Patents

Literature

104results about How to "High recycling rate of resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

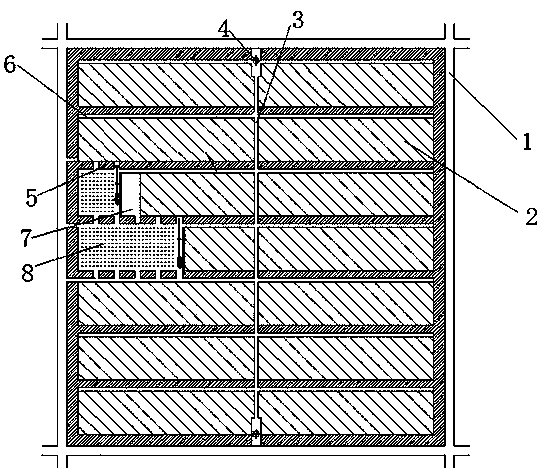

Sublevel open-stop and delayed filling mining method

InactiveCN102562065AImprove drilling positioning accuracyNo lossUnderground miningSurface miningTailings damFilling materials

The invention relates to a sublevel open-stop and delayed filling mining method. According to the method, cutting crosscuts are wholly undercut along the width of chambers and pillars so that the space of scope rock drilling is shared with ore drawing, drilling operations of vertical parallel blast holes are achieved in undercutting space, positioning accuracy of drilling the vertical parallel blast holes is high, the intervals among the blast holes are even, and the defect of high blasting boulder yield caused by drilling sector blast holes in traditional rock drilling cross cuts is avoided; during chamber (or pillar) scoping, driving of ore drawing gateways and ore drawing admission passages in fill materials of adjacent pillars (or chambers) isn't needed, and accordingly the safety is improved; simultaneously, ores are directly drawn from the undercutting space of the chambers and the pillars, the space of ore drawing is large, mutual interference is small, ore drawing efficiency is high, and ores are drawn completely without any dead space and secondary ore loss; artificial sill pillars are constructed, ore sill plates aren't needed to be reserved, the ores are free of primary loss, and the rate of resource recycling is high. Barren rocks and ore beneficiation tailings are used for filling gobs, the barren rocks are not taken out of pits, constructions of tailing dams and barren rock yards are reduced, and land occupation is small.

Owner:UNIV OF SCI & TECH BEIJING

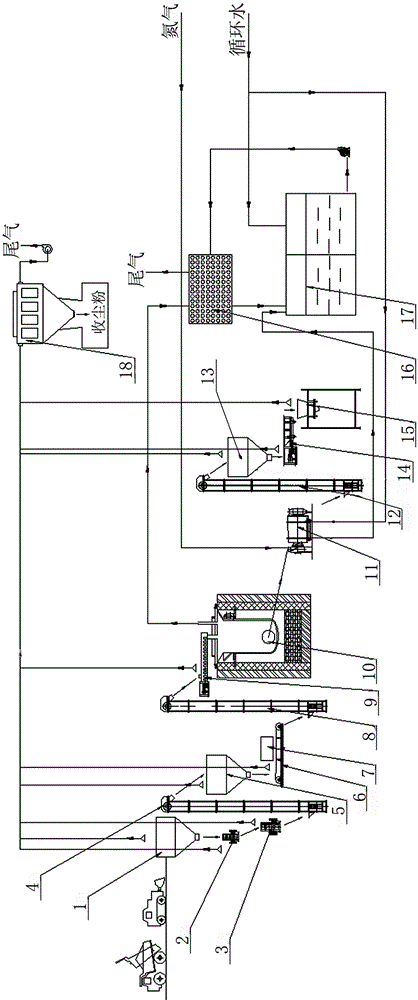

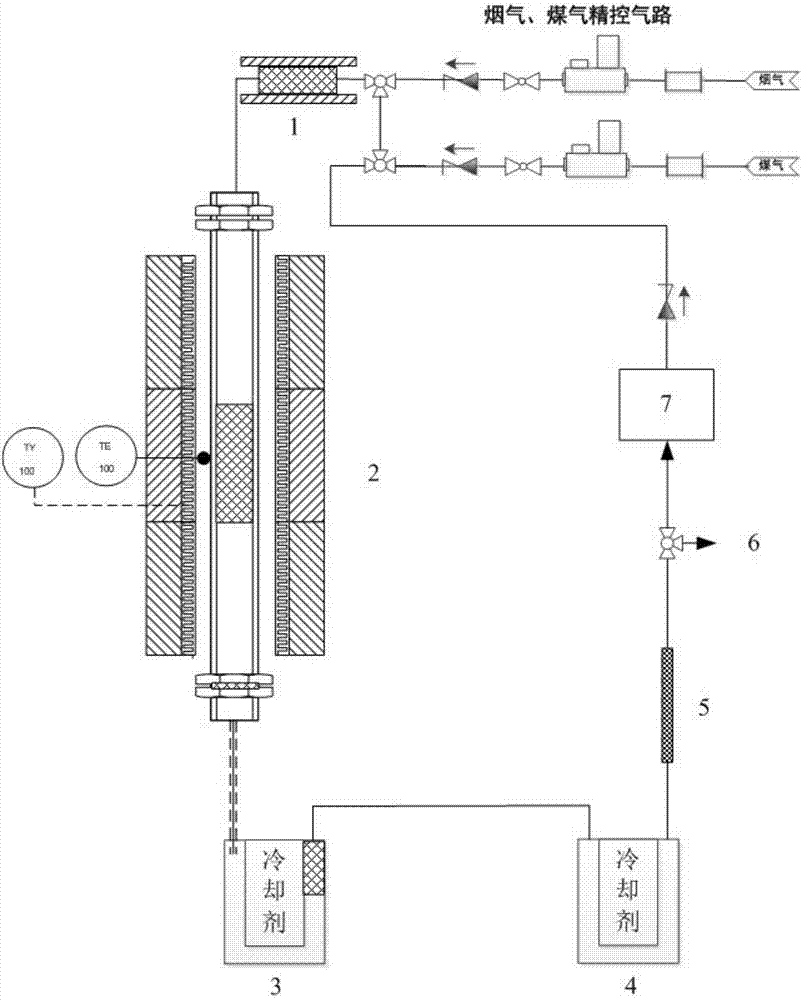

Method and device for producing crude antimony trioxide by smelting of rich oxygen side-blown volatile molten pool

The invention discloses a method and a device for producing crude antimony trioxide by smelting of a rich oxygen side-blown volatile molten pool. The method comprises the following steps: by taking an antimonial material as a raw material, blind coal or coke or a natural gas or a coal gas and the like as supplement fuel, and iron ore and lime as fluxes, blowing oxygen-enriched air, entering a furnace to react after metering a charging material, so as to produce high-temperature smoke and melt; condensing and dedusting the high-temperature smoke, and then feeding the smoke to an acid making system to prepare an acid, wherein the condensed powder is a crude antimony trioxide product to feed to the next procedure to process; respectively discharging the high-temperature melt after settling and layering in a hearth; quenching the slag to be directly used as a waste slag, and returning a little of produced antimony matte and crude antimony; and feeding noble antimony to the next procedure to process and extract gold. The invention also comprises a device for producing crude antimony trioxide by smelting of a rich oxygen side-blown volatile molten pool. The device has the advantages of being strong in raw material adaptability, low in energy consumption, high in smoke SO2 concentration, high in direct recovery rate and recovery rate of antimony and noble metal, clean and environment-friendly to produce, low in production cost and the like, and the acid can be directly prepared.

