Patents

Literature

35 results about "Ketogulonigenium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reconstruction method for producing Vitamin C precursor 2-keto-L-gulonic acid (2-KLG) with gluconobacter oxydans

InactiveCN102250822AEliminate dependenciesSimple production processBacteriaMicroorganism based processesVitamin CGenetic engineering

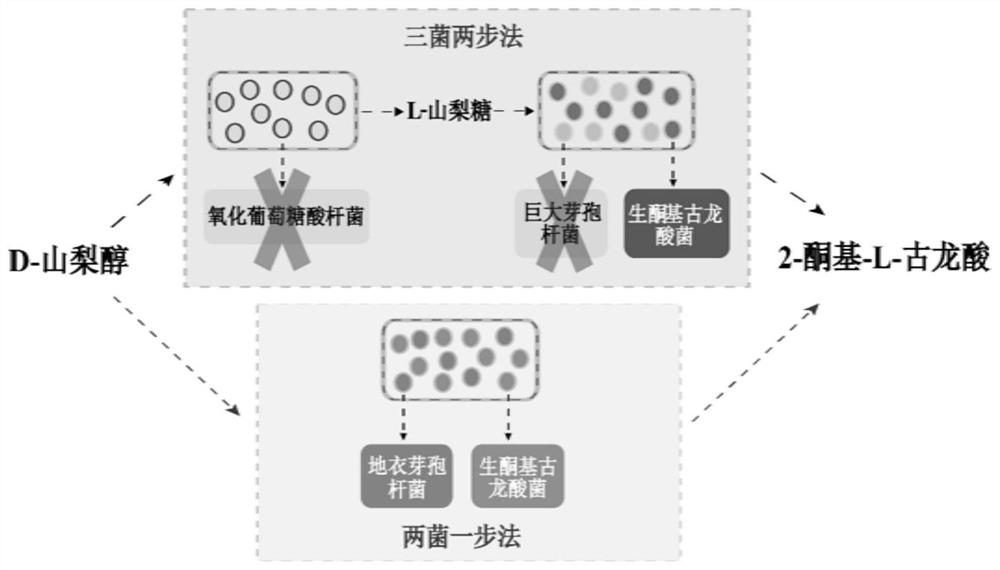

The invention discloses a reconstruction method for producing the Vitamin C precursor 2-KLG with gluconobacter oxydans, and belongs to the field of genetic engineering. According to the invention, a sorbose dehydrogenase (SDH) gene and a sorbosone dehydrogenase (SNDH) gene originated from ketogulonigenium vulgare are expressed in gluconobacter oxydans to obtain a G. oxydans engineering bacteria for production of 2-KLG by using sorbitol. G. oxydans is a frequently used strain in the first step of fermentation in the method of two-step fermentation; in the invention, the SDH and SNDH genes are expressed in G. oxydans, which enables the problem of dependency of ketogulonigenium vulgare on associated fungi to be overcome, direct conversion of D-sorbitol into 2-KLG to be realized and the production process for Vitamin C to be simplified; output of 2-KLG reaches 83 g / L; therefore, the invention has a very good application prospect.

Owner:JIANGNAN UNIV

Method for improving 2-keto-L-gulonic acid fermentation production strength

InactiveCN102465166AIncreased maximum spawn rateShorten the fermentation cycleMicroorganism based processesFermentationGeneration rateGelatin

The invention discloses a method for improving 2-keto-L-gulonic acid fermentation production strength. According to the method, a mixed strain comprising ketogulonigenium vulgare and bacillus megaterium is adopted as a production strain; L-sorbose is adopted as a substrate to carry out fermentation; 0.05-0.3% of gelatin is added to the fermentation culture media. According to the present invention, the process is adopted, such that the maximum generation rate of the 2-keto-L-gulonic acid and the maximum consumption rate of the sorbose in the fermentation liquid are respectively substantially improved, the fermentation period of the 2-keto-L-gulonic acid can be effectively shortened, and the vitamin C fermentation production strength can be improved.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

Method adding trehalose to strengthen production strength of 2-keto-L-Gulonic acid

InactiveCN101654695ASpeed up consumptionIncrease production intensityMicroorganism based processesFermentationGluconic acidTrehalose

The invention discloses a method adding trehalose to strengthen production strength of 2-keto-L-Gulonic acid, belonging to the technical filed of ferment preparation of vitamin C. The invention takesthe mixing strain of Ketogulonigenium vulgare and Bacillus megaterium as a production strain, and 10mmol.L<-1> of trehalose is exogenously added into fermentation culture medium to be used as protective agent, therefore, the cell growth and production of 2-keto-L-Gulonic acid (2-KLG) are promoted, and the efficient production of 2-KLG is realized. When 10mmol.L<-1> of trehalose is added under a hyperosmotic condition (1067.5mOsmol.kg<-1>), the content of 2-KLG is 56.83g.L<-1> at 72h, which is 1.94 times of the content of 2-KLG of a matched group that adds no trehalose under the hyperosmotic condition, wherein the content of 2-KLG of the matched group is 29.24g.L<-1>. When 10mmol.L<-1> of trehalose is added under a normal fermentation condition adding no NaCl, the fermentation period is shortened to 52h, the end point acid production is up to 69.38g.L<-1>, and the consumption speed of L-sorbose and the production intensity of 2-KLG are respectively increased by 43.1% and 45.5%.

Owner:JIANGNAN UNIV

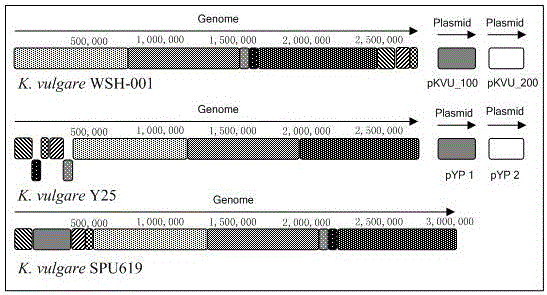

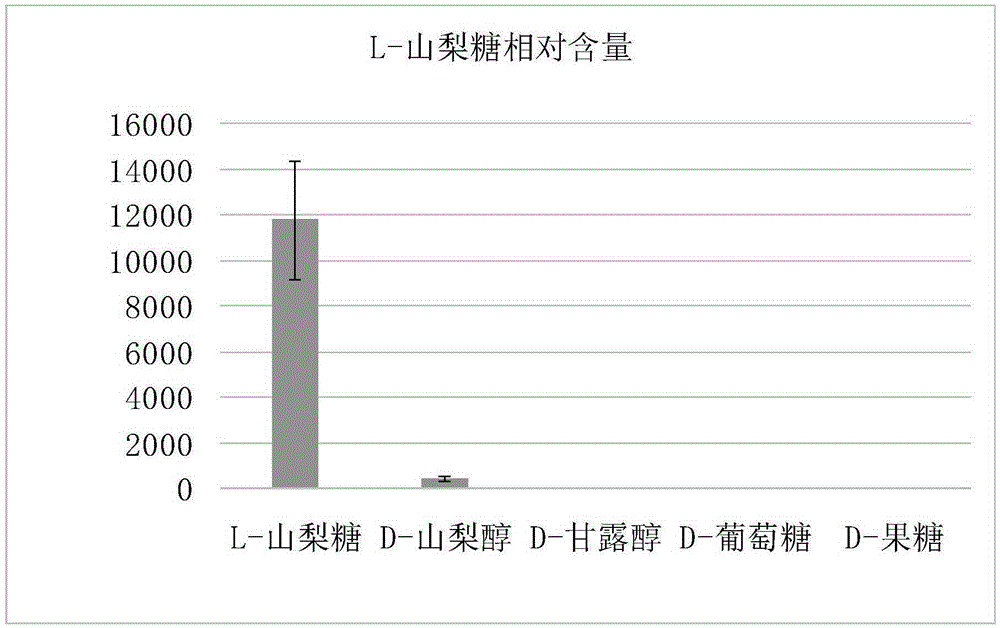

Gluconobacter oxydans engineering bacterium for producing sorbic ketone in high yield mode and construction method thereof

ActiveCN102851252ASimple production processEliminate dependenciesBacteriaMicroorganism based processesBiotechnologyD-Sorbitol

The invention discloses a Gluconobacter oxydans engineering bacterium for producing vitamin C synthesis intermediate sorbic ketone and a construction method and application thereof, and belongs to the field of genetic engineering. By means of the genetic engineering technique, a sorbose dehydrogenase gene (sdh) derived from common ketogenic base Ketogulonigenium vulgare is cloned onto Gluconobacter oxydans to obtain the G. oxydans engineering bacterium for producing the sorbic ketone by utilizing sorbitol. G. oxydans WSH-003 which is provided by Jiangsu Jiangshan Pharmaceutical Co., Ltd is a fermented industrial strain obtained in a first step of a two-step fermentation method for producing 2-keto-L-gulonic acid (2-KLG). The sdh is cloned into the G. oxydans so that conversion from D-sorbitol to the vitamin C synthesis intermediate sorbic ketone is achieved, the foundation for further constructing the fermented industrial strain in one step to produce the direct precursor 2-KLG of vitamin C is laid, and the yield of the sorbic ketone is as high as 72g / L. Therefore, the Gluconobacter oxydans engineering bacterium has good application prospects.

Owner:JIANGNAN UNIV

Gluconobacter oxydans gene engineering bacteria for producing 2-KLG and its application

InactiveCN103484418AEliminate dependenciesSimple production processBacteriaMicroorganism based processesVitamin CD-Sorbitol

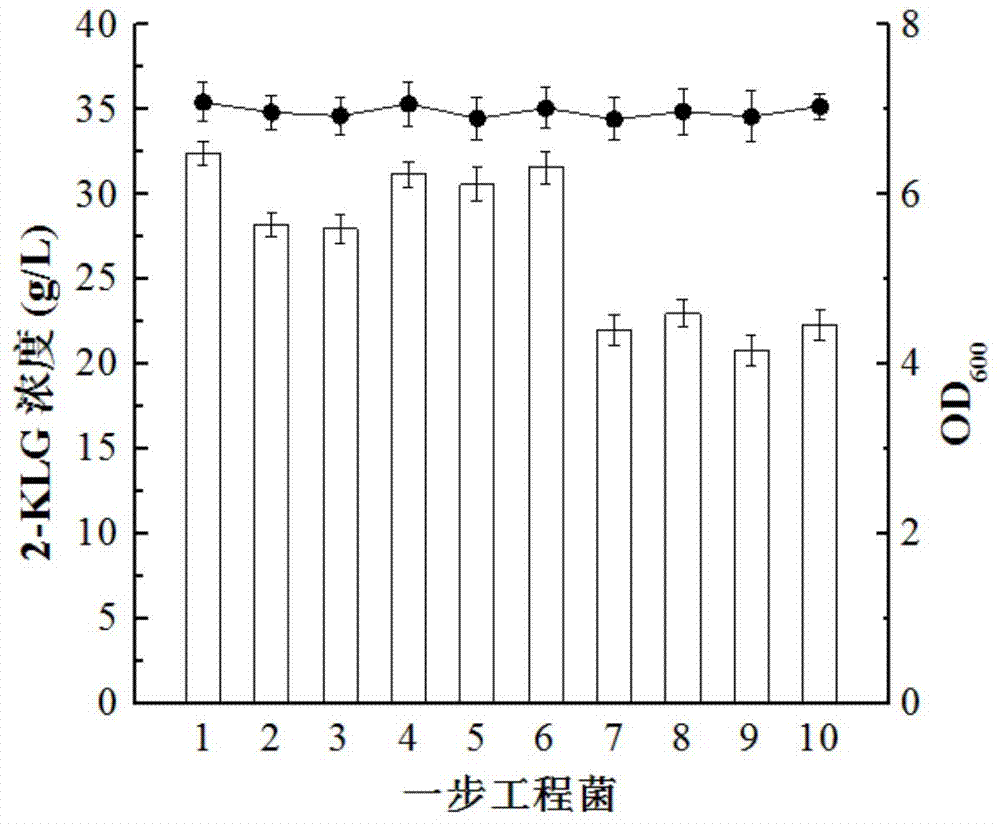

The invention discloses a Gluconobacter oxydans gene engineering bacteria for producing 2-KLG and its application. According to the invention, by means of a genetic engineering technology, sorbose dehydrogenase (SDH) and sorbosone dehydrogenase (SNDH) genes derived from Ketogulonigenium vulgare are connected by a connecting peptide and then expressed in Gluconobacter oxydans so as to obtain G. oxydans engineering bacteria for high efficiency production of 2-KLG. The G. oxydans is a strain commonly used in a first step fermentation process during two-step fermentation production of 2-KLG. The expression of sdh and sndh genes in G.oxydans can dissolve the dependence problem of small bacteria on associated bacteria, thus realizing direct conversion from D-sorbitol to 2-KLG, and simplifying the vitamin C production process. With a 2-KLG yield of 32.4g / L, the Gluconobacter oxydans gene engineering bacteria has very good application prospects.

