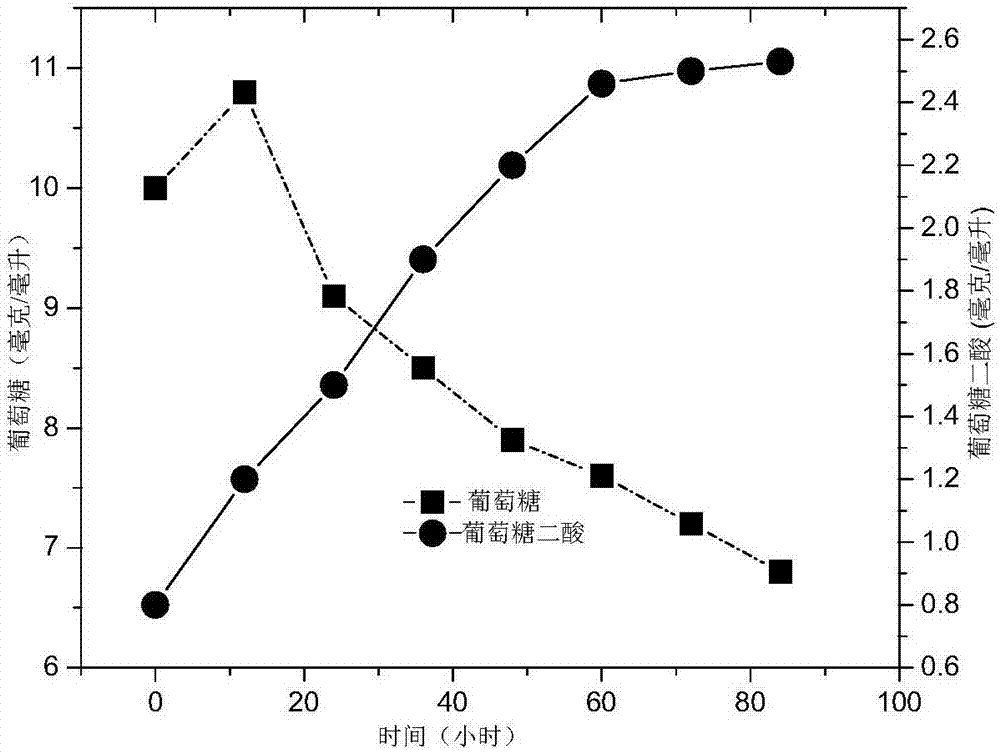

Method for producing glucaric acid by improving saccharomyces cerevisiae engineered strain fermentation

The invention discloses a method for producing glucaric acid by improving saccharomyces cerevisiae engineered strain fermentation, and belongs to the technical field of bioengineering. According to the method disclosed by the invention, Delta sites of multiple copies in a saccharomyces cerevisiae genome are used as exogenous gene module integration sites, so that one-time integration of an exogenous gene module is realized so as to fulfil the aim of expression of the multiple copies. According to the method disclosed by the invention, through an integration expression way, gene engineering bacteria subjected to the integration of genome Delta sites is passaged for 20 times; and under the same fermentation condition, the yield of the glucaric acid is still 3.8g / L, and the method has an important application meaning on industrial production of the glucaric acid.

Owner:JIANGNAN UNIV

Preparation method and application of Ni-MOF/NiF bifunctional catalyst for simultaneously preparing hydrogen and glucaric acid

InactiveCN109675639AConducive to loadImprove production efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsElectrolytic organic productionElectrolysisMetal-organic framework

The invention discloses a preparation method of a Ni-MOF / NiF bifunctional catalyst for simultaneously preparing hydrogen and glucaric acid and application of the catalyst in bifunctional electrocatalysis, and belongs to the technical fields of nano-catalysis, nano materials and metal organic framework object materials. The preparation method comprises the following main steps: taking a benzenetricarboxylic acid solution and a nickel nitrate solution as raw materials; carrying out room temperature electrodeposition on Ni-MOF to obtain foamed nickel NiF; activating to obtain the Ni-MOF / NiF catalyst. The cost of raw materials for preparing the catalyst is low; a preparation process has the advantages of simplicity, low reaction energy consumption and industrial application prospect. The catalyst is used for efficient catalytic electrolysis water hydrogen evolution and efficient oxidation of gluconic acid into the glucaric acid, and has the advantages of high electrocatalytic activity, high electrochemical stability and the like.

Owner:UNIV OF JINAN

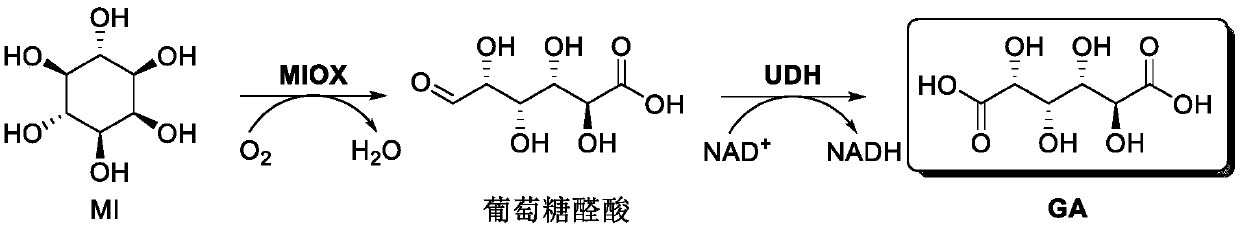

Recombinant escherichia coli, construction method thereof and method for producing glucaric acid by virtue of metabolic engineering

PendingCN106929459AShortened cultureLow nutritional requirementsBacteriaMicroorganism based processesEscherichia coliGluconic acid