Owner:锡矿山闪星锑业有限责任公司 +3

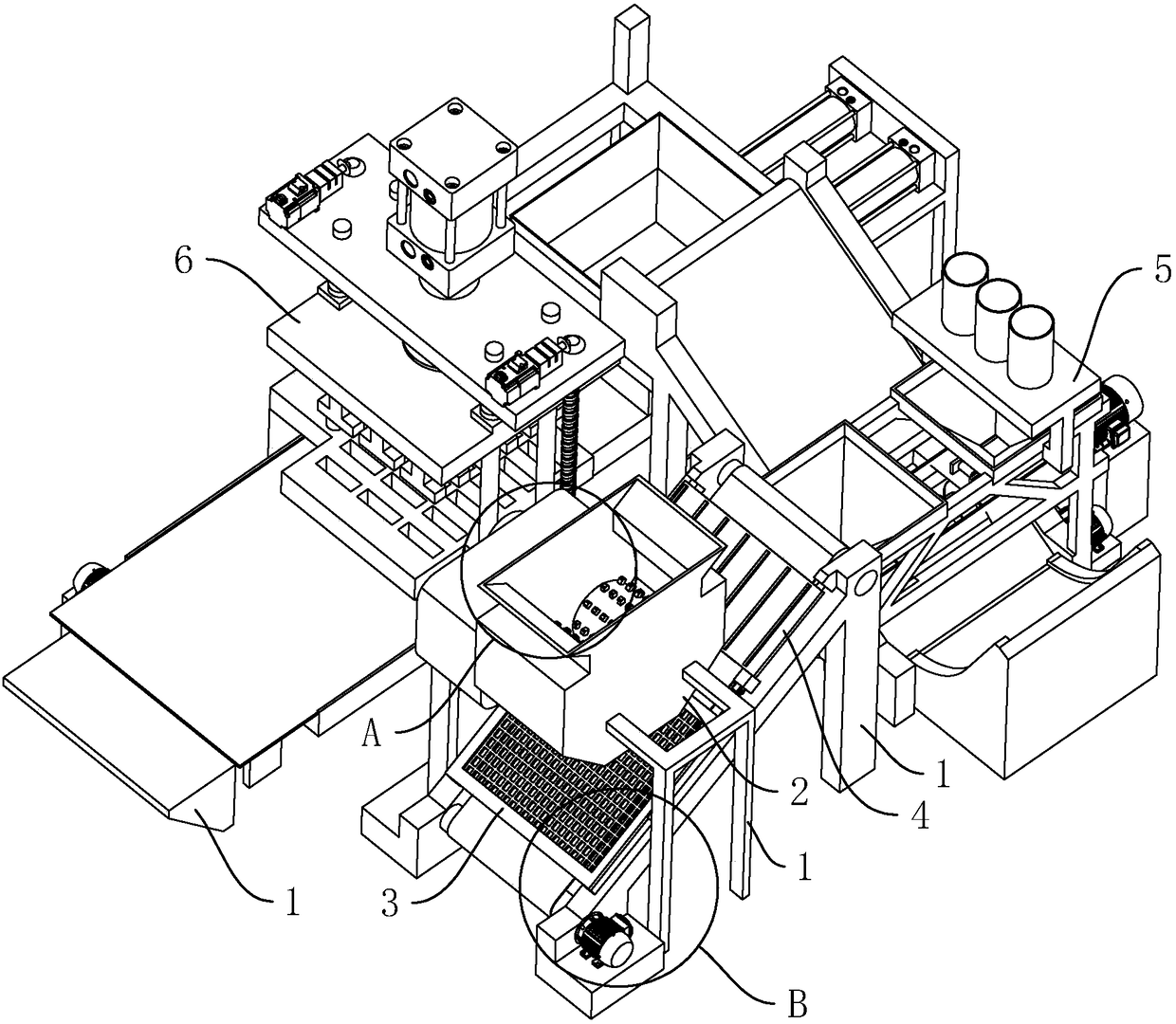

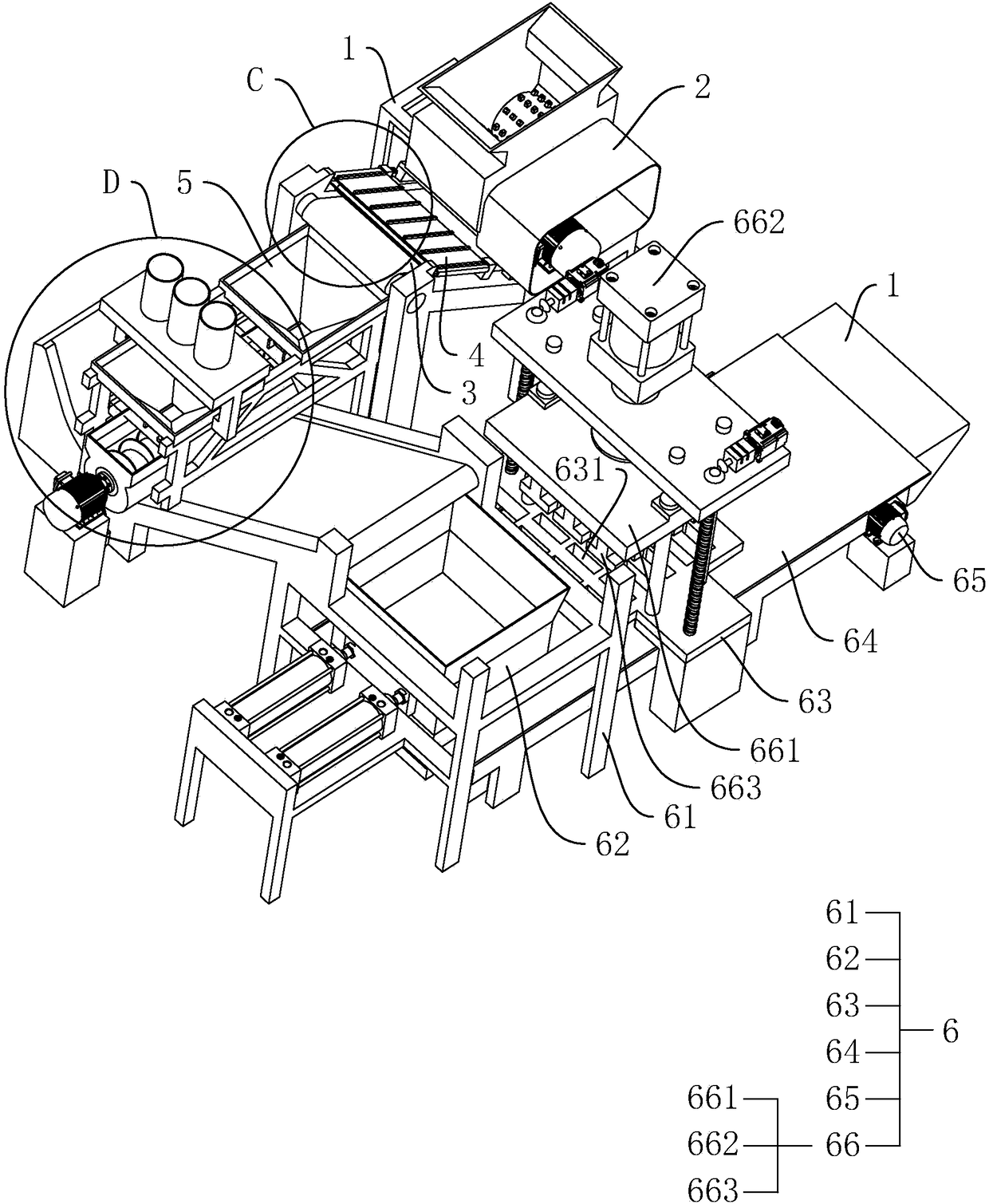

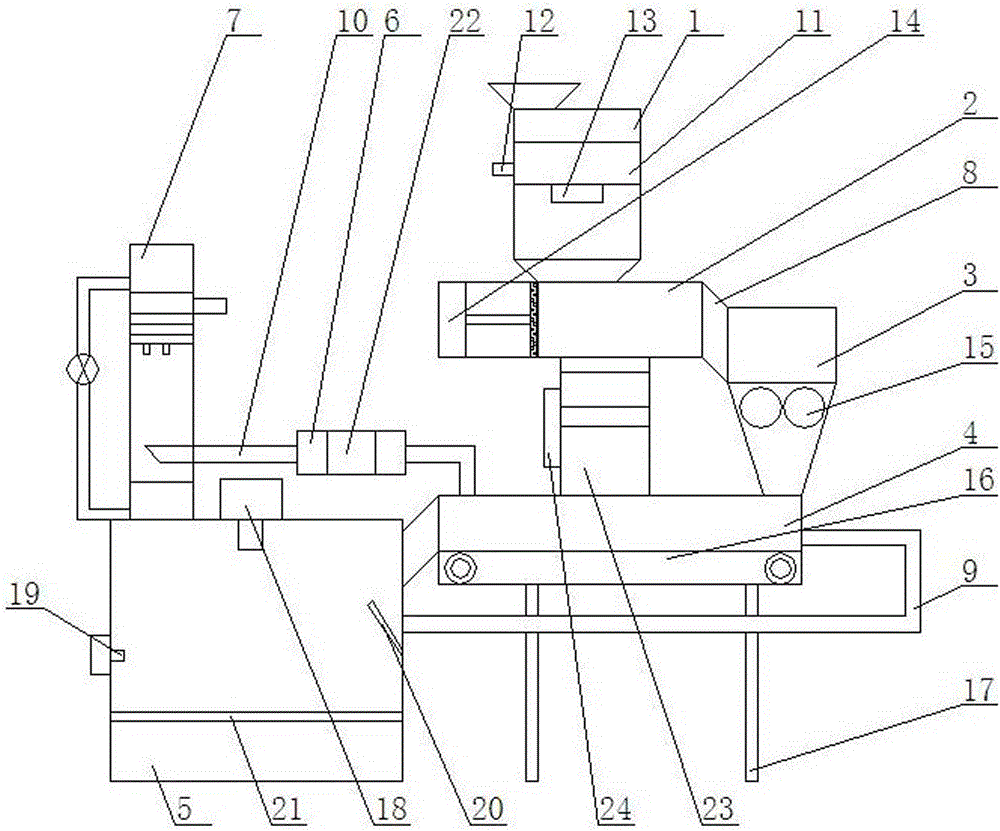

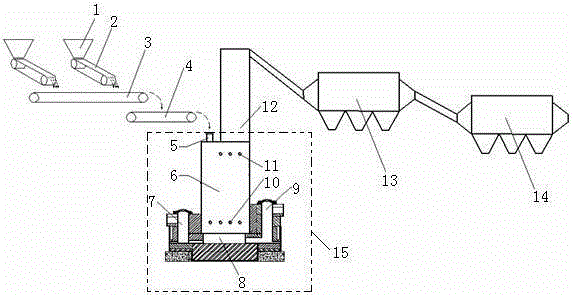

Eco-brick manufacturing system and eco-brick manufacturing method

ActiveCN108970699AReduce manufacturing costEfficient recyclingCeramic shaping apparatusMagnetic separationMobile vehicleAbsorption filter

The invention discloses an eco-brick manufacturing system and an eco-brick manufacturing method, belongs to the technical field of building materials manufacture. The invention aims at solving a problem that the production cost of the eco-brick is high. The eco-brick manufacturing system provided by the invention is mainly characterized by comprising: a rack arranged on a mobile vehicle; a crushing device arranged on the rack and configured to pulverize construction waste; a screening device arranged at a discharging port of the crushing device; a magnetic absorption filter member arranged onthe rack and close to the discharging port of the screening device; a batching device arranged at a discharging end of the magnetic absorption filter member; and a forming device arranged at a discharging end of the batching device and configured to extrude the brick-manufacturing raw materials prepared in the batching device into the eco-brick. Therefore, the purposes of recycling the construction waste and reducing the production cost of the eco-brick can be achieved.

Owner:广东合韵达建筑工程有限公司

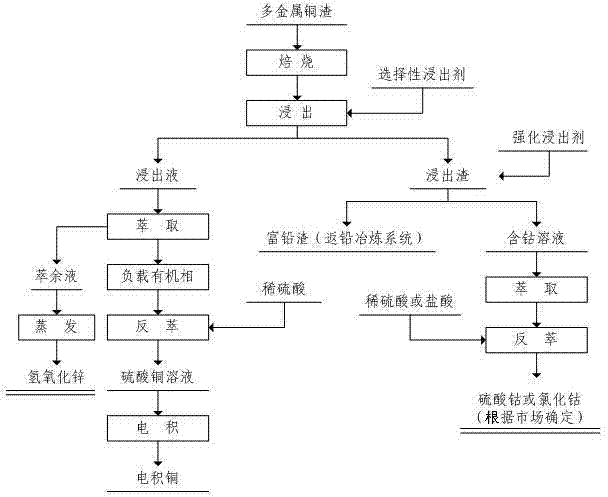

Method for producing electrodeposited copper from polymetallic copper slag

ActiveCN104846202AImprove leaching efficiencyHigh recovery ratePhotography auxillary processesProcess efficiency improvementZinc hydroxideLead smelting