Owner:JIANGNAN UNIV

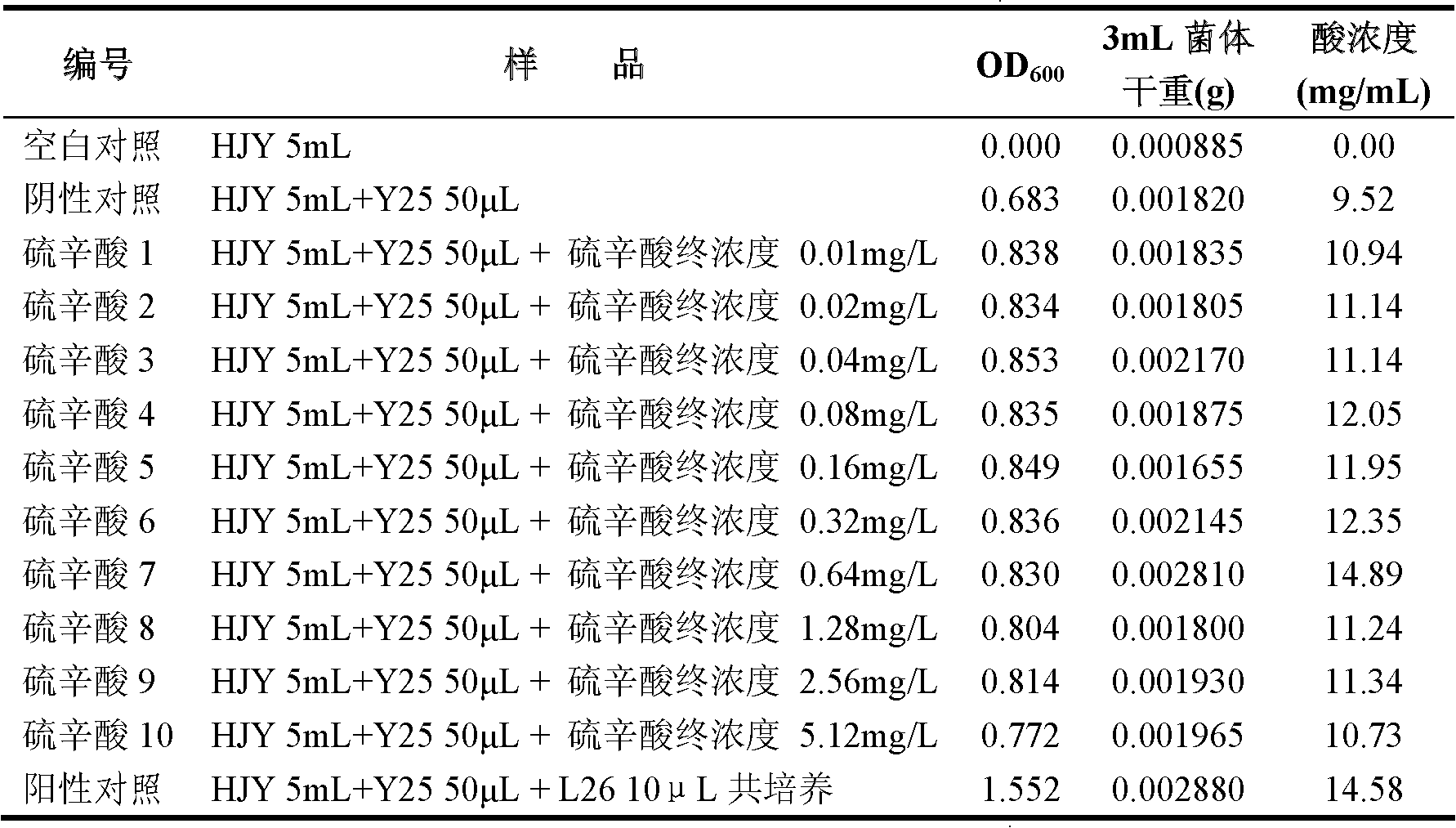

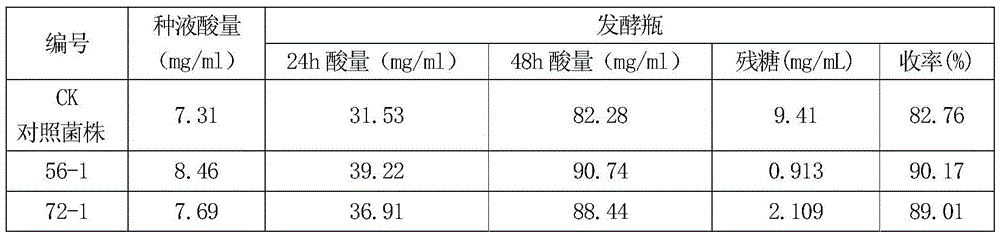

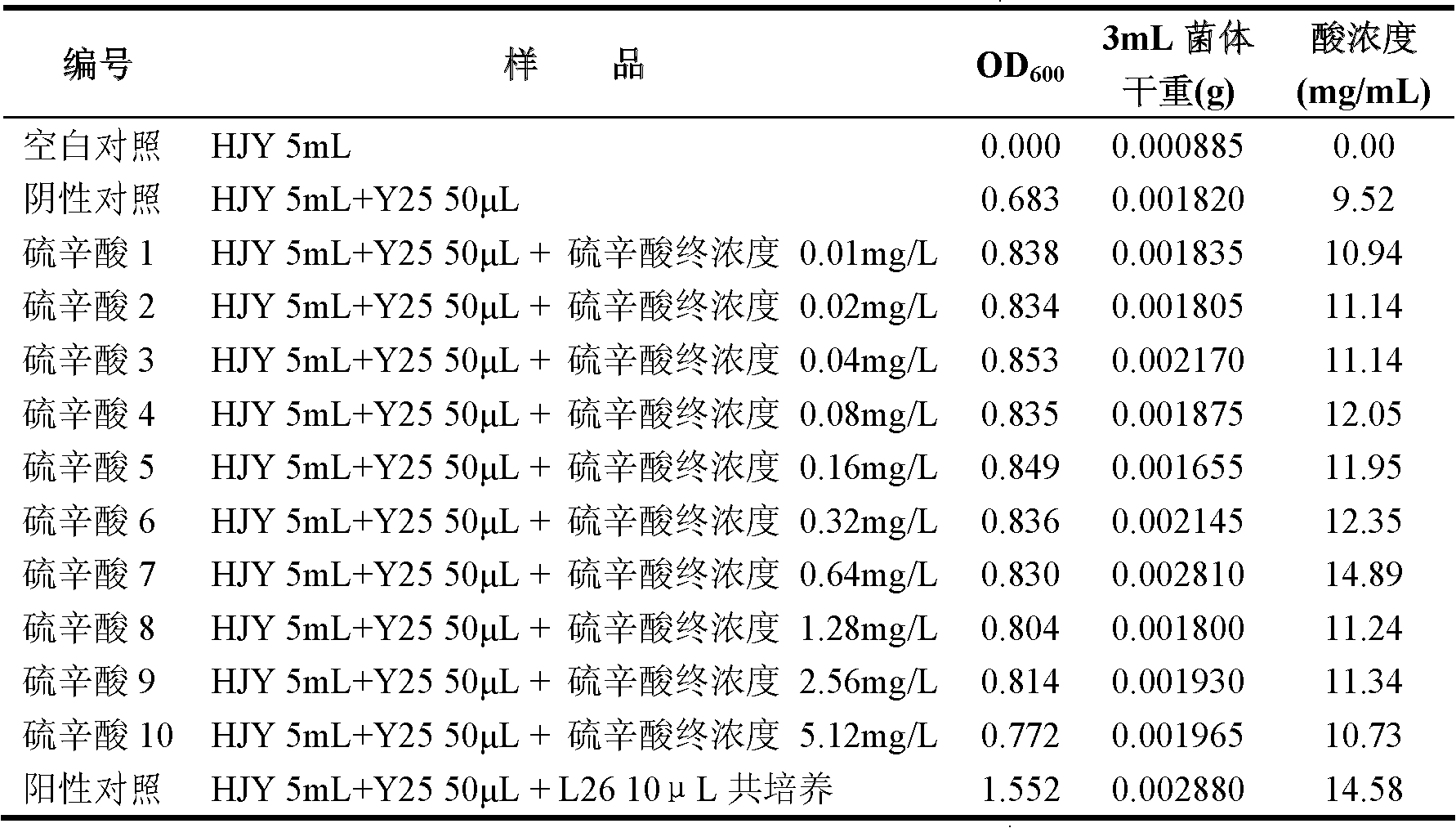

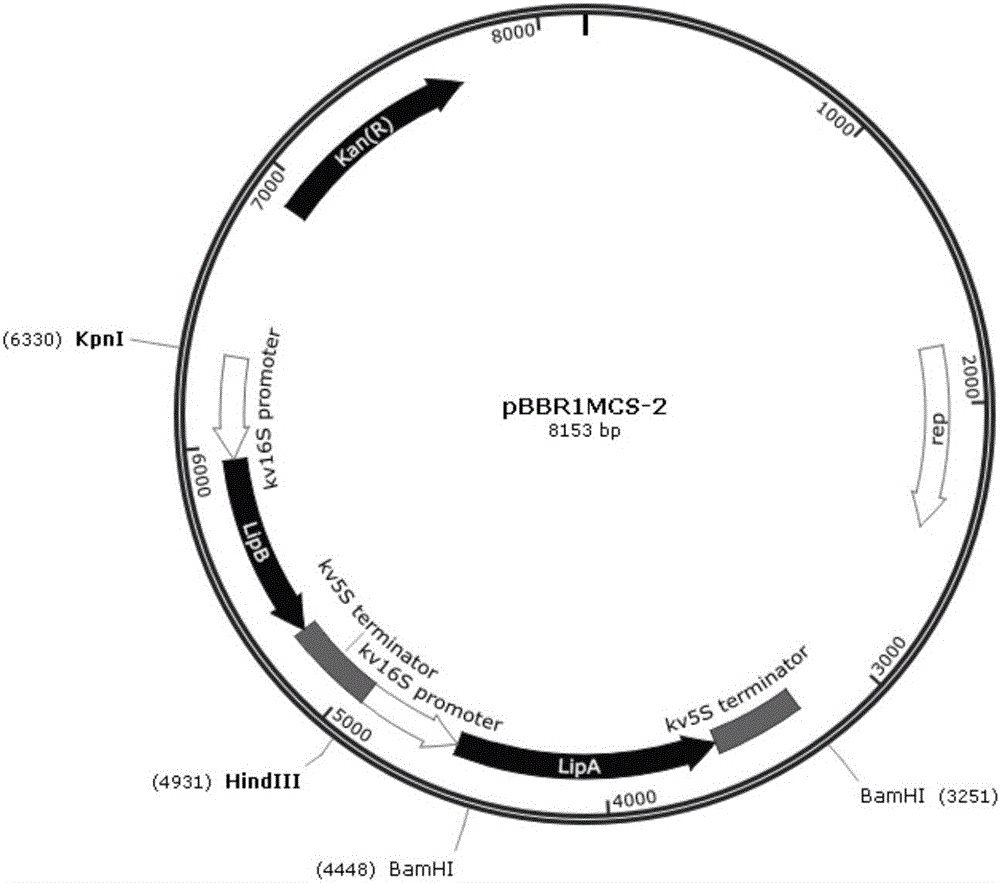

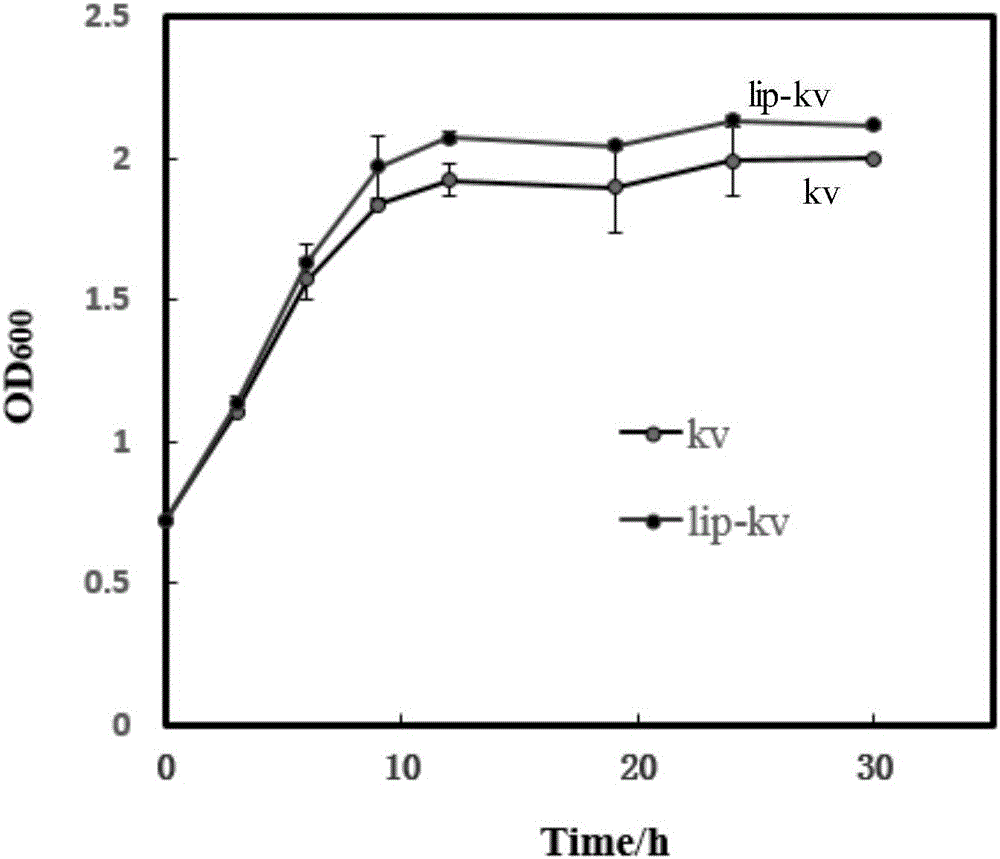

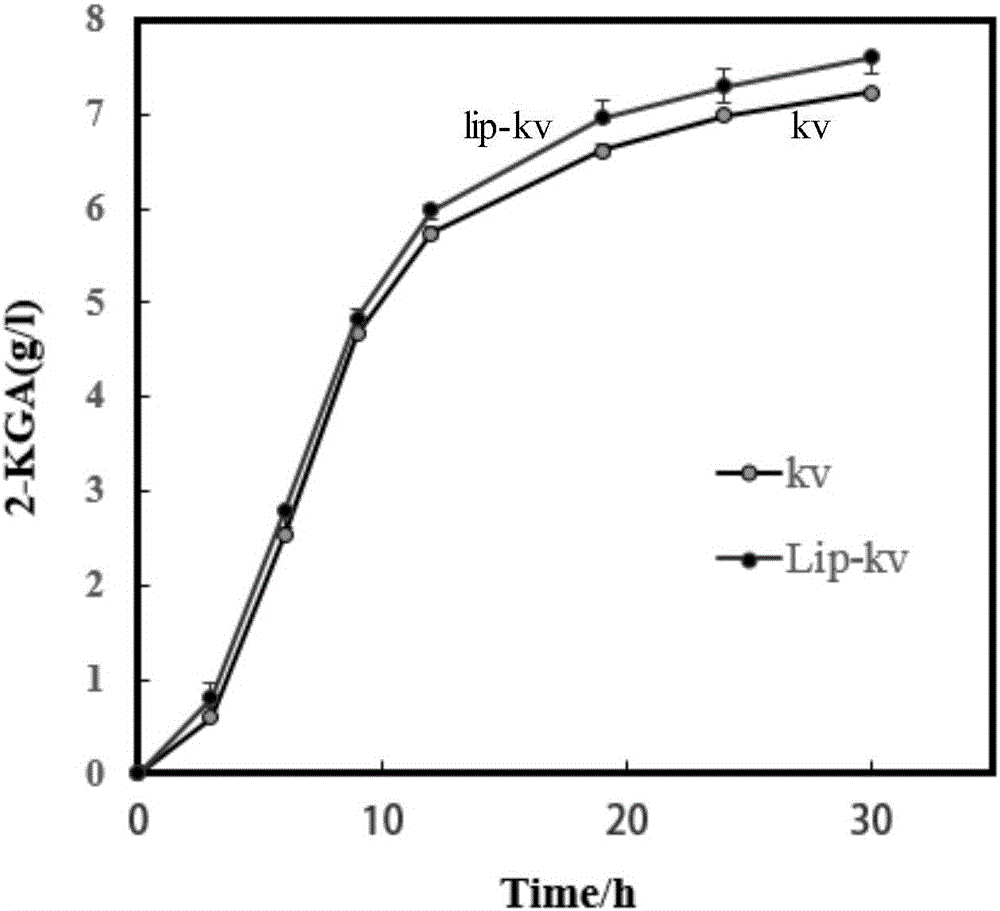

Method for promoting growth and acid production of Ketogulonigenium vulgare

InactiveCN102321698ASimple production processThe production process is simple and easy to controlMicroorganism based processesFermentationVitamin CSugar

The invention provides a method for promoting growth and acid generation of Ketogulonigenium vulgare. By adding trophic factor lipoic acid into a Ketogulonigenium vulgare culture medium, the growth rate and the acid production capacity of the Ketogulonigenium vulgare can be improved, thereby the object that a single bacterium fermentation method realizes sugar and acid conversion is achieved, andthe fermentation process of vitamin C is simplified.

