High-temperature flue gas waste heat recovery and dust extraction all-in-one device

A waste heat recovery and high-temperature flue gas technology, applied in waste heat treatment, lighting and heating equipment, chemical instruments and methods, etc., can solve problems such as unstable operation, difficult dust cleaning, and affecting dust removal efficiency, so as to improve combustion efficiency and reduce Substance pollution, large heat capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

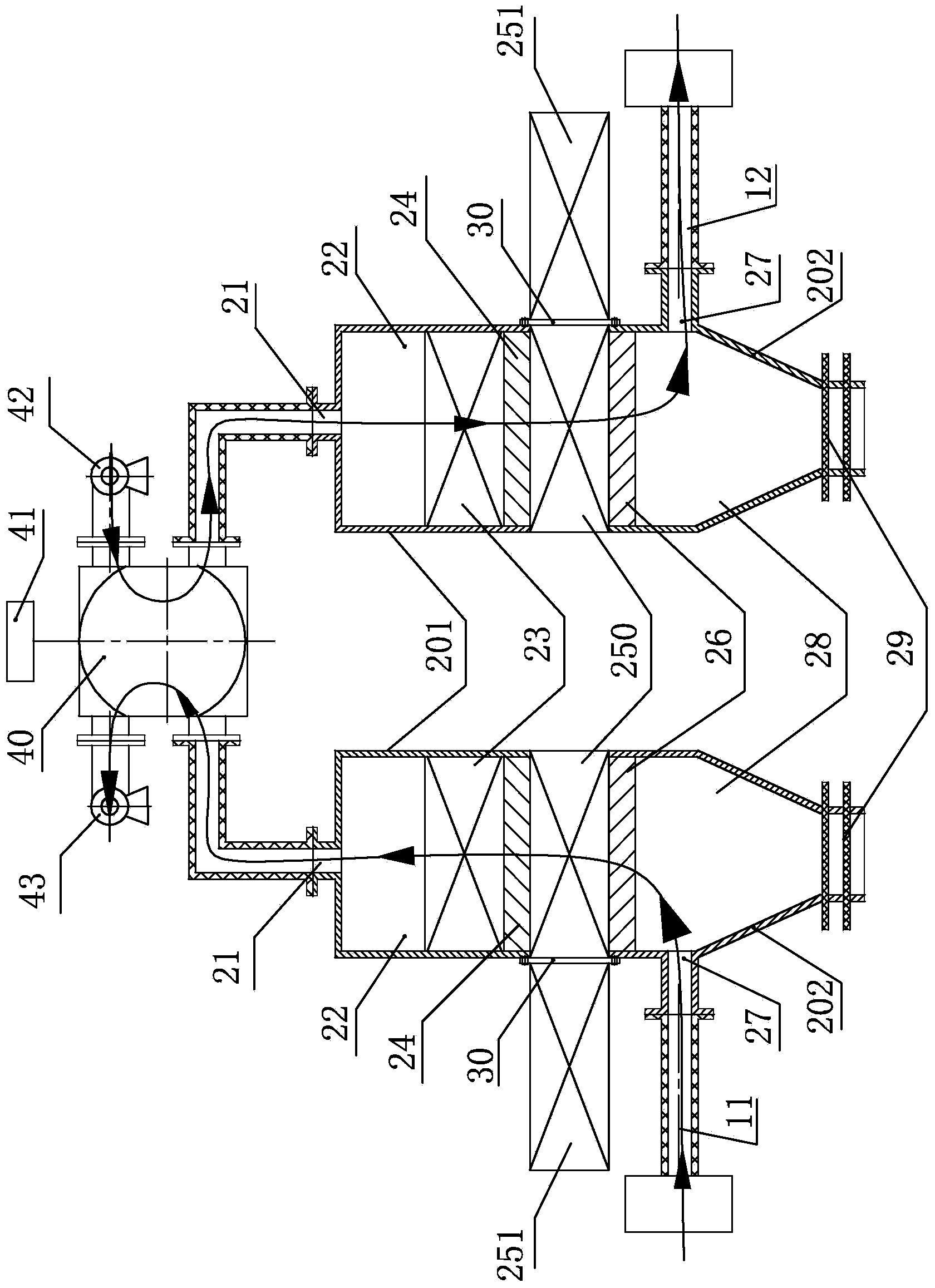