The invention discloses a method for producing electrodeposited copper from polymetallic copper slag, which includes the following steps: the polymetallic copper slag is roasted to oxidize, so that the complex states of valuable metals in the polymetallic copper slag are transformed into oxides, changed into a state which can be selectively leached; leaching first adopts selective leaching agent to leach copper and zinc, the leachate is extracted, reextracted and electrodeposited, so that electrodeposited copper is obtained, and raffinate is vaporized and crystallized, so that zinc hydroxide is obtained; mechanical intensified leaching agent is then used for intensely leaching leaching residue, so that cobalt, nickel and the like in the leaching residue are leached, lead, iron and the like are enriched into the slag, the lead-rich slag is adopted as material for lead smelting, the leachate is extracted and reextracted, so that cobaltous sulfate or cobalt chloride is obtained, and if the nickel content in the leachate is overhigh, multi-stage extraction can be carried out to separate cobalt and nickel, so that nickel sulfate or nickel chloride is produced. The method can comprehensively recover a variety of metals, the leaching efficiency is high, the recovery rate is high, the method is environment-friendly, and is easy to implement, the method ensures that all the valuable metals in the polymetallic copper slag can be effectively separated and recycled, and the solid waste utilization rate can reach more than 99 percent.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Process for recovering distillation waste liquid generated by producing 1,4-butanediol

InactiveCN103274898AHigh recovery rateImprove overall recoveryOrganic compound preparationHydroxy compound preparationDistillationButanediol

The invention relates to a process for recovering distillation waste liquid generated by producing 1,4-butanediol and belongs to the technical field of recycling of organic waste liquid in the industrial production. According to the invention, the distillation waste liquid generated in the process of producing 1,4-butanediol by a Reppe method is used as a raw material; drained wastewater is used as an extracting agent; sodium sulfate is used as a salting-out agent; sulfuric acid is used as a catalyst for depolymerizing reaction; and by a circulating process of salting-out-extraction, reduced pressure batch distillation separation and depolymerizing reaction, various products in the distillation waste liquid, such as 1,4-butanediol, butanol and 3-tetrahydrofurfuryl alcohol are recovered. The process disclosed by the invention has the characteristics that various products can be recovered, the recovery rate of the products is high and the recovery economic benefits are good; the process sufficiently utilizes waste liquid resources and is beneficial to environment protection; the process is simple, reaction conditions are mild, equipment is conventional and recovery cost is low; and the process has a wide application range and is convenient to popularize and apply. The process can be widely applied to recycling of the organic waste liquid in the industrial production and is particularly suitable for recycling the waste liquid generated in the process of producing 1,4-butanediol by the Reppe method.

Owner:CHONGQING UNIV

Recovering and utilizing method for solid waste acid-leaching lead slime on polar plate of storage battery and system

ActiveCN106129515ASolve the pollution of the environmentSolve the costWaste accumulators reclaimingBattery recyclingFiltrationResource recovery

The invention belongs to a recovering and utilizing method for a solid waste acid-leaching lead slime on a polar plate of a storage battery and a system. According to the method, an obtained lead-bearing suspension acid liquid is collected and lead powder in the lead-bearing suspension acid liquid is immediately separated from an acid leaching liquid through a pressure filtration method. The recovered lead powder is collected, dried, crushed and decontaminated and then is recycled according to the components and the amount of the lead powder. The system comprises a weighing control adder, a vacuum paste mixing machine, a plate coating machine and a crushing and decontaminating machine. The lead-bearing suspension acid liquid can be automatically separated and recycled immediately, so that the problems that the lead-bearing suspension acid liquid pollutes the environment, and is high in recovery cost and large in floor area can be effectively solved, and the system has the advantages of being reasonable in method, simple in structure, low in recovery cost, high in resource recovery utilization ratio and good in energy-saving and environment-friendly effects.

Owner:ANHUI YONGHENG STORAGE BATTERY

System and method for producing fully-graphitized carbon product through waste cathode carbon blocks of electrolyzed aluminum

The invention discloses a system and method for producing a fully-graphitized carbon product through waste cathode carbon blocks of electrolyzed aluminum. The system and method are high in recovery and utilization rate, high in economic value added, safe and environmental friendly. The system comprises a crushing unit, a weighting and feeding unit, a roasting unit, a cooling unit, a packing unit, a waste gas treating unit and a dust collecting unit. According to the system and method, the waste cathode carbon blocks are utilized to produce the fully-graphitized carbon product; the waste cathode carbon blocks are roasted at high temperature through a high-temperature furnace, thus cyanides in the waste cathode carbon blocks can be decomposed and volatilized, fluorides enters the exhaust gas in a steam form, and as a result, the ash contents in the waste cathode carbon blocks can be effectively reduced, the graphitizing degree can be increased to be more than 99%, and the waste cathode carbon blocks can be directly sold as the fully-graphitized carbon product. The system and method are high in degree of automation, easy to operate, safe and environmental friendly; the treatment efficiency of the waste cathode carbon blocks and the resource recovery and utilization rate can be effectively improved, the operation cost of an enterprise can be decreased, and the economic benefit of the enterprise can be increased.

Owner:ZHENGZHOU JINGWEI TECH & IND

Co-based catalyst for production of sulfur through reduction of SO2 in flue gas as well as preparation method and application of Co-based catalyst

InactiveCN107175108AEvenly dispersedImprove performanceHeterogenous catalyst chemical elementsDispersed particle separationSulfur dioxideFlue gas

The invention provides a Co-based catalyst for production of sulfur through reduction of SO2 in flue gas as well as a preparation method and an application of the Co-based catalyst. The catalyst comprises a supporter as well as an active component and an aid which are applied to the supporter, wherein the active component is oxide of Co, and the aid is one or at least two of oxides of Cu, Ni, La, Mg, Ca or Ba. The preparation method comprises the steps as follows: the active component and the aid are supported on the supporter with an equivalent-volume impregnation method, drying, roasting and vulcanization are performed, and the Co-based catalyst is prepared. The Co-based catalyst contains uniformly dispersed component, stable performance and uniform particle size and is applicable to catalysis of SO2 in the flue gas to produce sulfur in a fixed bed reactor.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