Owner:INST OF BIOENG ACAD OF MILITARY MEDICAL SCI OF THE CHINESE

Method for improving 2-keto-L-gluconic acid fermentation efficiency

InactiveCN106434830AIncrease production intensityPromote growthMicroorganism based processesFermentationBiotechnologyGluconic acid

The invention relates to a method for improving 2-keto-L-gluconic acid fermentation efficiency. The method is characterized in that in the process of mixed strains fermenting 2-keto-L-gluconic acid, the mixed strains comprise ketogulonigenium vulgare and bacillus megaterium, seed solution cultured to the middle and later periods of logarithmic growth is inoculated into fermentation tank optimum culture media to ferment and culture, sorbose is fed since fermentation time is 0h, and small material culture media are fed at the prior period of the logarithmic growth. According to the method, production intensity of the 2-keto-L-gluconic acid can be improved, efficiency is improved, production capacity is optimized, the content of the 2-keto-L-gluconic acid in fermentation solution can reach 115.6-150.3mg / ml, acid producing rate is 2.89-3.76g.(L.h)-1, and the conversion rate of glucose acid is 87.2-95.0%.

Owner:NINGXIA QIYUAN PHARMA

Method for producing 2-keto-L-gulonic acid vitamin C precursor by modifying Escherichia coli

ActiveCN102250821ASimple processEasy to buildBacteriaMicroorganism based processesEscherichia coliVitamin C

The invention discloses a method for producing a 2-keto-L-gulonic acid (2-KLG) vitamin C precursor by modifying Escherichia coli and belongs to the field of genetic engineering. In the method, a sorbitol dehydrogenase (SLDH) gene from gluconobacter oxydans, a pyrroloquinoline quinine (PQQ) gene cluster and a sorbose dehydrogenase (SDH) / sorbosone dehydrogenase gene (SNDH) from common ketogulonigenium vulgare are expressed in Escherichia coli by a genetic engineering technique to culture an Escherichia coli engineering strain for producing 2-KLG by sorbitol. At present, a two-step fermentationprocess adopted for industrial production of vitamin C in China has the problems of complicated process, many influencing factors, difficult accurate control and large raw material and energy consumption for growing three kinds of microbes at the same time. When the production of the 2-KLG by sorbitol fermentation by the E.coli engineering bacteria is adopted, the production process is simplified, raw materials and energy are saved, and the yield of the 2-KLG can reach 87g / L; and thus, the method has a very bright application prospect.

