Patents

Literature

162 results about "Gulonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing mycoprotein and polypeptide organic fertilizer by fermented waste of vitamin C

InactiveCN101747093ALow costImprove utilizationClimate change adaptationBioloigcal waste fertilisersMycoproteinHand parts

The invention relates to a method for producing mycoprotein and polypeptide organic fertilizer by waste fermented mash and gulonic acid mother solution formed in the vitamin C production technology, which belongs to the field of biotechnology and waste resource utilization technology, and comprises the following steps: adding 5 to 20 parts of gulonic acid mother solution in 100 parts of waste vitamin C fermented mash protein, adjusting pH value to 2.0 to 5.0, and hydrolyzing for 0.5 to 12 hours under the temperature of 40 to 70 DEG C. On the one hand part of protein in fermented mash protein is hydrolyzed to become polypeptide and amino acid to dissolve in water, through adjusting pH value and appropriate concentration, right amount of trace element is added, obtaining polypeptide organic fertilizer, on the other hand the rest protein in mash protein is precipitated, and the precipitated protein is made into mycoprotein through filter-pressing, drying and smashing. The invention recycles the vitamin C fermentation industry waste to produce mycoprotein and polypeptide organic fertilizer, thus not only solving the problem of industrial pollution, but also providing organic fertilizer and feed protein for agricultural production.

Owner:北京卓普元创科技有限公司

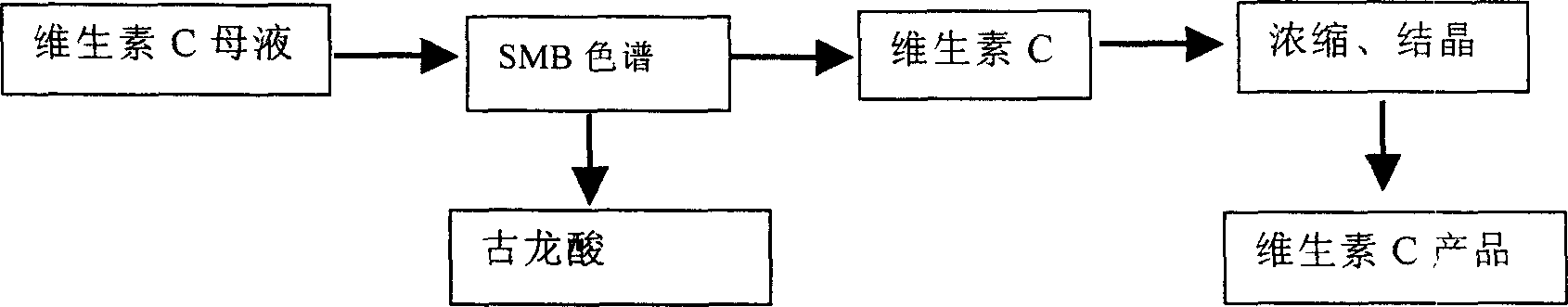

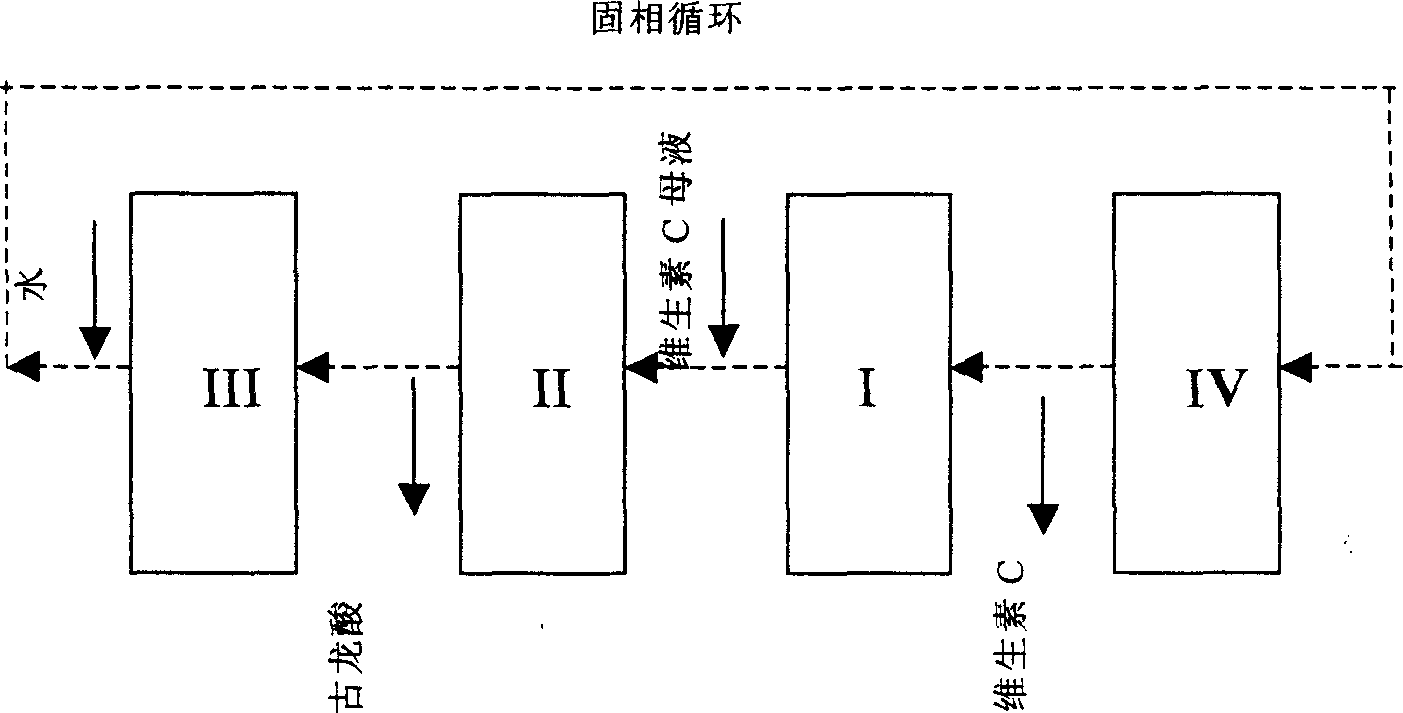

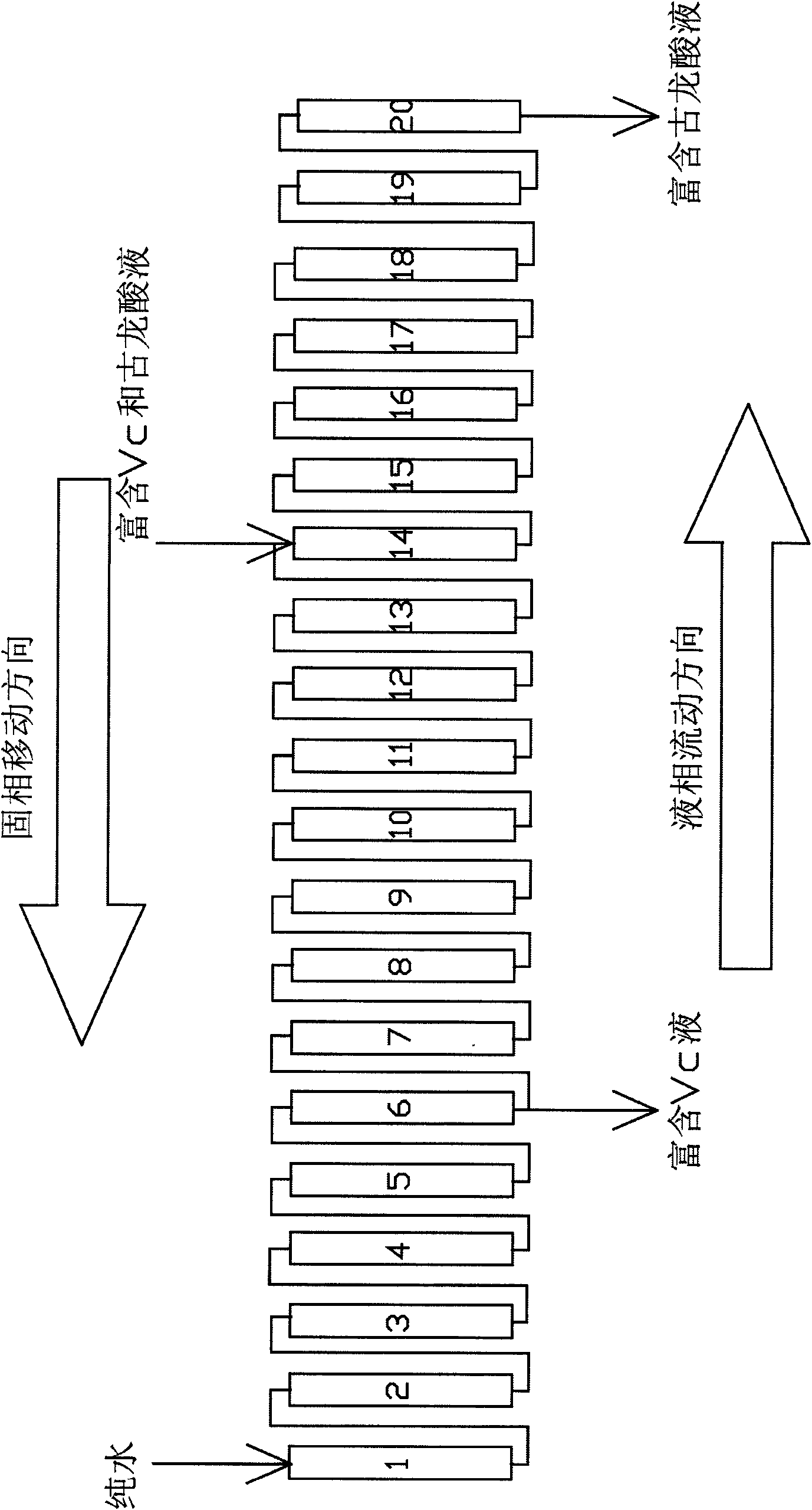

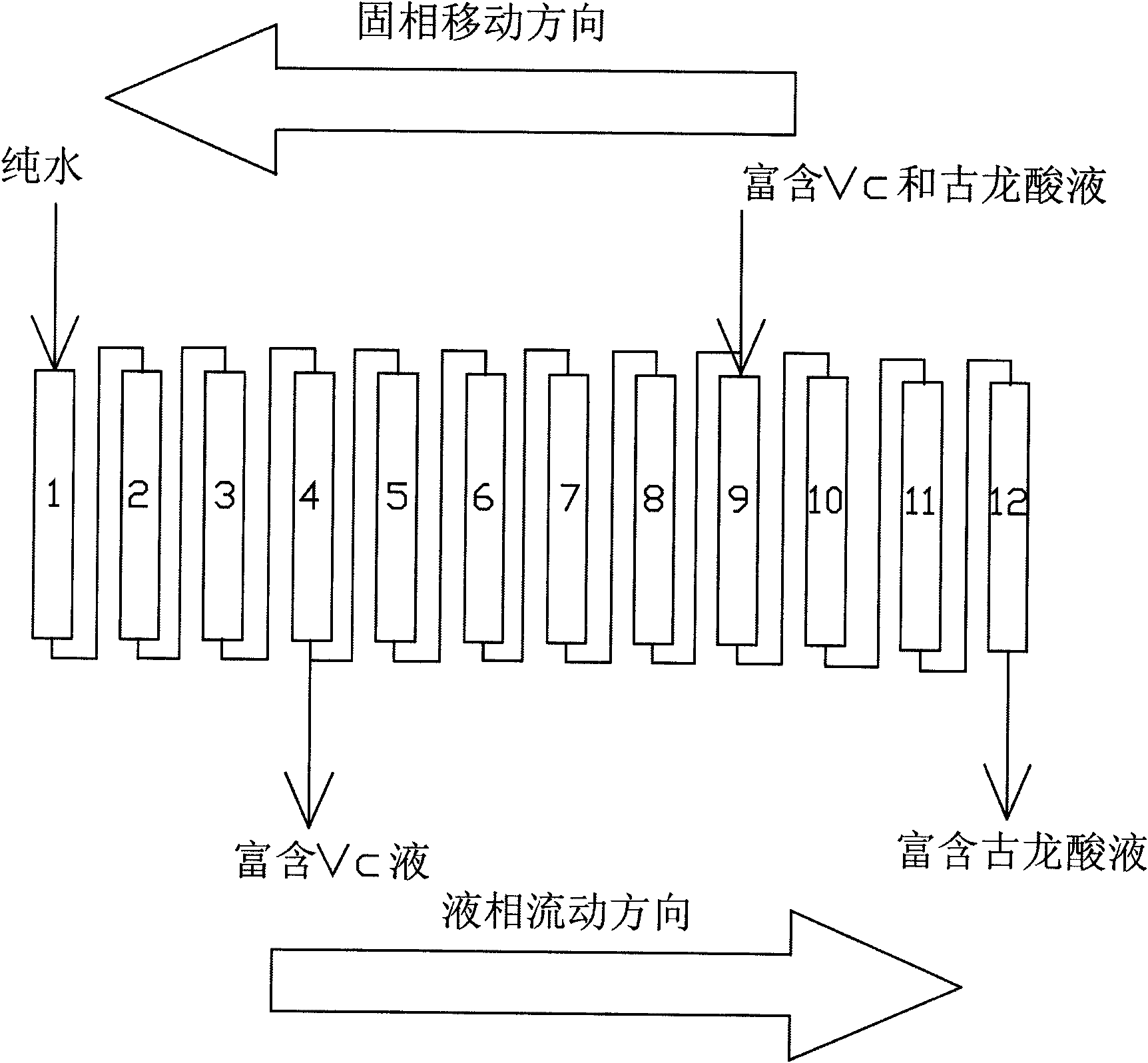

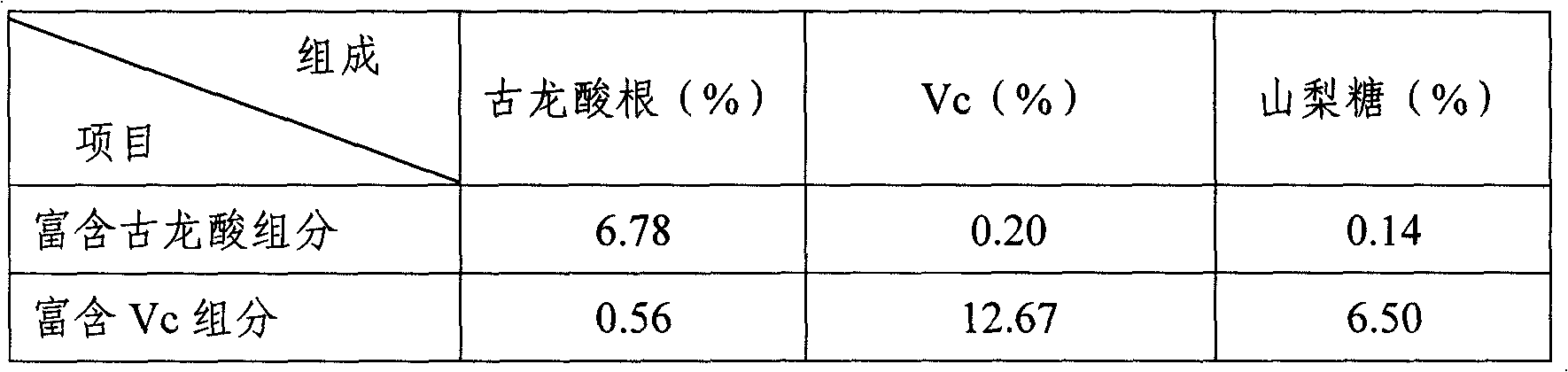

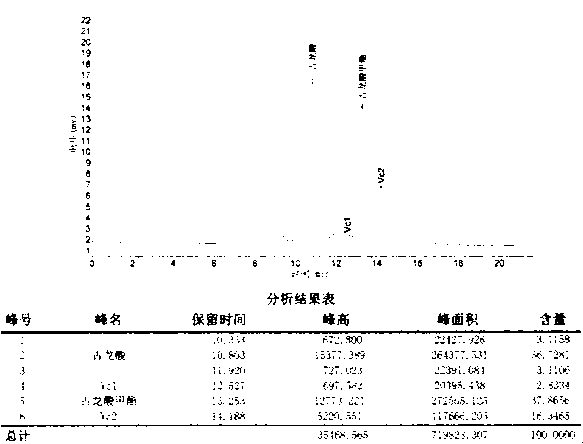

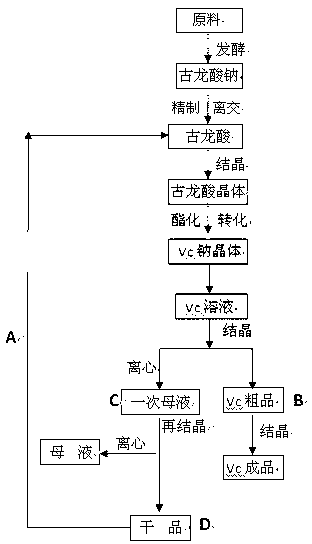

Method for extracting Vitamin C and gulonic acid from Vitamin C mother liquor

InactiveCN1733747AIncrease profitEfficient separationCarboxylic compound separation/purificationSimulated moving bedGluconic acid

The method to extract vitamin C and Gulonic acid from vitamin C mother liquor comprises, using the said mother liquor as material to separate the vitamin C and Gulonic acid completely on analog moving bed with water as eluant at 20~75Deg, and obtaining the said constituents. This invention uses common condensing crystallization separation method.