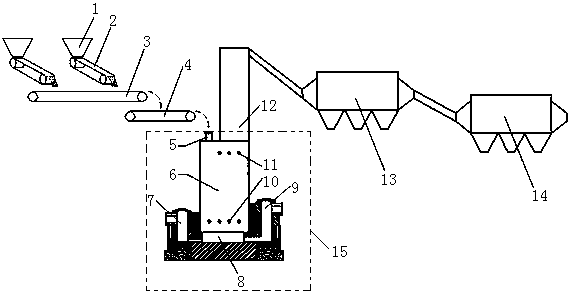

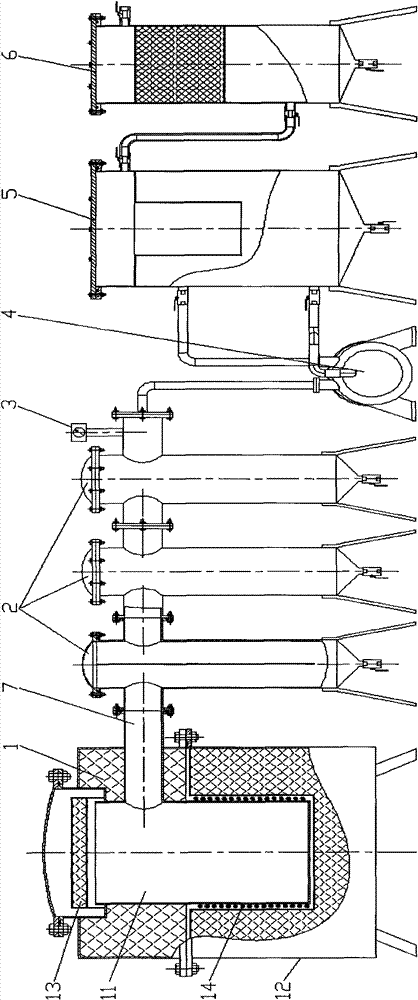

Waste incineration boiler device

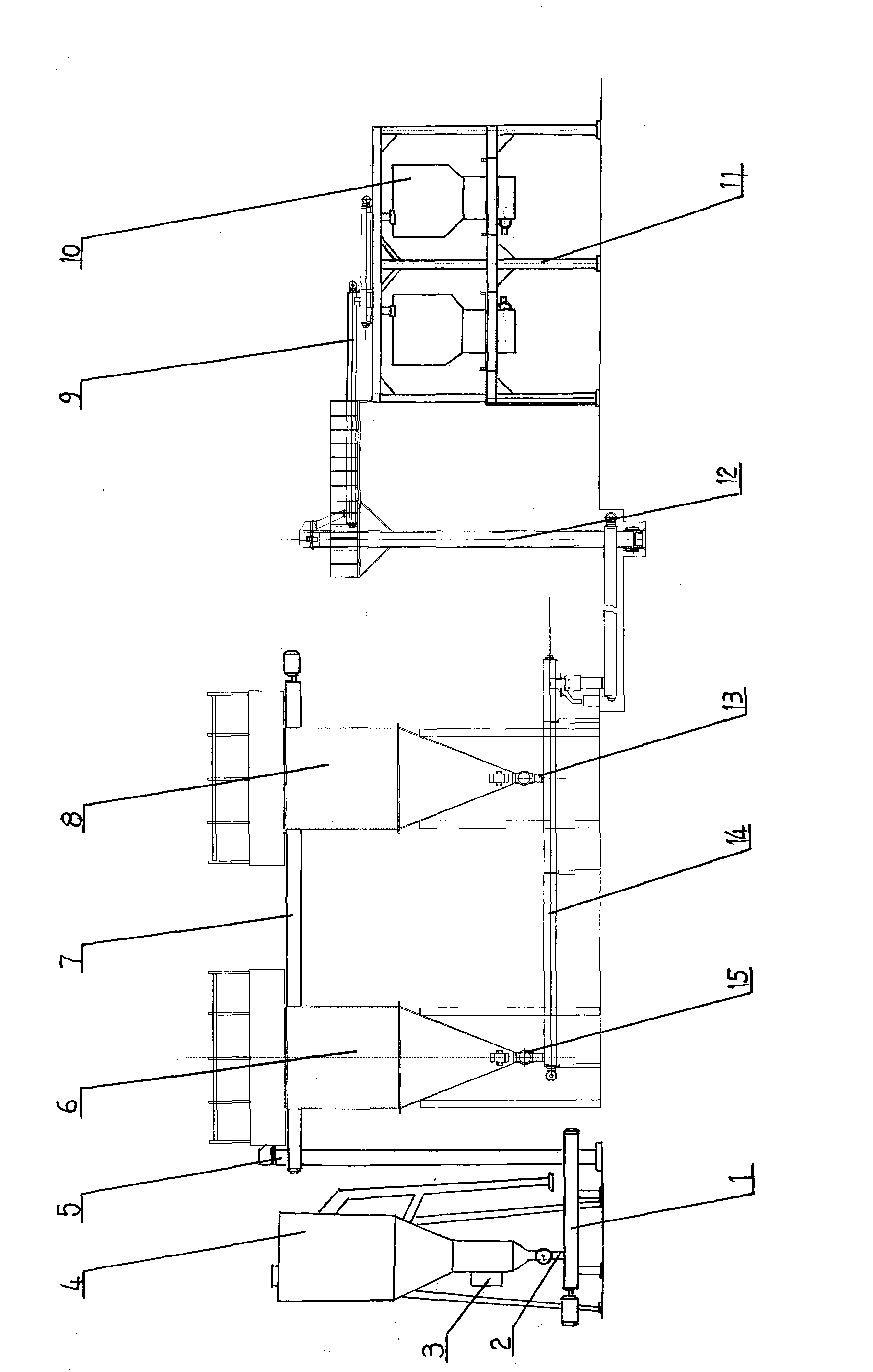

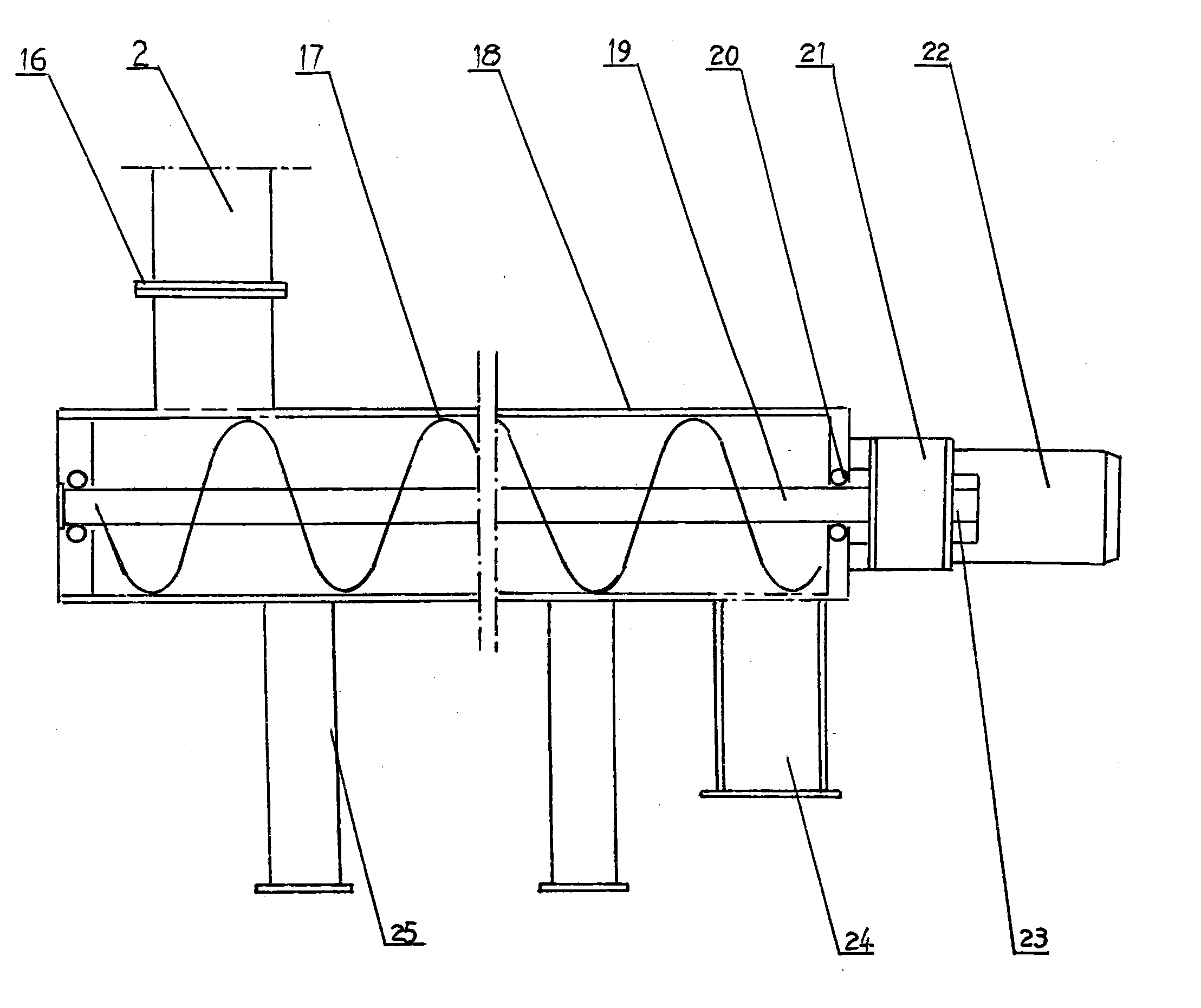

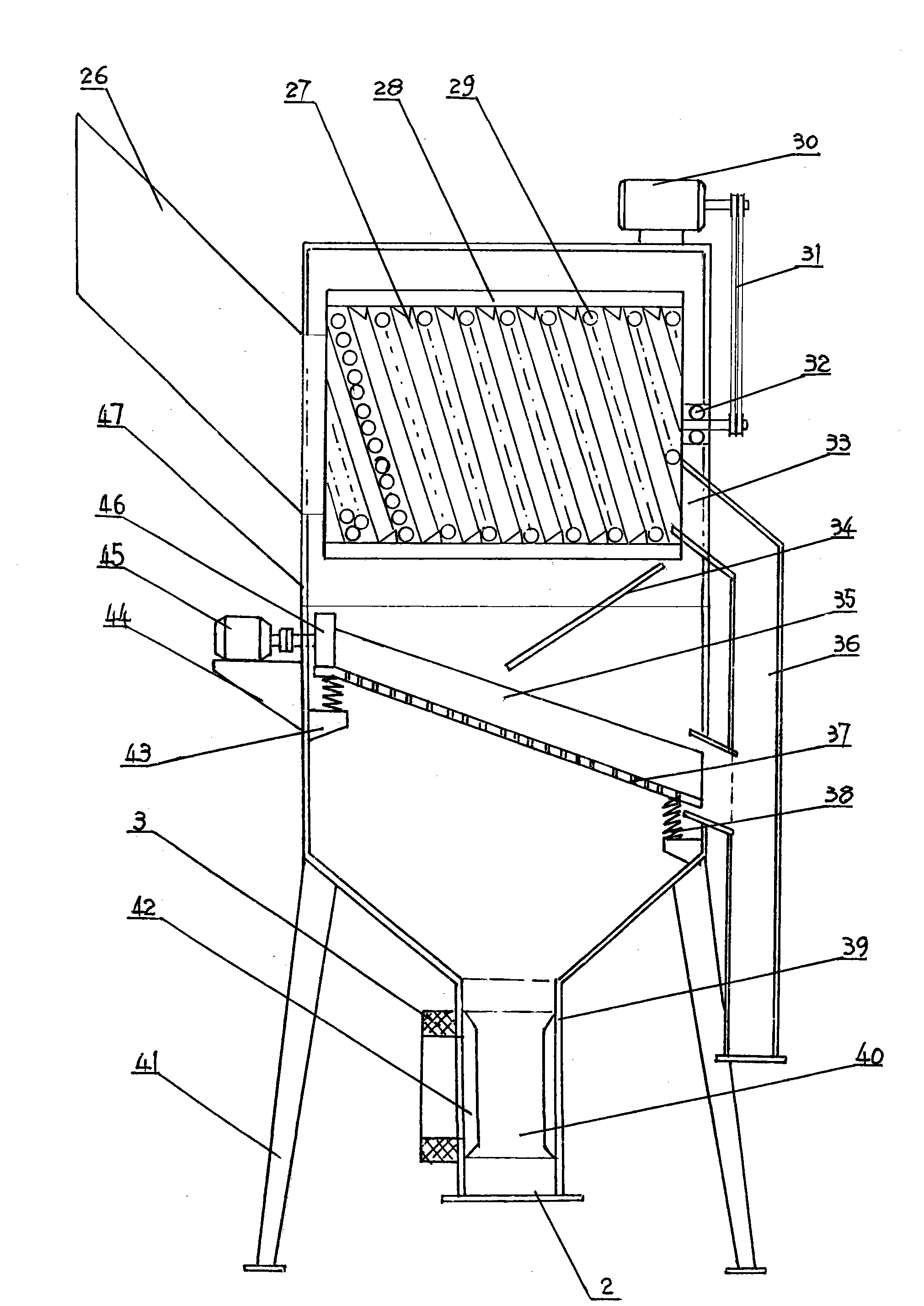

InactiveCN106016283AHigh recycling rate of resourcesHigh resource recovery and reuse rateIncinerator apparatusCombined combustion mitigationProcess engineeringEnvironmental geology

A waste incineration boiler device comprises a recycling chamber, a compressing chamber, a pulverizing chamber, a drying chamber, an incineration generator chamber, a smoke filtering chamber and a sprinkling treatment chamber, wherein the recycling chamber is arranged at the top end of the compressing chamber, the compressing chamber is connected with the pulverizing chamber through an oblique conveying pipe, the pulverizing chamber is arranged at the right upper end of the drying chamber, the drying chamber is connected with the incineration generator chamber through an oblique conveying pipe, the middle end of the right side of the incineration generator chamber is connected with the middle end of the right side of the drying chamber through a smoke pipe, the left side of the top end of the drying chamber is connected with the smoke filtering chamber through a smoke pipe, and the smoke filtering chamber is connected with the sprinkling treatment chamber through an exhaust pipe. The waste incineration boiler device adopts an efficient and environment-friendly method to treat living wastes, and heat produced in the treatment process can be converted to electricity to be utilized. The waste incineration boiler device has the advantages of being high in efficiency, saving in energy, high in resource recycling and reutilizing rate, friendly to environment and free of pollution.