The invention discloses a recombinant Escherichia coli, a construction method thereof and a method for producing glucaric acid by virtue of metabolic engineering and belongs to the field of metabolic engineering. According to the invention, a production way of glucuronic acid is realized by expressing an inositol-1-phosphate synthase gene (Ino1) and an inositol oxidase gene (MIOX) which are sourced from plants in Escherichia coli, and a synthesis route of the glucaric acid is also successfully constructed by expressing an aldehyde acid dehydrogenase gene (Udh) sourced from Agrobacterium tumefaciens, wherein the recombinant Escherichia coli generates 2.53g / L of glucaric acid in an LB-G (10g / L of glucose is added into an LB culture medium) fermentation culture medium. The method provided by the invention for producing the glucaric acid by the recombinant Escherichia coli through fermentation has a broad development prospect and lays a foundation for biosynthesis of the glucaric acid.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing glucaric acid

ActiveCN105777535AEasy to synthesizeOrganic compound preparationCarboxylic preparation by oxidationCatalytic oxidationPotassium hydroxide

The present invention relates to a method of producing glucaric acid. More particularly, provided is a method of producing glucaric acid, which comprises the steps of: (1) injecting aldohexose and potassium hydroxide to an aqueous solution; and (2) injecting a noble metal supported catalyst to the reactant in the presence of oxygen gas and inducing a catalytic oxidation reaction.

Owner:HYUNDAI MOTOR CO LTD +1

Preparation and separation of a di-carboxylic acid-containing mixture

ActiveUS20180086688A1Cation exchanger materialsOrganic compound preparationD-GlucoseGlucose polymers

Processes for separating a di-carboxylic acid or salt thereof from a mixture containing the di-carboxylic acid or salt thereof and one or more other components are provided. Also separation media useful for these separation processes is provided. In particular, processes for preparing an aldaric acid are described, such as glucaric acid from glucose, which includes separating the aldaric acid from the reaction product. Also, various glucaric acid products are described.

Owner:ARCHER DANIELS MIDLAND CO

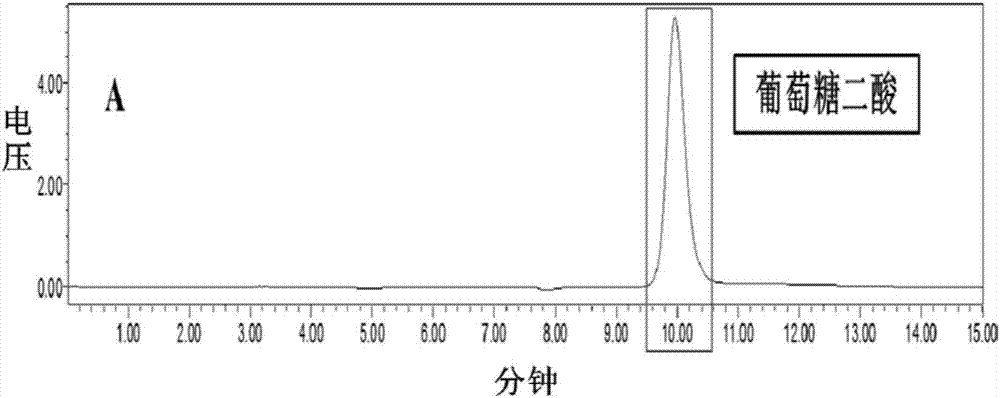

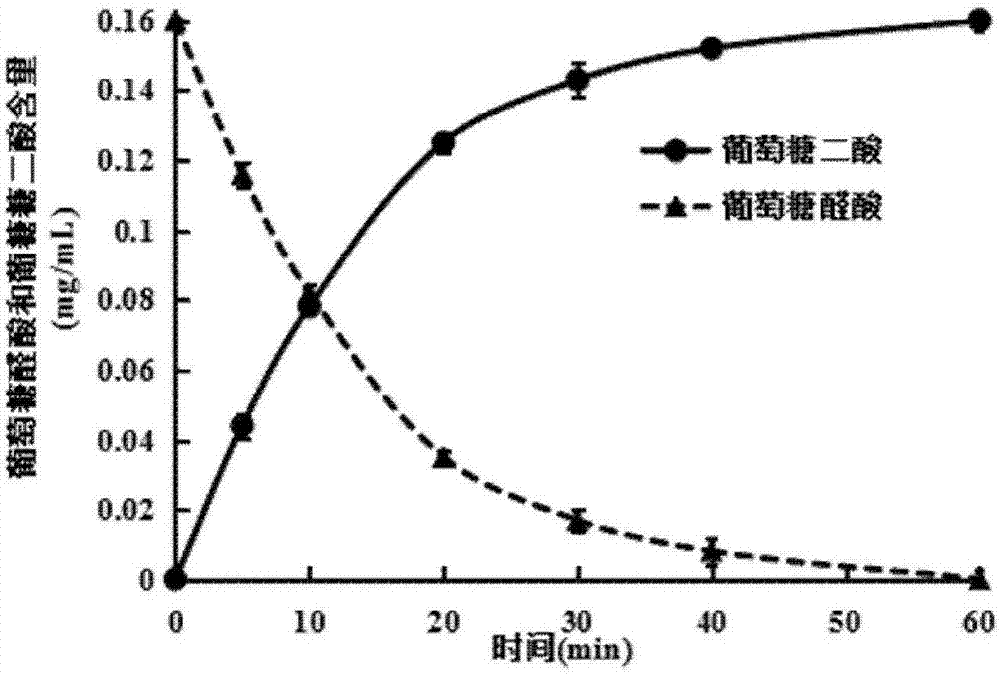

Preparation method of glucaric acid

The invention discloses a method for preparing glucaric acid from inositol by adopting a ''one pot-two step'' enzyme catalysis means, and comprises the following steps: catalyzing inositol by utilizing inositol oxidase so as to produce an intermediate glucuronic acid; and then, converting the intermediate glucuronic acid into the glucaric acid by utilizing aldehyde dehydrogenase. Compared with existing gluconic acid production methods, the method disclosed by the invention has the advantages of being simple in production process, green, friendly, high in yield, conducive to large-scale preparation and the like.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Preparation and separation of a di-carboxylic acid-containing mixture

Processes for separating a di-carboxylic acid or salt thereof from a mixture containing the di-carboxylic acid or salt thereof and one or more other components are provided. Also separation media useful for these separation processes is provided. In particular, processes for preparing an aldaric acid are described, such as glucaric acid from glucose, which includes separating the aldaric acid from the reaction product. Also, various glucaric acid products are described.

