Chromatographic separation of organic acids using polymeric macroporous adsorbent

A chromatographic separation and organic acid technology, applied in solid adsorbent liquid separation, separation/purification of carboxylic acid compounds, separation methods, etc., can solve problems such as difficult separation of organic acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

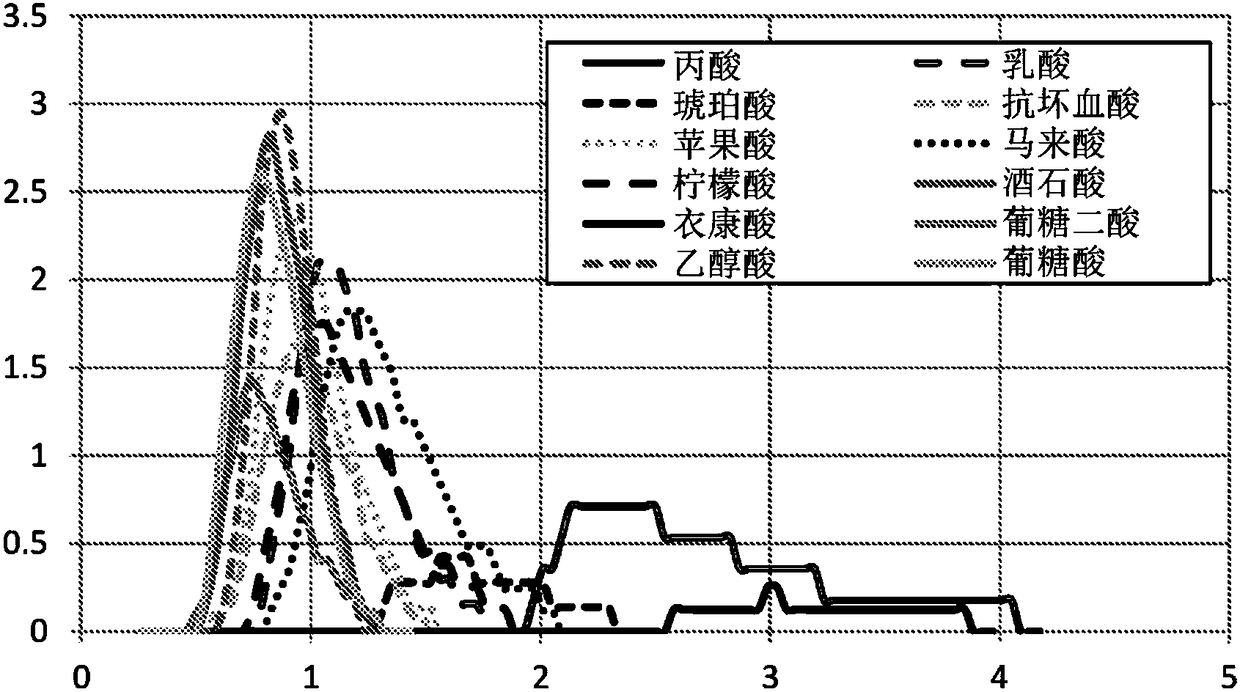

[0025] Individual compounds were injected into packed resin beds (91 cm long x 2.5 cm diameter AMBERLITE TM In FPX66, the concentration is 20% by weight or the maximum solubility of the compound in 2 g / L sulfuric acid at room temperature, whichever is lower. The injection volume was 0.05 column volume (26.3 mL). The mobile phase was 2 g / L sulfuric acid, and the column flow rate and column temperature were 3.0 column volume / hour (26.2 mL / min) and 53°C, respectively. Fractions (8 mL each) were collected and analyzed by a Reichert AR200 handheld refractometer to determine the compound concentration in each fraction. Compound standards of known concentration were used to convert the refractometer signal to concentration in g / L. figure 1 The results of this analysis for selected components are overlaid in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com