Synthetic process for vitamin C sodium salts

A synthesis process and vitamin technology, applied in the field of vitamin C sodium salt synthesis technology, can solve the problems of long synthesis time, grayish-yellow color, poor quality, etc., and achieve the improvement of production efficiency and equipment utilization, short synthesis time, and improved purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

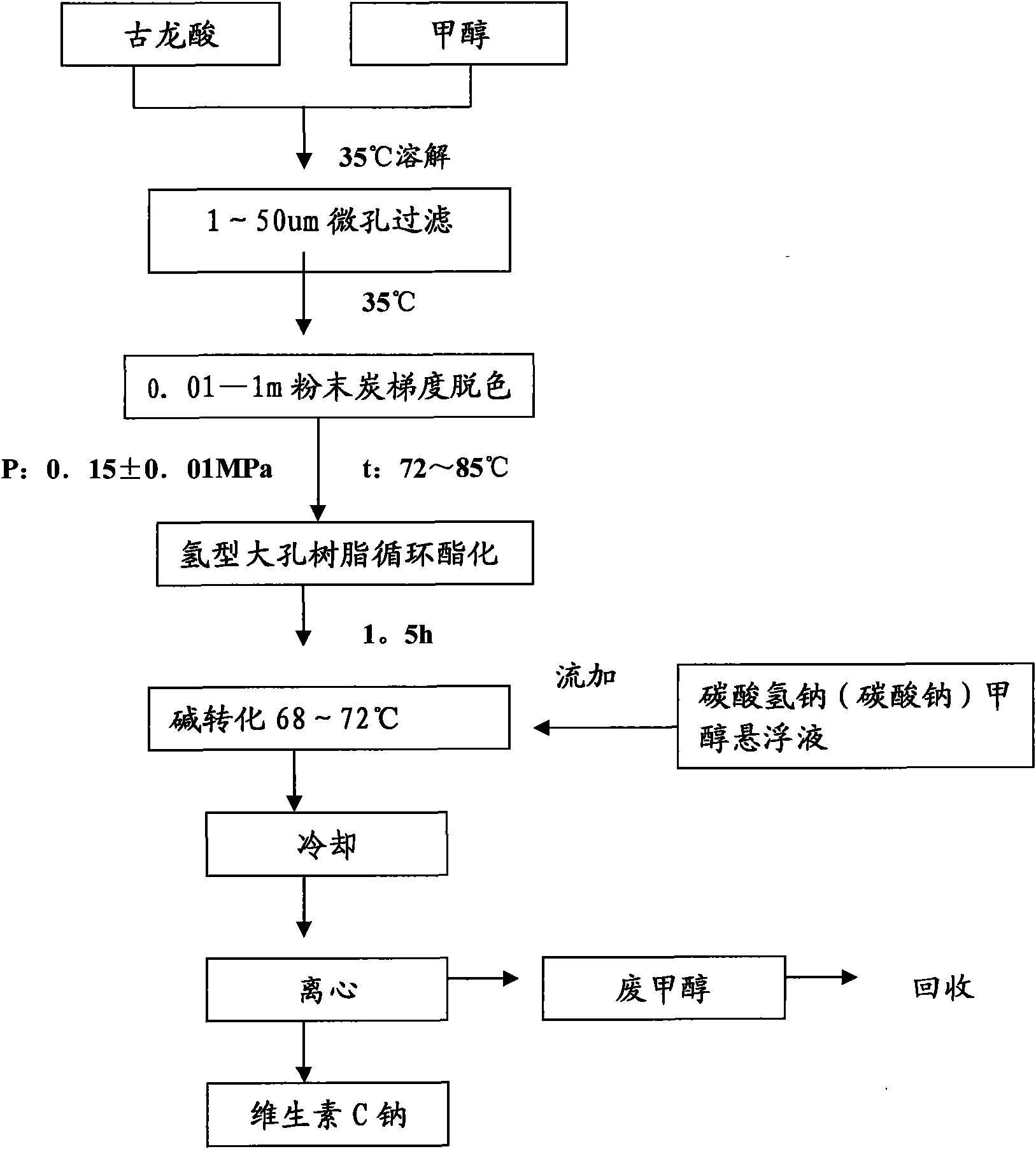

Image

Examples

Embodiment 1

[0015] Vitamin C sodium salt synthesis technique of the present invention, carry out according to the following steps successively:

[0016] (1) Gulonic acid is dissolved in 99% methanol with a weight ratio of 3.5 times at a temperature of 35° C., then passes through a filter with a pore size of 30 μm, and then passes through a filter with a pore size of 0.05 μm and a layer of powdered activated carbon for gradient decolorization to obtain a decolorizing solution stand-by;

[0017] (2) Under the temperature of 75°C and the pressure of 0.15±0.1Mpa, the decolorizing solution is circulated in the macroporous hydrogen resin for 1.5 hours to obtain the esterification reaction solution;

[0018] (3) Inject the esterification reaction liquid into the normal pressure container, keep stirring at a temperature of 70±2°C, mix sodium bicarbonate (0.505 times the molar amount of gulonic acid) with 99 % weight concentration of methanol was mixed to obtain a suspension, which was added to t...

Embodiment 2

[0020] Vitamin C sodium salt synthesis technique of the present invention, carry out according to the following steps successively:

[0021] (1) Gulonic acid is dissolved in the methanol of 99% weight concentration of 3 times of weight ratio at 28 DEG C of temperature, then pass through the filter of 20 μm aperture, then pass through the filter of 0.01 μm aperture and powder activated carbon layer gradient decolorization to obtain decolorization liquid stand-by;

[0022] (2) Under the temperature of 76°C and the pressure of 0.15±0.1Mpa, the decolorizing solution is circulated in the macroporous hydrogen resin for 1.6 hours to obtain the esterification reaction solution;

[0023] (3) The esterification reaction liquid is injected into the normal pressure container, and at a temperature of 70±2° C., keeping stirring, the sodium bicarbonate of 1.03 times the molar number of gulonic acid or the sodium carbonate of 0.508 times the molar number of guaronic acid are mixed with 99% we...

Embodiment 3

[0025] Vitamin C sodium salt synthesis technique of the present invention, carry out according to the following steps successively:

[0026] (1) Gulonic acid is dissolved in 99% methanol with a weight ratio of 4 times at a temperature of 32° C., then passes through a filter with a pore size of 15 μm, and then passes through a filter with a pore size of 0.09 μm and a layer of powdered activated carbon for gradient decolorization to obtain a decolorizing solution stand-by;

[0027] (2) Under the temperature of 78°C and the pressure of 0.15±0.1Mpa, the decolorizing solution is circulated in the macroporous hydrogen resin for 1.8 hours to obtain the esterification reaction solution;

[0028] (3) The esterification reaction solution is injected into the normal pressure container, and at a temperature of 70±2° C., and kept in a stirring state, sodium bicarbonate with 1.05 times the molar number of gulonic acid or sodium carbonate with 99% weight concentration The suspension mixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com