Owner:ARCHER DANIELS MIDLAND CO

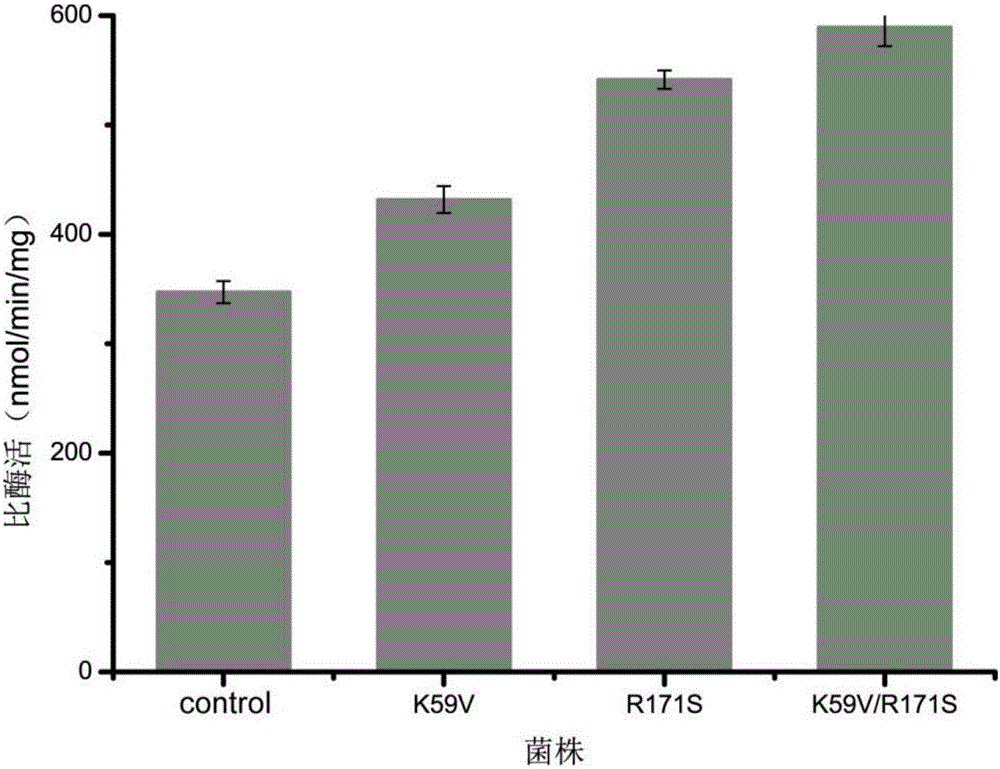

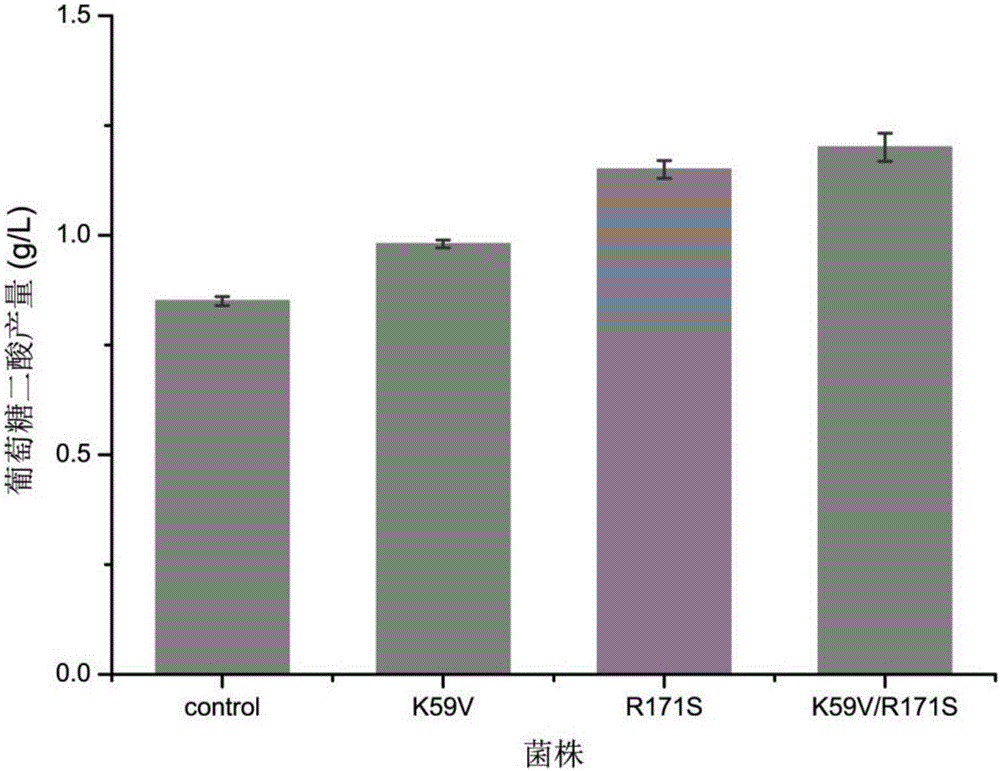

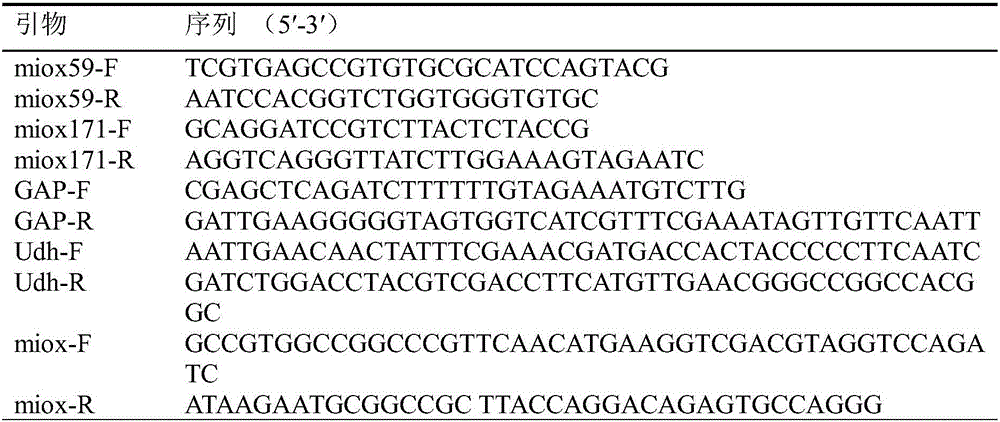

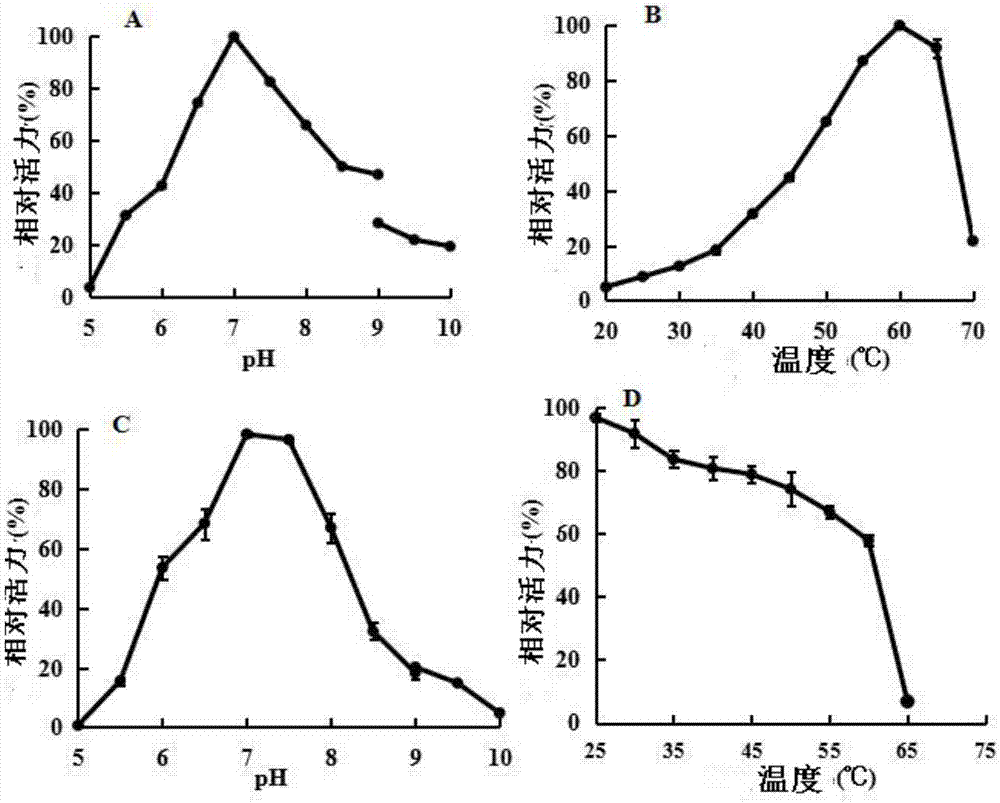

Inositol oxygenase mutant and application thereof

The invention discloses an inositol oxygenase mutant and application thereof, and belongs to the technical field of bioengineering. The method comprises the steps that an inositol oxygenase mutant with improved enzyme activity is obtained through site-specific mutagenesis and co-expressed with aldehyde dehydrogenase (udh) in yeast, and the glucaric acid synthetic route is enhanced. Through comparisons, the yield of recombinant Pichia pastoris GS115-udh-mioxK59V / R171S is the highest, and glucaric acid 1.20g / L is produced in a YPD-MI culture medium during flask shaking fermentation culture. A metabolic engineering strategy is adopted, microbiological strains are improved to synthesize the target product glucaric acid, and a certain foundation is laid for efficient production of glucaric acid through a biological method.