Owner:HARBIN JINJING BOILER

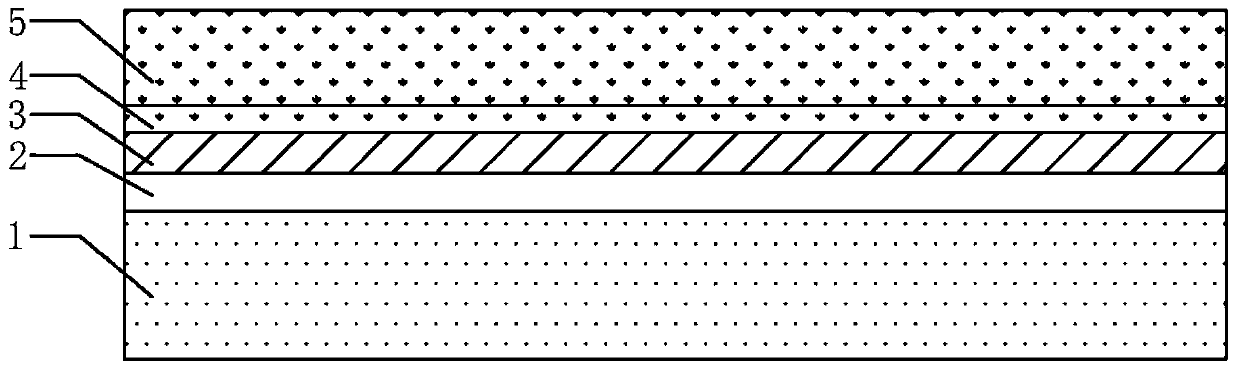

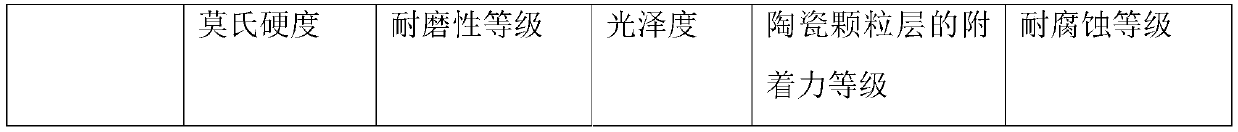

Three-dimensional glazed tile made of scraping waste and manufacturing method thereof

ActiveCN109849163AEasy to operateEasy to controlCovering/liningsCeramic shaping apparatusCeramic glazeScrap

The invention relates to the technical field of ceramic tiles, in particular to a three-dimensional glazed tile made of scraping waste and a manufacturing method thereof. The manufacturing method includes the following steps of A, drying a green body, specifically, the temperature of the green body is raised to 130-160 DEG C for drying; B, applying engobe, specifically, the engobe is performed onthe surface of the dried green body; C, carrying out pattern decoration, specifically, the pattern decoration is carried out on the surface, coated with the engobe, of the green body, and the green body is then dried; D, spraying transparent glaze slip, specifically, the transparent glaze slip is sprayed on the surface of the dried green body; and E, spreading ceramic particles, specifically, theceramic particles are spread on the surface, sprayed with the transparent glaze slip, of the green body, and then, the green body is fired to manufacture the three-dimensional glazed tile, and the rawmaterials for manufacturing the ceramic particles include scraping recovery materials. According to the method, the operation steps are easy to control, the production efficiency is high, the production cost is low, and the energy consumption is saved; the recycling rate of the waste raw materials is increased, no solid waste is generated, and the three-dimensional glazed tile is environmentallyfriendly; and the manufactured three-dimensional glazed tile has distinct layers, obvious dry granular feeling and good three-dimensional effect.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +3

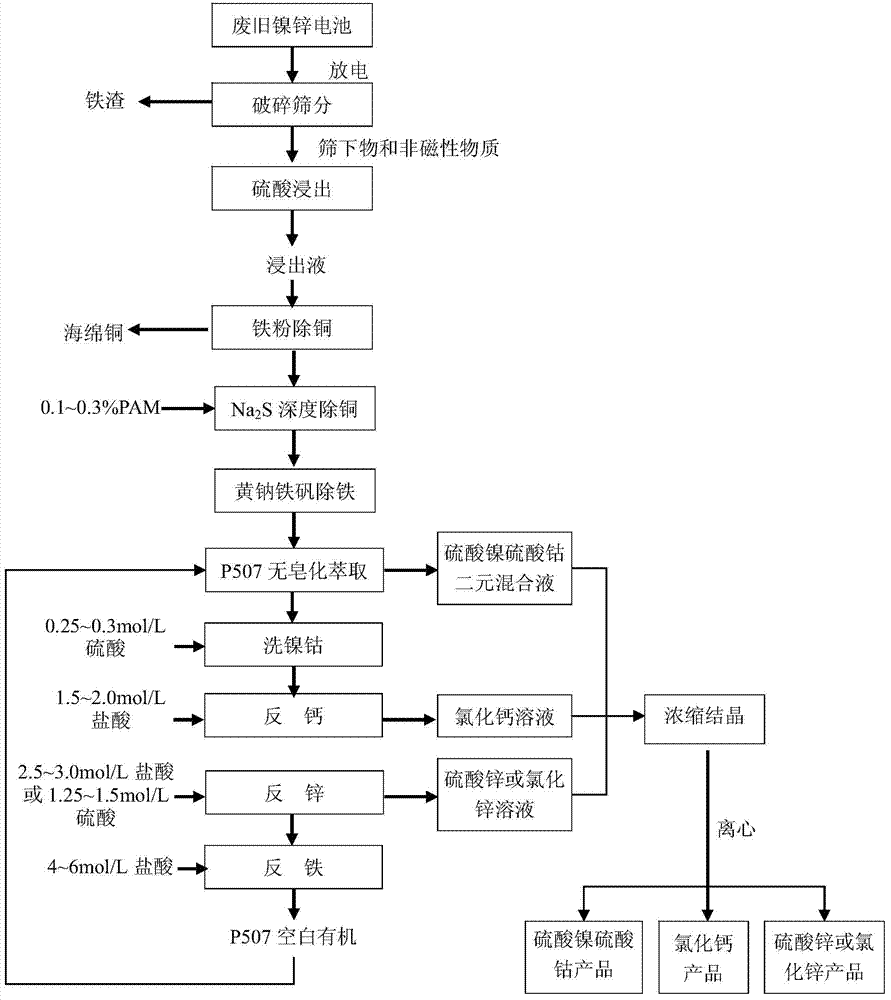

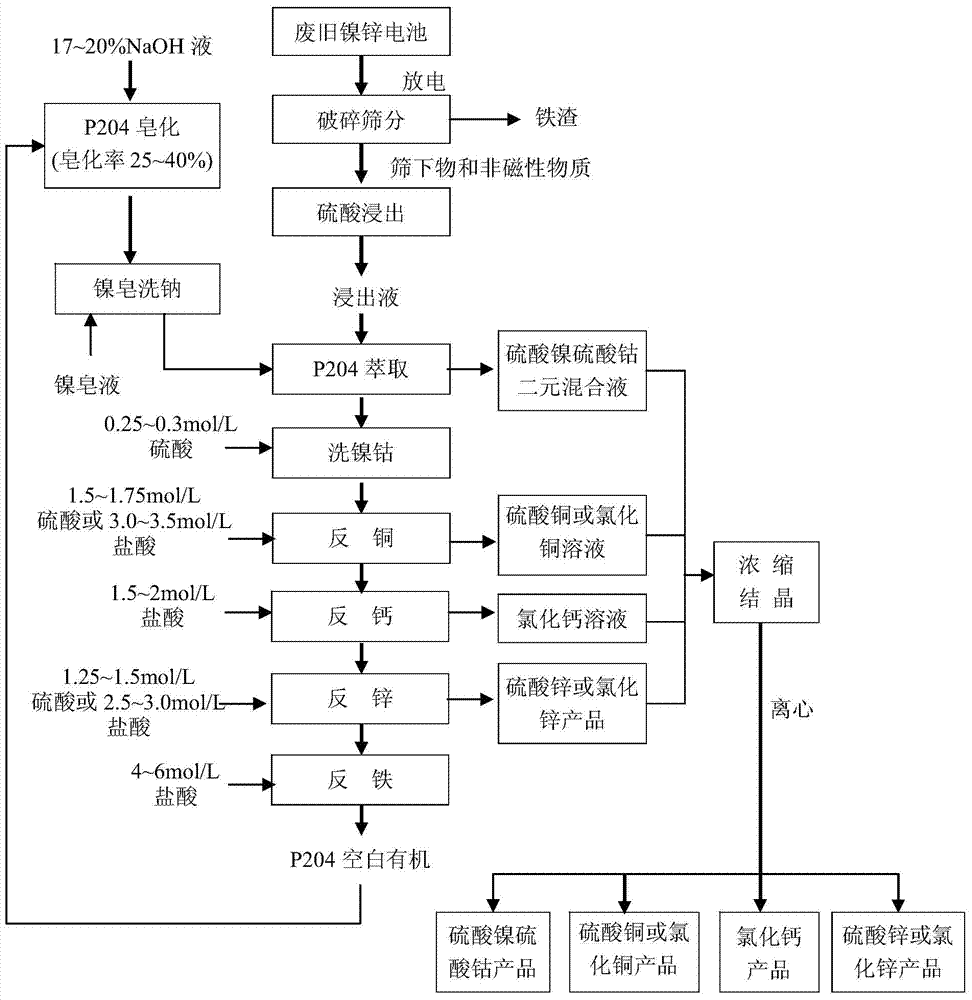

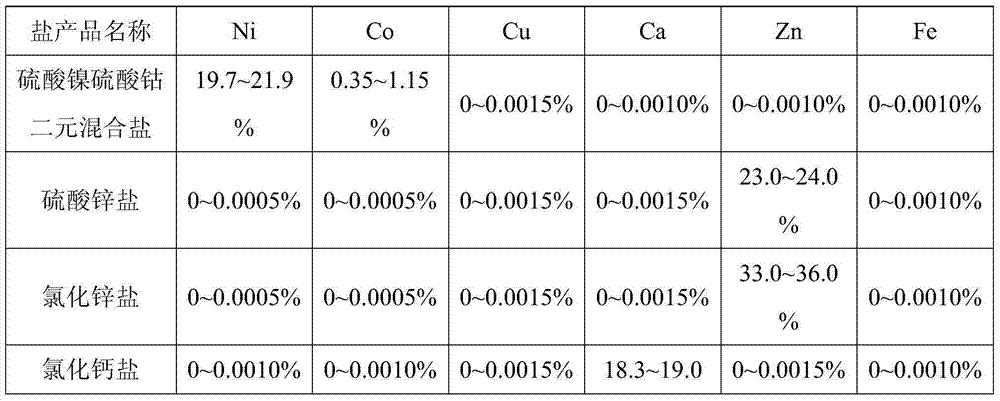

Method for recovering valuable metal from waste nickel-zinc battery

ActiveCN103794833AStrong choice flexibilityLow costWaste accumulators reclaimingProcess efficiency improvementPollutionCopper salt

The invention discloses a method for recovering valuable metal from a waste nickel-zinc battery. The method comprises the following steps: arranging the waste nickel-zinc battery into saturated salt water, and carrying out self-discharge treatment; crushing and screening the nickel-zinc battery subjected to self-discharging treatment to obtain oversize products and undersize products; carrying out magnetic separation on the oversize products to obtain iron residues and nonmagnetic substances; mixing the nonmagnetic substances with the undersize products, then leaching the mixture by sulfuric acid, and filtering to obtain leachate; treating the leachate by a chemical method, carrying out extraction separation to obtain binary mixed liquid of nickel sulfate and cobalt sulfate, zinc salt solution and calcium chloride solution, or binary mixed liquid of nickel sulfate and cobalt sulfate, zinc salt solution, copper salt solution and calcium chloride solution; respectively concentrating and crystallizing the obtained solution, and carrying out centrifugal separation the solution to complete the recovery of the valuable metal. According to the method, secondary pollution to the environment is avoided, the technological process is short, the resource recovery and utilization rate is high, the technical product selection flexibility is high, the cost is low and economical benefits are relatively high.