Owner:JIANGNAN UNIV

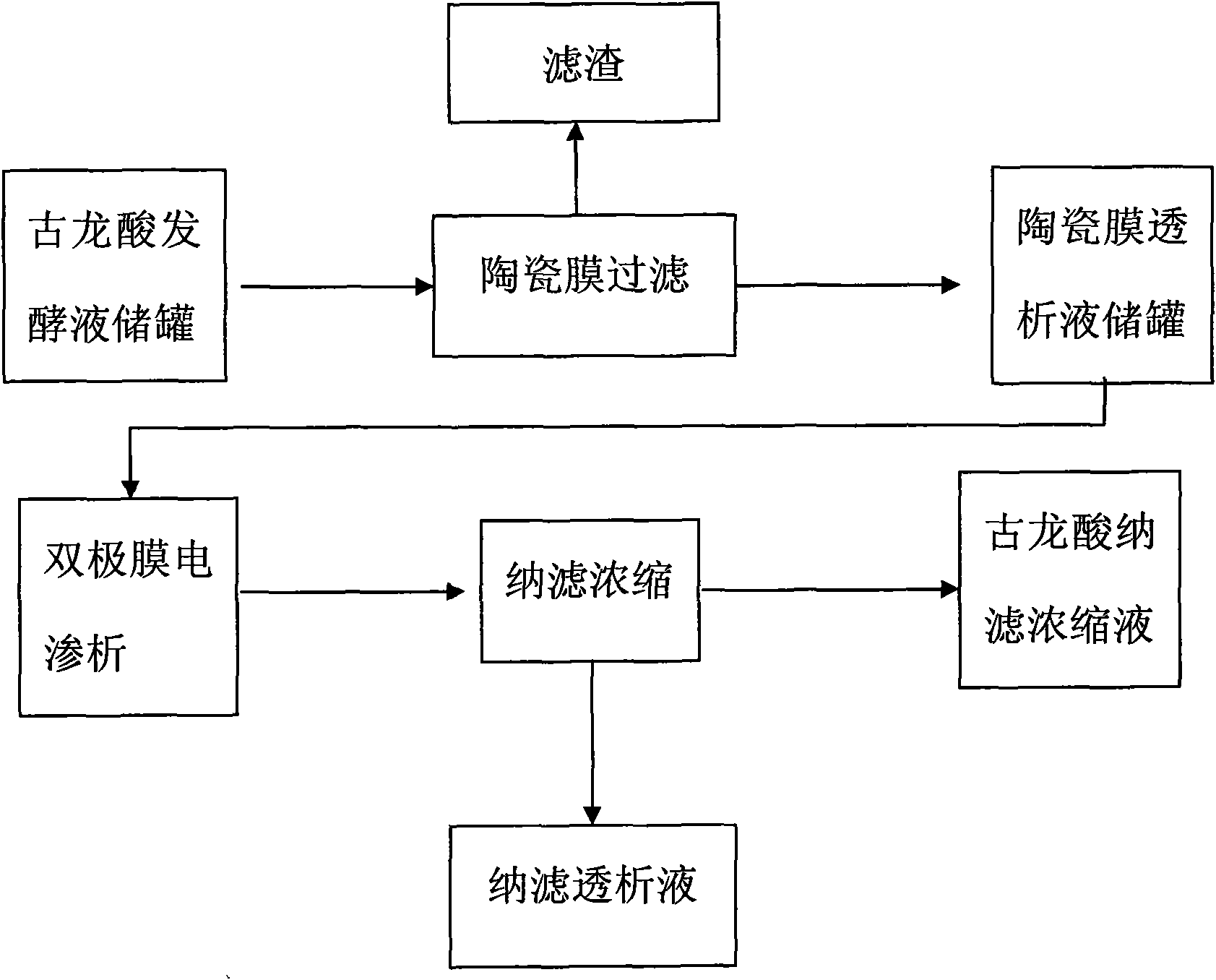

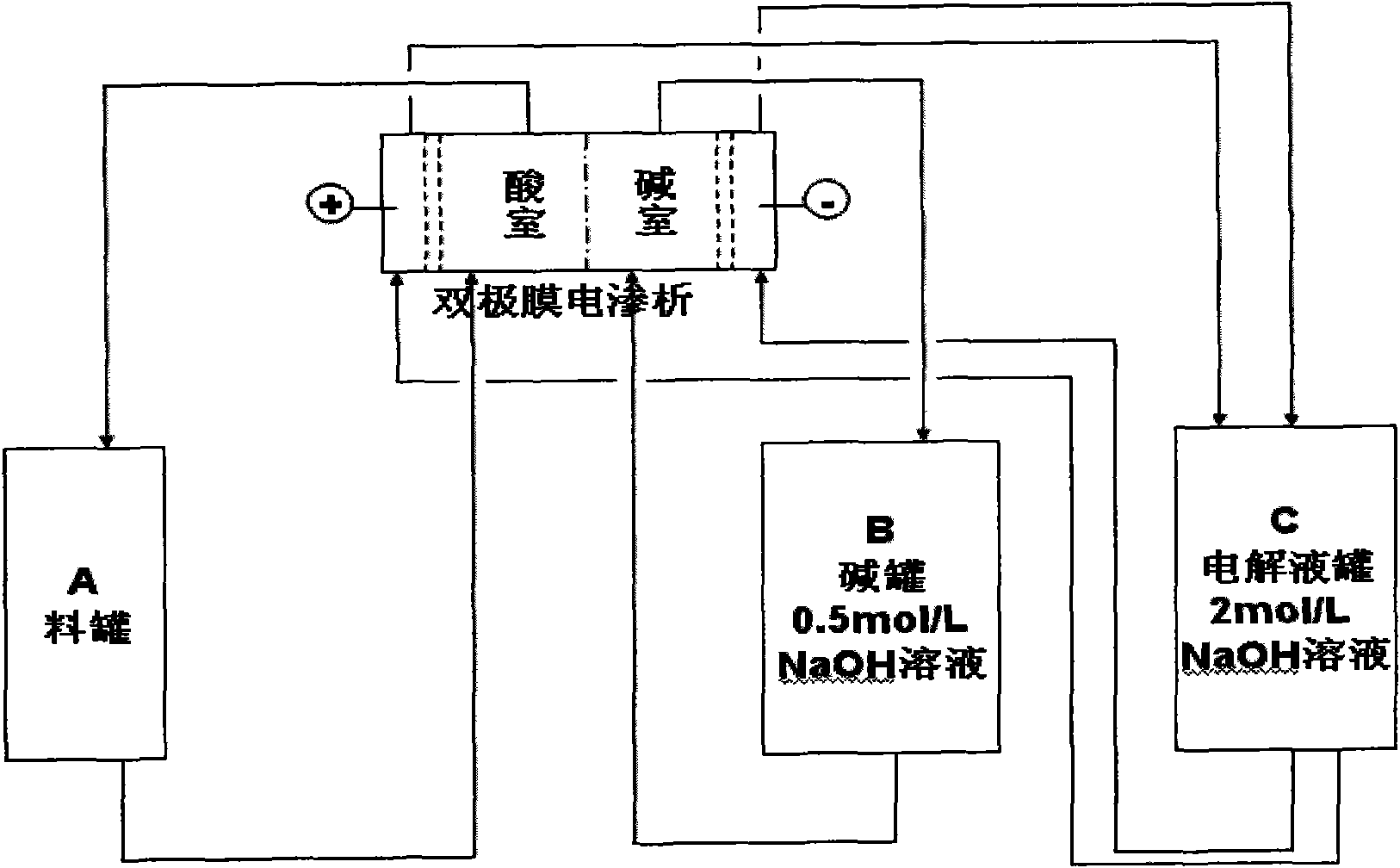

Production method of gulonic acid in production of vitamin C

InactiveCN101643408AReduce pollutionLow costCarboxylic compound separation/purificationVitamin CColloid

The invention provides a production method of gulonic acid in the production of vitamin C, which comprises the following steps: (1) ceramic film filtering: filtering and concentrating a fermentation broth through a ceramic-film filtering apparatus, and removing proteins, hypha, suspended substances, colloid, bacteria and other macromolecular organic substances in filter residues to obtain a gulconic sodium dialysate; (2) double-pole film electrodialysis system: processing the filtrate containing gulconic sodium salts by an electrodialysis system to as to convert the gulconic sodium into the gulconic acid solution; (3) nanofiltration concentration: concentrating the gulconic acid solution in a nanofiltration film apparatus to obtain the concentrated gulconic acid solution. The method can reduce the production cost, increase the total yield, enhance the product quality and achieve the aims of environmental protection and simple apparatus operation.

Owner:XIAMEN STARMEM TECH

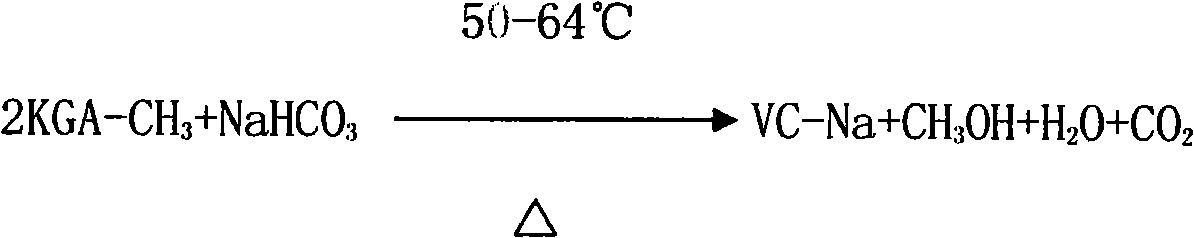

Method for directly preparing vitamin C with sodium gulonate

InactiveCN101298445ASignificant technological progressGood energy saving and emission reduction effectOrganic chemistryFermentationHigh concentrationVitamin C

The invention relates to a method for preparing ascorbic acid by using gulconic sodium to converse directly; the invention is importantly improved based on the existing two-step fermentation method for manufacturing VC: a 2KGA-Na crystal of high purity can be obtained by the techniques of hyperfiltration clarification, low temperature concentration and constant temperature crystallization, etc.; the completely novel method for separating the gulonic acid that are not converted into VC by the technique conditions of separating Na[2]SO[4] solid during the prophase of methyl reaction and optimizing and conversion reaction as well as by adopting an advanced chromatogram technology during the processes of acidification and refining leads to obtain the top-grade product from the crude VC by one-step crystallization, thereby leading the total yield for manufacturing VC by the two-step fermentation method to be improved to more than 86 percent; the waste water with high concentration is completely removed; and the energy consumption can be reduced by about 20 percent.

Owner:徐昌洪

Organic fertilizer prepared by use of cordyceps militaris waste medium and vitamin C fermentation waste gulonic acid mother liquor and preparation method thereof

The invention belongs to the technical field of resource utilization of industrial and agricultural production wastes, and in particular relates to an organic fertilizer prepared by use of cordyceps militaris waste medium and vitamin C fermentation waste gulonic acid mother liquor and a preparation method thereof, the cordyceps militaris waste medium is soaked into the gulonic acid mother liquor with the specific gravity of 1.000-130 for 20min 6 hours, the pH is adjusted to 6.0-7.0, proper amount of N, P, K and trace elements are replenished, and the organic fertilizer is obtained by drying or drying in air, wherein the specific gravity ratio of cordyceps militaris waste medium to vitamin C fermentation waste gulonic acid mother liquor is 1:0.051. By resource utilization of the cordyceps militaris waste medium and vitamin C fermentation industrial waste, high quality organic fertilizer is prepared, the environmental pollution problems of the industrial and agricultural production wastes can be solved, and the high quality organic fertilizer is provided for agricultural production.

Owner:SHENYANG YIKANG ENVIRONMENTAL BIOTECHNOLOGY DEV CO LTD

Reconstruction method for producing Vitamin C precursor 2-keto-L-gulonic acid (2-KLG) with gluconobacter oxydans

InactiveCN102250822AEliminate dependenciesSimple production processBacteriaMicroorganism based processesVitamin CGenetic engineering

The invention discloses a reconstruction method for producing the Vitamin C precursor 2-KLG with gluconobacter oxydans, and belongs to the field of genetic engineering. According to the invention, a sorbose dehydrogenase (SDH) gene and a sorbosone dehydrogenase (SNDH) gene originated from ketogulonigenium vulgare are expressed in gluconobacter oxydans to obtain a G. oxydans engineering bacteria for production of 2-KLG by using sorbitol. G. oxydans is a frequently used strain in the first step of fermentation in the method of two-step fermentation; in the invention, the SDH and SNDH genes are expressed in G. oxydans, which enables the problem of dependency of ketogulonigenium vulgare on associated fungi to be overcome, direct conversion of D-sorbitol into 2-KLG to be realized and the production process for Vitamin C to be simplified; output of 2-KLG reaches 83 g / L; therefore, the invention has a very good application prospect.

