Production method and apparatus for high-power concentration of gulonic acid

A production method and technology of gulon acid, which is applied in the field of concentration process of sodium gulonate solution, can solve the problems of high investment in evaporation equipment and energy consumption, increase of sodium gulonate, etc., and achieve outstanding effects of energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

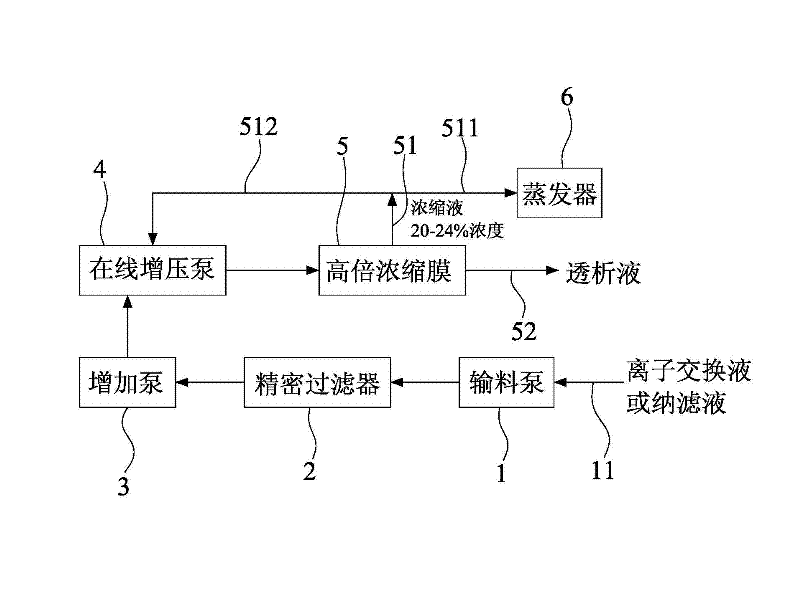

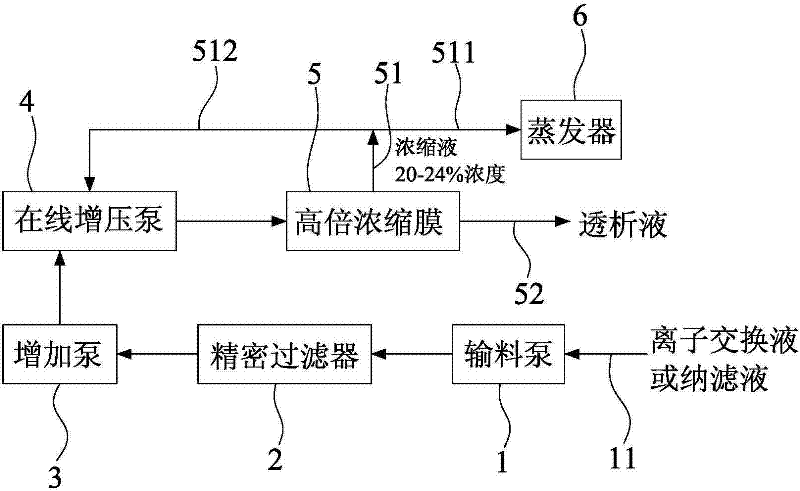

[0026] Such as figure 2 As shown, a high-concentration production equipment for gulong acid disclosed by the present invention includes a feed pump 1 , a precision filter 2 , a booster pump 3 , an online booster pump 4 and a high-concentration membrane 5 .

[0027] Wherein, the inlet of feeding pump 1 is connected to the feed liquid pipe 11 of ion exchange liquid or nanofiltration liquid, the outlet of feeding pump 1 is connected to the inlet of precision filter 2, and the outlet of precision filter 2 is connected to the inlet of booster pump 3, increasing The outlet of the pressure pump 3 is connected to the inlet of the online booster pump 4, and the outlet of the online booster pump 4 is connected to the inlet of the high-power concentration membrane 5, and the outlet of the high-power concentration membrane 5 includes a dialysate pipeline 52 and a concentrate pipeline 51, and the concentrate pipeline 51 forms two branches 511 and 512 , one branch 51 is connected to the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com