Owner:HUNAN BRUNP RECYCLING TECH +1

Method and system for recycling hazardous lead solid waste

ActiveCN103071668ASolve the pollution of the environmentSimple structureSievingScreeningElectrolysisResource recovery

The invention belongs to a method and a system for recycling hazardous lead solid waste. The method comprises the steps that the hazardous lead solid waste generated in a plate separation and brushing process of storage battery manufacturing is collected; lead alloy components, applications and quantity of the hazardous lead solid waste are recorded definitely; the hazardous lead solid waste is separated, subjected to impurity removal and purified in a sealed environment to form waste lead powder; the obtained waste lead powder is labeled according to the lead alloy components, the applications and the quantity, classified and stored; the stored waste lead powder with the identical lead alloy components and the applications is taken, and mixed with lead powder ground by electrolyzing lead; a ratio of the weight of the added waste lead powder to that of the lead powder ground by electrolyzing lead is (10-20):100; and a mixture is placed in a mixer, stirred uniformly and recycled. The system comprises a lead powder conveyor, a lifting conveyor and an electromagnetic sieve separator. The method and the system can automatically separate and recycle the hazardous lead solid waste, and can effectively solve the problem that the hazardous lead solid waste pollutes an environment, and have the advantages of simple structure, low recycling cost, high resource recycling ratio, and good energy saving and environmental protection effects.

Owner:江苏超威电源有限公司

Dry-mixed plastering mortar of replacing part of fly ash with stone flour

InactiveCN105669129AWide variety of sourcesReduce manufacturing costSolid waste managementResource recoveryEconomic benefits

The invention discloses dry-mixed plastering mortar of replacing part of fly ash with stone flour. The dry-mixed plastering mortar is prepared from the following raw materials: 750-800 kg of tailings aggregate, 120-160 kg of cement, 40-65 kg of fly ash, 45-70 kg of stone flour, 4-6 kg of a water reducer and 20-50 kg of an additive. The tailings aggregate is prepared by the use of mine tailings, and the sources are wide. In addition, the stone flour used in the invention is stone flour generated during machine-made sand making process of stone waste generated during production of the tailings aggregate. The stone flour generated during production of the tailings aggregate is fully utilized to replace part of fly ash. Resources recovery reutilization rate is high, energy is saved and emission is reduced. Production cost of the dry-mixed mortar is greatly reduced, and the economic benefit is high.

Owner:NANTONG TIEYUE BUILDING MATERIAL TECH CO LTD

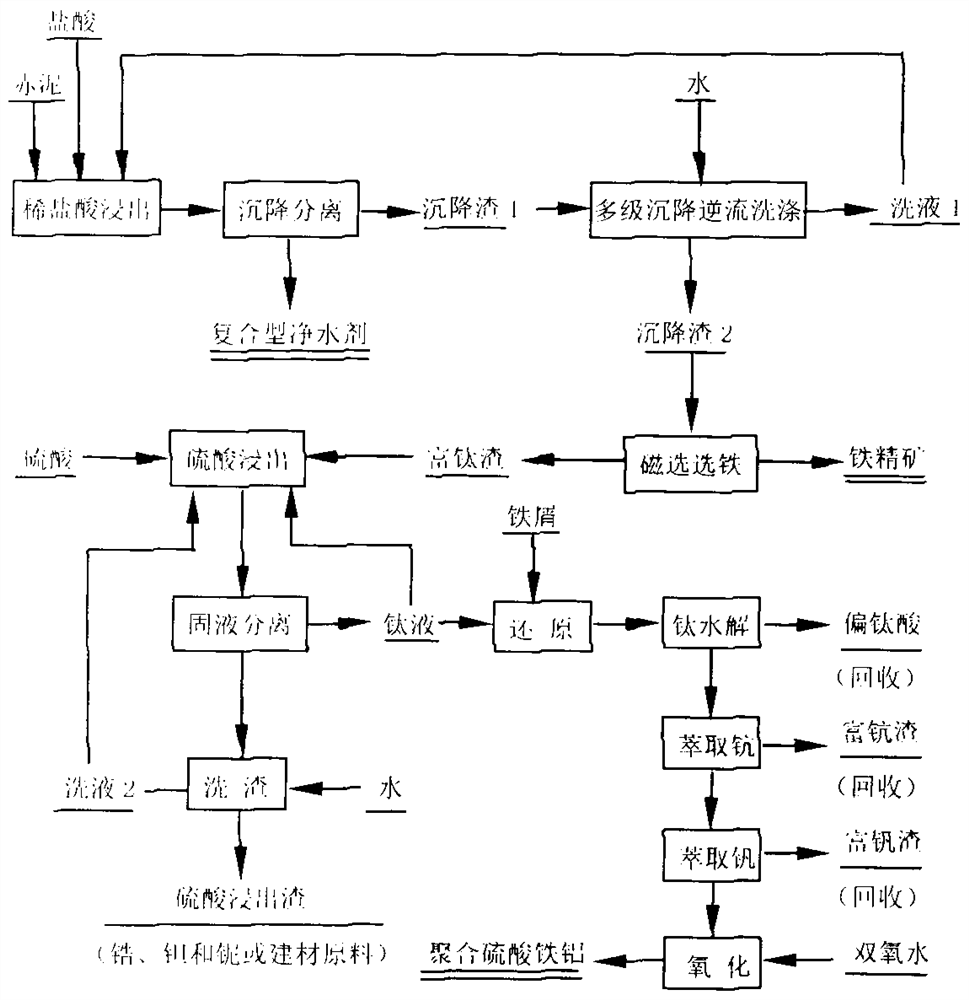

Efficient resource utilization method of red mud

PendingCN112011691AEasy to separateReduce production efficiencyProcess efficiency improvementEnvironmental geologyNiobium

The invention discloses an efficient resource utilization method of red mud. The red mud is leached out with diluted hydrochloric acid; the obtained ore pulp is separated with a thickener (or an ore washing tank); overflow (containing suspended solids, namely activated soil) at the upper part is used as a composite water purifying agent product; settling slag at the lower part is subjected to multi-stage thickener (or the ore washing tank) countercurrent washing with the diluted hydrochloric acid having a pH value of 0.5-1; washing liquid is used for diluting concentrated hydrochloric acid andthen used as leaching initial acid; iron ore concentrate products and titanium-rich slag are produced through magnetic separation of the settling slag of the last stage; the titanium-rich slag is circularly leached through sulfuric acid; titanium-rich liquid and sulfuric acid leaching slag are obtained; titanium, scandium and vanadium are recycled from the titanium-rich liquid; residual liquid isused for producing polymeric ferric sulfate aluminum products; and the sulfuric acid leaching slag serves as zirconium, tantalum and niobium extraction raw materials or building material raw materials. The method is simple in production process, low in energy consumption and good in production environment, no waste water or waste residues are discharged in the production process, red mud resources are completely consumed, and remarkable economic benefits can be obtained.

Owner:何耀

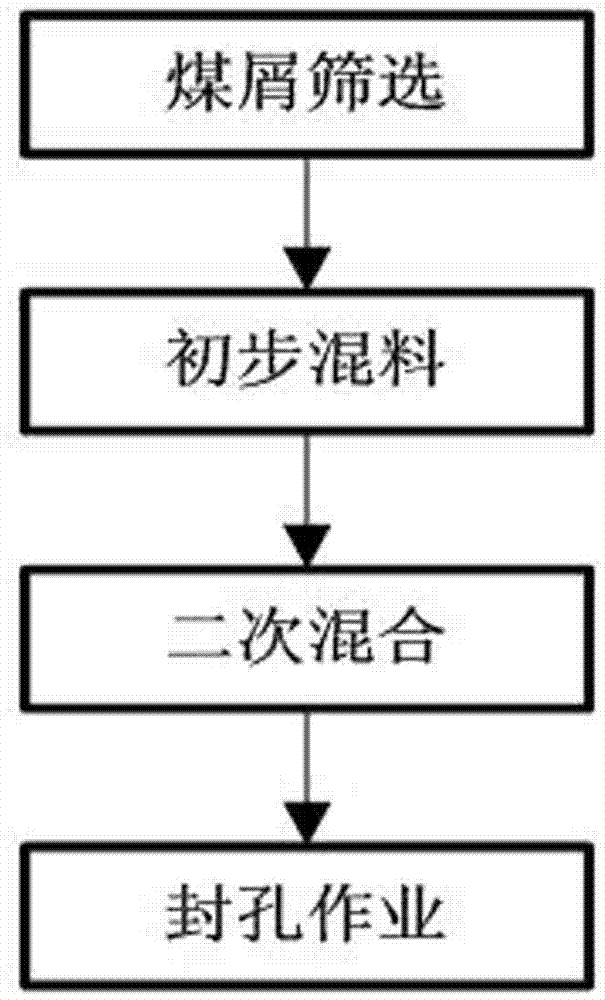

Mining coal dust based hole-sealing and grouting material, and preparation hole-sealing process

InactiveCN107011881AImprove bindingImprove compactionDrilling compositionSealing/packingAdhesiveWhole body

The invention relates to a mining coal dust based hole-sealing and grouting material. The mining coal dust based hole-sealing and grouting material consists of the following materials in parts by mass: 15.87 to 28.65 percent of coal dust, 28.65 to 31.75 percent of an adhesive, 0.48 to 0.93 percent of a crosslinking agent, 3.17 to 6.17 percent of an enhancer, 0.32 to 0.62 percent of an expanding agent, 0.14 to 0.63 percent of a flexibilizer, 0.16 to 0.57 percent of a coupling agent and the balance of water. The preparation hole-sealing process comprises four steps of screening the coal dust, mixing the materials primarily, mixing for the second time and performing hole-sealing operation. According to the grouting material, on one hand, the whole combining property of the structure, the compaction, blockage and leak blocking effects, and the weather tolerance of the grouting material are effectively improved, and on the other hand, the pulverized coal at the periphery of a drill hole can adhere to each other again to form a continuous whole body, the drilling stability is improved, the construction process of the drilling hole-sealing construction is greatly retarded while the dust pollution in the drilling construction operation field can be reduced, on-site construction operation is facilitated, the flexibility and the reliability of the drilling hole-sealing operation are improved, and wide application prospect is achieved.