Owner:JIANGNAN UNIV

Method for producing 2-keto-l-gulonic acid

ActiveCN101736071ASolve the shortcomings of slow growth and slow acid productionOptimizing Growth CorrelationsMicroorganism based processesFermentationMicroorganismAnimal science

The invention provides a method for producing 2-keto-l-gulonic acid, including the following steps of: feeding nitrogen source nutrient solution from the 20th to the 26th hour in the fermentation process to compensate nutritional demands of microorganism growth in the fermentation process, finishing feeding solution in the 40th to the 45th hour, wherein the dissolved oxygen is controlled to be 30-50% in the nutrient solution feeding process. The invention utilizes a method of feeding nutrient solution at middle and later stages of fermentation, overcomes disadvantage that biomass grows and generates acid slowly, combines control of factors of temperature, pH, dissolved oxygen, low initial glucose, fed-batch glucose compensation and the like, and optimizes the growth relations of biomasses with different sizes in microbial mixed fermentation. The gulonic acid content of the invention is 105-115mg / ml, and the glucose acid convert ratio is 92-95%.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Preparation technology for 2-keto -L-gulonic acid ferment strain

ActiveCN101575588AHigh densityIncrease vitalityBacteriaMicroorganism based processesSucroseSaccharum

The invention discloses a preparation technology for 2-keto-L-gulonic acid ferment strain, adopting large and small bacteria for mixed culture, wherein, the small bacteria is ordinary ketogenic gulonic acid bacteria, and the large bacteria is Bacillus megatherium. The invention comprises the following steps: firstly, inoculating the small bacteria onto a slant culture medium to cultivate for 16 to 48 hours separately; then, inoculating the large bacteria and continuing to cultivate for 24 to 72 hours with the quantity ratio between the large bacteria and the small bacteria being 1:(20-40); taking sucrose with the concentration of 5-30g / L or fructose with the concentration of 5-20g / L as the main carbon source in the culture medium; introducing the seed mixture of large and small bacteria into the culture medium for cultivation and controlling the bacteria count of seeding liquid to 10-10 / ml. The invention changes the proportion between large bacteria and small bacteria, increases the strain density, and improves the strain vitality, thus shortening the fermentation period; the invention is further characterized by unchanging strain, easy operation and widespread use.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

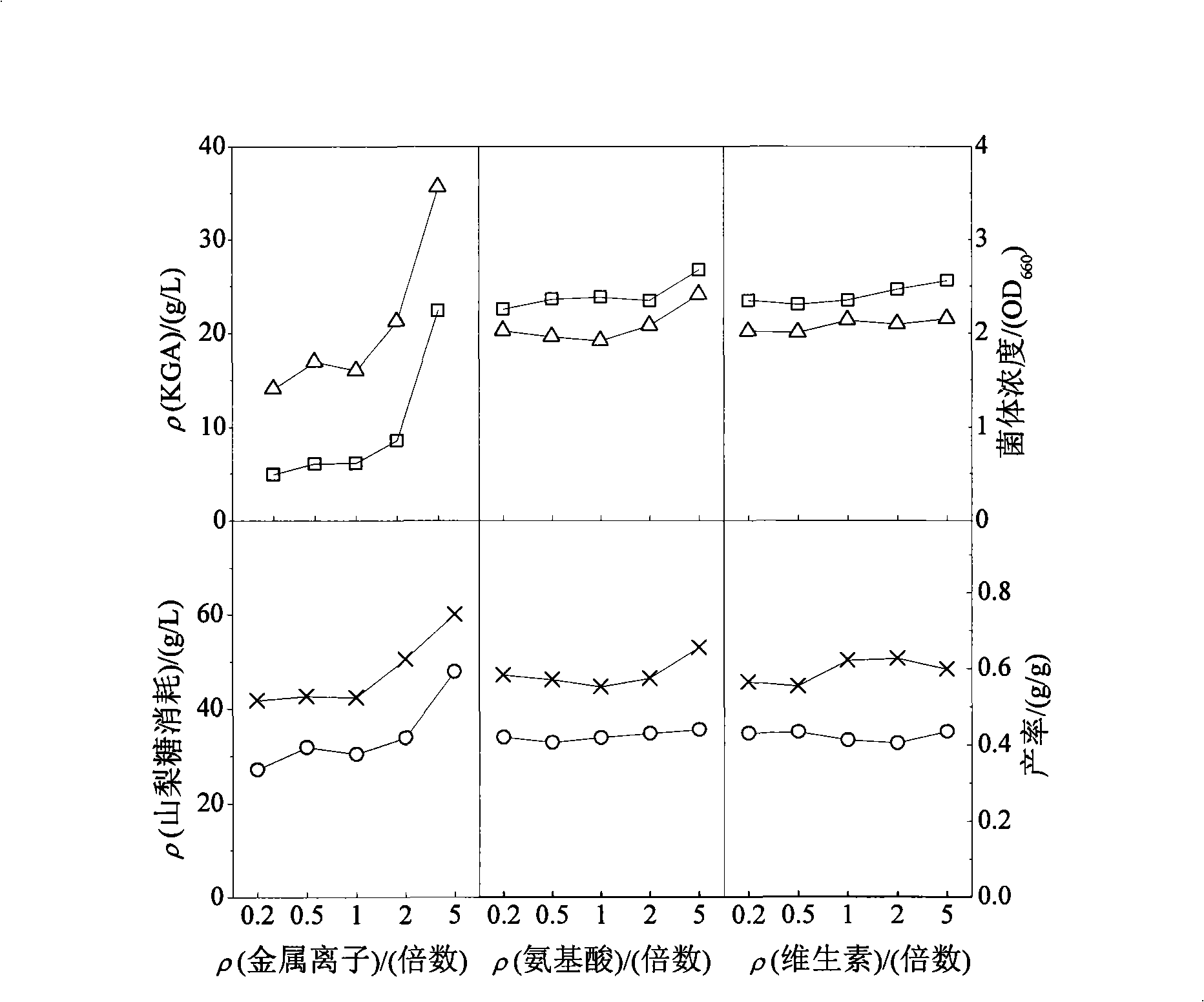

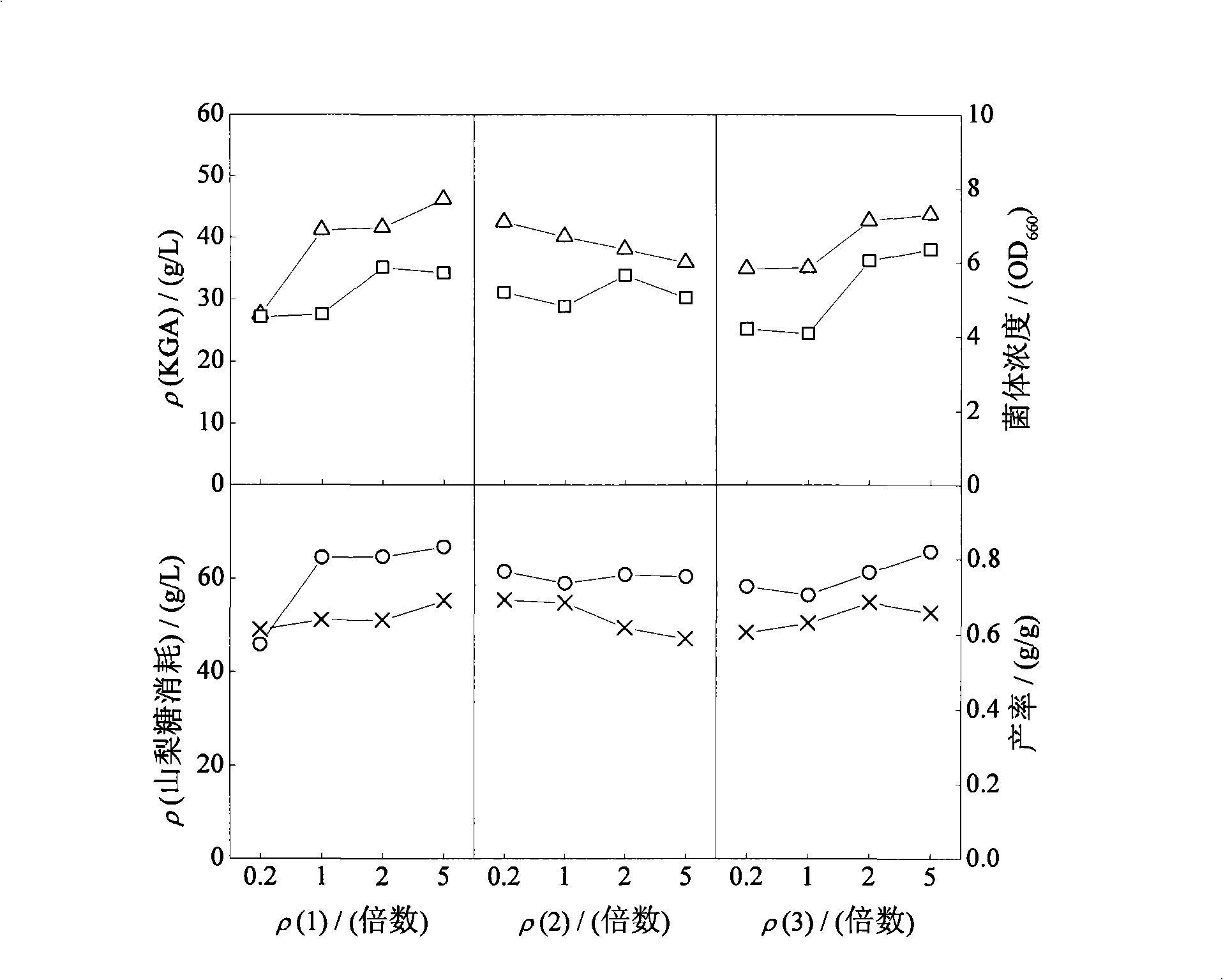

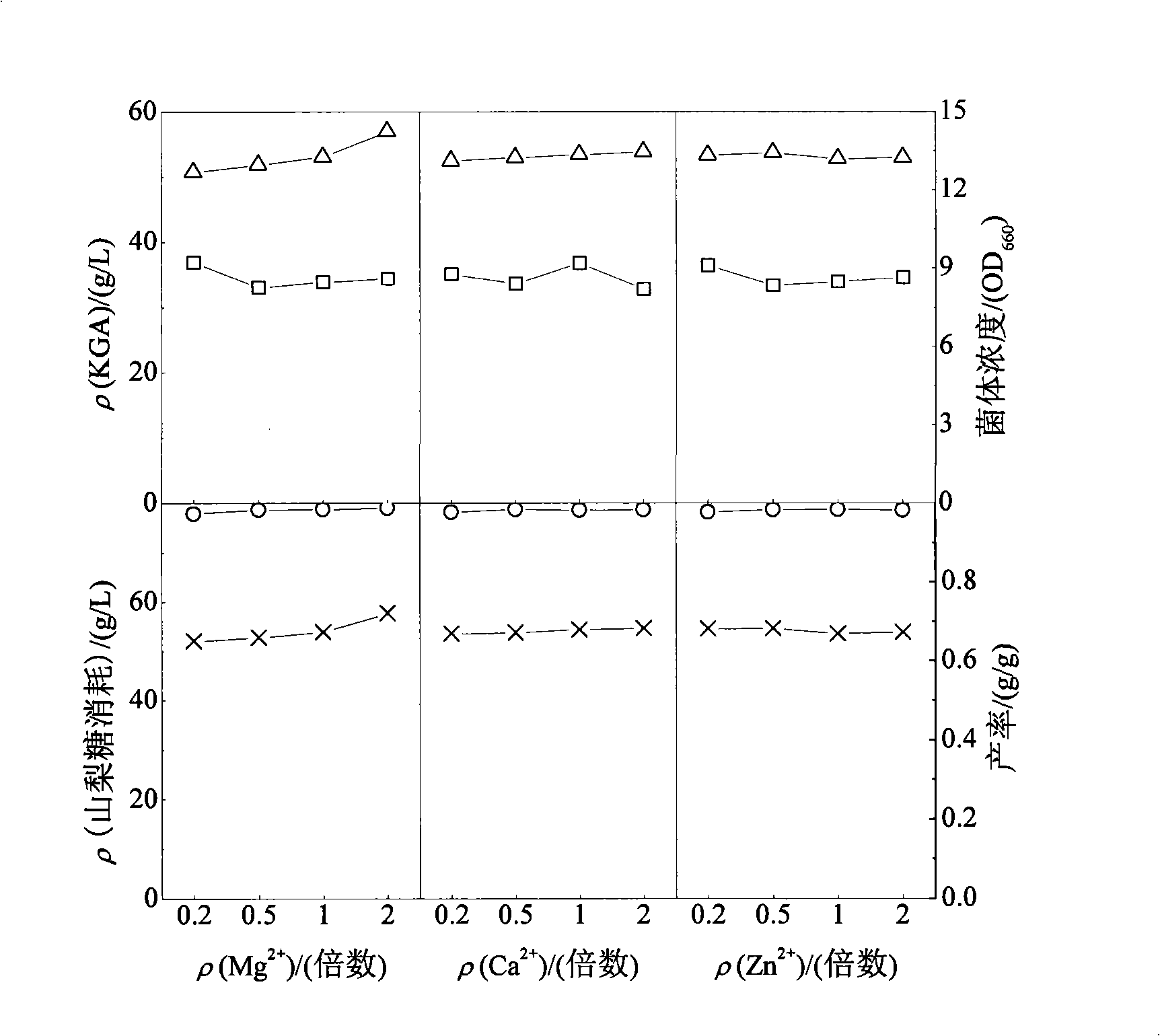

Method for enhancing fermentation and production stability of 2-ketone-L-Gulonic acid

InactiveCN101338335AIncrease productionHigh yieldMicroorganism based processesFermentationGluconic acidKetone

Owner:JIANGNAN UNIV

Enhancing method of production strength of 2-keto-L-gulonic acid

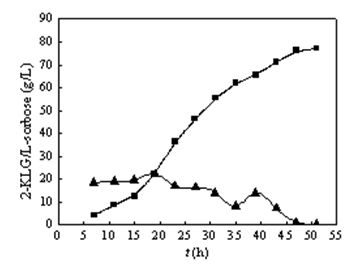

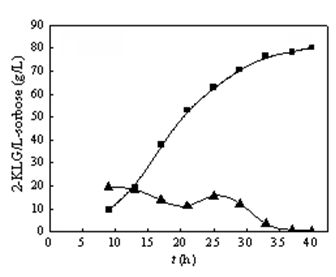

InactiveCN102010885AShorten the fermentation cycleLow costMicroorganism based processesFermentationBiotechnologyGlycine

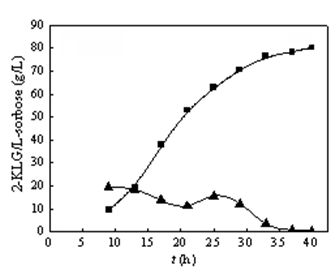

The invention discloses an enhancing method of the production strength of 2-keto-L-gulonic acid (2-KLG), belonging to the field of microbial fermentation engineering. The purpose of enhancing the production strength of 2-KLG is achieved through the addition of the key amino acids, namely L-glycine and L-proline which have significant promotion effect on the production of 2-KLG which adopts the mixed fermentation of the common Ketogulonigeniumvulgare and Bacillusmegaterium. When L-glycine and L-proline are used to enhance the key amino acid components of the corn steep liquor, the fermentationperiod is reduced to 40 hours which is reduced by 21.6%, the concentration of 2-KLG can reach 80.29g.L<-1>, and the acid production rate of 2-KLG can reach 2.00g.(L.h)<-1>, therefore the production strength of 2-KLG is significantly enhanced.