Owner:JIANGNAN UNIV

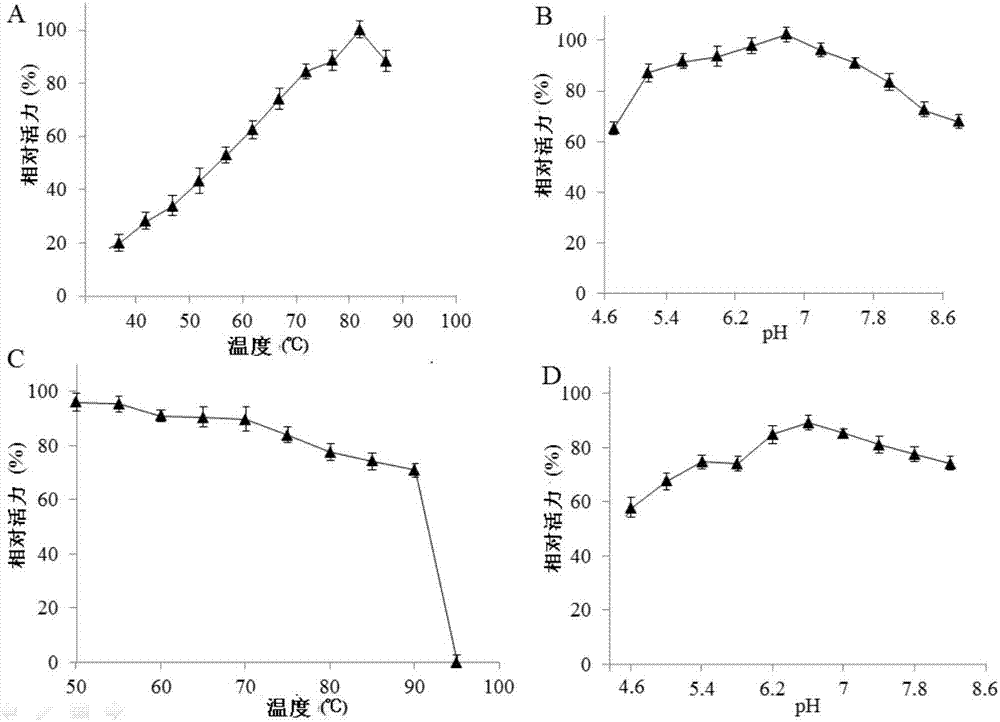

Preparation method of glucaric acid and uronic acid dehydrogenase-NADH oxidase and application thereof in preparation

ActiveCN107365806ASolve pollutionMild reaction conditionsOxidoreductasesFermentationFiberAlpha-glucuronidase

The invention discloses a preparation method of glucaric acid and uronic acid dehydrogenase-NADH oxidase and an application thereof in preparation. The preparation method includes: taking xylan extracted in wood fiber plants as a raw material; preparing glucuronic acid by adopting a high-temperature xylanase and alpha-glucuronidase hydrolyzing technology; preparing the glucaric acid by oxidizing the glucuronic acid generated through the double-functional uronic acid dehydrogenase-NADH oxidase. With the method, use amount of NAD can be effectively saved, the NAD is regenerated in situ by taking the NADN oxidase as uronic acid dehydrogenase to promote circulation of coenzyme, the uronic acid dehydrogenase continuously catalyzes the glucuronic acid to be converted into the glucaric acid, catalytic efficiency is improved, and conversion rate can be up to 100%; meanwhile, the preparation method has the advantages of high efficiency, rapidness, specificity and moderate reaction conditions, and chemical substances of acid, alkali and the like are not involved in the entire preparation process; the preparation method is low in energy consumption and small in pollution, and operation is simple and easy to control.

Owner:NANJING NORMAL UNIVERSITY

Production of adipic acid and derivatives from carbohydrate-containing materials

InactiveCN105348070ALactams preparationCarboxylic acid nitrile preparationCatalytic oxidationHydrodeoxygenation

The present invention generally relates to processes for the chemocatalytic conversion of a glucose source to an adipic acid product. The present invention includes processes for the conversion of glucose to an adipic acid product via glucaric acid or derivatives thereof. The present invention also includes processes comprising catalytic oxidation of glucose to glucaric acid or derivative thereof and processes comprising the catalytic hydrodeoxygenation of glucaric acid or derivatives thereof to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

Preparation method of calcium glucarate

ActiveCN109678695ANo pollution in the processEasy to operateOrganic compound preparationCarboxylic acid salt preparationCatalytic oxidationGluconic acid

The invention relates to a preparation method of calcium glucarate, and belongs to the field of pharmacy. The invention provides a preparation method of the calcium glucarate. The preparation method comprises the following steps: (1) putting glucose, oxygen and a metal catalyst palladium vanadium ammonium into a high-pressure reactor for catalytic oxidation reaction to obtain glucaric acid; (2) after the oxidation reaction, adding potassium-containing alkali to convert the glucaric acid into potassium gluconate; (3) enabling the potassium gluconate to react with an acid to release the glucaricacid; (4) enabling the glucaric acid to react with the calcium-containing alkali to obtain the calcium glucarate. The preparation method disclosed by the invention is pollution-free to the environment, and meanwhile, the total yield is increased; the catalyst can be repeatedly used; the cost is reduced; the calcium content is 98 to 102 percent; a small amount of industrial wastewater, waste residues and waste gas are generated; the preparation method is suitable for industrial production.