Owner:HENAN POLYTECHNIC UNIV

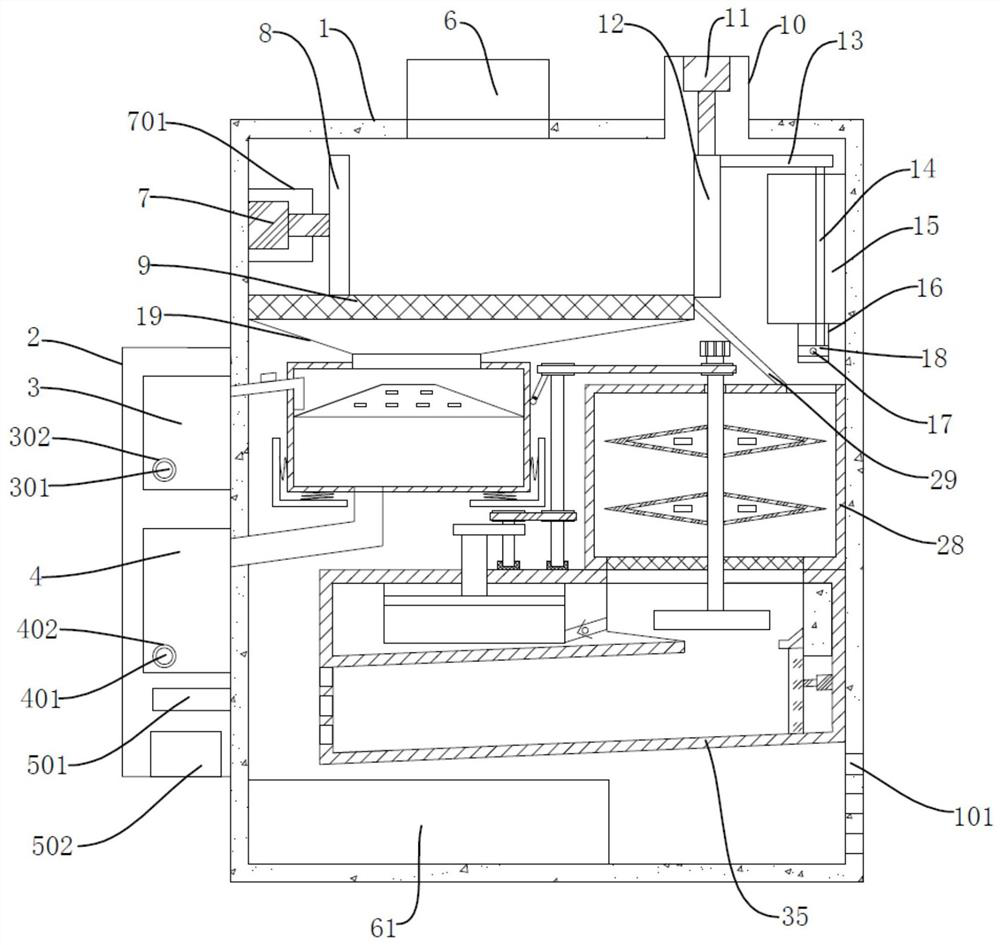

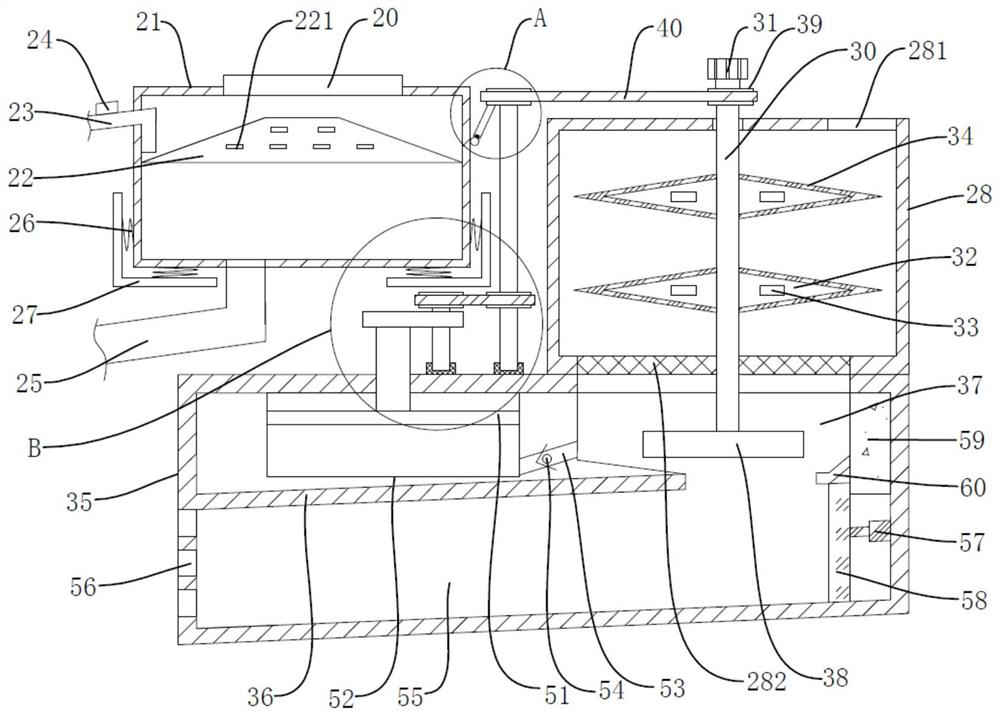

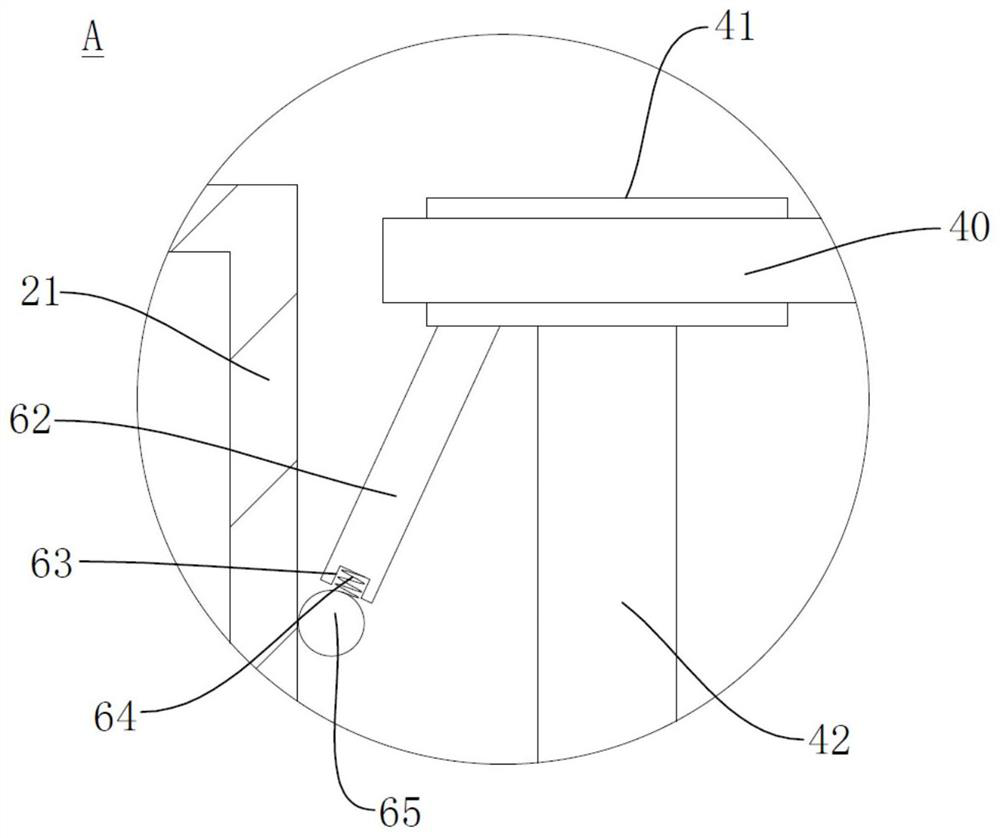

Kitchen garbage recycling treatment device

ActiveCN112222160AHigh recycling rate of resourcesEasy to useTransportation and packagingSolid waste disposalLeavening agentProcess engineering

The invention discloses kitchen garbage recycling treatment device. The kitchen garbage recycling treatment device comprises a box body. An oil collecting tank, a water collecting tank, a processor and a control panel are fixedly arranged in a side frame. A baffle is fixedly arranged at the output end of a second hydraulic cylinder, and a first push rod is fixedly connected to the non-center position of a circular blocking plate. An oil collecting disc is fixedly arranged in an inner cavity of an oil-water separation tank. A smashing box is fixedly arranged in an inner cavity of the box body,an ultraviolet lamp tube is embedded in a transparent cone, and metal cutting knife edges are fixedly arranged on the edges of the transparent cone. A pressing plate is movably arranged in a curing agent box, and a plurality of extrusion holes are formed in the side wall, located in a solidification cavity, of the operation box. The kitchen waste recycling treatment device is provided. Solid-liquid separation can be conducted at first and then oil-water separation is performed, the flotation effect is better, addition of a leavening agent and a curing agent can be achieved in a linkage mannerin the using process, manual operation is omitted, the function is concentrated, the structure is simple and device is very worthy of popularization.