Owner:JIANGNAN UNIV

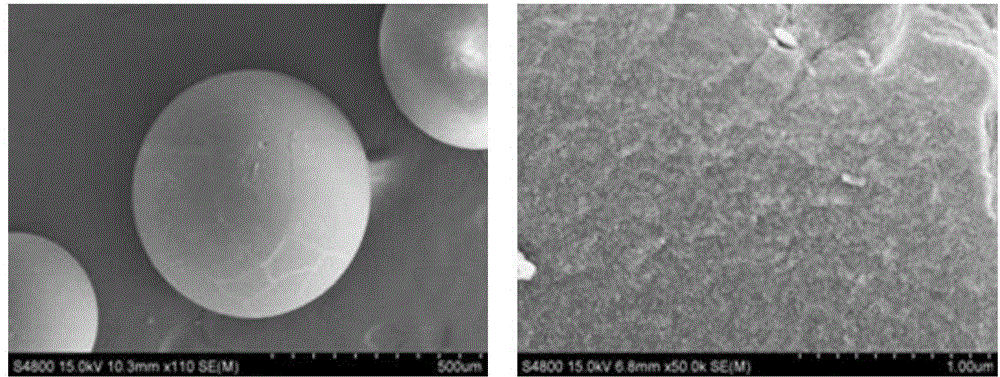

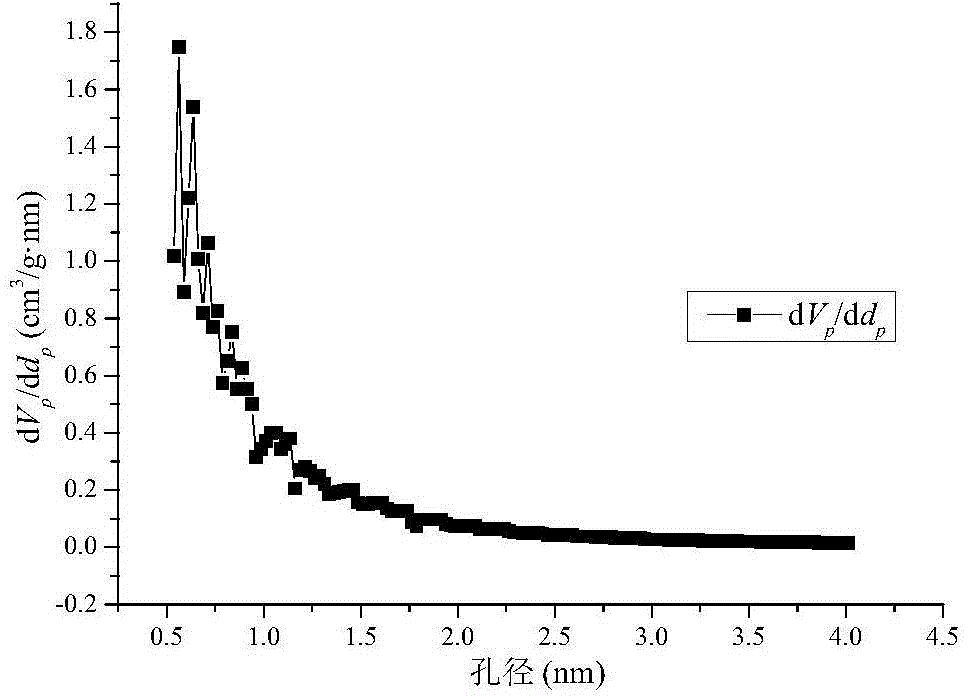

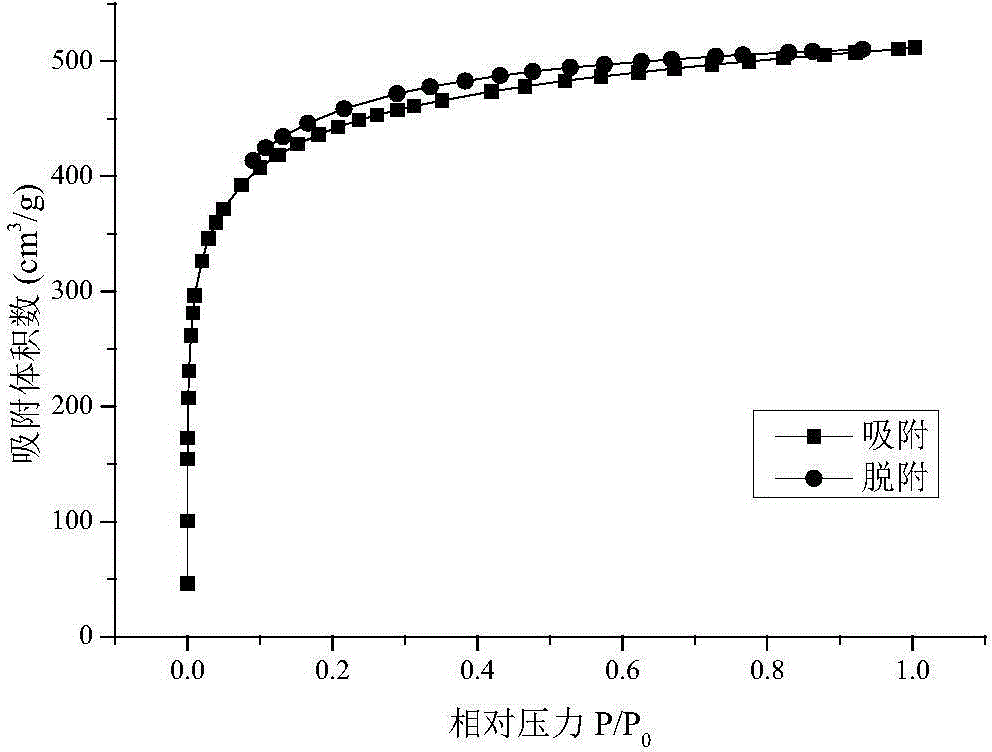

Gulonic acid adsorption separation method utilizing hyper-crosslinked resin

ActiveCN104530274AImprove adsorption capacityHigh adsorption selectivityOther chemical processesCarboxylic compound separation/purificationPorosityCross-link

Owner:NANJING UNIV OF TECH

Production method and apparatus for high-power concentration of gulonic acid

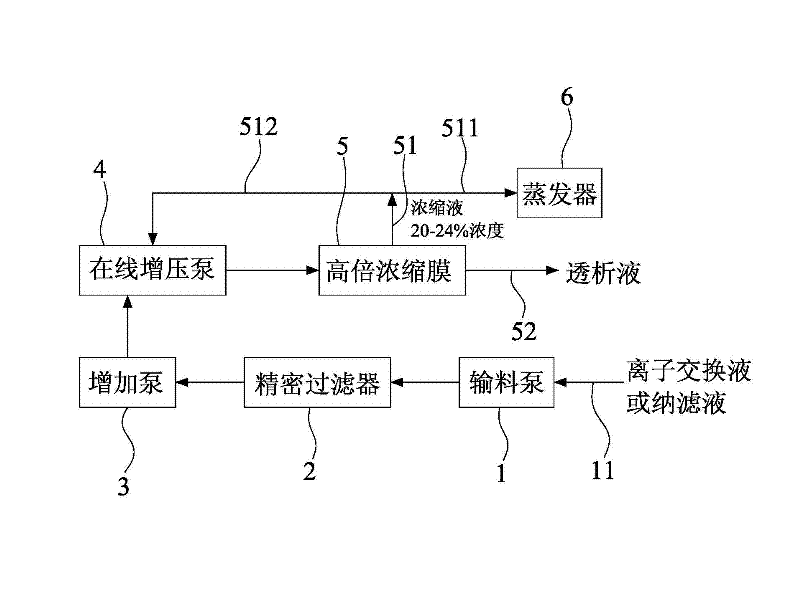

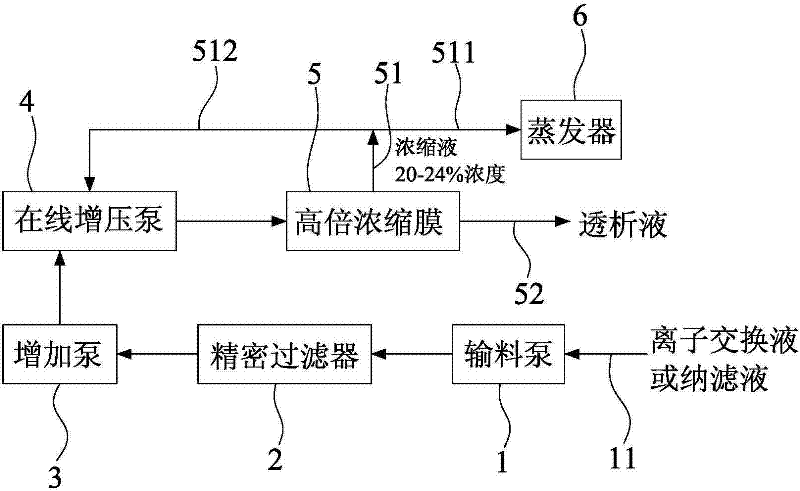

ActiveCN102503808AGood energy saving and environmental protection effectIncrease concentrationUltrafiltrationReverse osmosisIon exchangeHigh pressure

The invention discloses a production method and apparatus for high-power concentration of gulonic acid, which comprises delivering a resin ion-exchanged solution or concentrate from a conventional nanofilter to a precise filter through a delivery pump; delivering the material solution to a booster pump, and boosting a pressure to 50-70 bar; delivering the material solution to an online booster pump, mixing a part of concentrate from the outlet of a high-power concentration membrane and the material solution, and boosting the pressure to 55-75 bar; and separating the mixture through the high-power concentration membrane, driving water in the mixture under the high pressure to penetrate a membrane component to enter a dialysate pipe, discharging a part of the concentrated solution, and returning the rest of the concentrated solution to the inlet of the online booster pump. The invention also discloses a production apparatus for high-power concentration of gulonic acid. The invention can increase the concentration of gulonic acid to a higher level, reduce the investment cost of an evaporator, lower energy consumption by 90%, and improve the product quality.

Owner:XIAMEN JIARONG TECH CO LTD

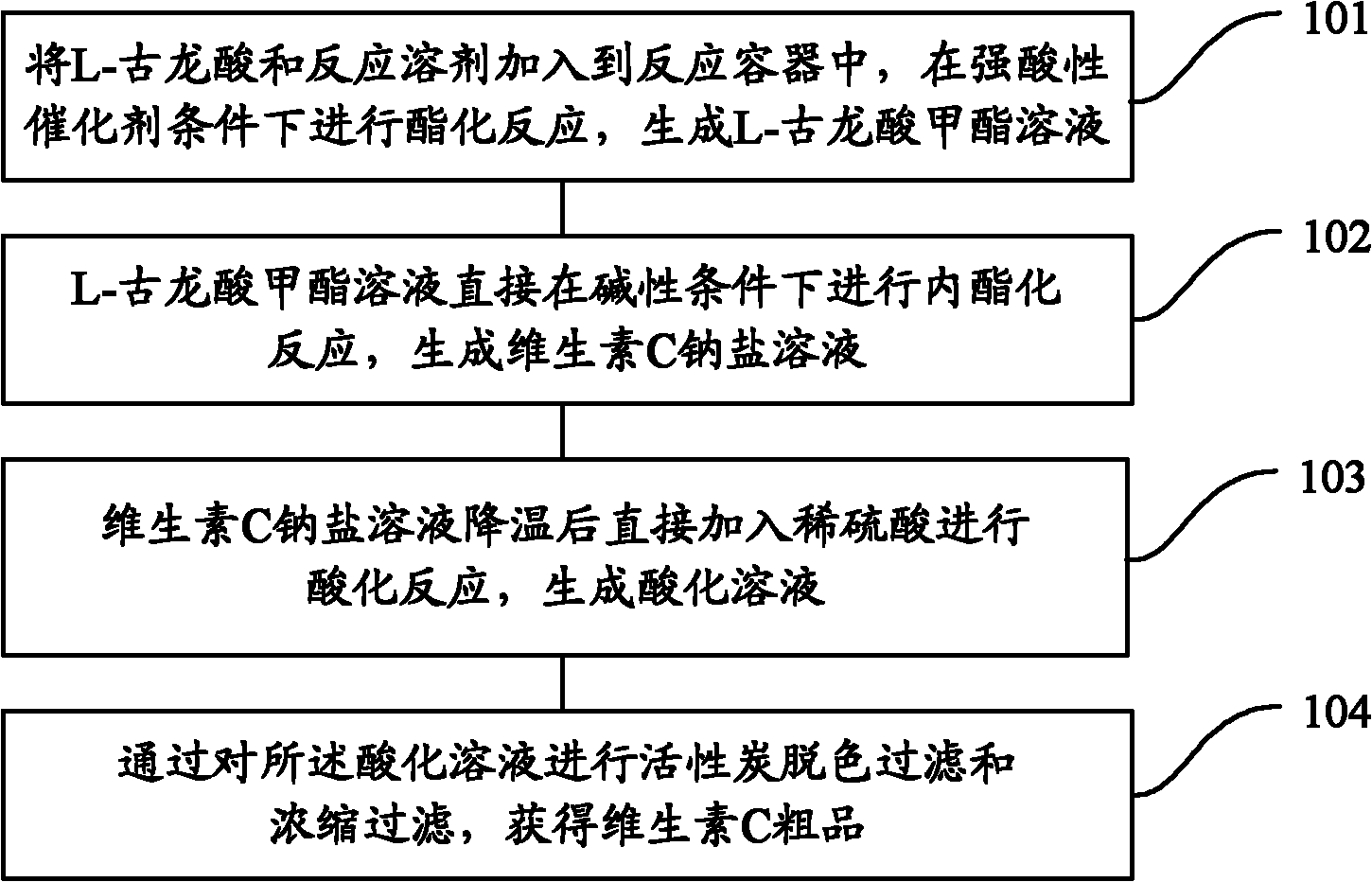

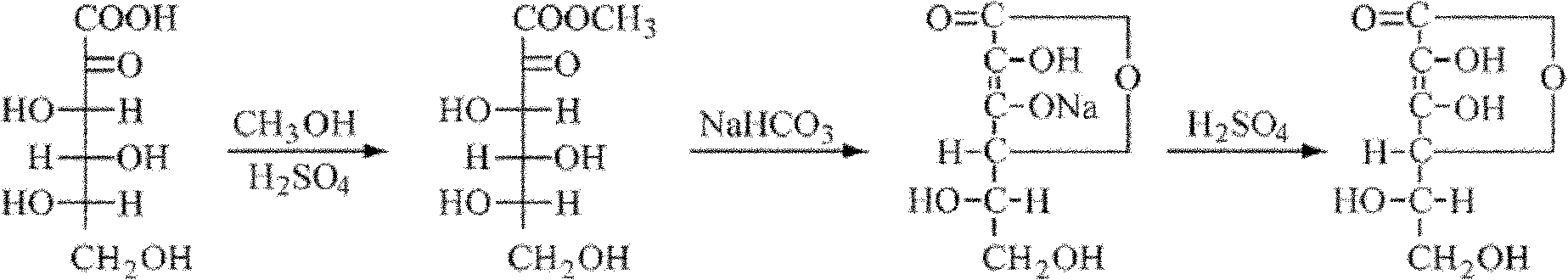

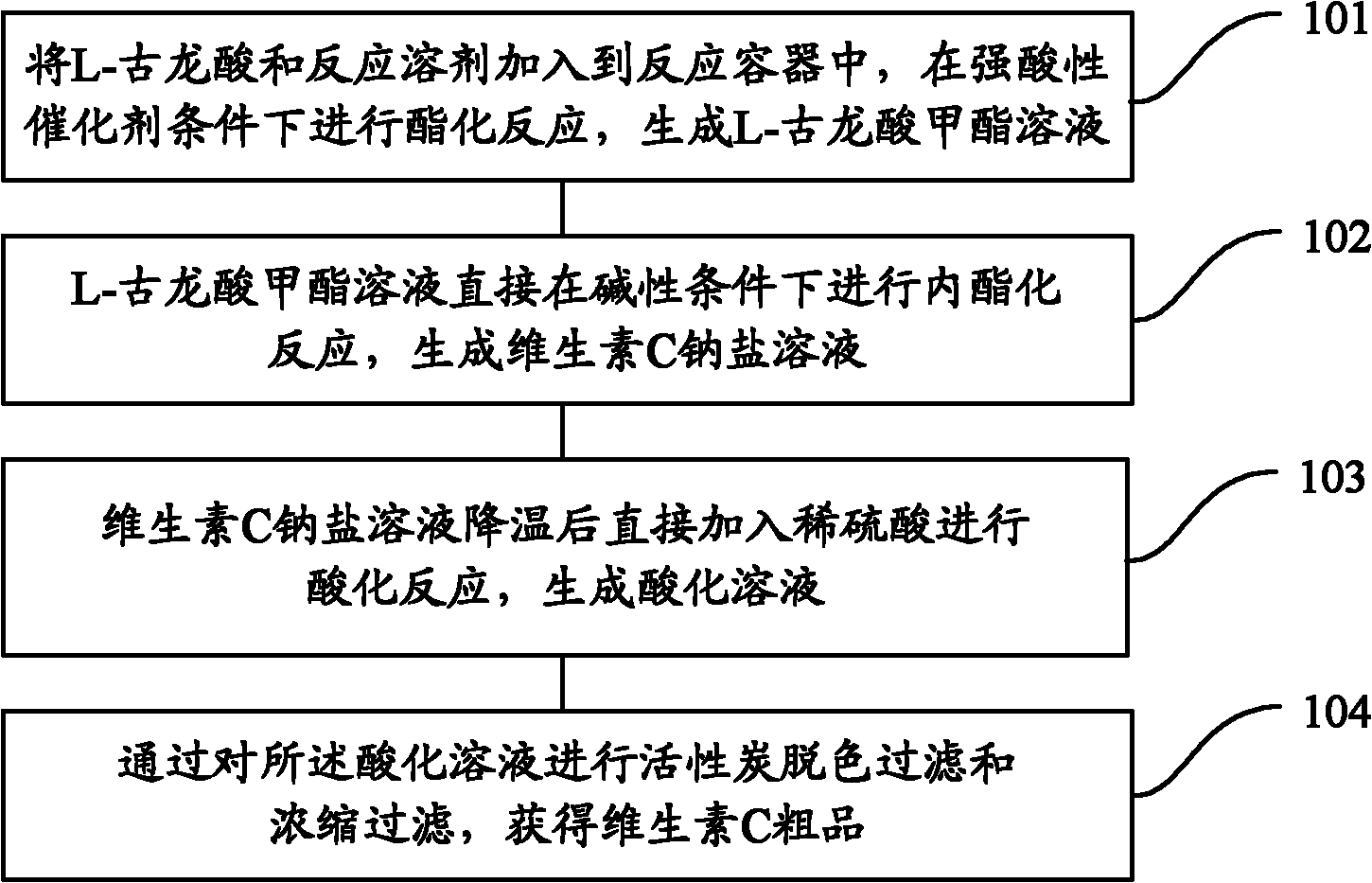

Method for synthesizing vitamin C crude product by adopting L-gulonic acid

The invention provides a method for synthesizing vitamin C crude product by adopting L-gulonic acid, which comprises the following steps: the L-gulonic acid and a reaction solvent are added to a reaction vessel, and esterification reaction is carried out on the L-gulonic acid and the reaction solvent in the condition of strong acid catalyst so as to generate an L-gulonic acid methyl ester solution; internal esterification reaction is directly carried out on the L-gulonic acid methyl ester solution in alkalinity condition so as to generate a vitamin C sodium salt solution; after the vitamin C sodium salt solution cools down, dilute sulphuric acid is added directly for acidification reaction so as to generate an acidification solution; activated carbon decoloration filtration and concentration filtration are carried out on the acidification solution so as to obtain the vitamin C crude product, wherein esterification reaction, internal esterification reaction and acidification reaction are carried out in the same reaction vessel. The method provided by the invention has simple process, improves production efficiency, reduces labor intensity of workers and improves production environment.