Owner:江苏东南纳米材料有限公司

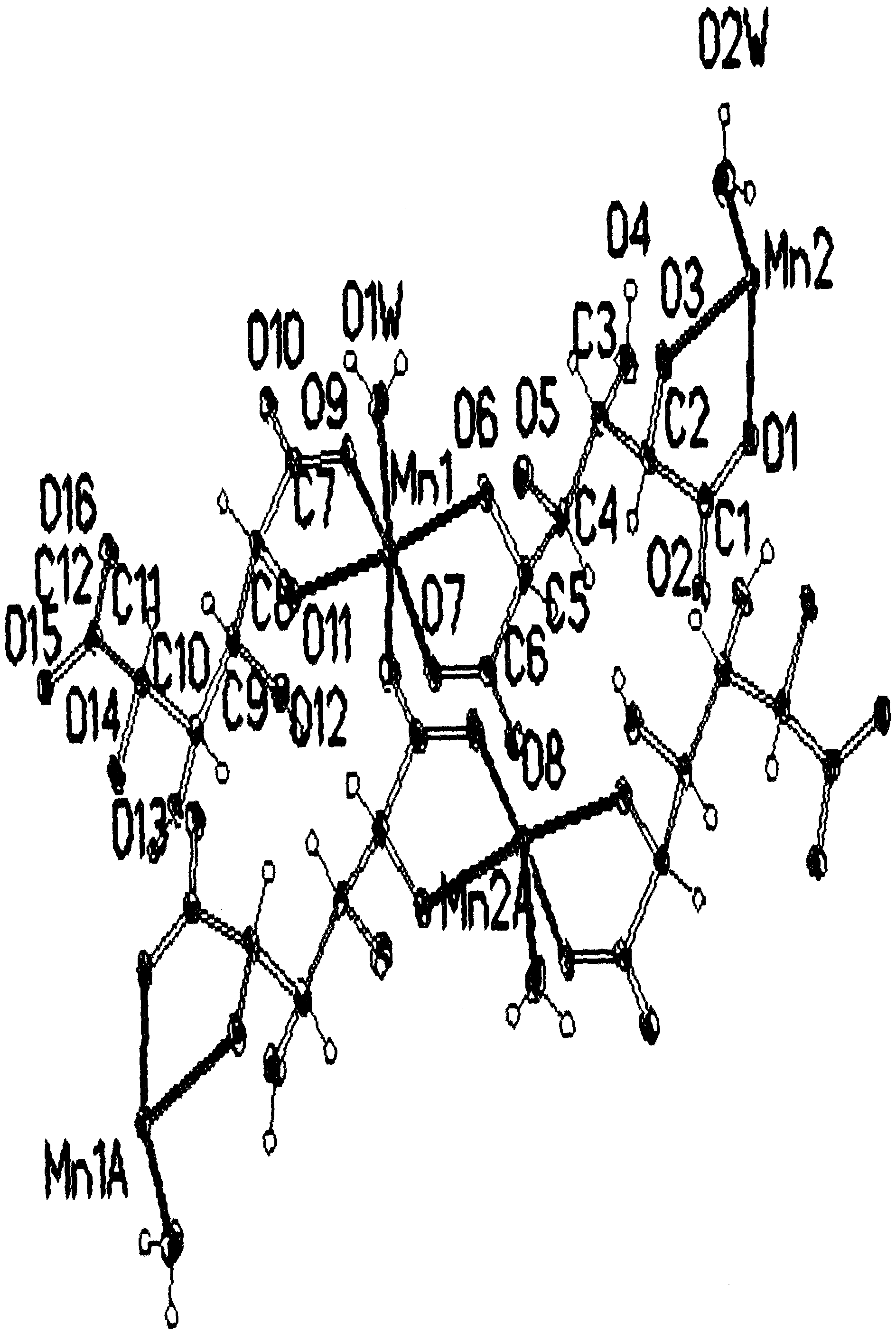

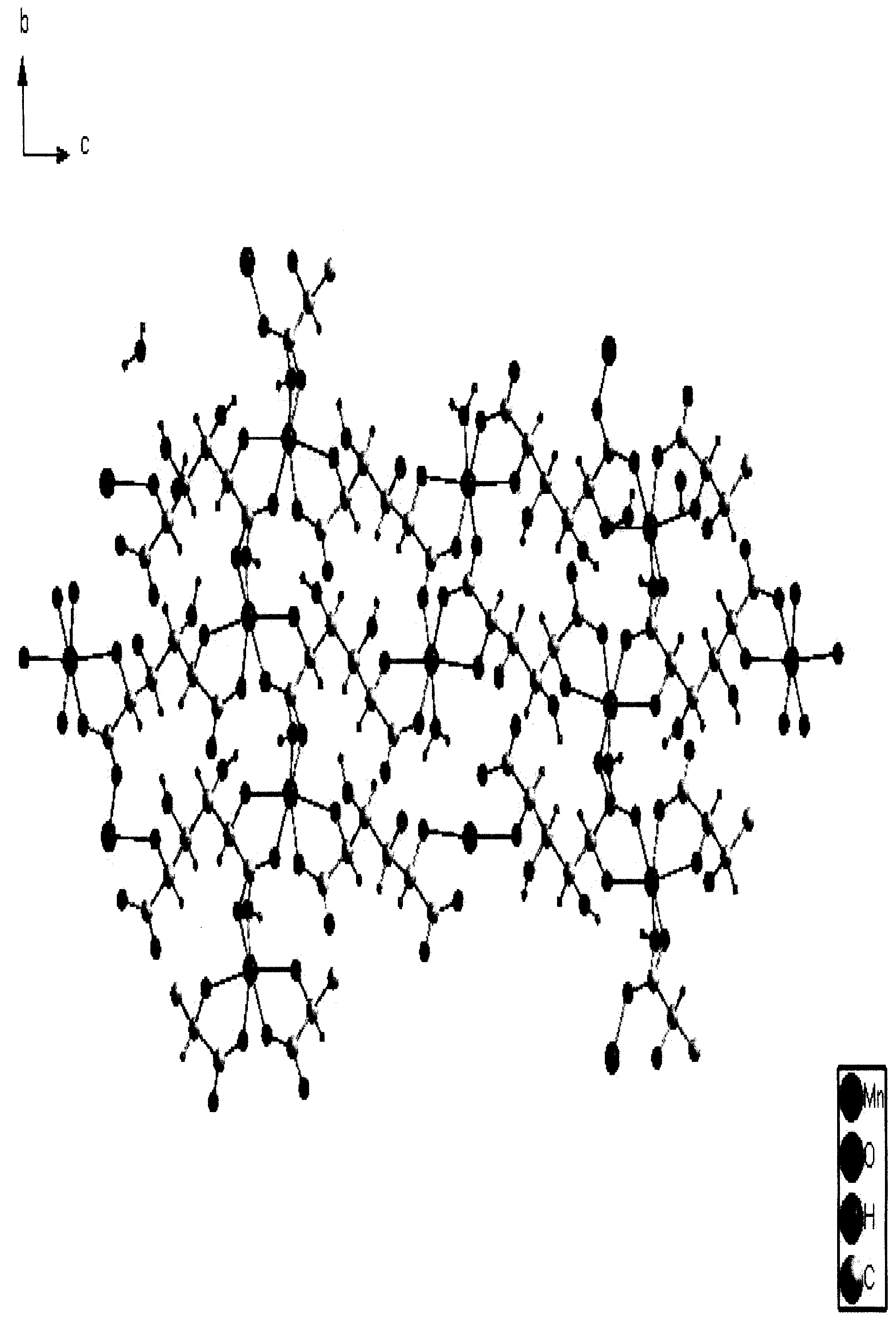

Nickel-hydrogen battery anode material prepared from glucaric acid metal complex doped beta-Ni(OH)2 and method thereof

InactiveCN101585561AIncrease capacityIncrease profitCell electrodesNickel oxides/hydroxidesAdhesiveSlurry

The invention discloses a nickel-hydrogen battery anode material prepared from glucaric acid metal complex doped beta-Ni(OH)2, comprising an anode active substance, electric conductive agent and adhesive, wherein the anode active substance is formed by the glucaric acid metal complex and the beta-Ni(OH)2 at the mass percent of 1.5-13.5 percent. The method for preparing the nickel-hydrogen battery anode material comprises the following steps: synthetizing glucaric acid metal complex powder; uniformly mixing a glucaric acid metal complex and beta-Ni(OH)2 under the basic condition by a solution method so as to prepare anode active substance powder; uniformly mixing the anode active substance powder, the electric conductive agent and the adhesive to form powder slurry; and filling the powder slurry into a foam nickel base plate and pressing and drying the powder slurry to prepare a battery anode. The material has high integrated electrical properties, and a nickel-hydrogen battery prepared by the invention is improved in the capacity by 1 percent to 7 percent and the utilization ratio, the cycle life and the charging efficiency in a high temperature environment.

