Gluconobacter oxydans engineering bacterium for producing sorbic ketone in high yield mode and construction method thereof

A technology of gluconic acid bacteria and glucose oxidation, applied in the field of genetic engineering, can solve the problems of difficult growth of small bacteria, difficulty in precise control, and many influencing factors, and achieve the effect of eliminating the dependence of associated bacteria, suitable for standardization, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

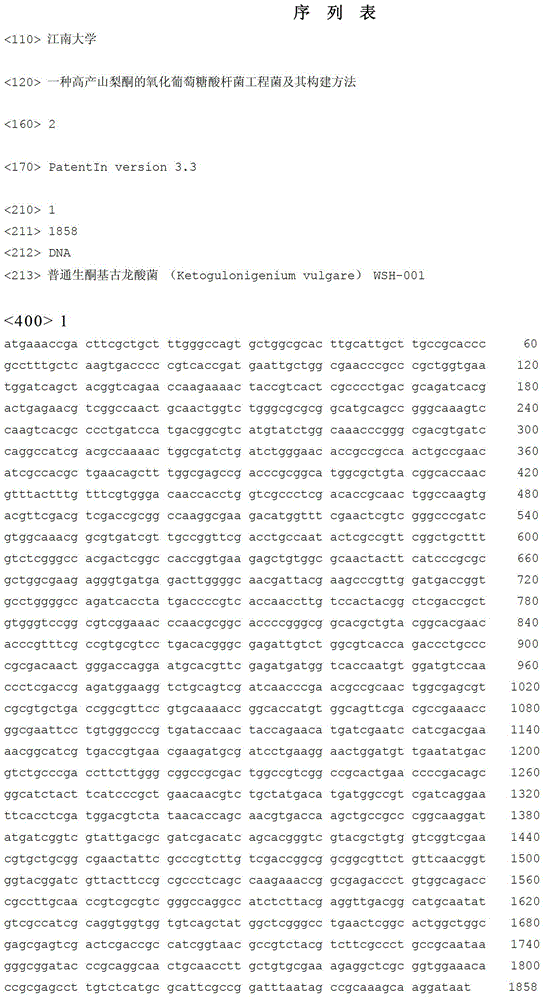

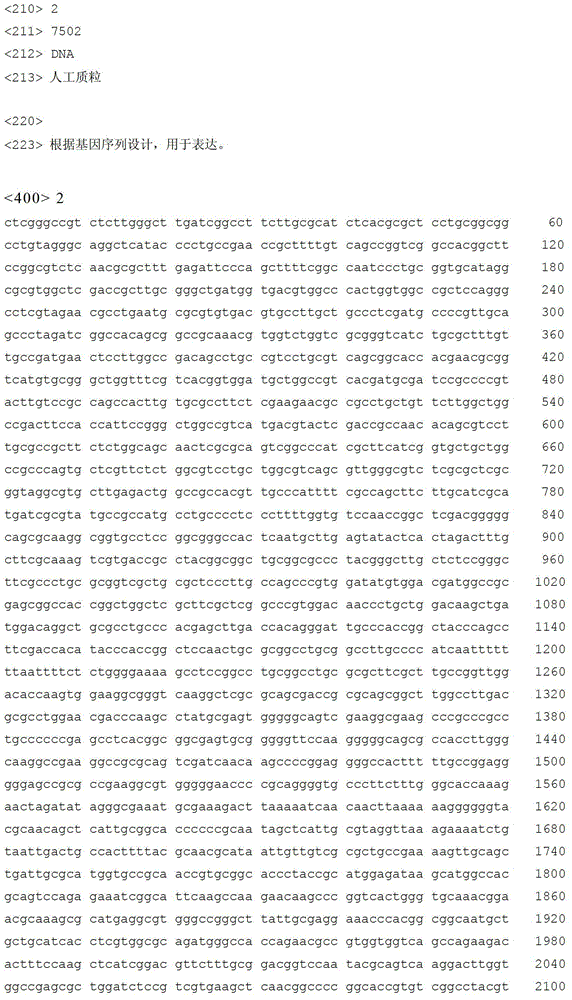

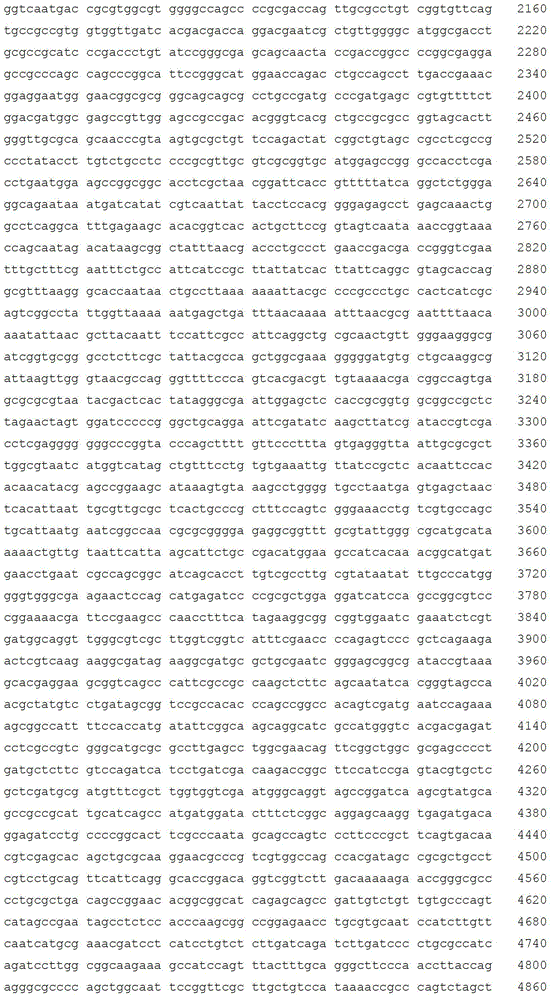

[0020] The construction of embodiment 1 expression vector

[0021] The sdh annotated in the whole genome sequencing results of K.vulgare WSH-001 in our laboratory and the promoter tufB of the elongation factor in G.oxydans WSH-003 were amplified and cloned into the pMD19-T vector, and positive transformants were picked Sequencing verification, the correct transformants were cultured to extract the plasmid, and the Gram-negative bacterial broad host shuttle plasmid vector pBBRMCS-2 was respectively digested with Xho I and Hind III and ligated, transformed into Escherichia coli (Escherichia coli) JM109, picked The transformant was cultured, and the extracted plasmid was verified by Xho I and Hind III digestion, and a 1858bp band appeared, which proved that the expression vector pBBRMCS-sdh had been successfully constructed. The sequenced correct pMD 19-T-tufB and pBBRMCS-sdh were digested with Kpn I and Xho I, then ligated, transformed into E.coli JM109, picked and cultured, and...

Embodiment 2

[0022] The construction of embodiment 2G.oxydans engineering bacteria