Owner:JIANGNAN UNIV

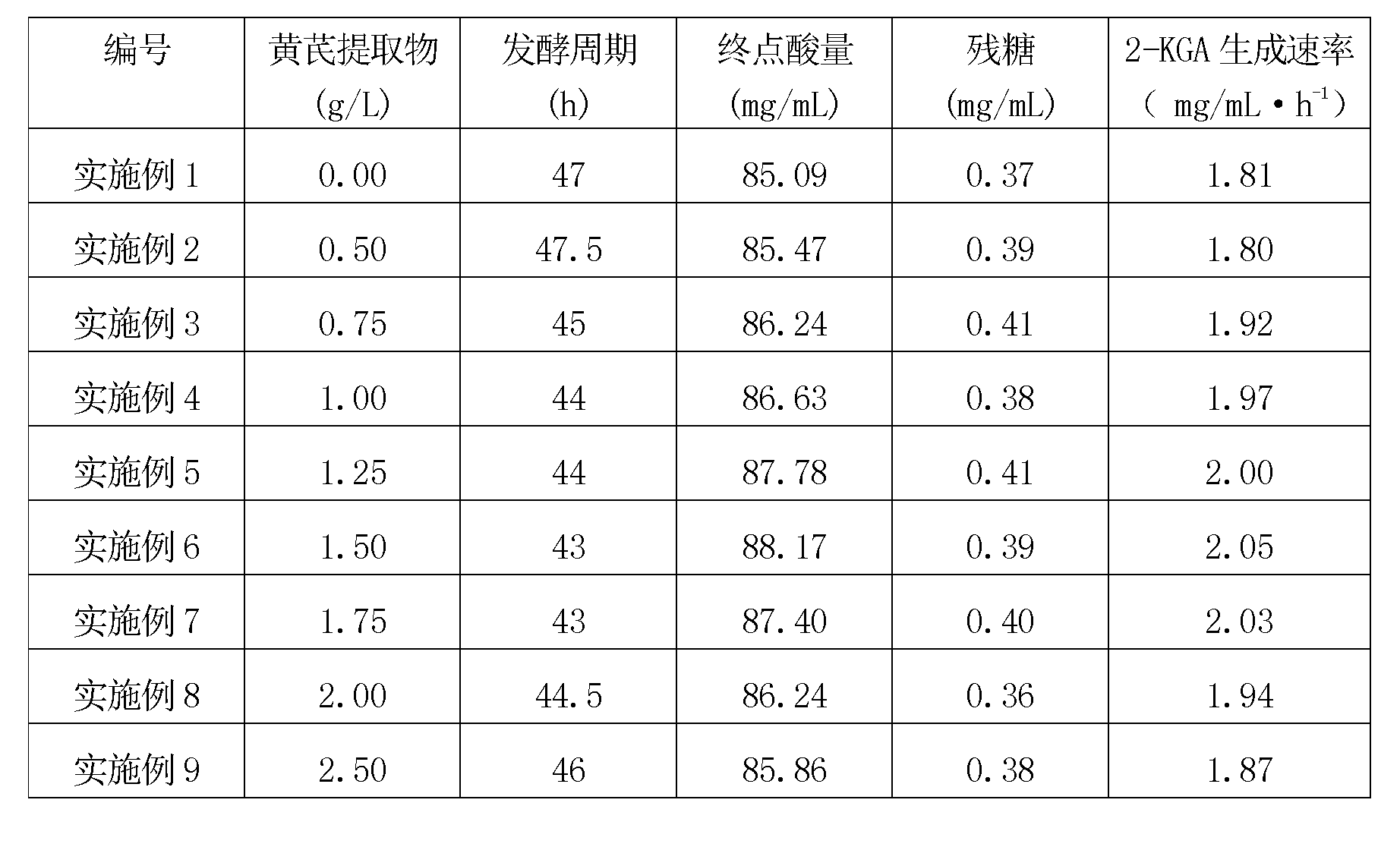

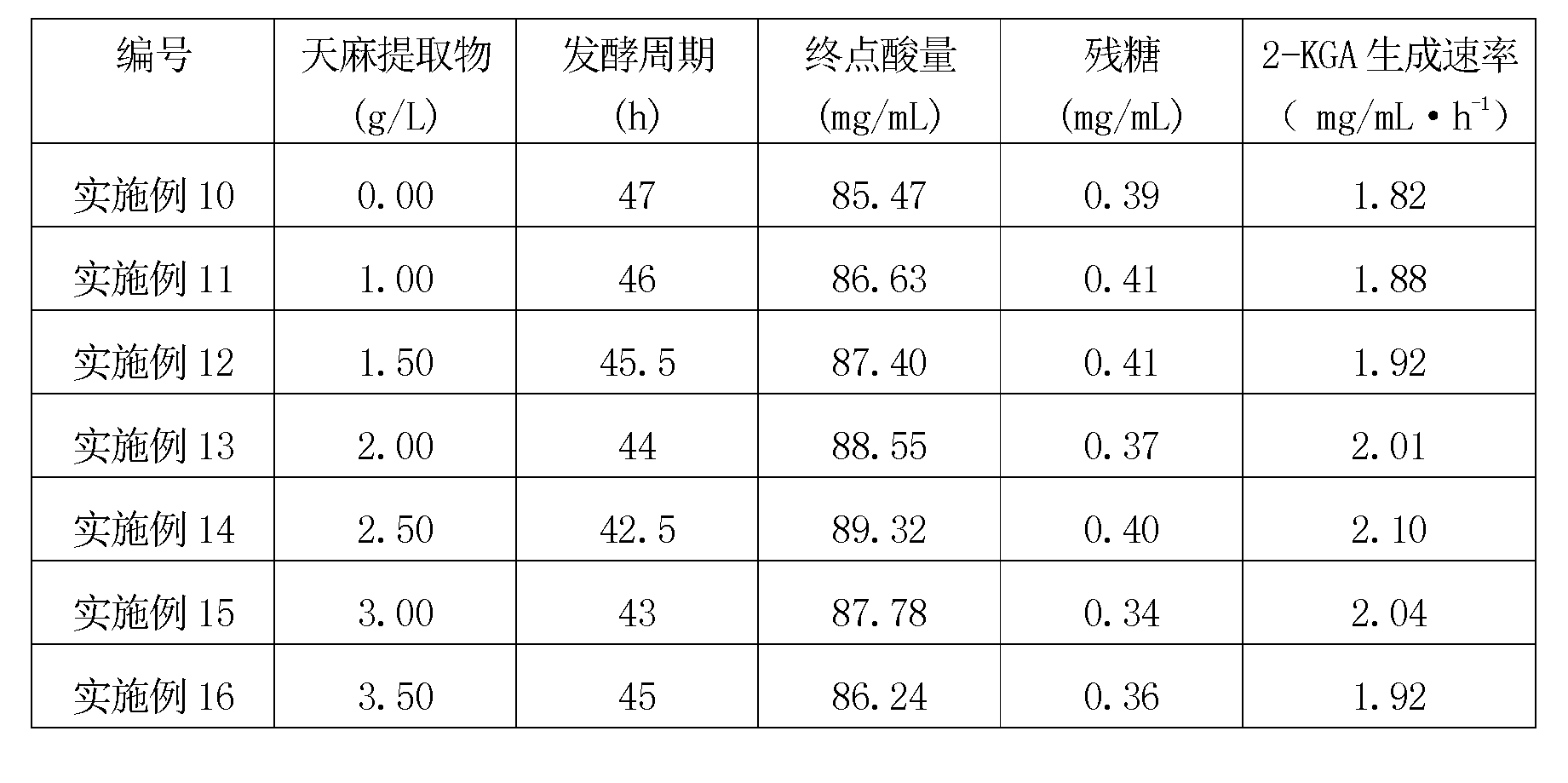

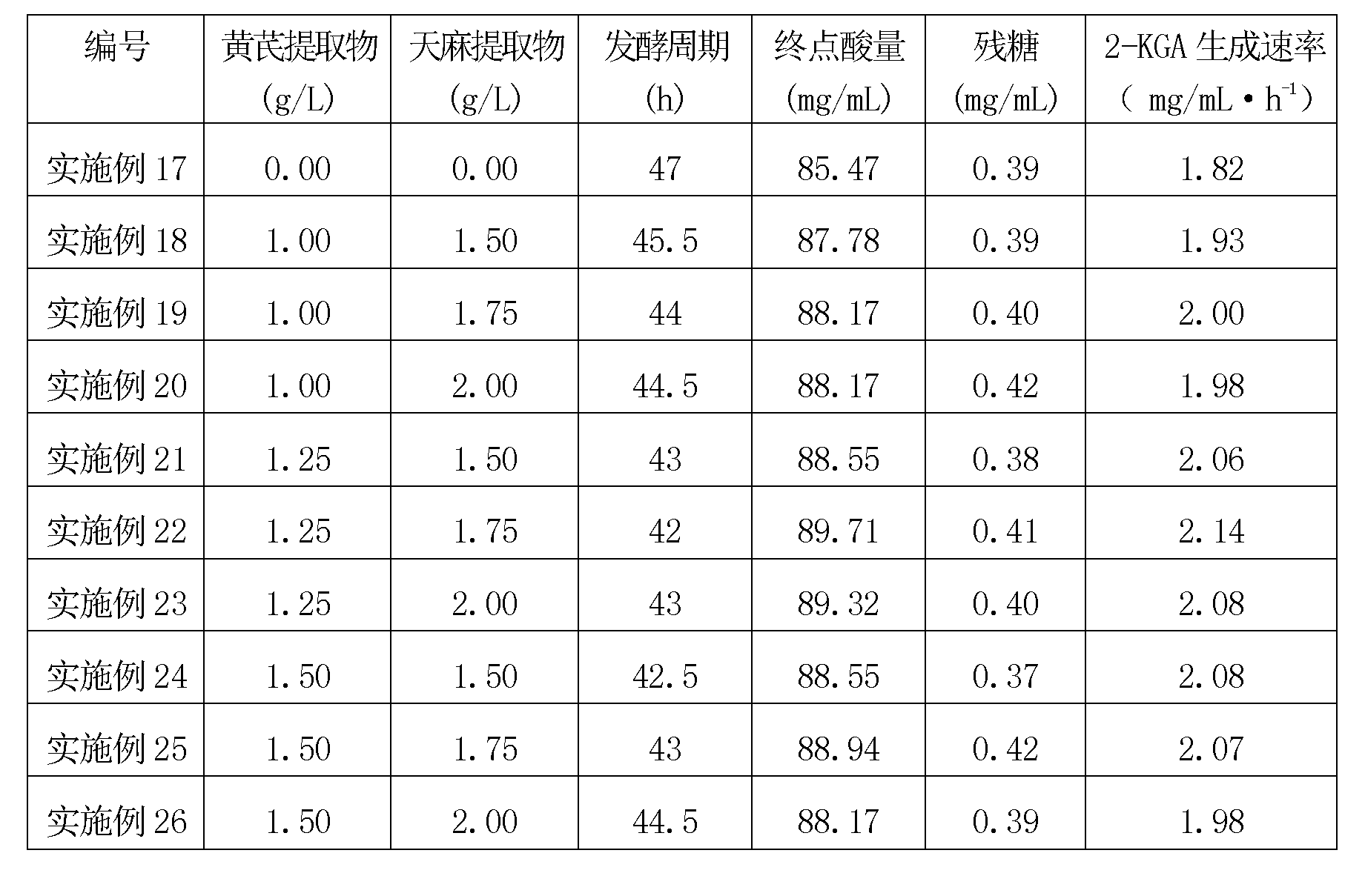

Method for promoting L-sorbose to convert to generate 2-keto-L-gulonic acid

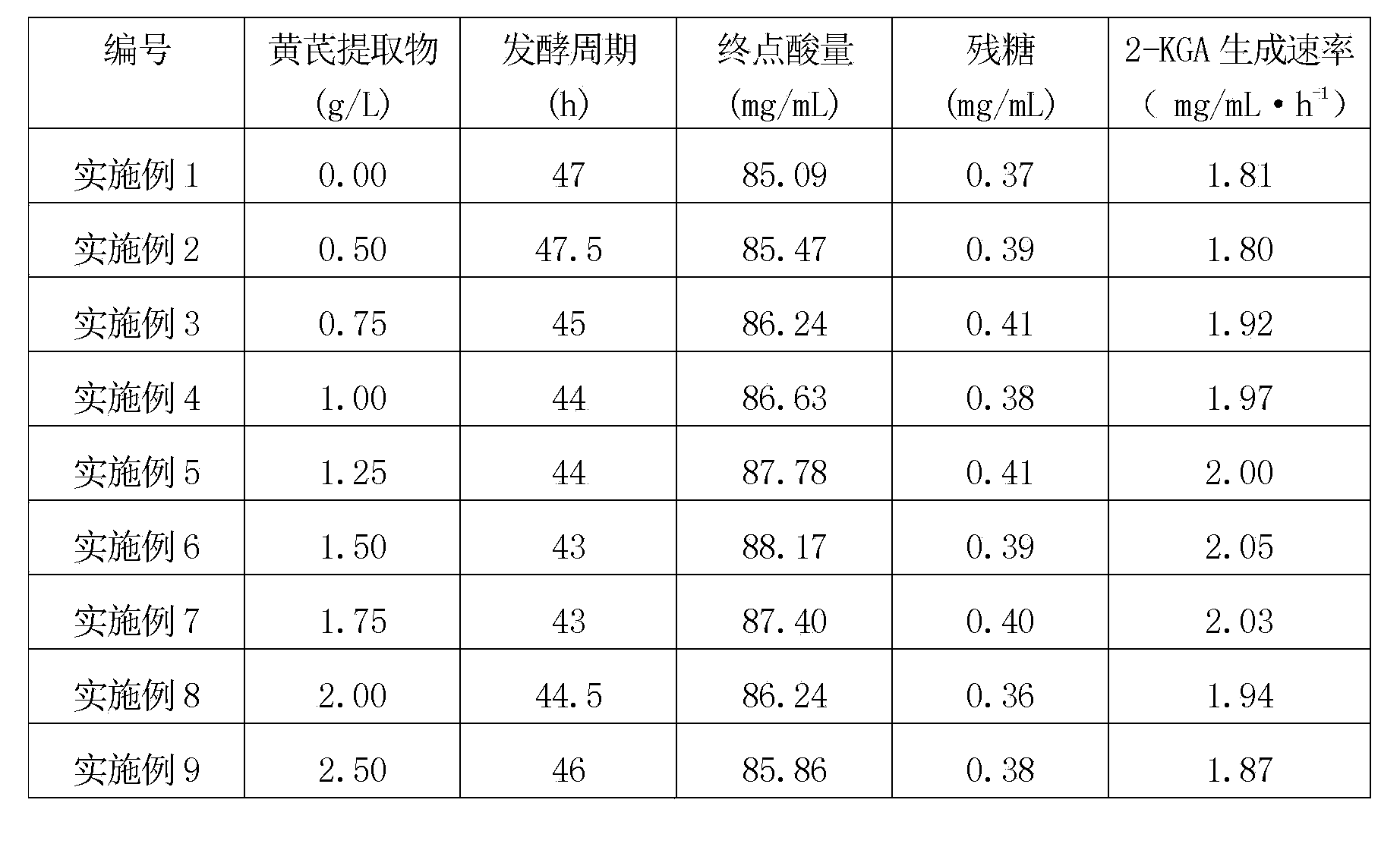

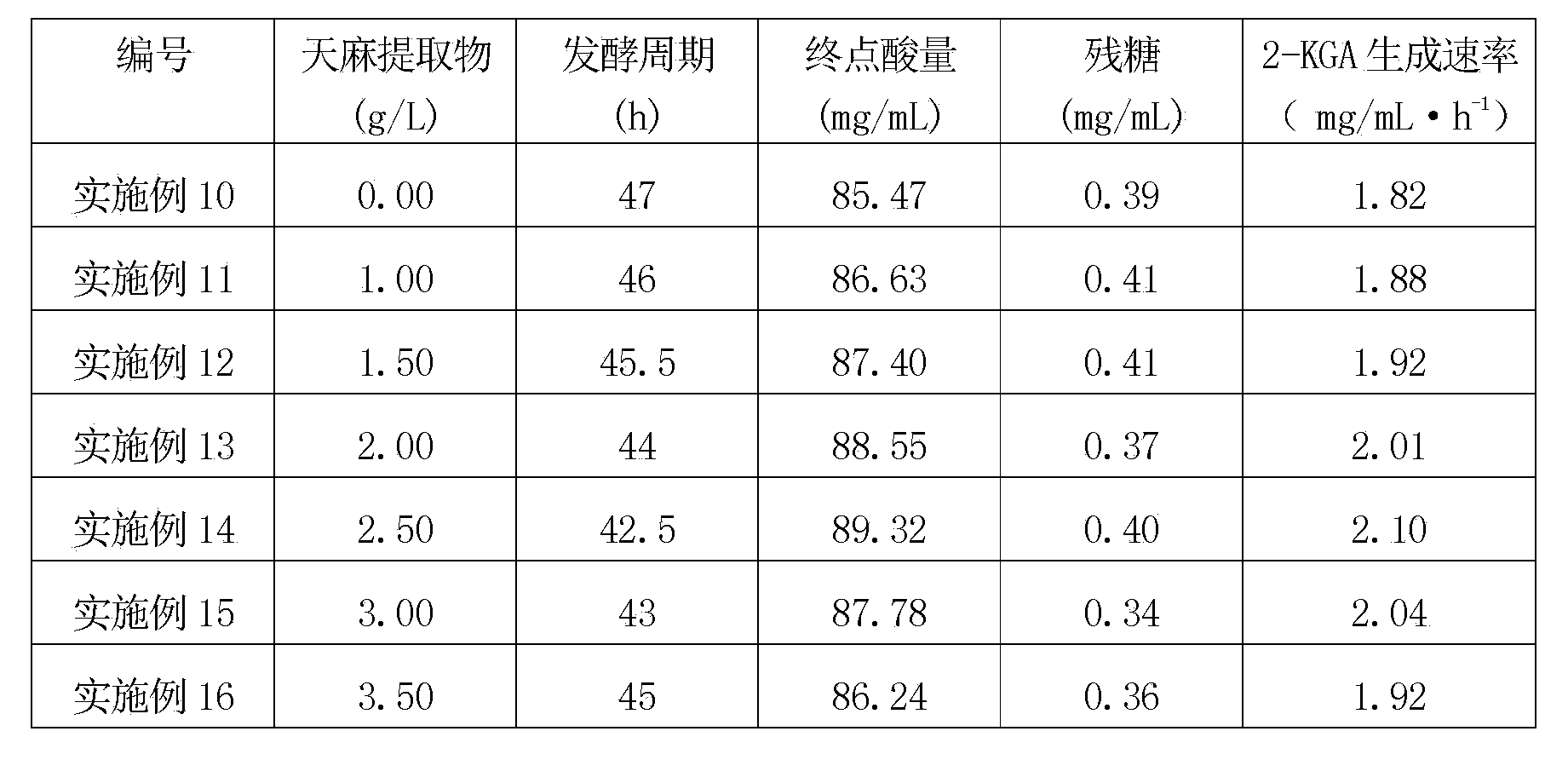

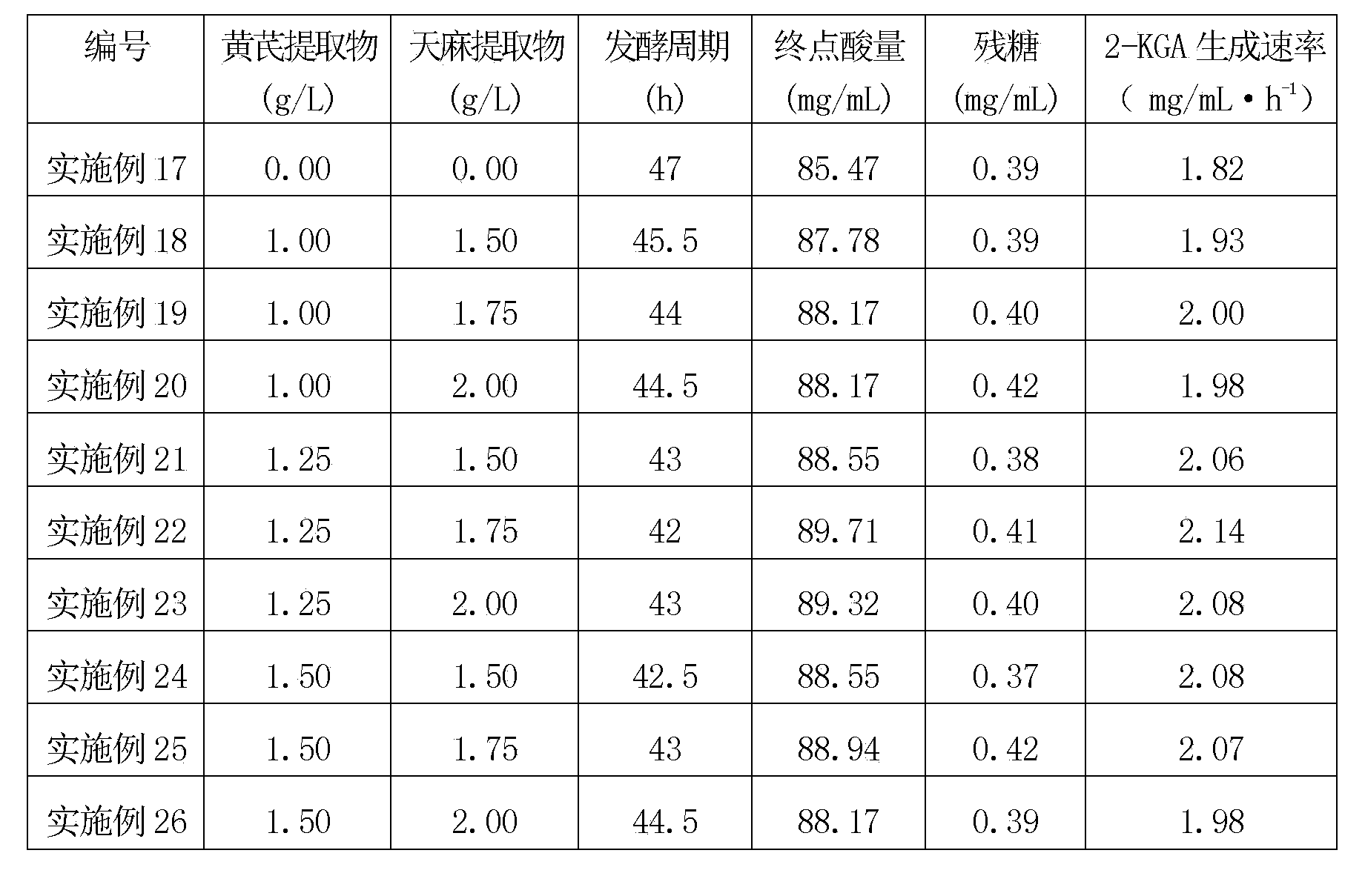

ActiveCN102936615APromote growthIncrease productionMicroorganism based processesFermentationGastrodia Elata ExtractMicroorganism

The invention discloses a method for promoting L-sorbose to convert to generate 2-keto-L-gulonic acid, belonging to the technical field of microbial fermentation. The method comprises two steps of seed cultivation and fermentative cultivation; according to the method, astragalus extract in an additive amount of 0.75-2.00g / L or gastrodia elata extract in an additive amount of 1.50-3.00g / L is added in a fermentation medium, or the astragalus extract and the astrodia elata extract in additive amounts of 1.00-1.50g / L and 1.50-2.00g / L are added in the fermentation medium at the same time, so as to promote the common ketogulonigenium vulgare (small bacterium) and huge bacillus (large bacterium) to coordinately grow to realize the efficient synthesis of the 2-keto-L-gulonic acid; and through coordinating the mutual functions of the two bacteria, the growth of the small bacterium is promoted, the output of the 2-keto-L-gulonic acid is improved and the fermentation period is shortened. According to the method, a 10L tank is used for the fermentation experiment and a predicted effect is obtained.