Owner:ZHEJIANG NORMAL UNIVERSITY

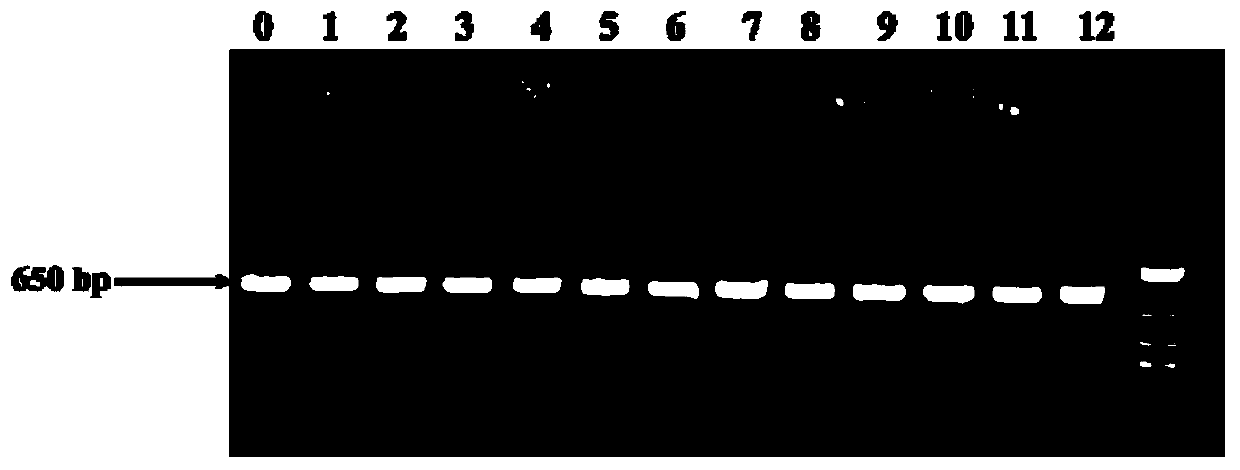

Method for improving efficiency of synthesizing glucaric acid by saccharomyces cerevisiae engineering strain

ActiveCN111019852APathway inefficiencyPathway Efficiency ImprovementFungiMicroorganism based processesUronic acidGlucaric Acid

The invention, which belongs to the technical field of bioengineering, discloses a method for improving the efficiency of synthesizing glucaric acid by a saccharomyces cerevisiae engineering strain. An opi1 deletion strain under the background of saccharomyces cerevisiae BY4741 is used as an original strain, myoinositol oxygenase MIOX4 derived from Arabidopsis thaliana and uronic acid dehydrogenase udh derived from pseudomonas syringae are linked through different linkers; and then integration to genome of a saccharomyces cerevisiae opi1 deletion strain is performed. After fusion expression, under the same fermentation condition, the maximum yield of the Bga-L12 engineering bacteria reaches 1.45 g / L, and the yield of the Bga-L12 engineering bacteria is increased by about 5 times by being compared with that of saccharomyces cerevisiae engineering bacteria which are not subjected to MIOX4 and udh fusion expression. And a foundation is laid for further metabolic transformation of the glucaric acid engineering bacteria.