Owner:山东润鑫投资有限公司

Method for preparing 2-keto-L-gulonic acid

ActiveCN103290071AIncrease the number ofIncrease concentrationMicroorganism based processesFermentationBiotechnologyActive enzyme

The invention discloses a method for preparing 2-keto-L-gulonic acid. The method is characterized by comprising the steps of: independently cultivating large bacteria, successively carrying out microfiltration and ultrafiltration treatment on the obtained large bacteria fermentation liquor to obtain an active substance concentrated solution; and feeding the obtained active substance concentrated solution of the large bacteria to a small bacteria culture medium to promote small bacteria to convert sorbose into 2-keto-L-gulonic acid. By adopting the method, the large bacteria are independently cultivated; preferably, the large bacteria are synchronously cultivated, so that the optimum growth condition of the large bacteria can be met; the production efficiency is improved; an active enzyme substance of the large bacteria is collected to transfer into small bacteria fermentation liquor by adopting advanced microfiltration and ultrafiltration technologies; bottom sugar and pH of the small bacteria fermentation liquor can be further stabilized by feeding the sorbose solution and a pH maintaining agent; the quantity of the small bacteria is increased; the growth time of thallus is shortened; the reaction rate of converting the sorbose oxidized by the small bacteria into 2-KLG is quickened; the fermentation cycle is shortened; the concentration of a product is improved; the production cost is reduced; and the market competitiveness of an enterprise is improved.

Owner:SHANDONG TIANLI PHARMA

2-keto-l-gulonic acid high concentration fermentation production technology

InactiveCN101392274AIncrease concentrationIncreased Gulonic Acid ConcentrationMicroorganism based processesFermentationHigh concentrationAlcohol

The invention discloses a production technique of 2-keto-L-gulonic acid by high concentration fermentation. In a fermentation medium adopted by the production technique, the initial sorbin concentration is 15mg / ml to 25mg / ml; fermentation is carried out for 4 hours to 8 hours; continuous sorbin feeding is started; fermentation is carried out for 36 hours to 44 hours and then sorbin feeding is finished; during the feeding process, the content of sorbin is controlled to be 15 mg / ml to 30 mg / ml; when fermentation is carried out for 24 hours to 40 hours, pH value is adjusted to be 7.1 to 7.3; when fermentation is carried out for 40 hours to 44 hours, pH value is adjusted to be 7.4 to 7.6 until fermentation is finished; and dissolved oxygen during the whole fermentation process is controlled to be 30 percent to 50 percent. The technique adopted by the invention has total fed sorbin with a concentration of 10.5 percent to 11.5 percent (W / V) at the end of fermentation; the concentration of gulonic acid of fermentation solution is raised by 10 percent to 15 percent; the conversion rates of alcohol and acid are respectively promoted by 3 percentage points; and stability is good; besides, the technique process has simple and convenient operation and is easy for wide application.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

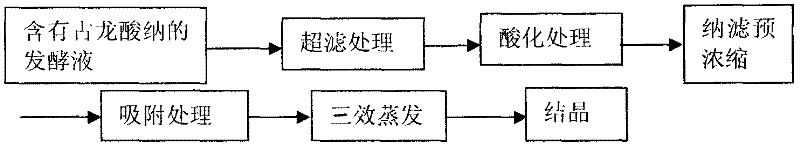

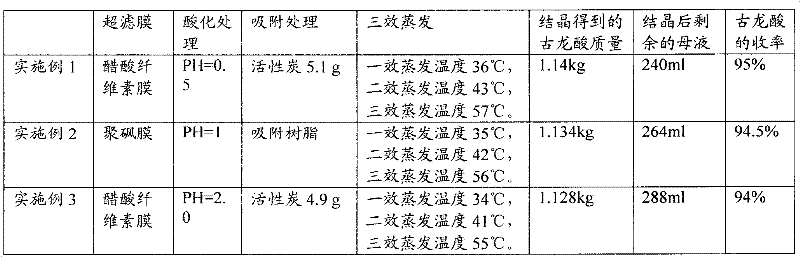

Process for refining gulonic acid

InactiveCN102391101AImprove hydrophobicityReduce non-specificityPreparation from carboxylic acid saltsCarboxylic compound separation/purificationUltrafiltrationIon exchange

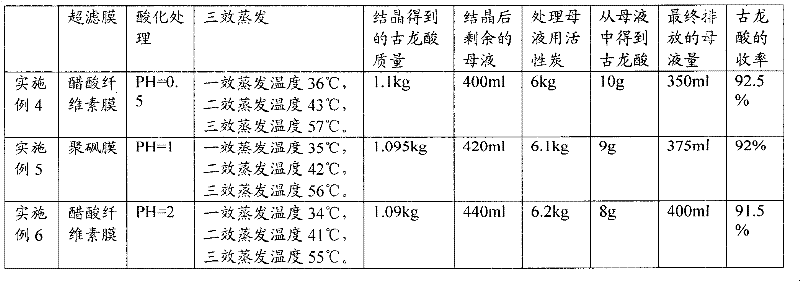

The invention discloses a process for refining gulonic acid. The process comprises the following steps of: performing ultrafiltration on fermentation liquor containing sodium gulonate; acidizing the fermentation liquor subjected to the ultrafiltration by using an ion exchange device, wherein the pH value of the fermentation liquor in the ion exchange device is below 2.0; performing nanofiltration preconcentration on the acidized fermentation liquor to obtain preconcentrated liquor; adsorbing the preconcentrated liquor by using active carbon or adsorbent resin; and performing triple effect evaporation on the adsorbed preconcentrated liquor to obtain concentrated liquor, and crystallizing the concentrated liquor to obtain a gulonic acid crystal. In a refining process route, the fermentation liquor is subjected to the ultrafiltration, ion exchange, the nanofiltration preconcentration to remove a large number of macromolecular impurities and soluble protein, and the preconcentrated liquor subjected to the nanofiltration preconcentration is adsorbed to remove impurities such as residual sugar, the soluble protein, pigments and the like further, so the quality of feed liquor before crystallization is optimized, the purity and yield of products are improved, and the discharge capacity of mother liquor is reduced.

Owner:HEBEI THINK DO ENVIRONMENT CO LTD

Method for producing vitamin C by esterification reaction-infiltration evaporation barrier separation integral process

InactiveCN101139290AStable production processSimple production processOrganic compound preparationCarboxylic acid esters preparationProduction lineVitamin C

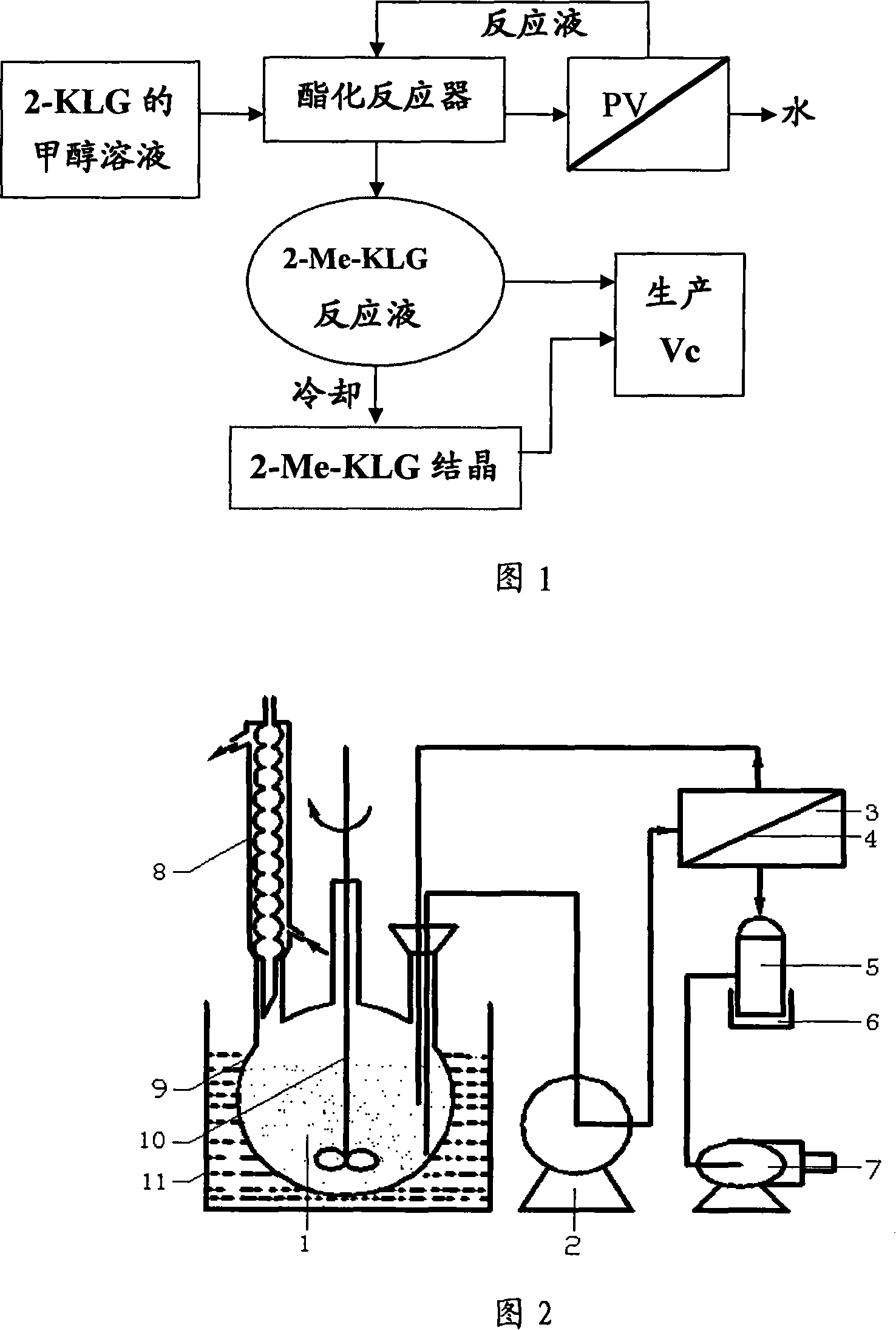

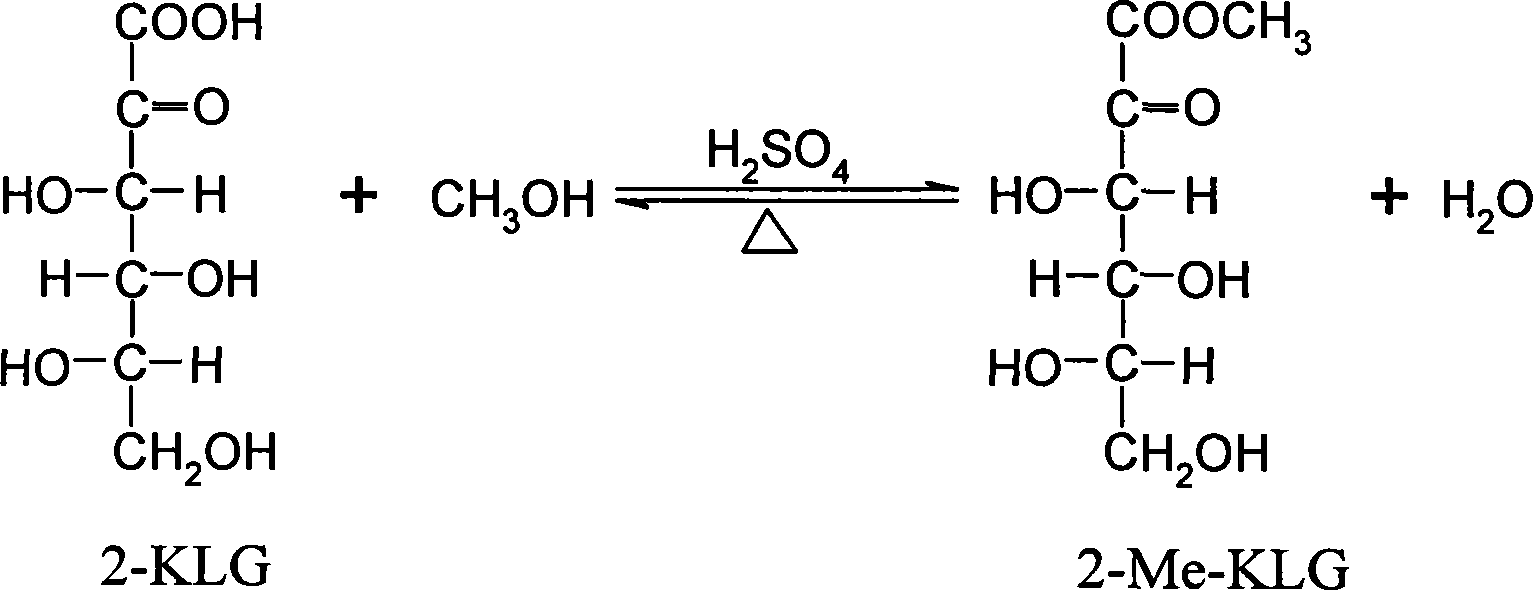

The present invention provides a method of synthesizing the vitamin C (V C ) through the esterification, the pervaporation (PV) membrane separation and integration technology, comprising the process of the methyl esterification between the methanol and the 2-ketone-L-gulonic acid (2-KLG) to produce the 2-ketone-L-gulonic methyl ester (2-Me-KLG). The process comprises the following steps: (1) the solid or liquid 2-KLG is dissolved in the methanol; the temperature is then raised and the catalyst is added; (2) the reaction solution prepared in the first step is pumped into the PV membrane separation device; the reaction solution after the membrane dehydration circulates into the esterification reactor; (3) the product 2-Me-KLG or the reaction solution is directly provided for the later production of the VC. In the method of the present invention, the area of the used membrane is small; the ratio between the alcohol and acid of the raw material liquid and the reaction temperature are relatively low; the invention greatly improves the purity and collection rate of the 2-Me-KLG; the technology is simple and the process is stable; the present invention is suitable for the industrial production-line.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