Owner:石药集团维生药业(石家庄)有限公司

Method for improving fermentation production efficiency of 2-keto-L-gulonic acid

ActiveCN103627775AIncrease the rate of biosynthesisImprove filtration efficiencyMicroorganism based processesFermentationPhosphatePhosphoric acid

The invention discloses a method for improving fermentation production efficiency of 2-keto-L-gulonic acid. The method comprises the following steps: inoculating a well cultured mixed bacterial liquid of ketogulonigenium vulgare and bacillus megaterium into a fermentation culture medium containing 2% of sorbitol, 1.1% of corn steep liquor, 0.2% of urea, 0.02% of magnesium sulfate and 0.05% of potassium dihydrogen phosphate, stirring the fermentation culture medium in a fermentation container at the rotational speed of 400rpm, enabling the ventilation ratio to be 1: 1, enabling the initial pH value of the culture medium to be 6.7, starting to perform flow feeding of a sorbitol solution with the concentration of 25% after 10h of the culture, and controlling the final total polysaccharide concentration of fermentation to be 10%; and regulating the pH value to 4.5-5.0 by using 50% of phosphoric acid solution, then continuously controlling the fermentation pH value to 6.7-7.3 by using 25% of sodium carbonate solution and adding casein tryptone. According to the method disclosed by the invention, the biological synthesis rate of the 2-KLG (2-keto-L-gulonic acid) by a mixed bacterial system is effectively improved, and the purpose of improving the fermentation production efficiency is achieved.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

Method for improving production intensity of 2-keto-L-gulonic acid (2-KLG) by adding betaine

InactiveCN103642889AModerate proportionIncrease vitalityMicroorganism based processesFermentationBiotechnologyBetaine

The invention discloses a method for improving the production intensity of 2-keto-L-gulonic acid (2-KLG) by adding betaine, belonging to the technical field of vitamin C preparation through fermentation. A mixed bacteria system of ketogulonigenium vulgare and bacillus megaterium is adopted as a production strain, and 0.05-1.0% betaine is exogenously added into a fermentation medium as an osmotic pressure regulator so as to promote the cell growth and 2-KLG production and realize efficient production of 2-KLG. By adopting the process, the method disclosed by the invention can effectively shorten the fermentation period of 2-KLG and improve the production intensity.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

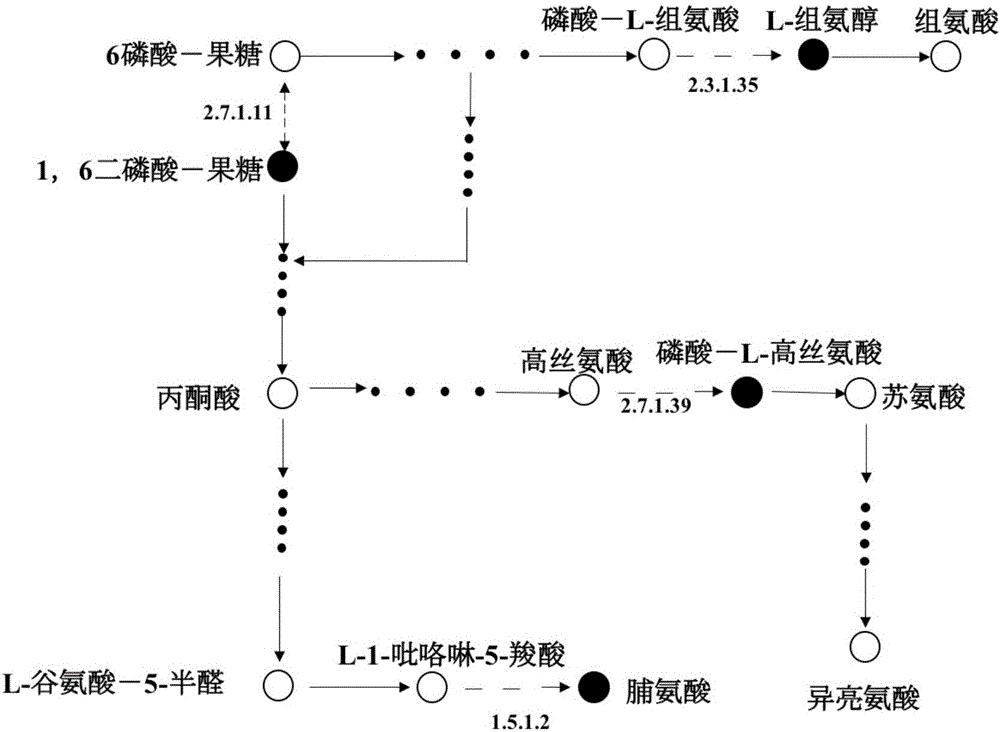

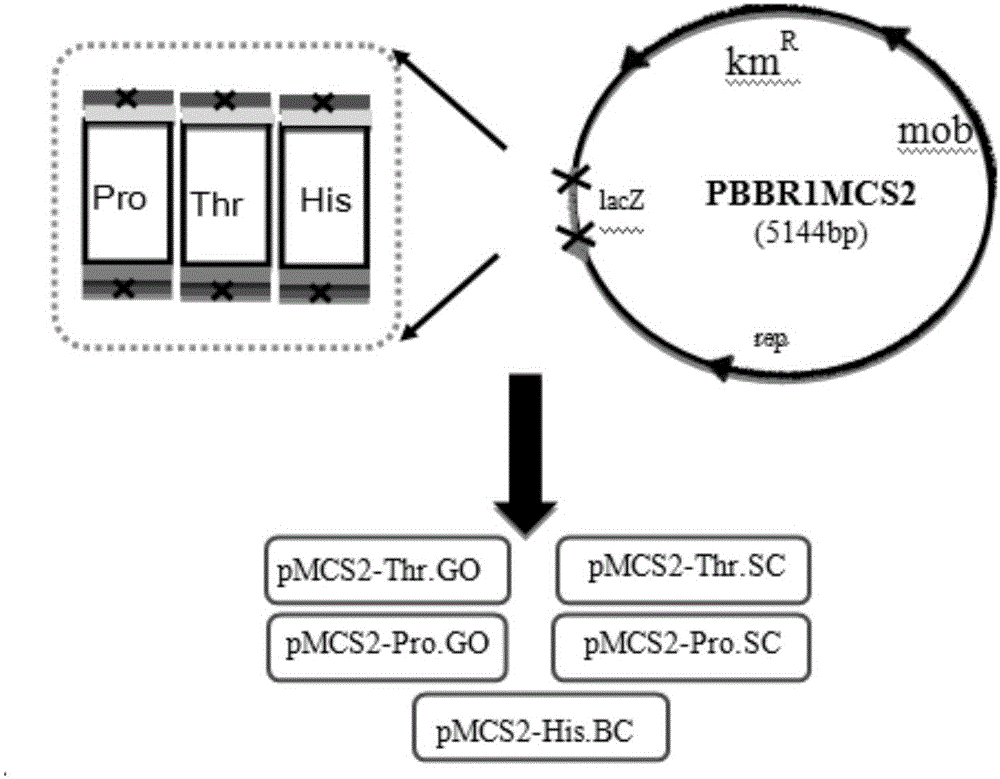

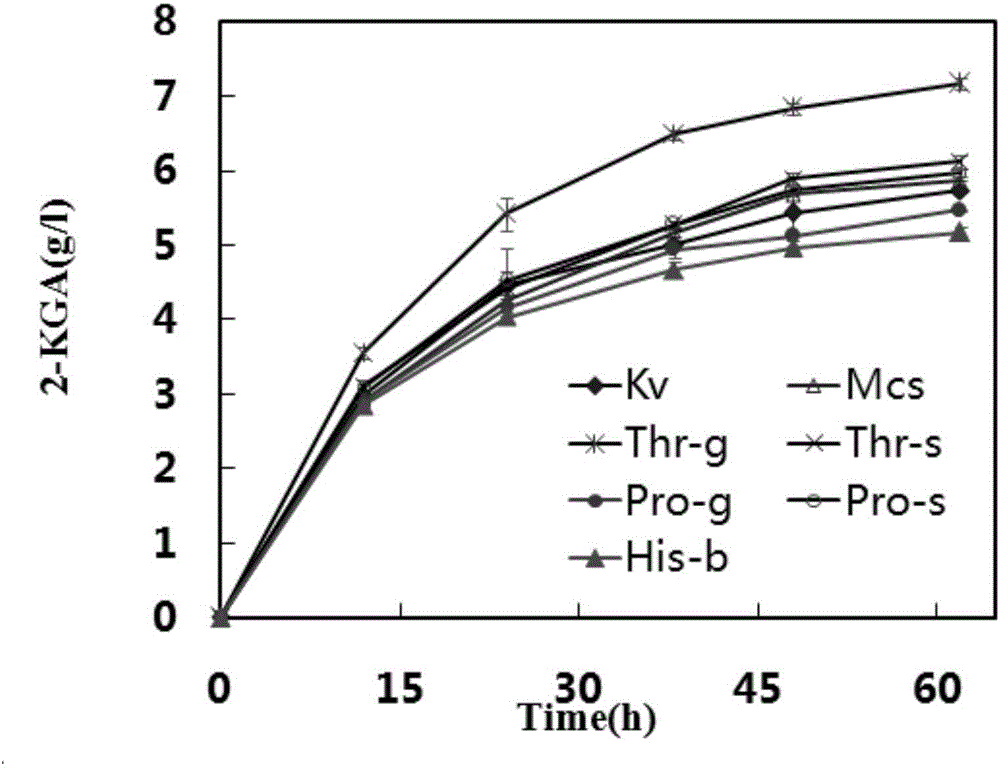

Ketogulonigenium vulgare engineering strain, preparation method and application thereof

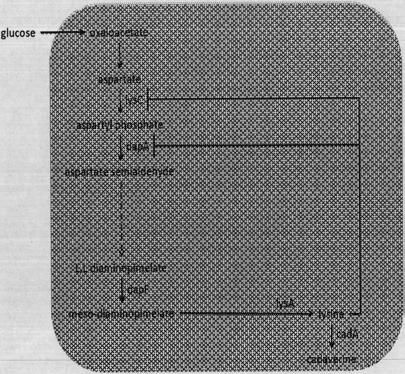

The invention relates to the technical field of biological engineering, and especially relates to a ketogulonigenium vulgare engineering strain, a preparation method and an application thereof. The ketogulonigenium vulgare engineering strain comprises a key gene during an amino acid synthesis process; and the key gene in the amino acid synthesis process is in the key gene during a threonine synthesis process, the key gene during a proline synthesis process and the key gene during a histidine synthesis process. By constructing the deleted gene during the amino acid synthesis process in the bacterial strain, when individual fermentation of the ketogulonigenium vulgare engineering strain is carried out, sorbose can better conversed to ketogulonigenium vulgare; when ketogulonigenium vulgare engineering strain and the endophytic bacillus are subjected to mixed fermentation, the fermentation period is reduced, compared with the original bacterial strain, the period is shortened by about 10 h, the time cost is saved; from the yield aspect, the yield is increased by about 20% by comparing with the original strain; effect of companion fungus dependence is reduced when mixed fermentation is carried out, amount of the companion fungus which is Bacillus spp is reduced, and the cost and pollution are reduced.

Owner:TIANJIN UNIV

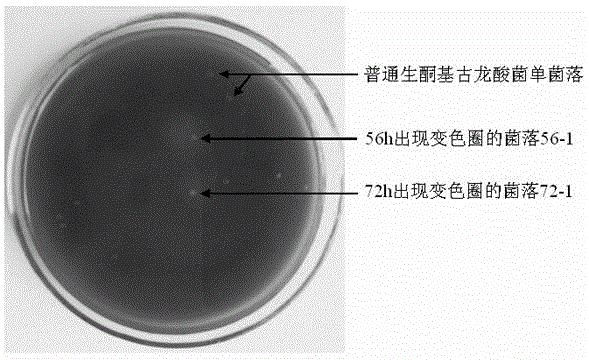

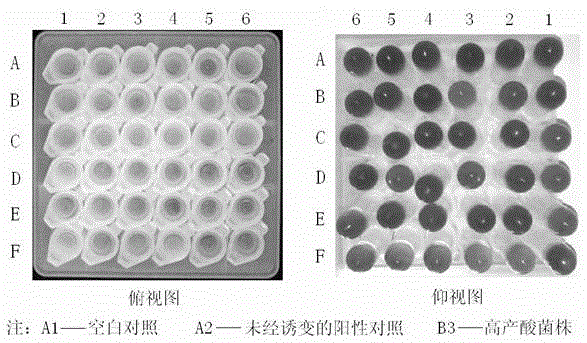

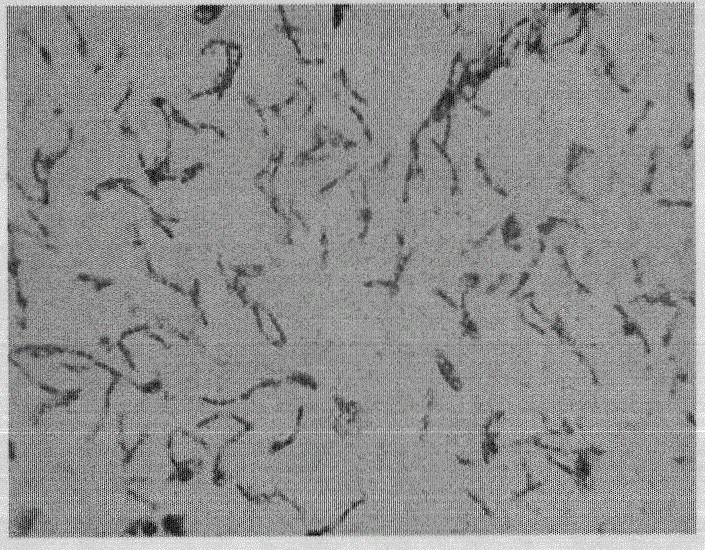

High-throughput screening method for fast-growing type acid-producing strains of ketogulonigenium vulgare

InactiveCN105543213AEasy to identifyRapid identificationMutant preparationMicroorganismLiquid medium

The invention provides a high-throughput screening method for fast-growing type acid-producing strains of ketogulonigenium vulgare, and belongs to the technical field of microbial strain breeding. According to the high-throughput screening method, the ketogulonigenium vulgare subjected to mutagenic treatment is cultured on a solid medium panel, a certain dose of an indicator is added to the solid medium, and simple and fast identification for the fast-growing type acid-producing strains of the ketogulonigenium vulgare is realized; according to design, the selected fast-growing type acid-producing strains of the ketogulonigenium vulgare are inoculated to a strain liquid medium for culturing, a certain dose of the indicator is added to the strain liquid medium, simple and fast determination for the selected fast-growing type acid-producing strains of the ketogulonigenium vulgare is realized, then the indicator identification is combined with a centrifuge tube group culture technology, and the batch culturing effect is realized while the requirement for independent sterile operation in single colony inoculation culture and detection processes of the ketogulonigenium vulgare is met, so that the purpose of rapid, convenient and accurate high-throughput screening is achieved.

Owner:石药集团维生药业(石家庄)有限公司

Method for promoting growth and acid production of Ketogulonigenium vulgare

InactiveCN102321698BSimple production processThe production process is simple and easy to controlMicroorganism based processesFermentationVitamin CSugar

The invention provides a method for promoting growth and acid generation of Ketogulonigenium vulgare. By adding trophic factor lipoic acid into a Ketogulonigenium vulgare culture medium, the growth rate and the acid production capacity of the Ketogulonigenium vulgare can be improved, thereby the object that a single bacterium fermentation method realizes sugar and acid conversion is achieved, andthe fermentation process of vitamin C is simplified.

