Method and system for recycling hazardous lead solid waste

A solid waste and dangerous technology, which is applied in the field of recycling and utilization of lead hazardous solid waste, can solve the problems of lead hazardous solid waste polluting the environment, achieve significant energy saving and emission reduction effects, low recycling costs, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

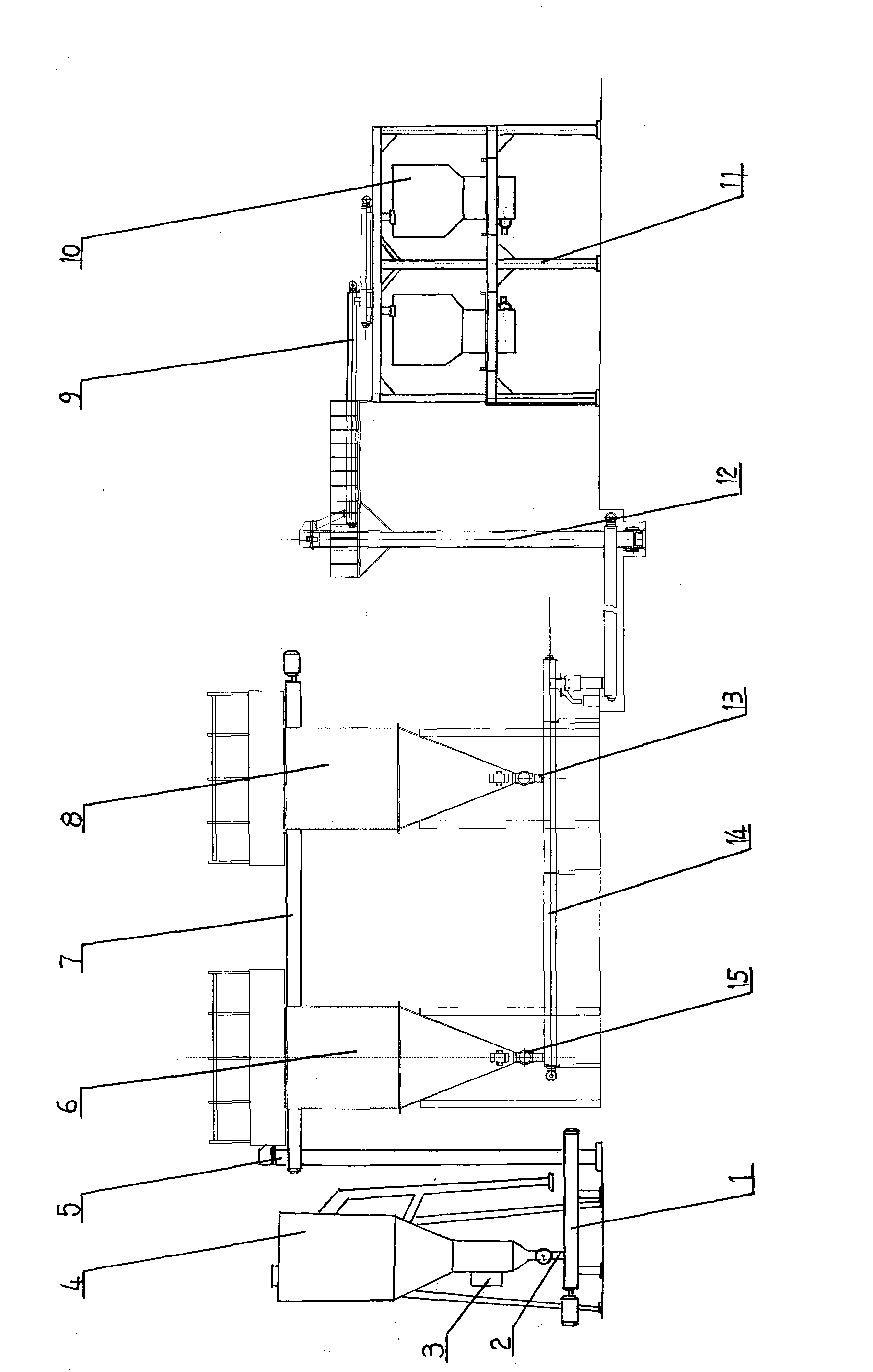

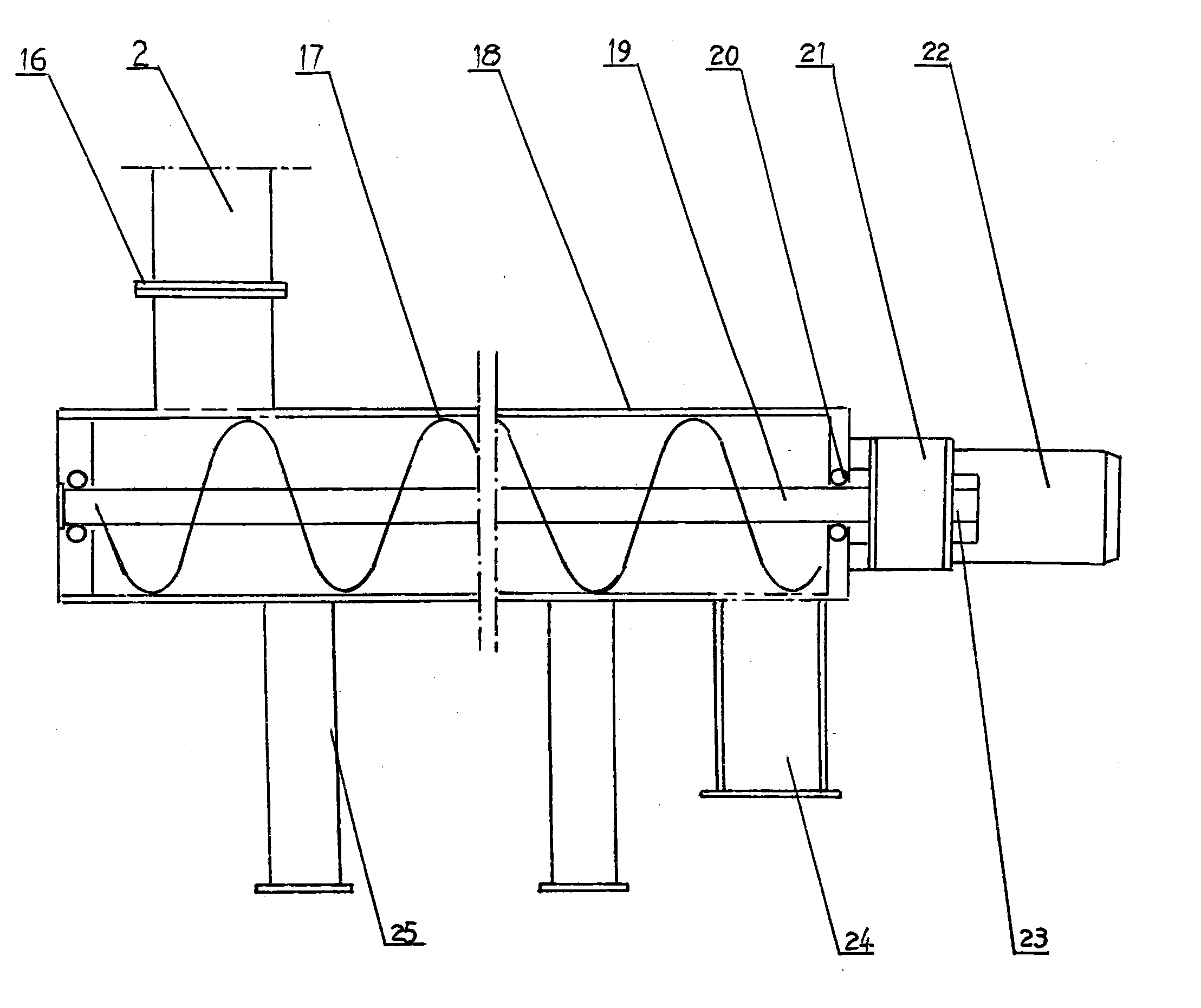

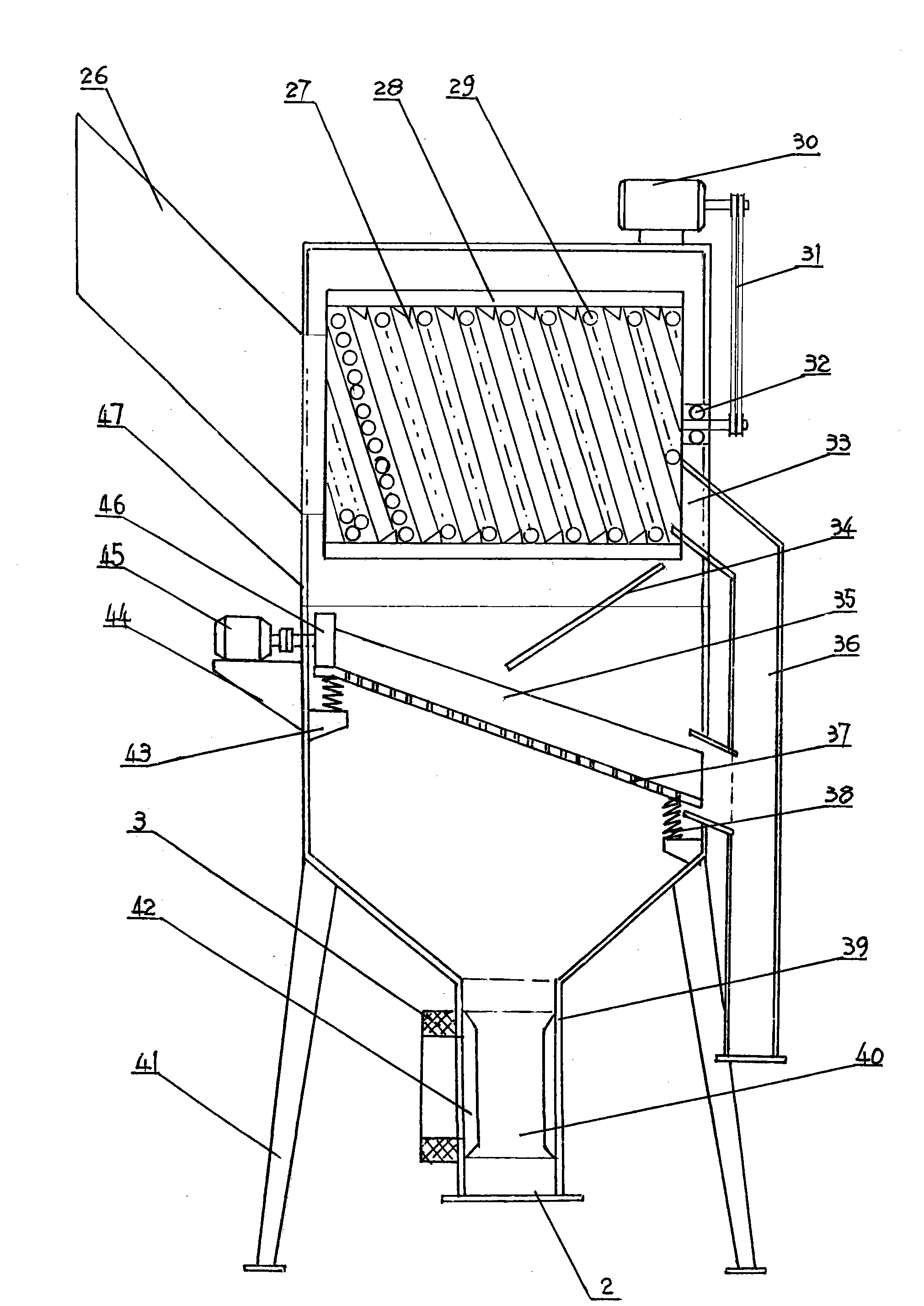

Image

Examples

Embodiment Construction

[0027] A method for recycling and utilizing lead hazardous solid waste, comprising the steps of,

[0028] (1) Collect the lead hazardous solid waste generated in the process of separating and brushing the battery manufacturing, and clearly record the lead alloy composition, use, and quantity of the lead hazardous solid waste. The collection of waste lead powder produced during the process of separating and brushing the positive and negative plates should be handled separately and collected collectively, and because the additive components in the positive and negative plates are different, they cannot be used in confusion. In order to facilitate recycling and reduce reuse raw materials and costs, batch manufacturing of the same electrode should be carried out in the separation and brushing process of battery plates, that is, positive plates should be produced in batches at the same time; The composition, use, and quantity of waste are clearly recorded.

[0029] (2) Separating,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com