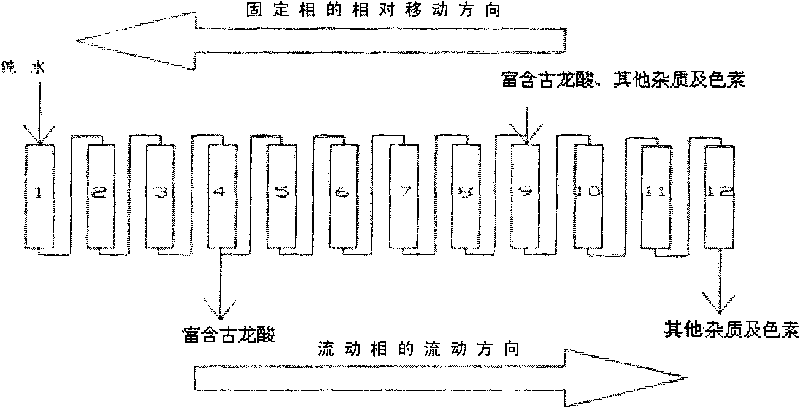

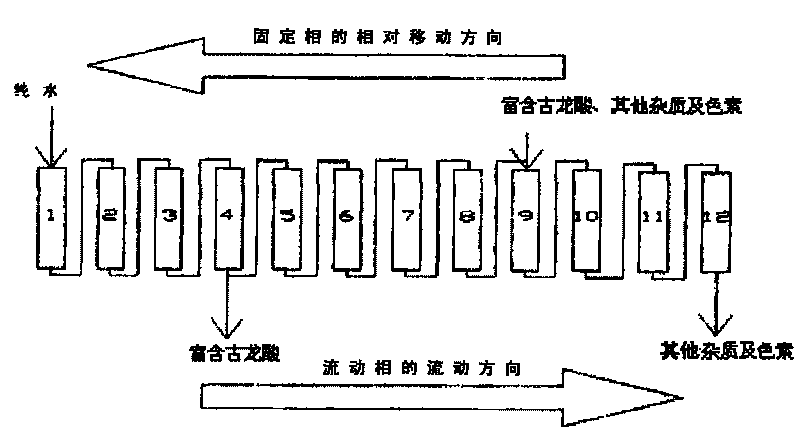

Chromatographic separation device, and method for separating vitamin C mother liquor by using same

ActiveCN109925742ANo need to heat upLow costIon-exchange process apparatusCation exchanger materialsChromatographic separationVitamin C

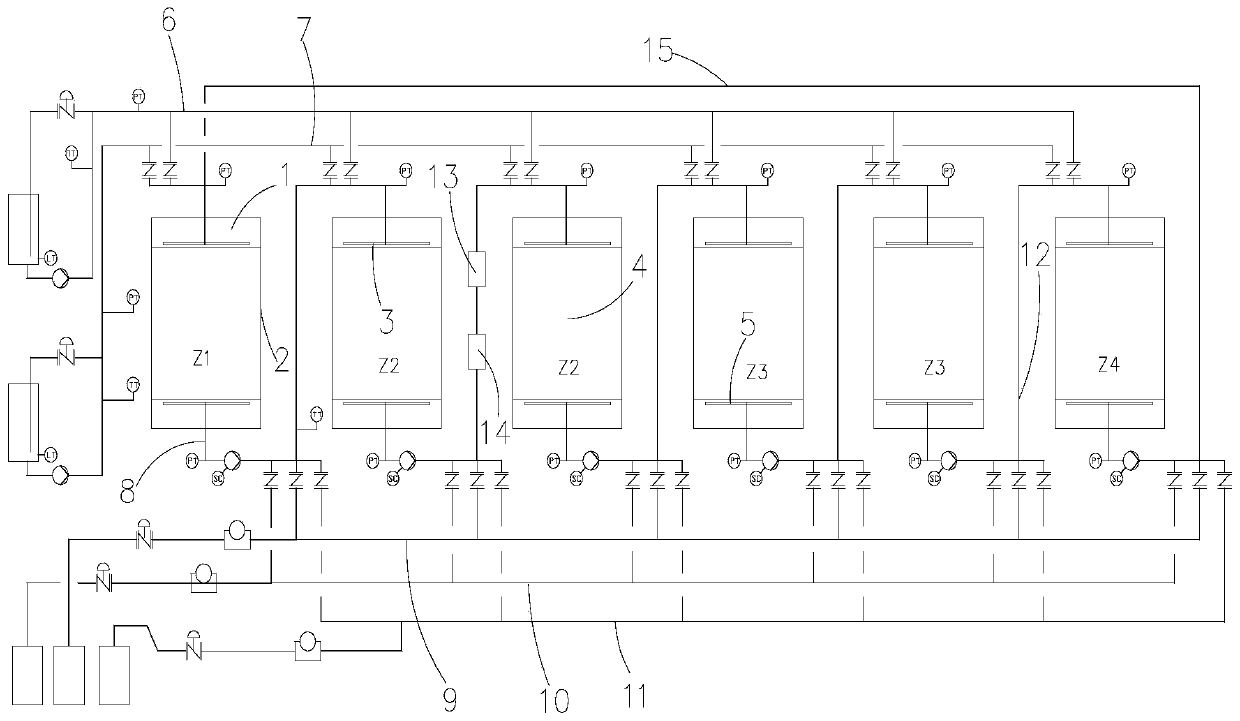

The invention provides a chromatographic separation device, and a method for separating a vitamin C mother liquor by using the same. The chromatographic separation device comprises a feed tube, discharge tubes and a plurality of separators connected in series, a distributor, a separation material layer and a collector are sequentially arranged in the tank body of every separator from top to bottom, the distributors are connected with the feed tube, and the collectors are communicated with the discharge tubes; the outlet of the collector of every separator is communicated with the inlet of thedistributor of the next separator; and the outlet of the collector of the last separator is communicated with the inlet of the distributor of the first separator. The vitamin C mother liquor is subjected to decolorizing, filtration, concentration, ion exchange and secondary filtration, then is conveyed into the chromatographic separation device, and is separated to obtain gulonic acid and vitaminC. The chromatographic separation device, and a method for separating a vitamin C mother liquor by using the same have the advantages of short process route, low running cost, and great reduction of the sewage discharge amount.

Owner:山东兆光色谱分离技术有限公司

Method for removing pigment in gulonic acid mother solution

ActiveCN101717133AImprove decolorization efficiencyHigh puritySugar derivativesWater/sewage treatment by ion-exchangeSimulated moving bedPigment

The invention relates to a method for removing pigment in gulonic acid mother solution, which is characterized in that a simulated moving bed filled with acidic cation resin is adopted, and water is used as a mobile phase. The method has a pigment removing rate of above 70%, is beneficial to enhancing the purity and the yield coefficient of the product and improving the luster of product greatly, and has the advantages of simple operation, low manufacturing cost, environment protection and the like, thus the method is more suitable for large-scale industrial production.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

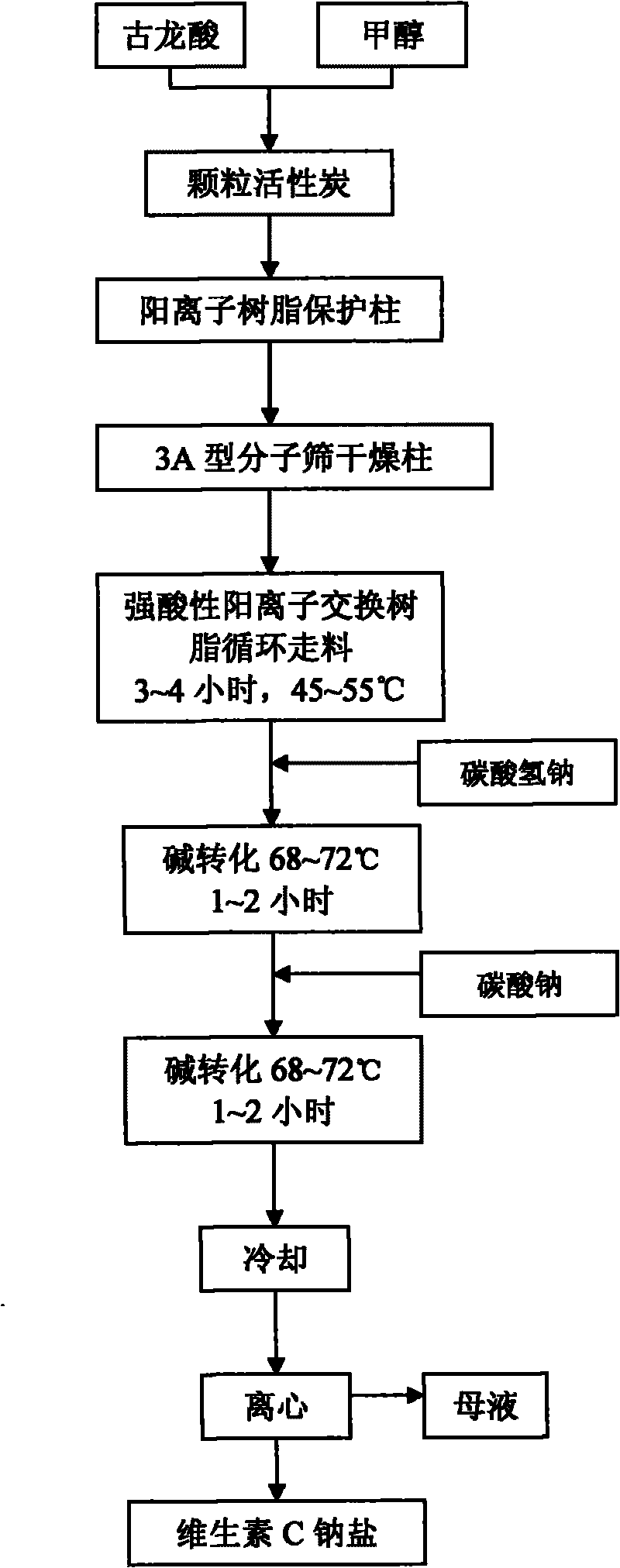

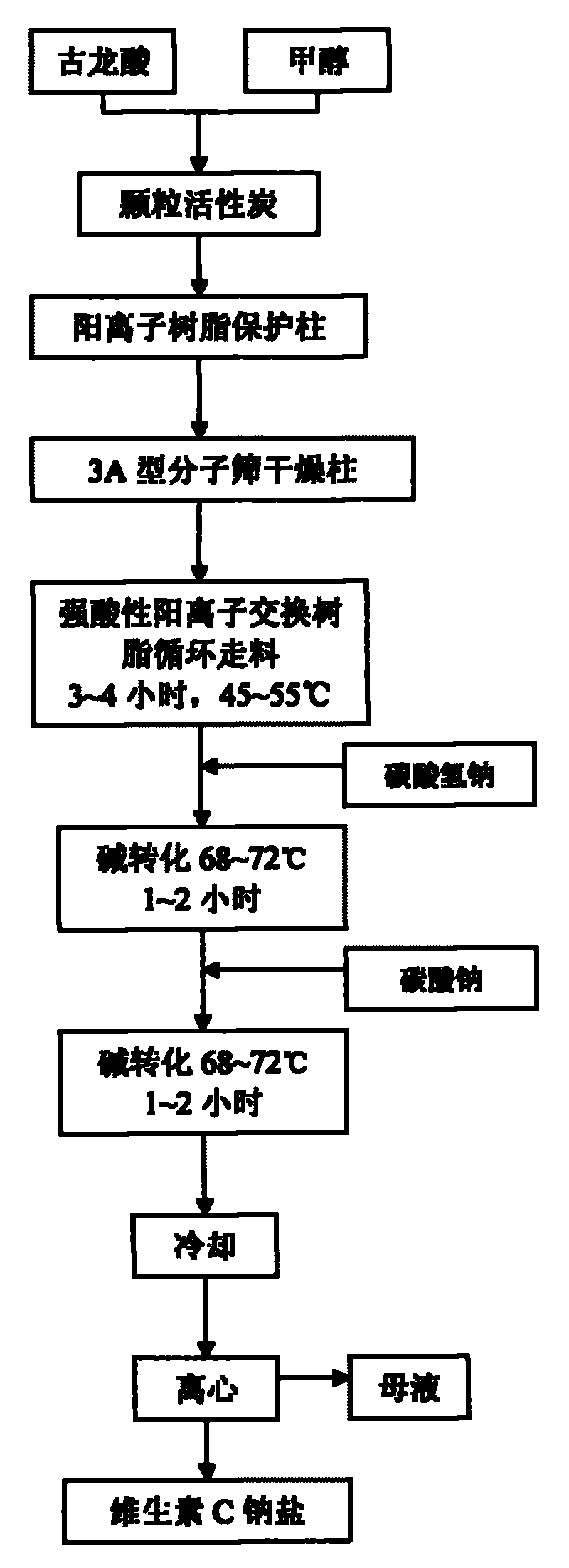

Method for synthesizing vitamin C sodium salt

The invention discloses a method for synthesizing vitamin C sodium salt which comprises the steps of: (a) mixing Gulonic acid with methanol solution, and orderly passing through a granular active carbon column and a cation resin column, (b) passing the treating fluid through a dry filter, (c) performing a recycle esterification reaction by passing the treating fluid acquired from the step b through the resin column so as to acquire esterified liquid, (d) pouring the esterified liquid into a constant pressure reactor and performing conversion reaction, and (e) cooling the liquid material B to room temperature after finishing the reaction and centrifuging so as to acquire the vitamin C sodium salt. The method of the invention efficiently promotes the esterifying ratio of products and the yield of the vitamin C sodium salt, shortens the conversion reaction time, simplifies the process, lowers the energy consumption and producing cost, decreases the environmental pollution and prolongs the service life of the device.

Owner:HEBEI WELCOME PHARMACEUTICAL CO LTD

Method for producing 2-keto-L-gulonic acid vitamin C precursor by modifying Escherichia coli

ActiveCN102250821ASimple processEasy to buildBacteriaMicroorganism based processesEscherichia coliVitamin C

The invention discloses a method for producing a 2-keto-L-gulonic acid (2-KLG) vitamin C precursor by modifying Escherichia coli and belongs to the field of genetic engineering. In the method, a sorbitol dehydrogenase (SLDH) gene from gluconobacter oxydans, a pyrroloquinoline quinine (PQQ) gene cluster and a sorbose dehydrogenase (SDH) / sorbosone dehydrogenase gene (SNDH) from common ketogulonigenium vulgare are expressed in Escherichia coli by a genetic engineering technique to culture an Escherichia coli engineering strain for producing 2-KLG by sorbitol. At present, a two-step fermentationprocess adopted for industrial production of vitamin C in China has the problems of complicated process, many influencing factors, difficult accurate control and large raw material and energy consumption for growing three kinds of microbes at the same time. When the production of the 2-KLG by sorbitol fermentation by the E.coli engineering bacteria is adopted, the production process is simplified, raw materials and energy are saved, and the yield of the 2-KLG can reach 87g / L; and thus, the method has a very bright application prospect.

Owner:JIANGNAN UNIV

Preparation method of vitamin C

ActiveCN104693160ASynthesis temperature is lowImprove qualityOrganic chemistryInorganic saltsVitamin C

The invention relates to a preparation method of vitamin C. The preparation method comprises the following steps: by using gulonic acid inorganic salt or gulonic acid as the raw material, adding a 0-38 wt% hydrochloric acid solution, stirring, cooling, introducing HCl gas, heating, and keeping the temperature until the reaction finishes, thereby obtaining the vitamin C. The preparation method has the advantages of simple technique, short reaction time and more environment-friendly production environment, obviously enhances the vitamin C quality and is suitable for vigorous popularization.