[0023] Culture the Escherichia coli recombinant strain E.coli / pBBRMCS-tufB-sdh constructed above, the auxiliary strain E.coli / pRK2013 (ATCC deposit number: 37159) and the recipient strain G.oxydans 621H to the logarithmic phase, press 2 Centrifuge after mixing at a ratio of 1:1, wash the cell pellet with normal saline, resuspend in 100 μL of normal saline, spread all the bacterial suspension on the sterile filter membrane of the sorbitol plate, incubate for 12 hours, and scrape the cell After appropriate dilution, apply to a selective plate with a final concentration of 50 μg / mL cefoxitin sodium and 50 μg / mL kanamycin, pick positive transfers for PCR verification, and extract the positive transfers after culture The plasmid was converted to E.coli JM109, and the extracted plasmid was verified by Kpn I, Xho I and Xho I, Hind III double enzyme digestion respectively, and bands of 1858bp and 500bp appeared, w...

Embodiment 3

[0024] Embodiment 3 fermentation produces sorbitol

[0025] Seed and slant medium (g / L): sorbitol 20, yeast extract 2, pH 4.8-5.1, agar 20 (slant medium), pH 7.0, sterilized at 121°C for 15 minutes, final concentration of kanamycin 50 μg / L mL.

[0026] Fermentation medium (g / L): Sorbitol 80, yeast extract 5, initial pH 5.1-5.4, sterilized at 121°C for 15 minutes, final concentration of kanamycin 50 μg / mL.

[0027] Culture conditions: inoculate the recombinant bacteria from the slant in 20mL seed medium, cultivate at 30°C and 200rpm for 24h, then inoculate in the fermentation medium with 15% inoculation amount, carry out shake flask fermentation at 30°C and 220rpm, and the fermentation period is 48h. Sorbitone yield was 72g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com