Owner:JIANGNAN UNIV

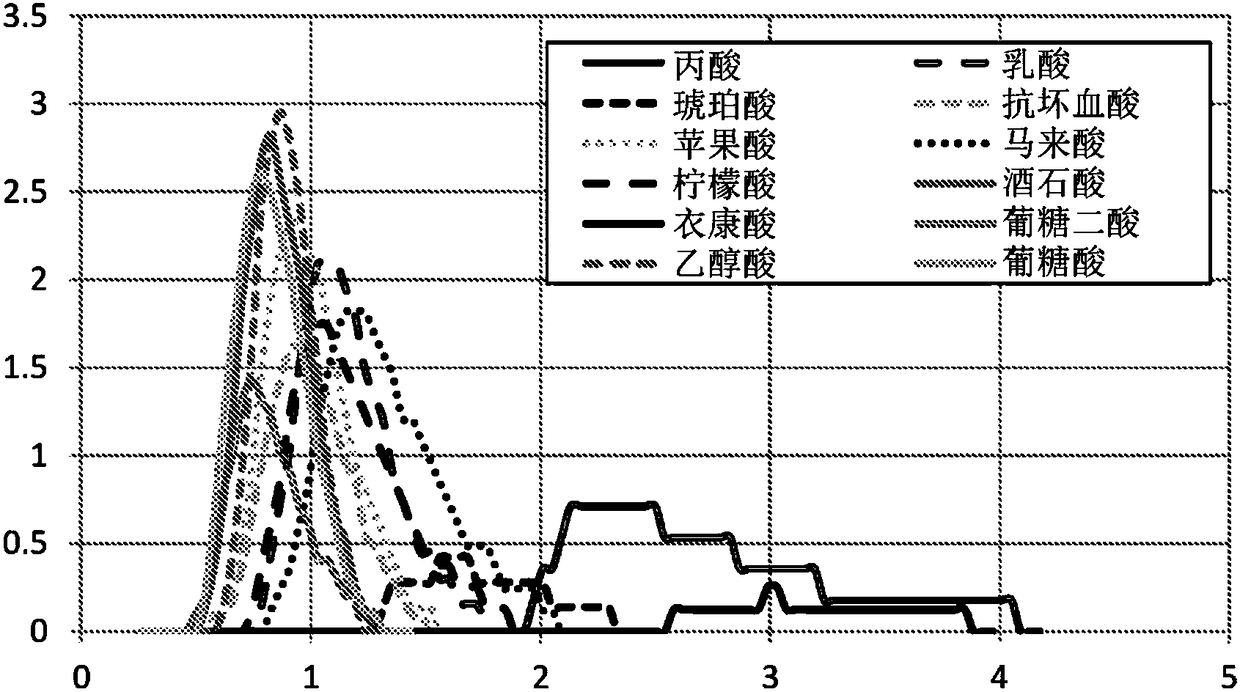

Chromatographic separation of organic acids using polymeric macroporous adsorbent

PendingCN108367212AIon-exchange process apparatusIon-exchanger regenerationSaccharic acidChromatographic separation

Provided is a method for chromatographically separating a first class of organic acids from a second class of acids which are both present in a liquid feed mixture by passing the liquid feed mixture through a bed including a non-functionalized polymeric macroporous adsorbent, wherein: i) the first class of organic acids are selected from one or more of: propionic acid, lactic acid, itaconic acid,succinic acid, maleic acid, citric acid, ascorbic acid and alpha-ketoglutaric acid; and ii) the second class of organic acids are selected from one or more of: glycolic acid, gluconic acid, malic acid, tartaric acid and saccharic acid.

Owner:DOW GLOBAL TECH LLC +1

Culture medium for eukaryotic cells

InactiveUS20150017717A1Attractive performanceReduce varianceAnimal cellsCulture process2-Hydroxybutyric acidErythronic acid

The invention pertains to the use of C2-C6alpha-hydroxy acids selected from L-3-phenyl lactic acid, mucic (galactaric) acid, gluconic acid, glucaric acid, glyceric acid, 2-hydroxy butyric acid, alpha-hydroxyisovaleric acid, alpha-hydroxyisocaproic acid and erythronic acid and combinations thereof, as a growth- and production promoting ingredient, in culture media for culturing eukaryotic cells. The invention further pertains to culture media containing these alpha-hydroxy acid derivatives at levels of at least 0.001 mg / l.

Owner:FRIESLAND BRANDS BV

Engineering strain for efficient biosynthesis of glucaric acid (GA) and application of engineering strain

InactiveCN111647543AGentle production processReduce manufacturing costBacteriaMicroorganism based processesEscherichia coliRecombinant escherichia coli

The invention provides an engineering strain for efficient biosynthesis of glucaric acid (GA) and an application of the engineering strain. The method successfully constructs a synthesis path from glucuronic acid to GA by expressing Udh derived from Pseudomonas synxantha strain KENGFT3 and Pseudomonas fragi strain P121 in Escherichia coli; recombinant Escherichia coli is subjected to cell transparent treatment, and when the cell concentration is 20 g / L, the content of GA reaches 975.5 mg / L+ / -0.15. The recombinant strain and a transformation process provided by the present invention have greatadvantages in the preparation of the GA, and have the potential for industrial application.

Owner:UNIV OF JINAN

Process for making esters of 2,5-furandicarboxylic acid

A process is provided for making esters of FDCA, in which an aqueous feed comprising glucaric acid is first reacted with a high boiling first alcohol in the presence of an acid catalyst and with removing water during the reaction, to form a first product mixture comprising a first ester of FDCA and the high boiling first alcohol, then unreacted high boiling first alcohol is removed from the first product mixture. The first ester of FDCA and the high boiling first alcohol is then transesterified with a lower boiling second alcohol selected from the group consisting of methanol, ethanol, isopropanol and n-propanol, to form a second product mixture comprising a second ester of FDCA with the lower boiling second alcohol, and the second ester of FDCA with the lower boiling second alcohol is recovered.

Owner:ARCHER DANIELS MIDLAND CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com