Owner:安徽泰格生物技术股份有限公司

Method for separating solution rich in gulonic acid and vitamin C by ion exclusion chromatography

ActiveCN101613332AHigh yieldReduce manufacturing costIon-exchange process apparatusIon-exchanger regenerationChromatographic separationVitamin C

The invention provides a method for separating solution rich in gulonic acid and vitamin C by ion exclusion chromatography, which mainly uses different repulsion forces of strong-acidic group of strong-acidic ion exchange resin on the gulonic acid and the vitamin C to separate the gulonic acid and the vitamin C. The method is realized through a moving bed system or a simulated moving bed system, can improve the yield of vitamin C (Vc) products, reduce production cost, and ensure the yield of gulonic acid and vitamin C over 90 percent.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Process for one-step fermentation production of gulonic acid (VC precursor) from glucose

InactiveCN1966703AEasy to prepareReduce manufacturing costMicroorganism based processesFermentationCulture fluidGlucose polymers

The invention discloses a method for producing gulonic acid (VC precursor). The method comprises the steps as follows: 1) inducing proper amount of Xanthomonas campestris with ray, 2) culturing on a plate at 25-35DEG C for 2-5d, selecting the fine colony which satisfies the requirement of smooth colony, inoculating in a conical flask with culture fluid for culturing, 3) adding into the medium containing glucose for culturing to producegulonic acid. The invention realizes direct production ofgulonic acid from glucose to produce VC, with a converting ratio of 35-50%, has the advantages of simple production, reduces the production cost greatly.

Owner:葛忠良 +2

Vitamin C production process improvement method

InactiveCN103254159AThe process conditions are matureShort processCarboxylic acid esters separation/purificationCarboxylic compound separation/purificationChromatographic separationVitamin C

The invention discloses a vitamin C production process improvement method, which comprises: adopting a simulated movement bed chromatographic separation device to separate and purify Vc, gulonic acid and gulonic acid methyl ester in a centrifugation separation mother liquor of Vc production, wherein three materials can be concurrently obtained through separation, the first material is an extraction liquid and is a vitamin C-rich component, the vitamin C purity is more than 90%, the vitamin C-rich component is concentrated and then directly returns to be subjected to crystallization with the original Vc solution, the second material is a raffinate and is a gulonic acid-rich component, the gulonic acid purity is more than 90%, the gulonic acid-rich component is concentrated and then returns to the original process to be esterified, converted and crystallized so as to be recycled, the third material is a raffinate and is a gulonic acid methyl ester-rich component, the gulonic acid methyl ester purity is more than 35%, and the gulonic acid methyl ester-rich component and the second component are combined and concentrated, and returns to the original process to be esterified, converted and crystallized so as to be recycled.

Owner:南京凯通粮食生化研究设计有限公司

Vitamin C clean production method

The invention discloses a cleaner production method of Vitamin C. In the method, the steps of converting sodium gulonic acid into gulonic acid are as follows: a. strong acid is added into sodium gulonic acid solution and then the pH of the solution is regulated to be 3.0 to 4.5; b. the solution film with the regulated pH is ultrafiltered; c. the strong acid is added into the ultrafiltered solution so as to regulate the pH to be 1.6 to 1.7; d. the solution with regulated pH in step c is subjected to concentration, crystallization and centrifugation so as to prepare mixed dry products; e. the mixed dry products are dissolved in methanol and then filtered so as to prepare the methanol solution of the gulonic acid. The production method of the invention has the advantages that a large amount of water, caustic soda liquid and hydrochloric acids are saved, and basically no sewage is discharged in the process of conversion, thereby solving the problem of environmental contamination, and meeting the discharge standard prescribed by the state. The production method has basically no loss on yield in the process of conversion, thereby greatly reducing investment and production costs.

Owner:陈星

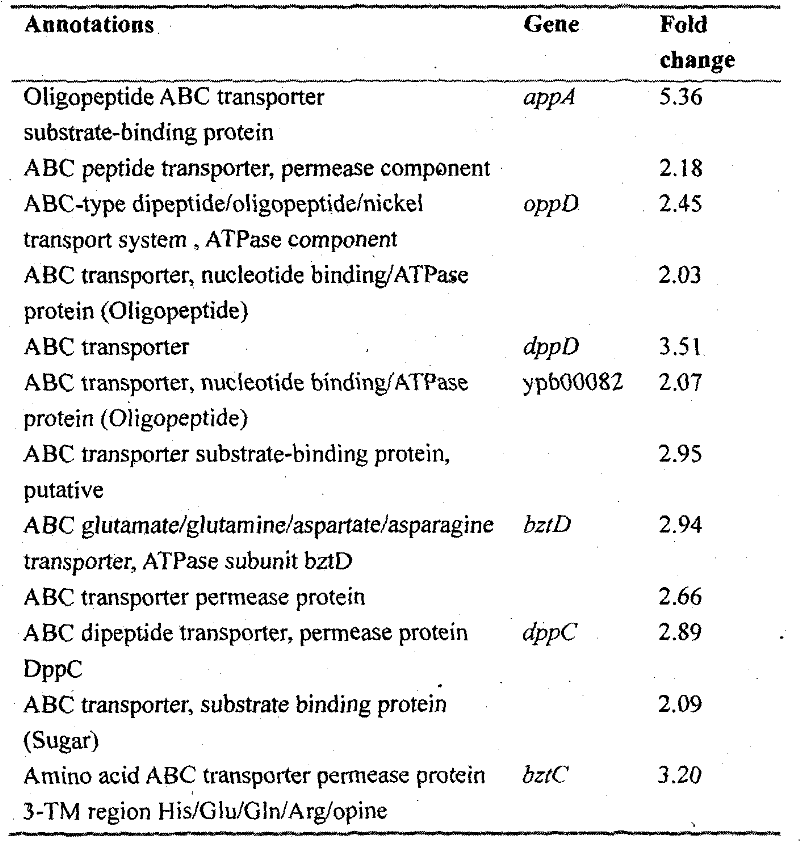

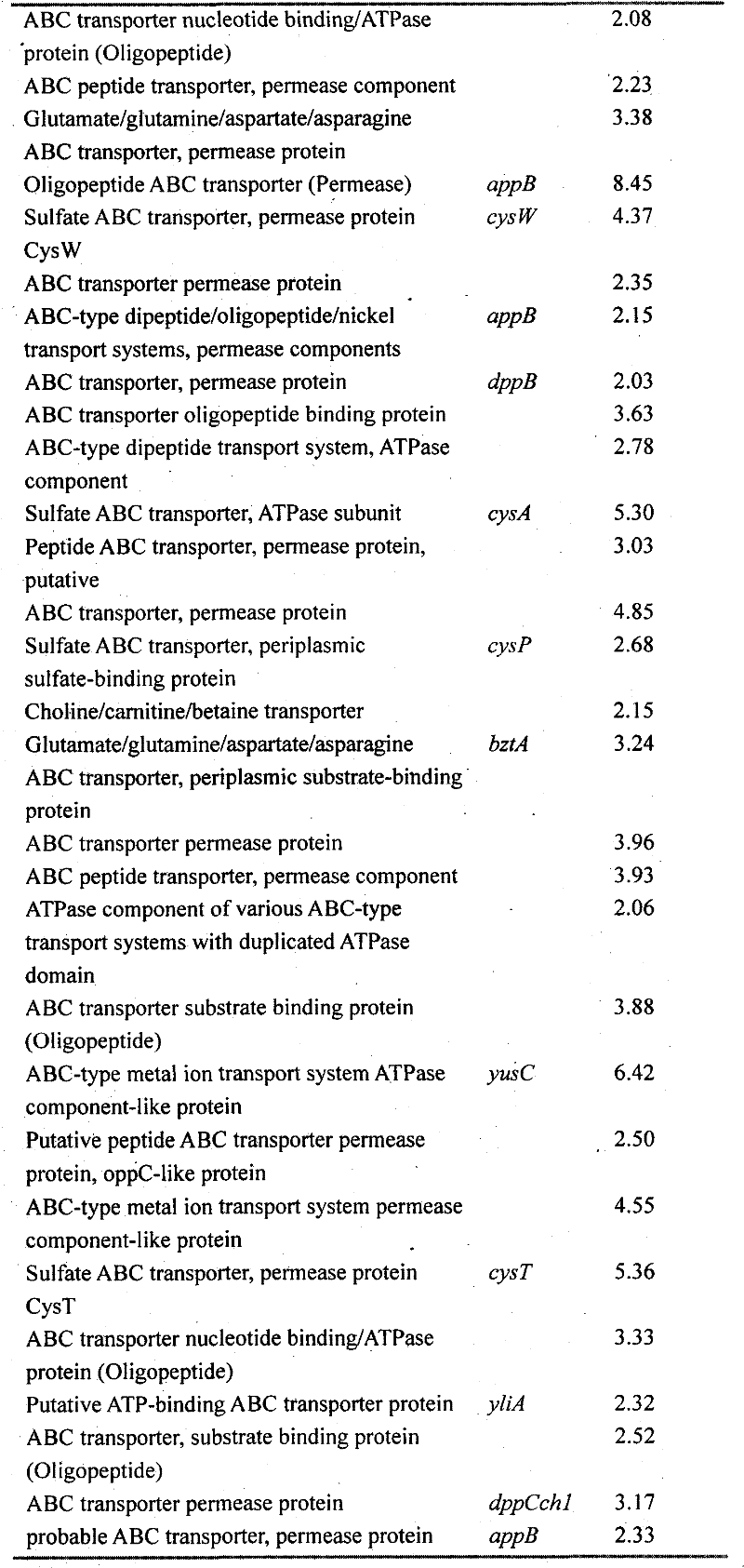

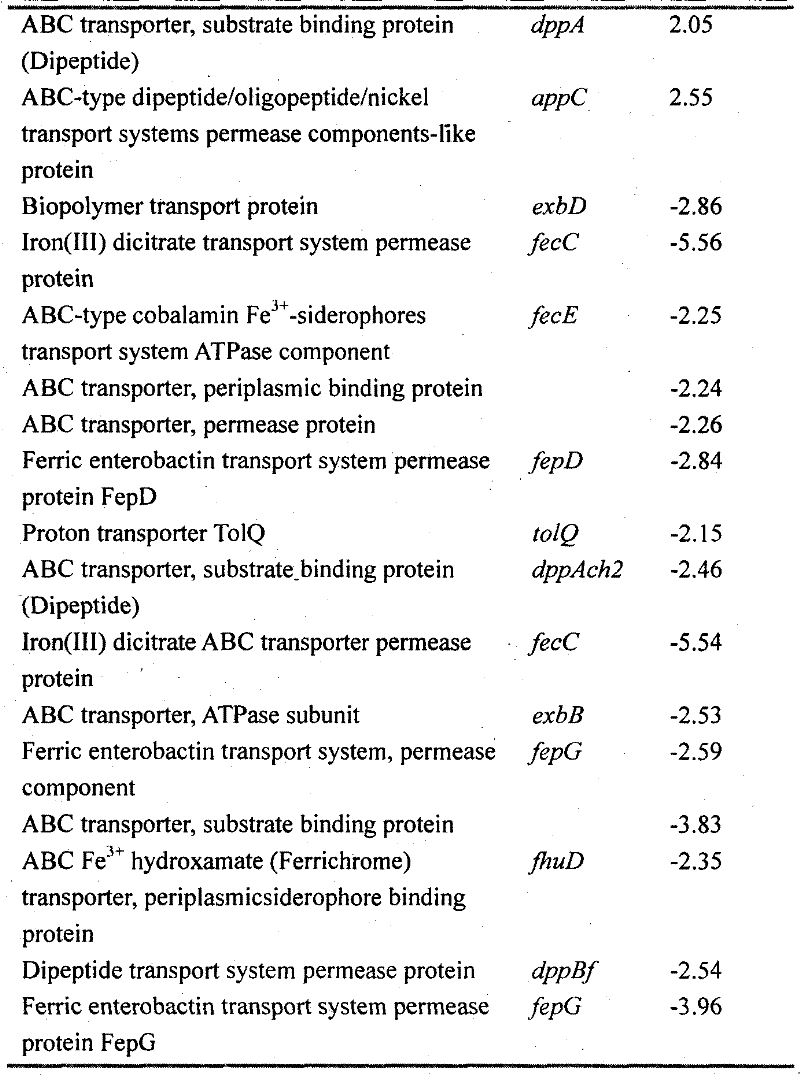

Gene capable of regulating and controlling inhibition of vitamin C fermented strain acid production during acid stress

InactiveCN102286614AReduce outputMicrobiological testing/measurementFermentationMembrane TransportersBasic research

The invention relates to a gene capable of regulating and controlling inhibition of vitamin C fermented strain acid production during acid stress and belongs to the technical fields of basic research on vitamin C prepared by fermentation and biological engineering. The key gene for regulating and controlling yield reduction of acid stress induced 2-Keto-L-Gulonic acid (2-KLG) in the production strains is determined, so a metabolic engineering strategy with high pertinence is generated. The expression condition of genes, in particular membrane transport protein genes, of acid-forming bacteria in the vitamin C mixed bacteria fermented system is analyzed by an expression profile chip technology. Compared with ketogenic gulonic acid bacteria subjected to single cultivation, the ketogenic gulonic acid bacteria subjected to mixed bacteria cultivation have 45 upregulated membrane transport protein genes and 15 down regulated membrane transport protein genes. The notable thing is that: 7 iron ion transport protein genes are inhibited to express. After acid stress, the iron ion transport protein genes are over expressed. During fermentation, the iron ions are added to inhibit mixed bacteria to ferment and generate acid. The result shows that the iron ion transport protein exerts reverse action in the process of yield reduction of 2-KLG generated by the acid stress induced mixed bacteria fermentation.

Owner:JIANGNAN UNIV

Preparation method for R-(+)-alpha-phenylethylamine salt and R-(+)-alpha-phenylethylamine

ActiveCN104860830ALess waste waterMild reaction conditionsAmino compound purification/separationOrganic compound preparationSolventEthylamine

The invention provides a preparation method for R-(+)-alpha-phenylethylamine salt and R-(+)-alpha-phenylethylamine. The preparation method comprises a step of subjecting DL-alpha-phenylethylamine and a resolving agent to a salt formation reaction in a reaction solvent, wherein the resolving agent is one selected from the group consisting of N-p-nitrobenzoyl-L-glutamic acid, L-glutamic acid and gulonic acid, the reaction solvent is one or more selected from the group consisting of acetone and ethanol, the salt formation reaction is to add the resolving agent into the reaction solvent, then add DL-alpha-phenylethylamine and carry out the reaction, DL-alpha-phenylethylamine is added drop by drop for 20 to 40 min, the ethanol is 95% ethanol, and a ratio of the volume of the reaction solvent to the mass of DL-alpha-phenylethylamine is 2-8: 1, preferably 3-5: 1. The method is finished in only one step, does not need refining, produces little waste water, has high yield, enables high-optical purity R-(+)-alpha-phenylethylamine salt and R-(+)-alpha-phenylethylamine to be obtained, uses commercially available reagents and raw materials and is applicable to industrialization.

