Method for improving gluconobacter oxydans for producing 2-keto-L-gulconic acid

A technology for oxidizing glucose and acid bacteria, applied in the field of genetic engineering, can solve problems such as difficulty, prolong production cycle, pouring cans, etc., and achieve the effect of simple construction method and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The construction of embodiment 1 expression vector and one-step engineering bacterium

[0034] For the construction method of the Escherichia coli-Gluconobacter oxydans shuttle plasmid vector pGUC, please refer to the 2014 doctoral dissertation of Jiangnan University: Construction and optimization of engineering bacteria for the production of 2-keto-L-gulonic acid by single-step fermentation, Korea Lili.

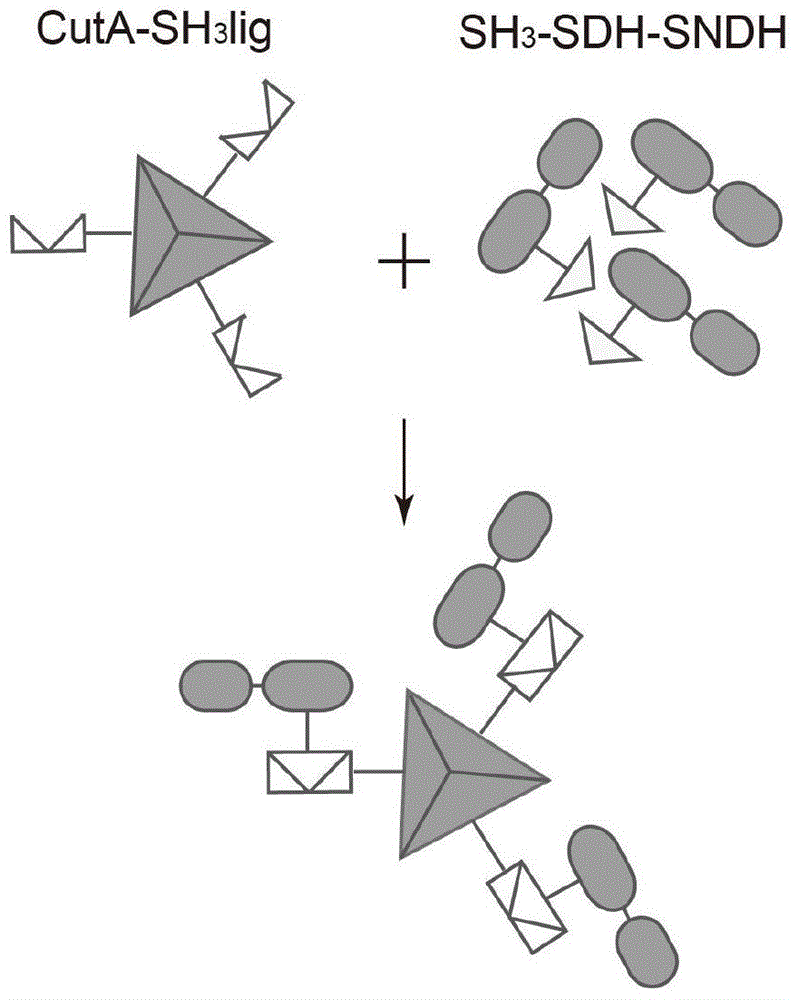

[0035] (1) connecting the gene sdh encoding sorbose dehydrogenase and the gene sndh encoding sorbose dehydrogenase with the gene encoding the connecting peptide GGGGS to obtain the sequence of sdh-GGGGS-sndh as shown in SEQ ID NO.5; The sequence encoding the adapter protein SH3 (SEQ ID NO.2) was fused with sdh-GGGGS-sndh to obtain SH3-sdh-GGGGS-sndh; the plasmid pGUC was used as a vector, and the tufB (SEQ ID NO.4) promoter was ligated by enzyme digestion, The dehydrogenase fusion expression vector pGUC-tufB-SH3-sdh-GGGGS-sndh with adapter protein was obtained;

[00...

Embodiment 2

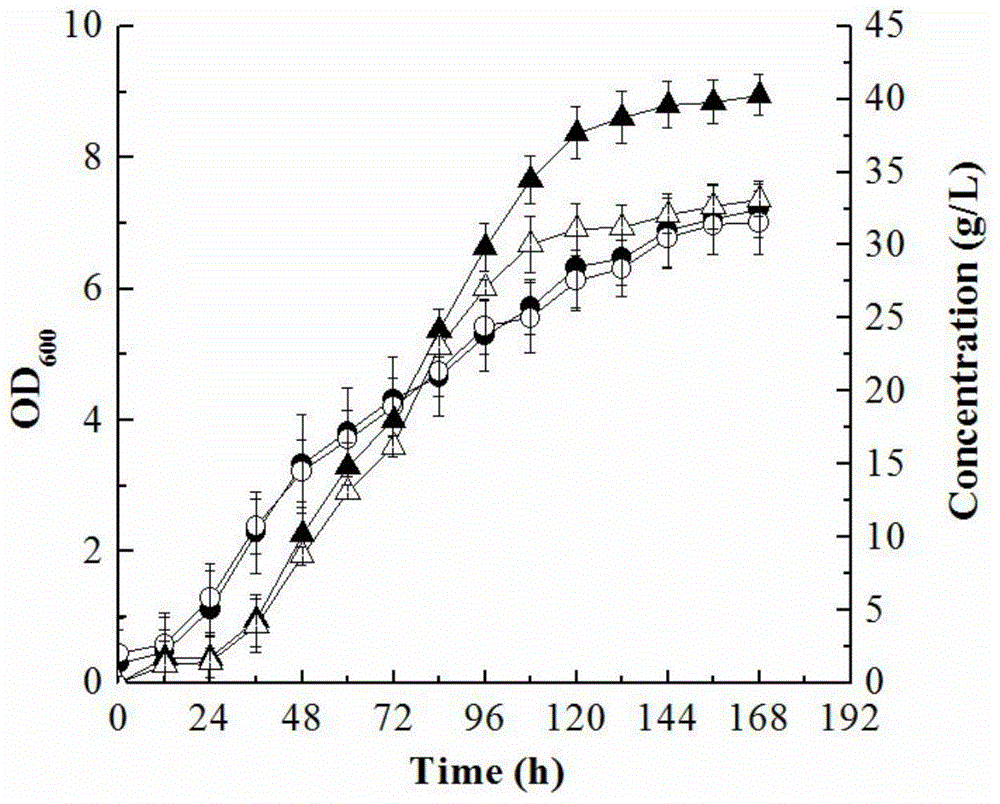

[0041] Embodiment 2 fermentation produces 2-KLG

[0042] Seed medium (g / L): sorbitol 15, yeast powder 1, pH 4.8-5.1, agar 20 (solid medium), sterilized at 121°C for 15 minutes, final concentration of ampicillin 100 μg / mL.

[0043] Fermentation medium (g / L): sorbitol 15, yeast extract 1.2, calcium chloride 0.2, initial pH 5.1-5.4, sterilized at 121°C for 15 minutes, final concentration of ampicillin 100 μg / mL.

[0044] Culture conditions: Scrape a few rings of bacteria from the solid plate and inoculate them in a 500mL double-thorn shaker flask filled with 50mL of liquid medium (added with a final concentration of 75μg / mL ampicillin), and culture on a rotary shaker at 30°C at 200r / min To the logarithmic growth phase (about 30h), according to the 15% (v / v) inoculation amount, transfer to the fresh medium of ampicillin with a final concentration of 75 μg / mL, and then culture to the logarithmic growth phase, according to 15% (v / v) ) inoculum amount was transferred to the fermenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com