Owner:INST OF BIOENG ACAD OF MILITARY MEDICAL SCI OF THE CHINESE

Method for producing fermented products by utilizing two or more than two microorganism strains

ActiveCN104561221AAddress metabolic disordersResolve inhibitionFermentationMicroorganismMixed culture

The invention relates to a method utilizing various microorganisms for co-culture or coupling fermentation. With difference from a relationship that vitamin C fermentation bacillus megaterium is mainly used for assisting ketogulonigenium vulgare to grow and produce acids, the method mainly utilizes a method utilizing various microorganisms for co-culture or coupling fermentation to overcome metabolic regulation obstacles for producing fermentation products. The co-culture comprises that two or more than two microorganism strains are subjected to mixed culture from the beginning, or firstly one strain is cultured, and when the strain is cultured to a proper time, other strains are added for culture.

Owner:CATHAY R&D CENT CO LTD +2

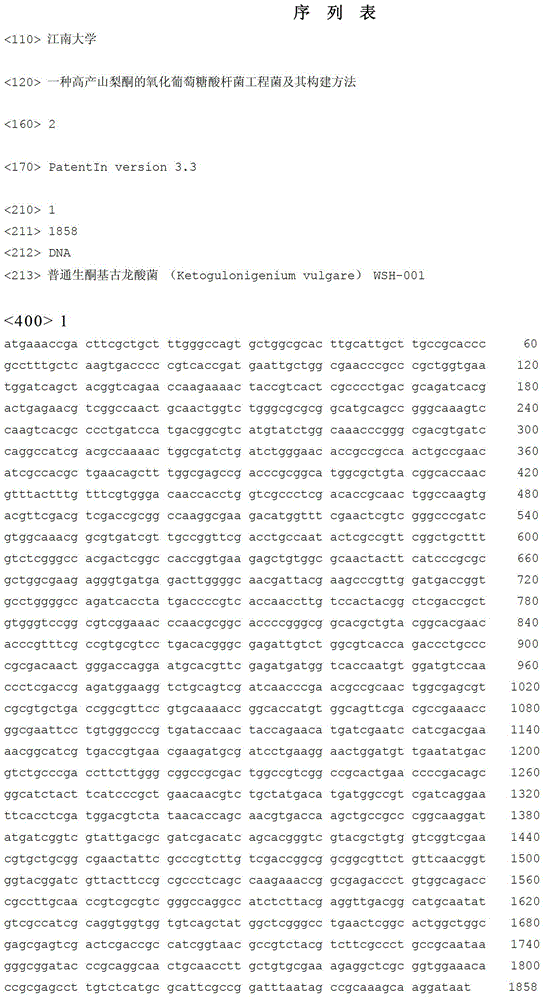

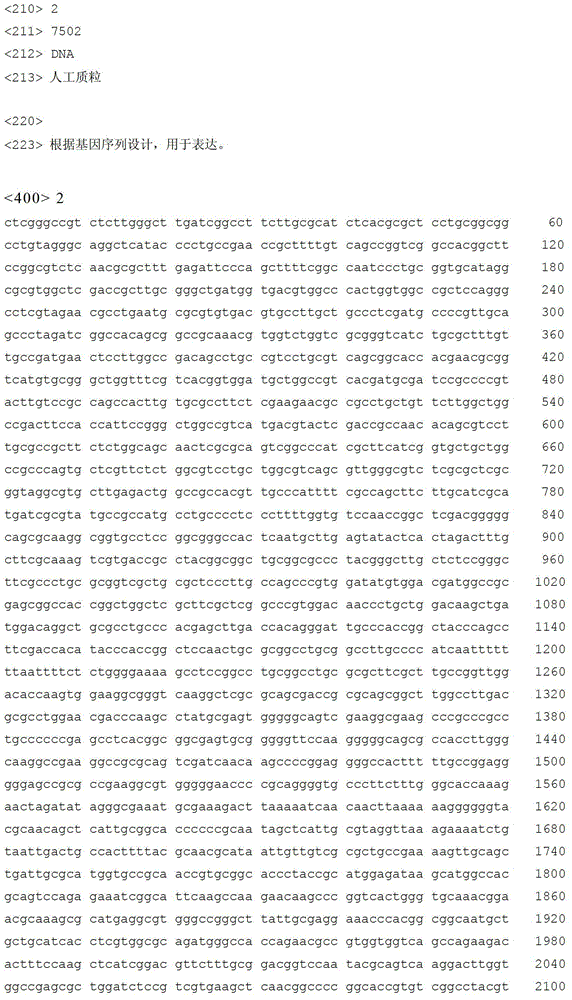

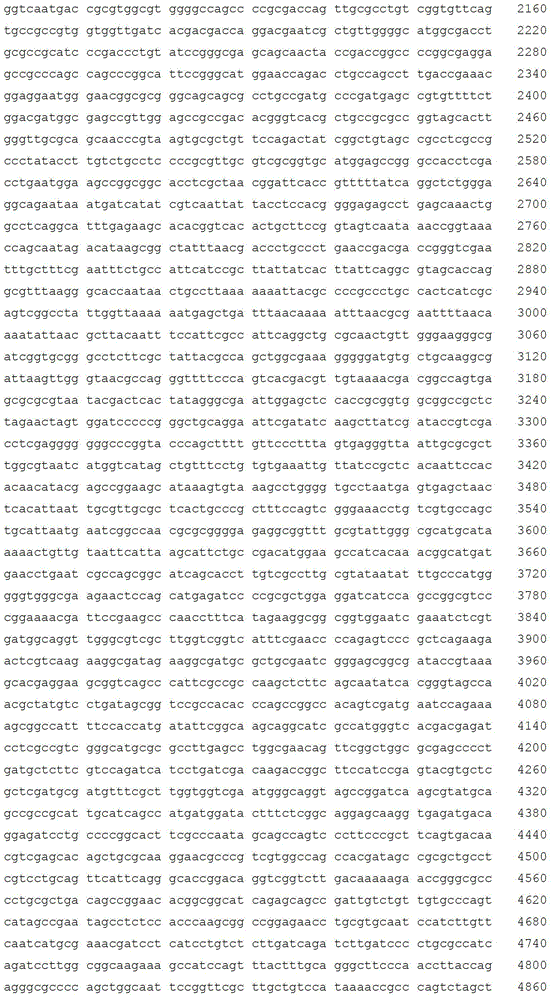

One group of DNA (Deoxyribose Nucleic Acid) molecules, recombinant vector, recombinant ketogulonigenium sp and method for producing 2-keto-L-gulonic acid

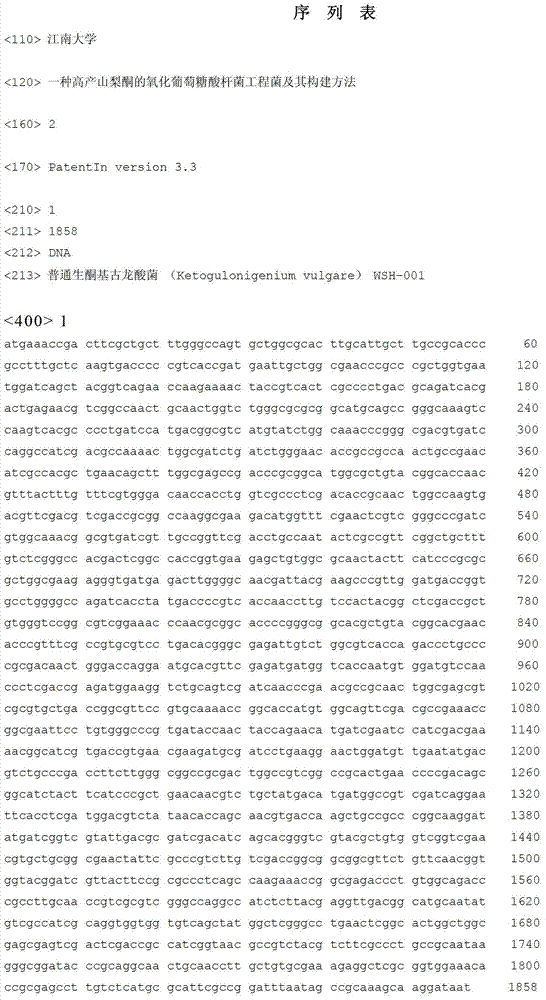

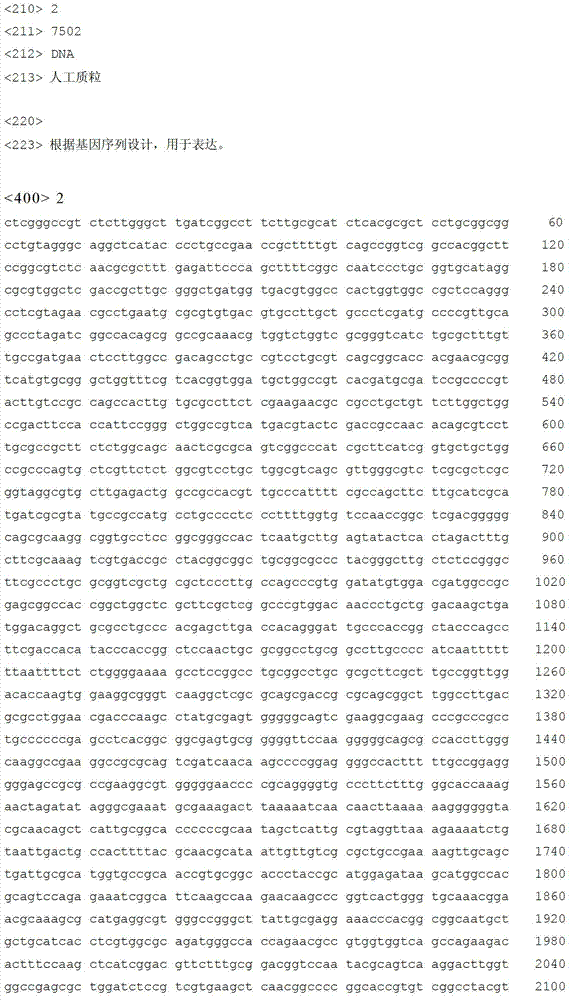

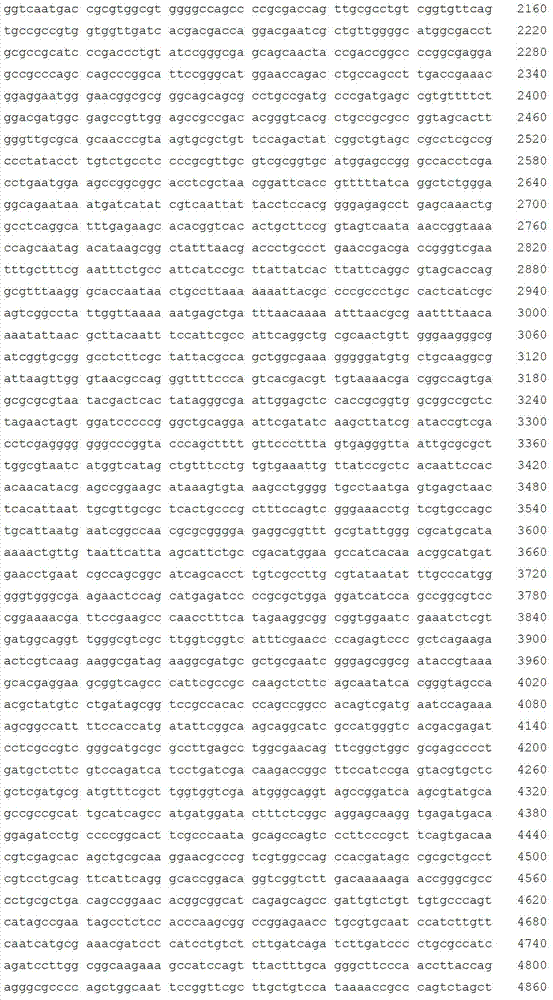

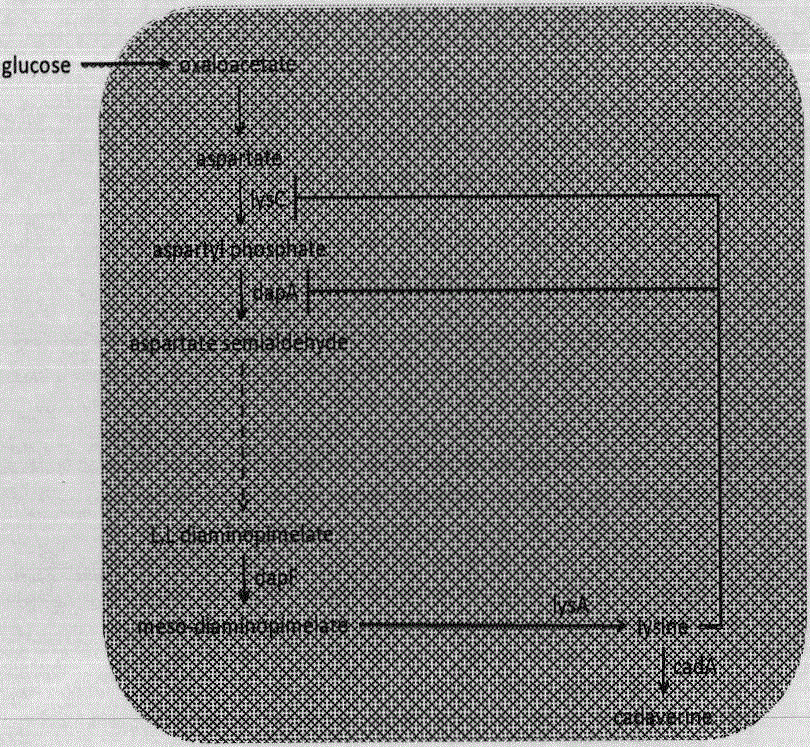

InactiveCN105861526APromote growthIncrease acid productionBacteriaHydrolasesBiotechnology3-deoxyribose

The invention relates to the technical field of genetic engineering, and discloses one group of DNA (Deoxyribose Nucleic Acid) molecules, a recombinant vector, a recombinant ketogulonigenium sp and a method for producing 2-keto-L-gulonic acid. The DNA molecules at least comprise one of nucleotide sequences shown by SEQ ID NO:1 and SEQ ID NO:2. The invention provides the DNA molecules capable of coding a key enzyme in a ketogulonigenium sp lipoic acid metabolic pathway, and the vector is transformed into the ketogulonigenium sp through an embedding way, so that the missing key enzyme can be expressed, endogenous lipoic acid is generated, the growth of bacterial strains is promoted, the acid yield and the acid production efficiency are improved, and the aim of carrying out monoxenie fermentation and acid production without adding exogenous lipoic acid nutritional factors with higher cost can be realized.