Owner:NORTHEAST PHARMA GRP

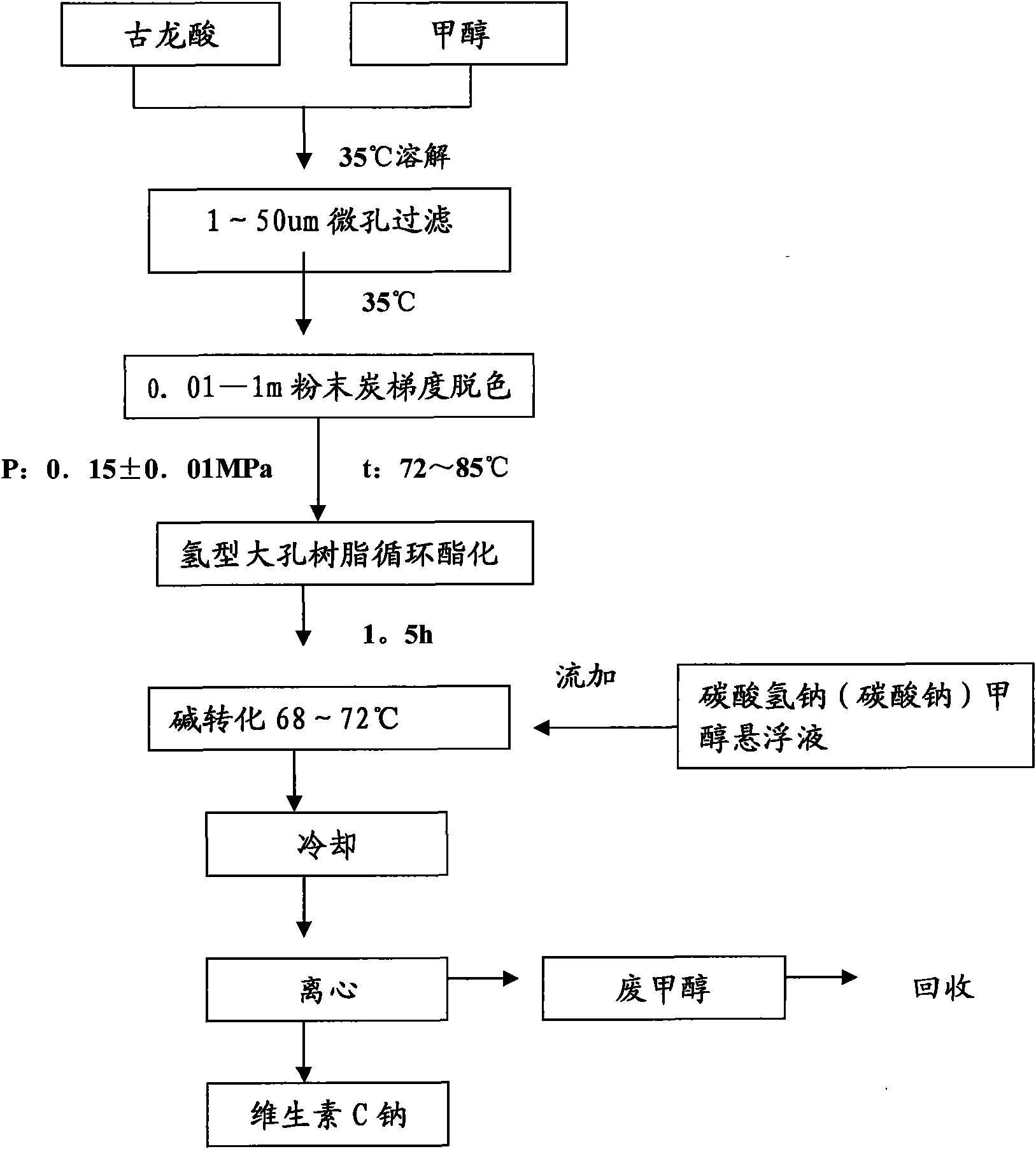

Synthetic process for vitamin C sodium salts

ActiveCN101550118AShort synthesis timeIncrease productivityOrganic active ingredientsOrganic chemistrySodium bicarbonateVitamin C

The invention relates to a synthetic process for vitamin C and sodium salts, which pertains to the technical field of chemistry. Gulonic acid and methanol carry out esterification reaction and then react with the sodium salts. The synthetic process is characterized by be executed according to the following steps: (1) the gulonic acid is dissolved in methanol and then goes through a filter with the aperture ranging from 1 Mum to 50 Mum and goes through a filter with the aperture ranging from 0.01 Mum to 1 Mum and a powdered activated carbon layer for gradient decolorization, thus obtaining a destaining solution for further use; (2) the destaining solution circularly reacts for 1.2 hours to 1.8 hours in macroporous hydrogenous resin, thus obtaining esterification solution; (3) the esterification solution is injected into a normal pressure container, kept being stirred at the temperature of 70 DEG C plus or minus 2 DEG C and uniformly added with suspending liquid obtained by mixing sodium bicarbonate with the mole number of 1.01 times to 1.05 times of the gulonic acid or the sodium carbonate with the mole number of 0.505 time to 0.51 time of the gulonic acid with methanol, and then is cooled to the room temperature after thermal insulation is executed continuously, thus obtaining the vitamin C sodium salts after centrifugal dehydration. The process has short synthesis time, products with high purity and good quality, and low energy consumption.

Owner:徐建涛

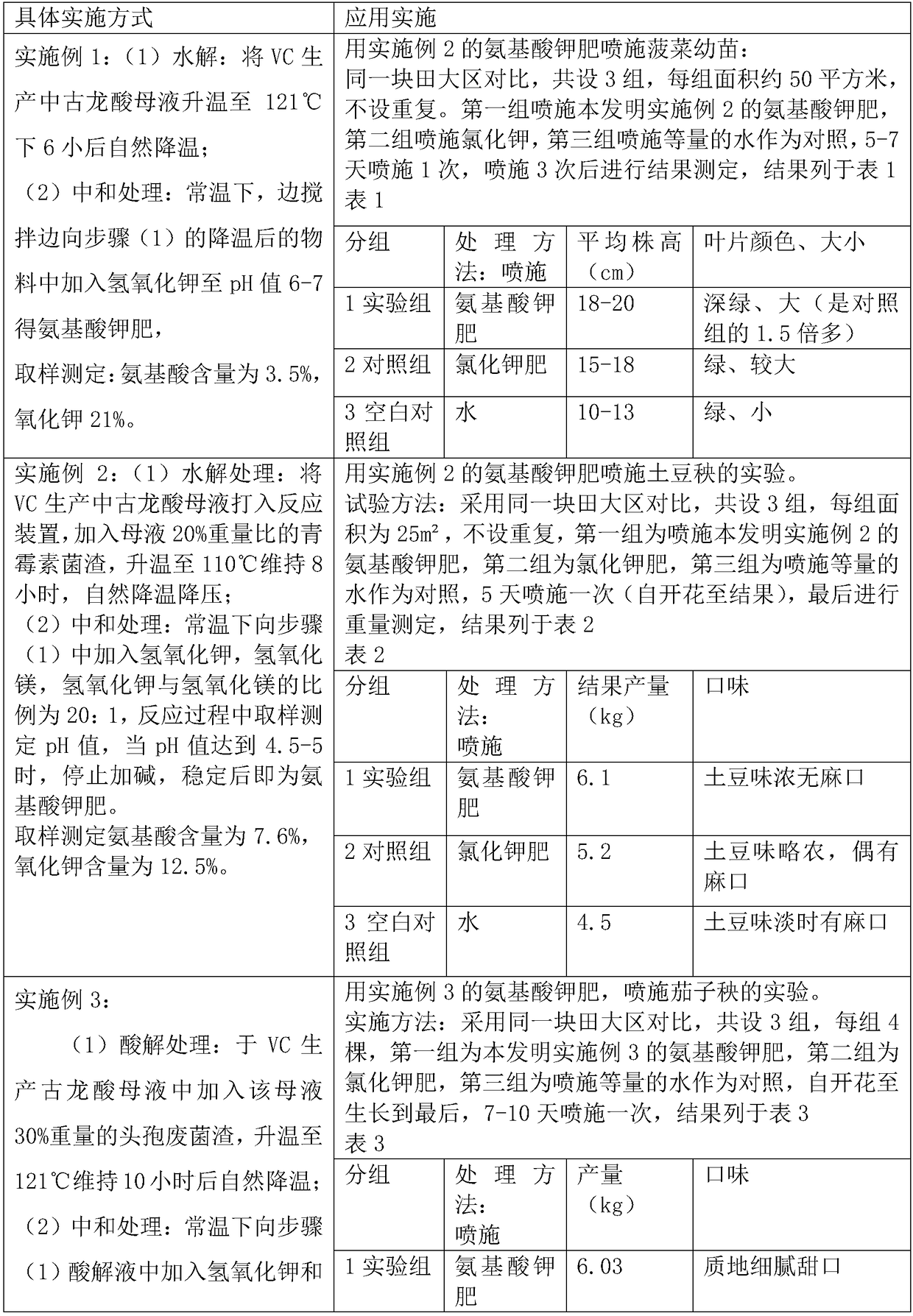

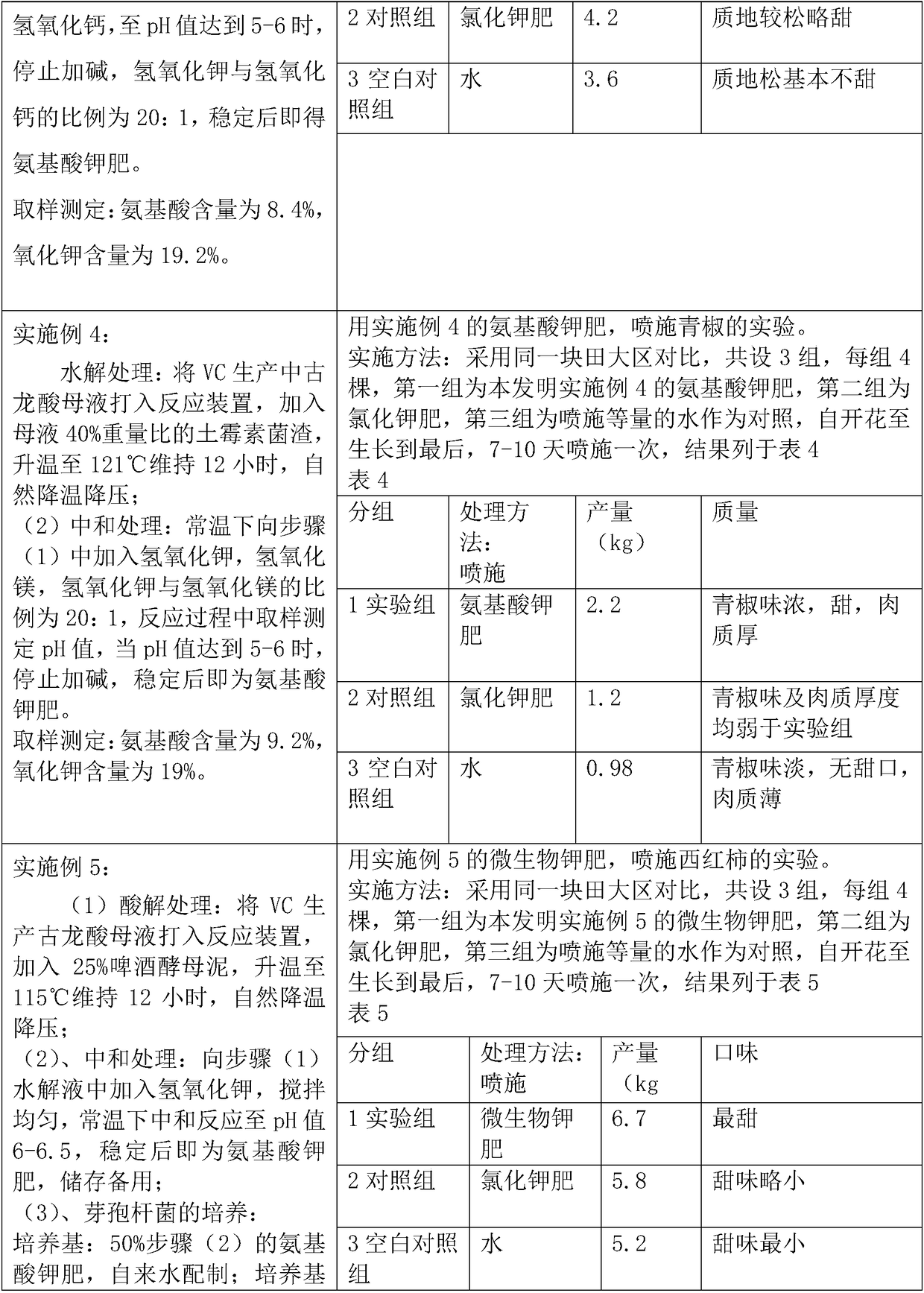

Treatment method for gulonic acid mother liquor in VC production

InactiveCN109265215AGood effectPromote absorptionNitrogenous fertilisersNature of treatment waterResource utilizationPotassium hydroxide

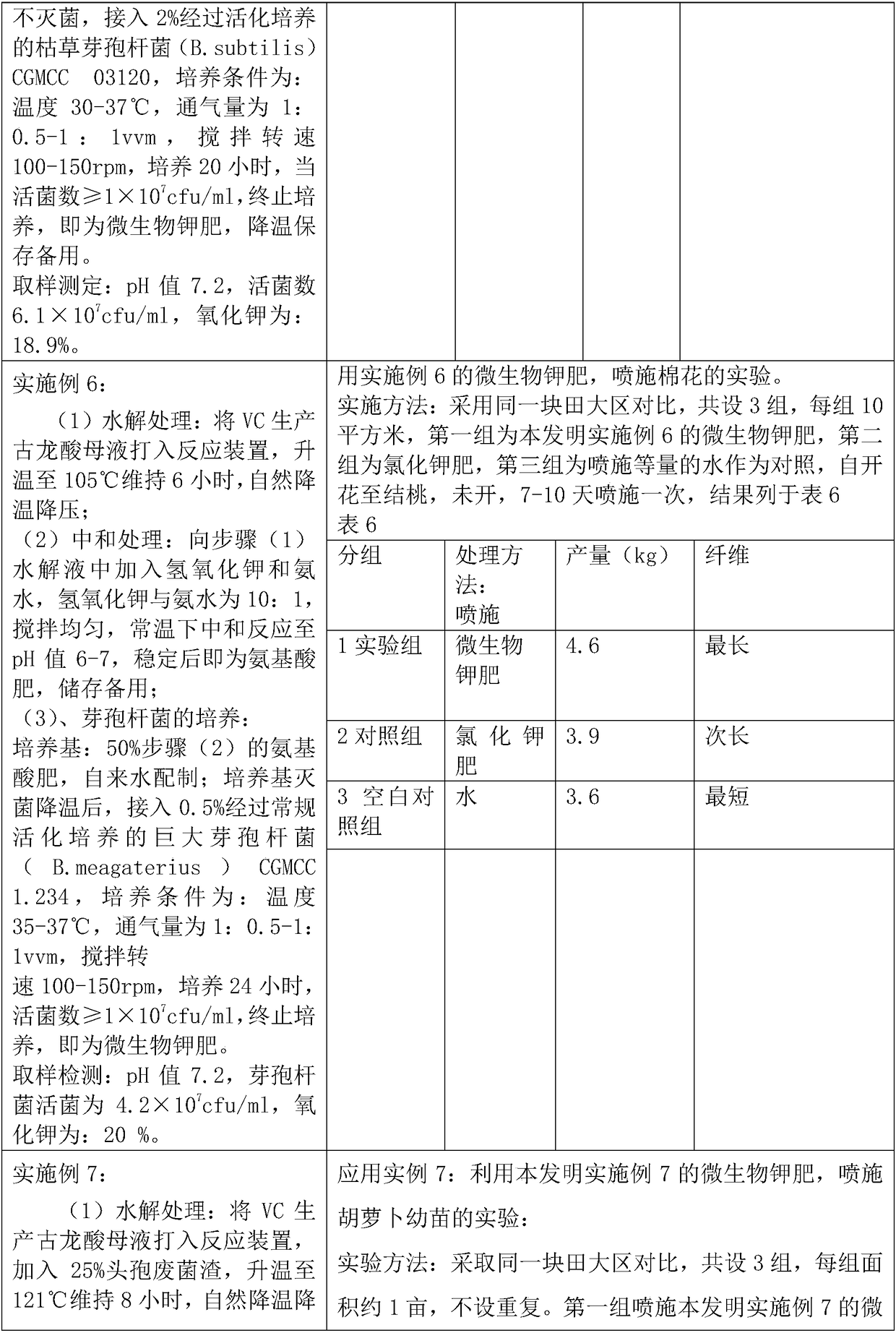

The invention relates to treatment of a gulonic acid mother liquor in VC production, and a method for preparing a fertilizer by using a product obtained by the treatment, wherein the treatment of thegulonic acid mother liquor comprises: hydrolyzing original bacteria or externally added other bacterial residue in a waste liquid at a temperature of 105-121 DEG C by using hydrochloric acid containedin a gulonic acid mother liquor, and the hydrolyzate is neutralized with potassium hydroxide to achieve a pH value of 4-9 to produce an amino acid potassium fertilizer, or the amino acid potassium fertilizer as a culture medium is inoculated with 0.5-2% of Bacillus, and fermentation culture is performed to produce a microbial potassium fertilizer. According to the present invention, the method using the hydrochloric acid contained in the gulonic acid mother liquor or the method for treating the waste with the waste develops the new resource utilization way for the gulonic acid mother liquor,and further develops the new way for treating other waste bacterial residue.

Owner:何立肖 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com