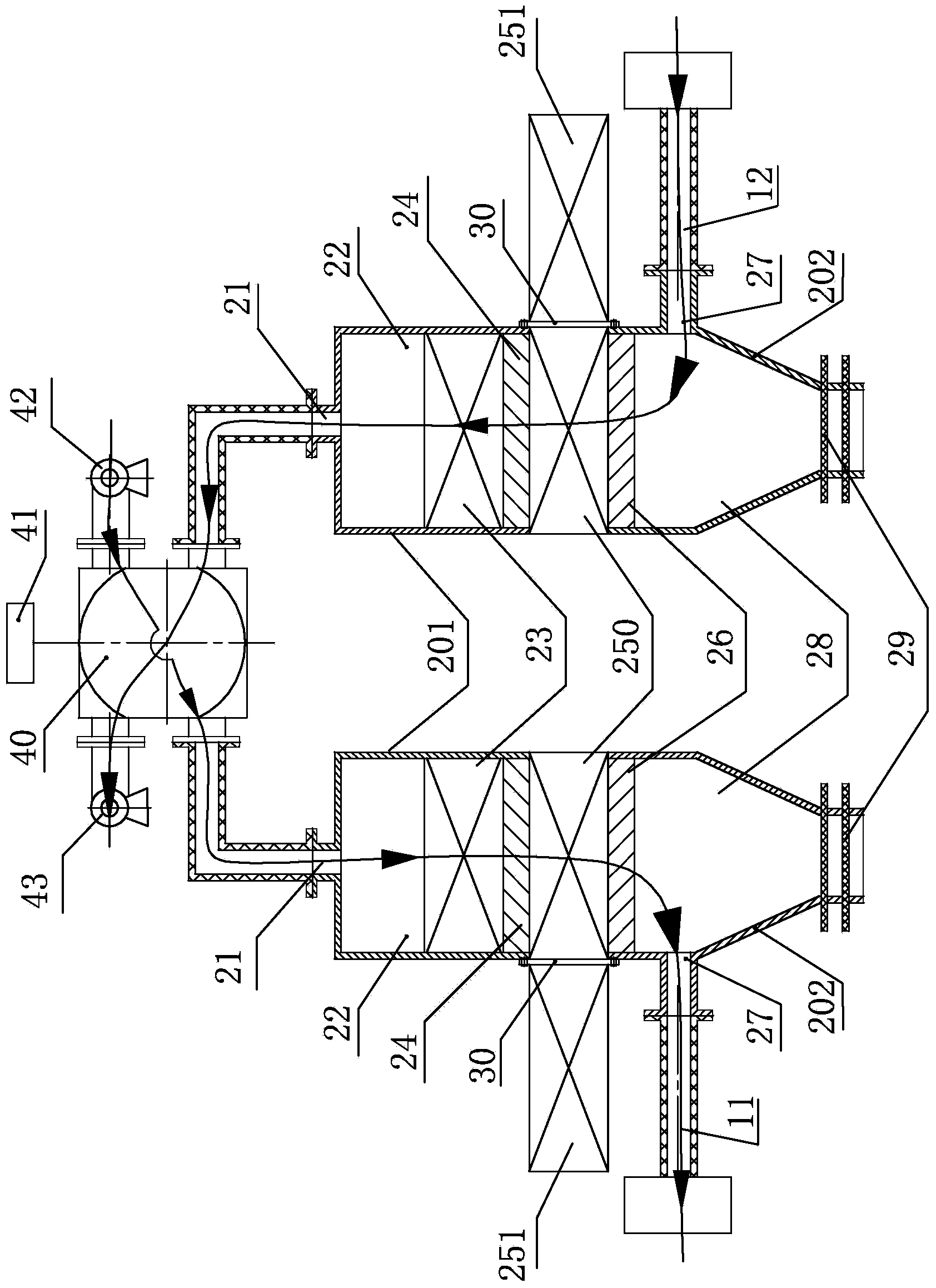

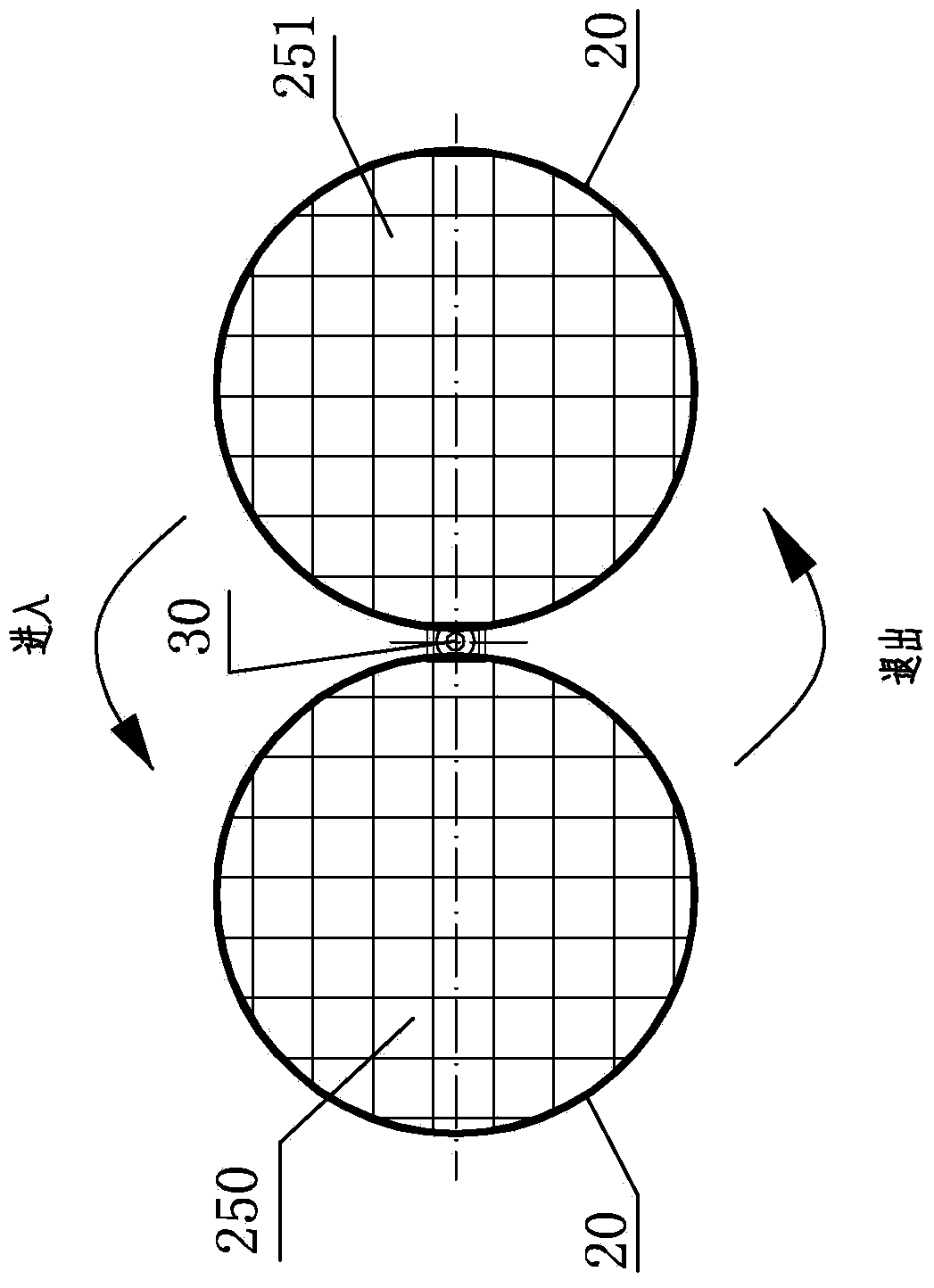

[0038] Such as figure 1 , 2 , which are schematic diagrams of the structure of the integrated device embodiment of the present invention under different switching conditions. An embodiment of an integrated device for recovering high-temperature flue gas waste heat and dust removal according to the present invention, which includes a furnace interface 27 and a filter bed connected to the double-sided gas channels 11 and 12 of a high-temperature kiln (not shown). The filter bed includes a stainless steel filter basket 20 containing ceramic balls (not shown) (see image 3 ), the ceramic balls with particle size of 10-20mm accumulated in the filter material basket 20; the packing density of the ceramic balls in the filter material bed is 1700-2100kg / m3. The integrated device includes two left and right air passing units, and a four-way reversing valve 40 with an electric switching actuator 41 .

[0039] The left and right air passage units include an upper cylinder 201 and a lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com