Owner:TIANJIN UNIV

Medium for cordyceps militaris liquid deep fermentation and use method thereof

InactiveCN104498367AImprove fermentation yieldReduce manufacturing costFungiMicroorganism based processesMycoproteinCorn steep liquor

The invention discloses a medium for cordyceps militaris liquid deep fermentation. The medium comprises 10-30g of cane sugar, 1-5g of corn steep liquor, 4-100g of fermenting mash protein residue, 0-4g of peptone, 0-4g of beef extract, 0.5-2.0g of MgSO4.7H2O, 0.2-1.0g of KH2PO4, 1-5mg of vitamin B1 and 1000ml of water. The medium contains waste fermenting mash protein residue obtained by vitamin C fermentation, the fermenting mash protein residue contains mycoprotein of bacillus megatherium and ketogulonigenium vulgare, and the mycoprotein is similar to silkworm pupa protein and thus the mycoprotein can completely or partially replace beef extract and peptone in the medium. The medium can improve a cordyceps militaris mycelium fermentation yield, realize resource utilization of the waste fermenting mash protein residue obtained by a vitamin C fermentation industry and effectively reduce a production cost. The invention also provides a use method of the medium for cordyceps militaris liquid deep fermentation.

Owner:SHENYANG YUANKANG BIOTECH

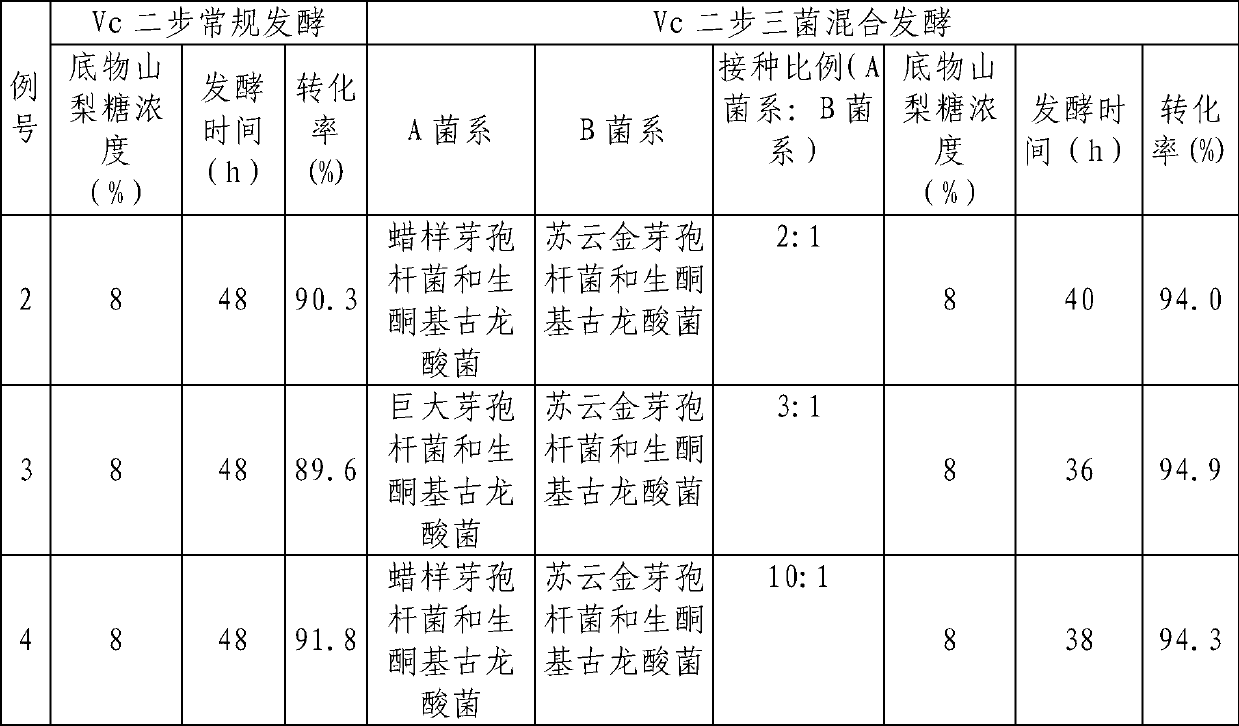

Method using three-bacterium mixed fermentation to convert sorbose into 2-keto-L-gulonic acid

ActiveCN102978273AShorten the fermentation cycleReduce energy consumptionMicroorganism based processesFermentationBacillus thuringiensisAureobasidium sp.

The invention belongs to the technical field of vitamin C biological fermentation, and particularly relates to a method using three-bacterium mixed fermentation to convert sorbose into 2-keto-L-gulonic acid which is in a second step of the vitamin C biological fermentation. Seed solution of manufacturing technique of the second step of the vitamin C biological fermentation is enlarged step by step, when in fermental cultivation, with total inoculation amount with volume percent of 15-20%, seed solution of A isolates and B isolates are introduced into a fermentation tank to be fermented and cultivated to a fermentation ending point (namely when the concentration of remained sorbose in fermentation liquor is smaller than or equal to 1mg / ml), and the purpose that the mixed bacteria fermentation is adopted for converting the sorbose to the 2-keto-L-gulonic is achieved. The A isolates is composed of companion fungus bacillus cereus / companion fungus bacillus megatherium and acid-forming bacteria ketogenic base ketogulonigenium vulgare. The B isolates is composed of companion fungus bacillus thuringiensis and acid-forming bacteria ketogenic base ketogulonigenium vulgare. According to the novel method using the three-bacterium mixed fermentation, respective advantages of the two kinds of the companion funguses are made full use, fermentation period can be shortened by 6-8 hours, energy consumption is reduced by 10-15%, and fermentation conversion percent is improved by 2-4%.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

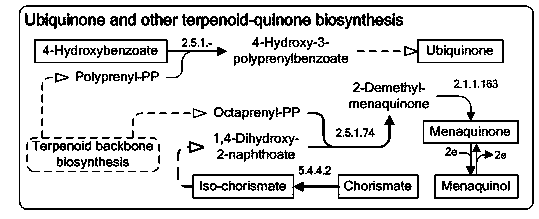

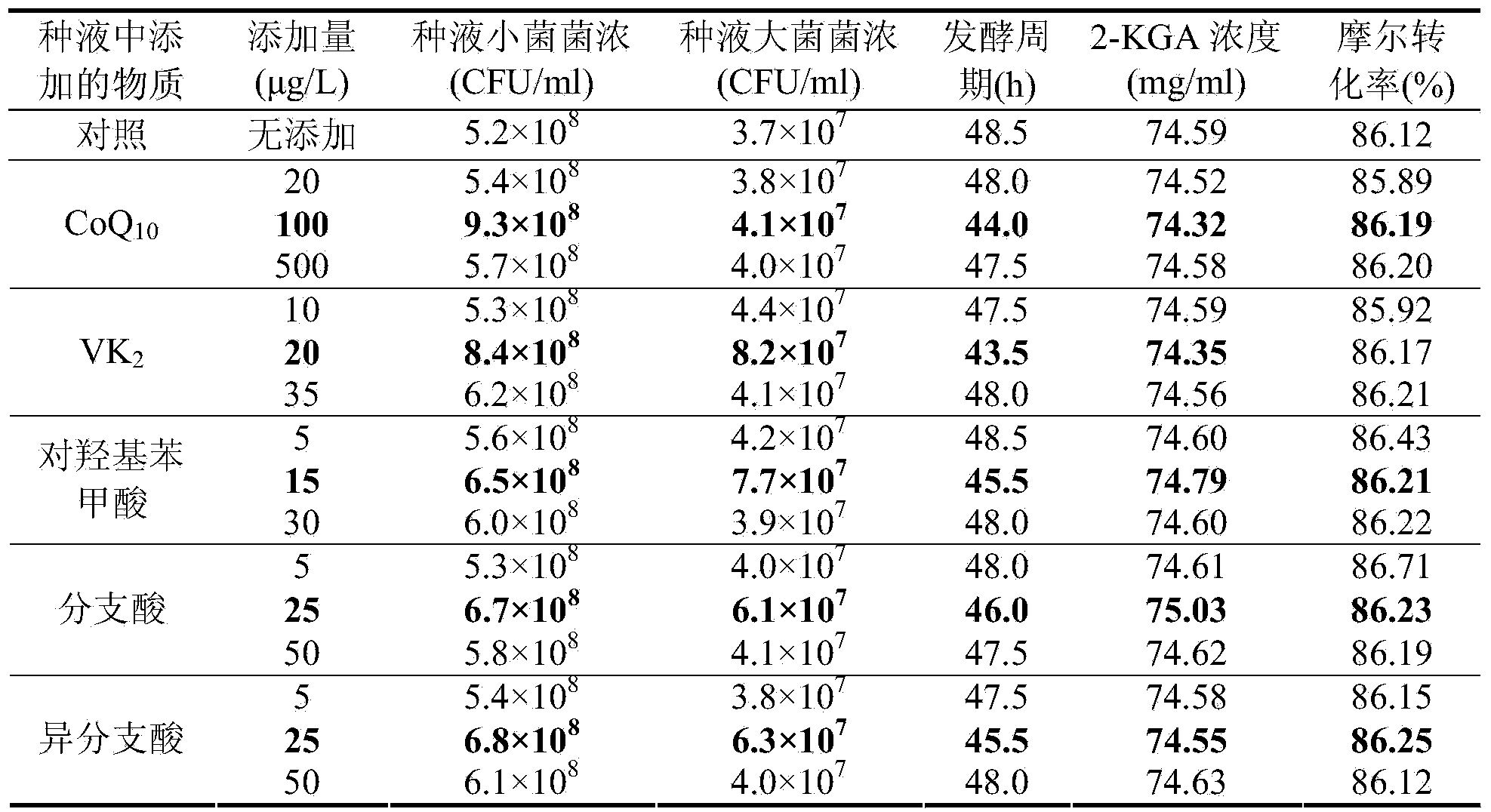

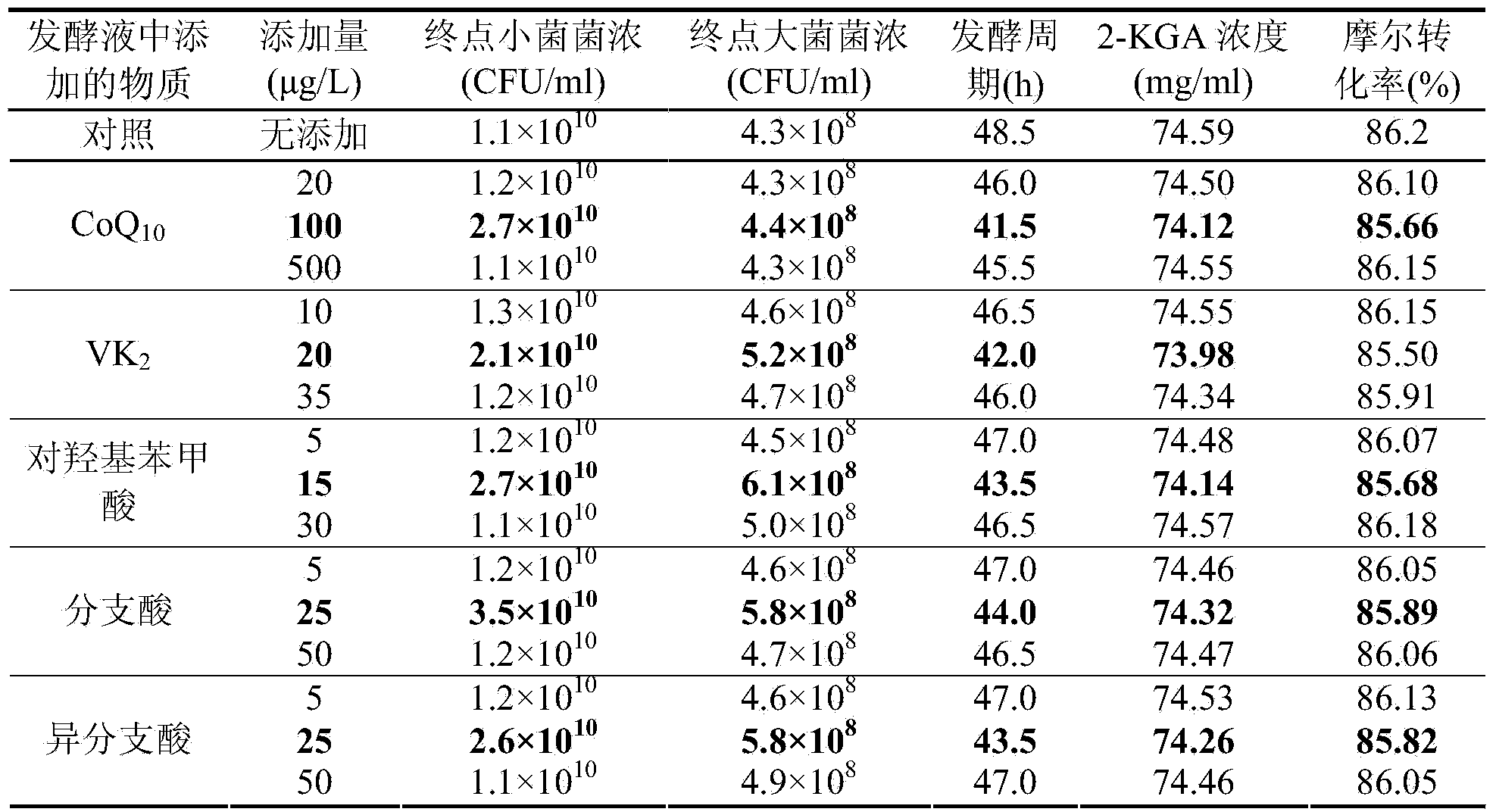

Method for repairing metabolic defects of ketogulonigenium sp. cofactors and improving 2-KGA (2-keto-L- gulonic acid) producing capacity

ActiveCN104357530AImprove metabolic efficiencyIncreased metabolic defectsMicroorganism based processesFermentationEnvironmental resistanceVITAMIN C PREPARATIONS

The invention discloses a method for improving the respiratory chain electron transport level of the ketogulonigenium sp. and increasing the thallus metabolic efficiency by adding a cofactor ubiquinone (CoQ10) and menaquinone (VK2) (in oxidized forms and reduced forms) as well as precursors including PHBA (p-hydroxybenzoic acid), chorismic acid and isochorismic acid of CoQ10 and VK2 in a two-step mixed fermentation process of vitamin C. By means of enhancement of the respiratory function of the ketogulonigenium sp., on one hand, the basal metabolic rate of the ketogulonigenium sp. can be increased, and the thallus quantity can be remarkably increased; on the other hand, the2-KGA producing speed can be increased due to the fact that a 2-KGA producing process of the ketogulonigenium sp. is coupled with the electron transport level of a respiratory chain electron transport process, and the fermentation period can be shortened by 15.38% to the maximum for a 5L fermentation tank. The method is advanced in production technology, low in raw material cost and suitable for large-scale industrial production, and is an improvement and upgrading of a biological fermentation process which is used for nearly 40 years for the vitamin C preparation; and further, emission of harmful substances in the production process is avoided, the surrounding environment is not contaminated, and the method is pollution-free and meets environmental requirements.

Owner:SHENYANG PHARMA UNIVERSITY

Method for promoting growth and acid production of ketogulonigenium vulgare

InactiveCN111893073AActivity that stimulates fermentationSpeed up fermentationBacteriaMicroorganism based processesBiotechnologyBacilli

The invention discloses a method for promoting growth and acid production of ketogulonigenium vulgare. The method comprises the following steps: S1, seed culture: preparing a mixed bacterium of commonketogulonigenium vulgare and bacillus megaterium as a production strain; S2, preparing a culture medium solution; S3, preparing a seed culture solution; S4, preparing a seed culture medium; and S5, carrying out seed fermentation culture, maintaining the pH value in a fermentation tank at 6.2-7.2, and carrying out fermentation to generate 2-keto-L-gulonic acid; according to the method, lipoic acidis added into the seed culture medium, it is guaranteed that mixed bacteria of the common ketogulonigenium vulgare and bacillus megaterium can be directly subjected to single-bacterium fermentation through the small bacteria (ketogulonigenium vulgare), the fermentation process of 2-keto-L-gulonic acid is simplified, and in the seed fermentation culture process, electrolyte is added into the seedculture medium, so that the activity of seed fermentation is stimulated, the speed of seed fermentation is increased, and the purpose of efficiently producing 2-keto-L-gulonic acid is achieved.

Owner:SHANDONG LUWEI PHARMA

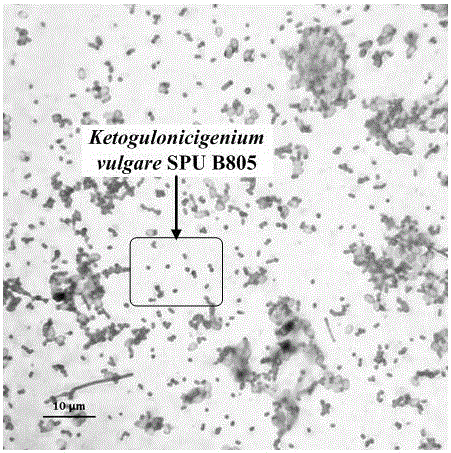

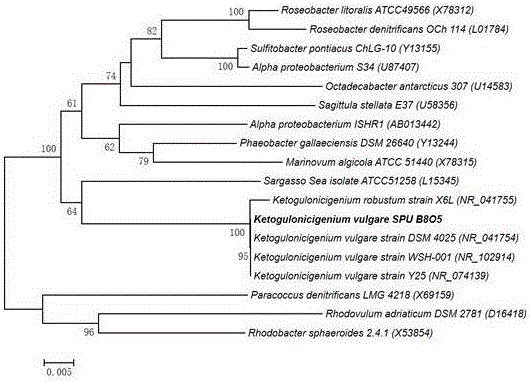

Ketogulonigenium vulgare lacking ED metabolic pathways and 2-KGA production method thereof

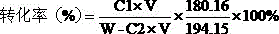

The invention belongs to the field of microbial fermentation and relates to a bacterial strain for production of 2-keto-L-gulonic acid and a production method thereof, specifically to a bacterial strain for converting a substrate L-sorbose to 2-keto-L-gulonic acid (2-KGA) by the means of microbial fermentation and a technology thereof. By isolating and screening from soil and further artificial domesticating, a new bacterial strain SPU B805, which has stable genetic traits and can match industrial fermentation associated bacterial strain Bacillus megaterium to generate 2-KGA, is obtained. The SPUB 805 is identified as Ketogulonigenium vulgare and has been sent into the China General Microbiological Culture Collection Center (CGMCC) to be preserved. When the SPU B805 matches currently industrial production bacterial strain Bacillus megaterium and under the condition of not changing existing culture technologies, 2-KGA can grow and can be produced at 26-34 DEG C. when concentration of the substrate L-sorbose is 8% and through 32-44 h of fermentation in a shaking flask, conversion rate of 2-KGA is 90% and above. When concentration of the substrate L-sorbose is 10% and through 36-48 h of fermentation in a 5L fermentation tank, conversion rate of 2-KGA can reach 95% and above.

Owner:SHENYANG PHARMA UNIVERSITY

A kind of medium for liquid submerged fermentation of Cordyceps militaris and using method thereof

InactiveCN104498367BImprove fermentation yieldReduce manufacturing costFungiMicroorganism based processesVitamin CSaccharum

The invention discloses a medium for cordyceps militaris liquid deep fermentation. The medium comprises 10-30g of cane sugar, 1-5g of corn steep liquor, 4-100g of fermenting mash protein residue, 0-4g of peptone, 0-4g of beef extract, 0.5-2.0g of MgSO4.7H2O, 0.2-1.0g of KH2PO4, 1-5mg of vitamin B1 and 1000ml of water. The medium contains waste fermenting mash protein residue obtained by vitamin C fermentation, the fermenting mash protein residue contains mycoprotein of bacillus megatherium and ketogulonigenium vulgare, and the mycoprotein is similar to silkworm pupa protein and thus the mycoprotein can completely or partially replace beef extract and peptone in the medium. The medium can improve a cordyceps militaris mycelium fermentation yield, realize resource utilization of the waste fermenting mash protein residue obtained by a vitamin C fermentation industry and effectively reduce a production cost. The invention also provides a use method of the medium for cordyceps militaris liquid deep fermentation.

Owner:SHENYANG YUANKANG BIOTECH

A method for producing fermented products using two or more microbial strains

ActiveCN104561221BAddress metabolic disordersResolve inhibitionFermentationMixed cultureMicroorganism

The invention relates to a method utilizing various microorganisms for co-culture or coupling fermentation. With difference from a relationship that vitamin C fermentation bacillus megaterium is mainly used for assisting ketogulonigenium vulgare to grow and produce acids, the method mainly utilizes a method utilizing various microorganisms for co-culture or coupling fermentation to overcome metabolic regulation obstacles for producing fermentation products. The co-culture comprises that two or more than two microorganism strains are subjected to mixed culture from the beginning, or firstly one strain is cultured, and when the strain is cultured to a proper time, other strains are added for culture.

Owner:CATHAY R&D CENT CO LTD +2

Mutation screening method of ketogulonigenium vulgare

InactiveCN105420222AStrains are stable in parallelControl parallel stabilityBacteriaMutant preparationVitamin CMutation screening

The invention provides a mutation screening method of ketogulonigenium vulgare. The ketogulonigenium vulgare in the vitamin C fermentation production is used as an original strain, low-temperature normal-pressure plasma mutation equipment is adopted for mutation, a solid medium is coated with the ketogulonigenium vulgare, single colonies evenly grow out, single-bacterium multiplication and enlarged culture continue to be carried out, and target bacterial strains are screened out through a companion fungus shaking bottle. By means of the technology, the mutation screening parallelity of the ketogulonigenium vulgare is improved, and the probability of obtaining efficient bacterial strains is increased.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

Method for promoting L-sorbose to convert to generate 2-keto-L-gulonic acid

ActiveCN102936615BPromote growthIncrease productionMicroorganism based processesFermentationGastrodia Elata ExtractMicroorganism

The invention discloses a method for promoting L-sorbose to convert to generate 2-keto-L-gulonic acid, belonging to the technical field of microbial fermentation. The method comprises two steps of seed cultivation and fermentative cultivation; according to the method, astragalus extract in an additive amount of 0.75-2.00g / L or gastrodia elata extract in an additive amount of 1.50-3.00g / L is added in a fermentation medium, or the astragalus extract and the astrodia elata extract in additive amounts of 1.00-1.50g / L and 1.50-2.00g / L are added in the fermentation medium at the same time, so as to promote the common ketogulonigenium vulgare (small bacterium) and huge bacillus (large bacterium) to coordinately grow to realize the efficient synthesis of the 2-keto-L-gulonic acid; and through coordinating the mutual functions of the two bacteria, the growth of the small bacterium is promoted, the output of the 2-keto-L-gulonic acid is improved and the fermentation period is shortened. According to the method, a 10L tank is used for the fermentation experiment and a predicted effect is obtained.

Owner:石药集团维生药业(石家庄)有限公司

Method for improving 2-keto-L-gluconic acid production intensity through addition of betaine

InactiveCN104988201AModerate proportionIncrease vitalityMicroorganism based processesFermentationBiotechnologyBetaine

The invention discloses a method for improving the production intensity of 2-keto-L-gulonic acid (2-KLG) by adding betaine, belonging to the technical field of vitamin C preparation through fermentation. A mixed bacteria system of ketogulonigenium vulgare and bacillus megaterium is adopted as a production strain, and 0.05-1.0% betaine is exogenously added into a fermentation medium as an osmotic pressure regulator so as to promote the cell growth and 2-KLG production and realize efficient production of 2-KLG. By adopting the process, the method disclosed by the invention can effectively shorten the fermentation period of 2-KLG and improve the production intensity.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

A kind of method for fermenting and producing vitamin C precursor 2-keto-l-gulonic acid

ActiveCN109234350BFast conversionSimple cultivation conditionsBacteriaMicroorganism based processesBiotechnologyBacillus licheniformis

Owner:JIANGNAN UNIV

Cultivation method of ketogulonigenium sp

InactiveCN105368759AShorten the timeHigh-quality fermented strainsBacteriaMicroorganism based processesVitamin CFermentation

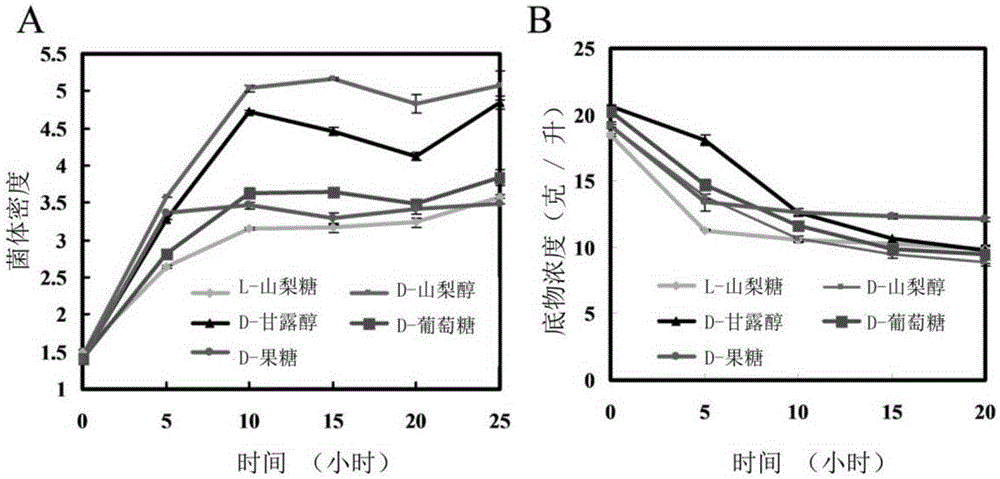

The invention relates to the field of microorganisms, in particular to a cultivation method of ketogulonigenium sp. A new technological process of vitamin C precursor 2-ketone-L-gulonic acid is established, in the process, a brand-new ketogulonigenium sp seed cultivation mode is used, and sorbitol and / or mannitol serve / serves as a carbon source in replacement of sorbose. Under the same cultivation time and cultivation condition, the mycelia content is increased by 1.6 times or more through seed cultivation of sorbitol / mannitol than a sorbose cultivation mode, and high-quality fermentation strains are provided for follow-up fermentation. As for the aspect of the same mycelia content, the highest biomass obtained after 25 hours of cultivation in sorbose can be obtained after 5 hours of cultivation in sorbitol and mannitol. Accordingly, the seed cultivation time is greatly shortened by at least 10 hours.

Owner:TIANJIN UNIV

Method for producing 2-keto-L-gulonic acid vitamin C precursor by modifying Escherichia coli

ActiveCN102250821BSimple processEasy to buildBacteriaMicroorganism based processesEscherichia coliVitamin C

The invention discloses a method for transforming Escherichia coli to produce vitamin C precursor 2-keto-L-gulonic acid, which belongs to the field of genetic engineering. In the present invention, through genetic engineering technology, sorbitol dehydrogenase (SLDH), coenzyme pyrroloquinoline quinone (Pyrroloquinoline quinone, PQQ) gene cluster derived from Gluconobacter oxydans and common ketogenic gluconic acid The sorbose dehydrogenase (SDH) / sorbone dehydrogenase (SNDH) gene of Ketogulonigenium vulgare was expressed in Escherichia coli, and a strain of E.coli that utilizes sorbitol to produce 2-KLG was obtained. bacteria. At present, the two-step fermentation process used in the industrial production of vitamin C in China is complicated, with many influencing factors, and it is difficult to control accurately. At the same time, the growth of three kinds of microorganisms consumes a lot of raw materials and energy. E.coli engineering bacteria are used for fermentation production with sorbitol 2-KLG simplifies the production process, saves raw materials and energy, and the output of 2-KLG can reach 87g / L, which has a good application prospect.

Owner:JIANGNAN UNIV

Gluconobacter oxydans engineering bacterium for producing sorbic ketone in high yield mode and construction method thereof

ActiveCN102851252BSimple production processEliminate dependenciesBacteriaMicroorganism based processesBiotechnologyD-Sorbitol

The invention discloses a Gluconobacter oxydans engineering bacterium for producing vitamin C synthesis intermediate sorbic ketone and a construction method and application thereof, and belongs to the field of genetic engineering. By means of the genetic engineering technique, a sorbose dehydrogenase gene (sdh) derived from common ketogenic base Ketogulonigenium vulgare is cloned onto Gluconobacter oxydans to obtain the G. oxydans engineering bacterium for producing the sorbic ketone by utilizing sorbitol. G. oxydans WSH-003 which is provided by Jiangsu Jiangshan Pharmaceutical Co., Ltd is a fermented industrial strain obtained in a first step of a two-step fermentation method for producing 2-keto-L-gulonic acid (2-KLG). The sdh is cloned into the G. oxydans so that conversion from D-sorbitol to the vitamin C synthesis intermediate sorbic ketone is achieved, the foundation for further constructing the fermented industrial strain in one step to produce the direct precursor 2-KLG of vitamin C is laid, and the yield of the sorbic ketone is as high as 72g / L. Therefore, the Gluconobacter oxydans engineering bacterium has good application prospects.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com