Owner:北京申城生物科技集团有限公司

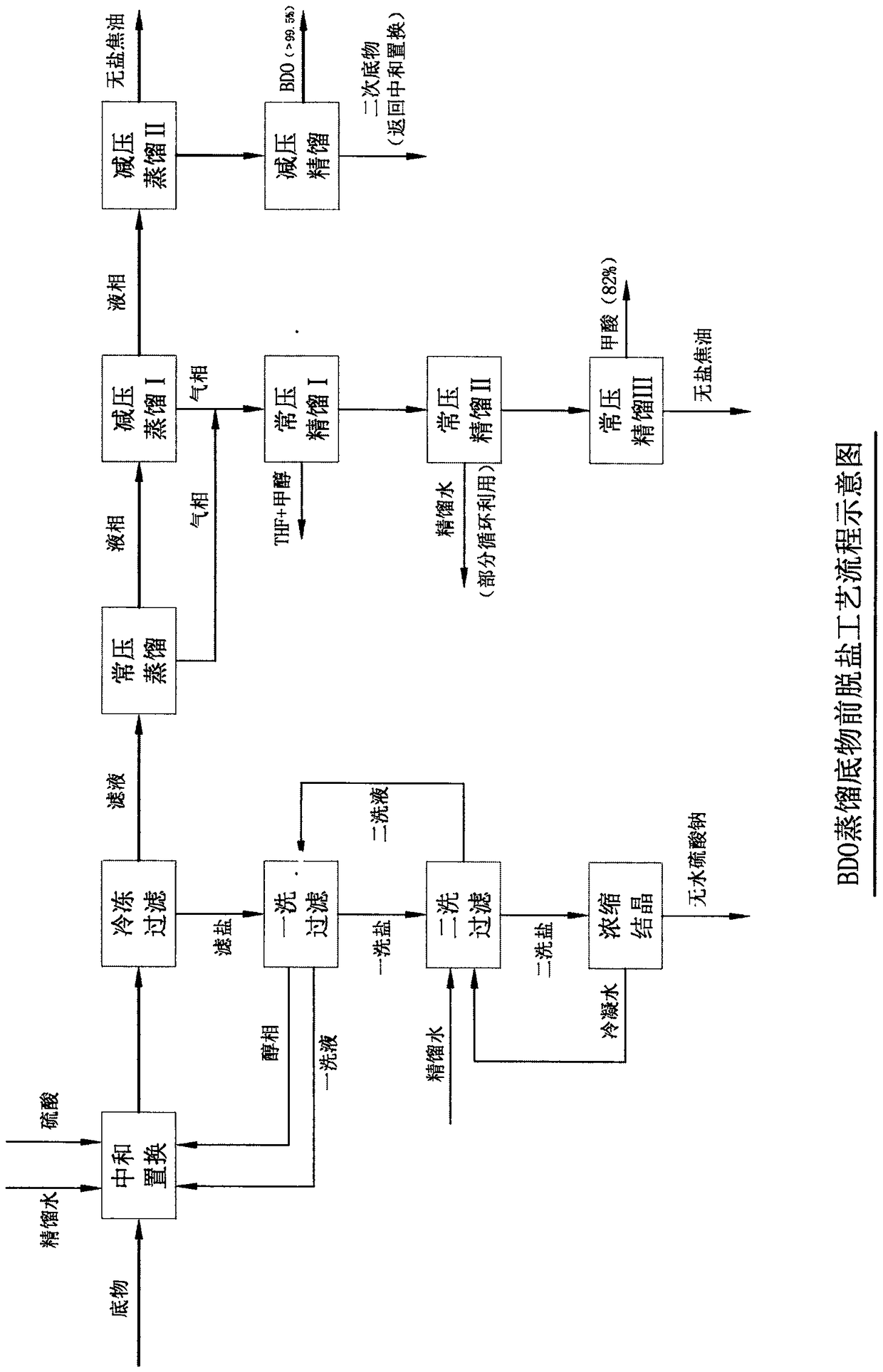

Continuous desalination technology before steaming for resource utilization of BDO device waste liquid

InactiveCN109336736AHigh recovery rateImprove product added valuePreparation from carboxylic acid saltsOrganic compound preparationSalt freeResource utilization

The invention discloses a continuous desalination technology before steaming for resource utilization of BDO device waste liquid, and belongs to the technical field of organic waste liquid recycling in industrial production. According to the technology, the BDO device waste liquid is mixed with return salt-leaching water, and sodium formate in the mixed liquid is completely displaced with sodium sulfate through neutralization and displacement of sulfuric acid; a displacement solution is frozen and filtered, and filter salt is washed and concentrated twice to obtain anhydrous sodium sulfate; filter liquor is subjected to atmospheric concentration and first-stage reduced pressure membrane scraping distillation, light components in the filter liquor is steamed out, and low boiling alcohol, water and a formic acid water solution are separated from the light components through third-stage rectification; a remaining solution after the first-stage reduced pressure membrane scraping distillation is subjected to second-stage reduced pressure membrane scarping distillation, a BDO product with the content of 99.5% or more than 99.5% is obtained after rectification of the distilled coarse BDO,and a distillation substrate is salt-free tar which can be used for oil burning boiler byproduct steam. The technology has the advantages that various products can be recycled, the product recycle rate is high, waste liquid resources are utilized sufficiently, the environmental protection is facilitated, the recycle cost is low, the applicable range of the technology is wide, the technology is convenient for popularization and application and the like.

Owner:CHONGQING UNIV

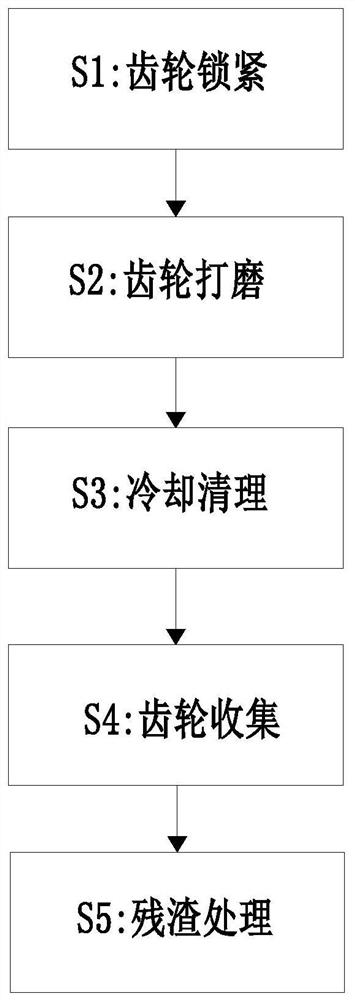

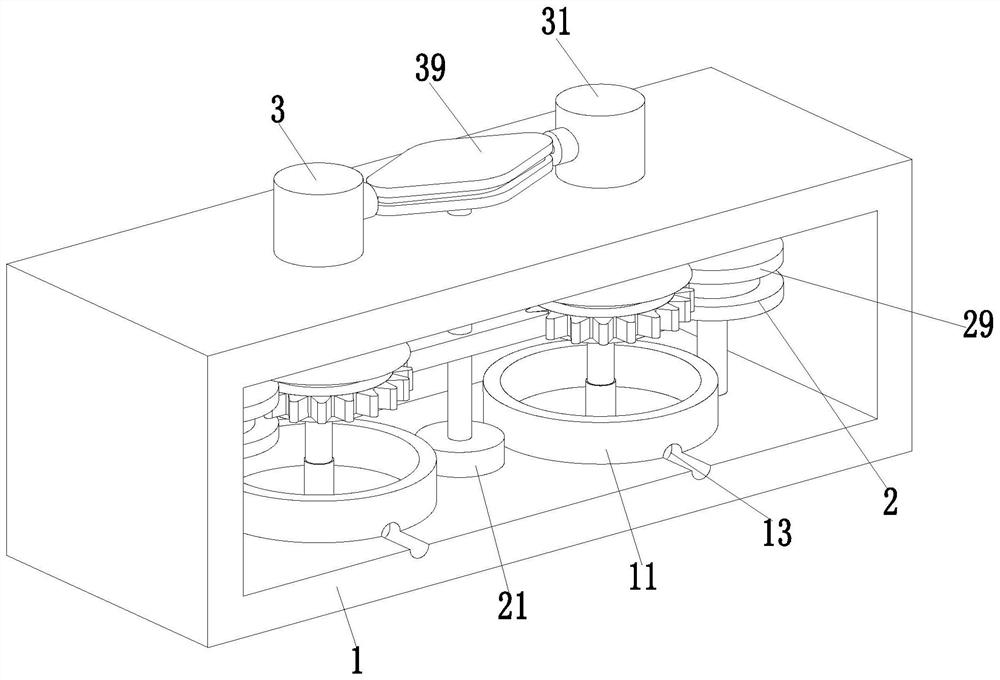

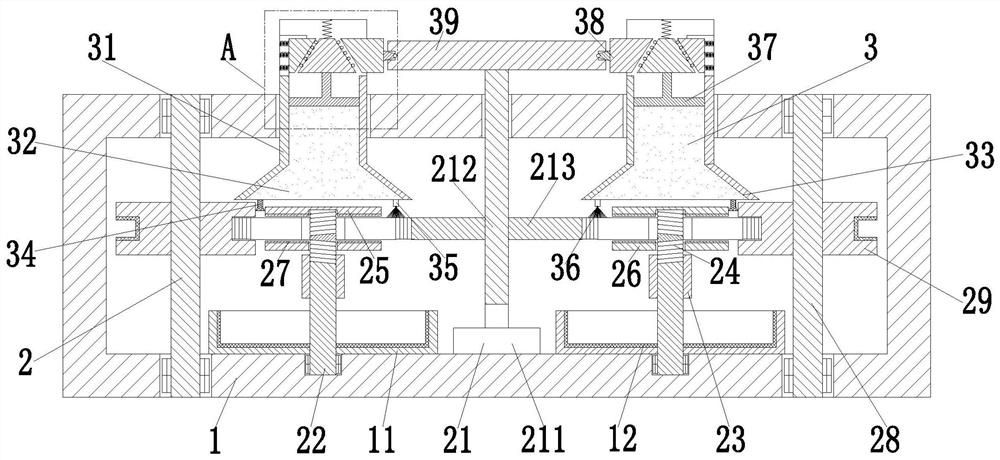

Precision gear manufacturing process

InactiveCN112518044AImprove grinding efficiencyImprove finenessGear-cutting machinesMaintainance and safety accessoriesGear driveGear wheel

The invention relates to a precision gear manufacturing process. A precision gear manufacturing device is used in the process. The precision gear manufacturing device comprises a supporting frame, a polishing mechanism and a cooling and clearing mechanism, the section of the supporting frame is of a rectangular structure, the polishing mechanism is installed in the middle of the lower end surfaceof the supporting frame, and the cooling and clearing mechanism is connected to the polishing mechanism. The cooling and clearing mechanism is installed on the supporting frame. The problems that an existing device cannot effectively polish complex notches of a gear groove, surface burrs of gear teeth cannot be removed effectively and the transmission precision of a gear is influenced can be solved. The problems that when the existing device polishes the gear, the gear cannot be cooled in time, as a result, due to too high temperature of the surface of the gear, the gear teeth are deformed, iron scrap residues generated by polishing cannot be cleared in time, as a result, the iron scrap residues adhere to the gear groove and the surfaces of the gear teeth again at high temperature, and thepolishing efficiency of the gear and precision of gear transmission are influenced can also be solved.

Owner:南京旺财办公用品有限公司

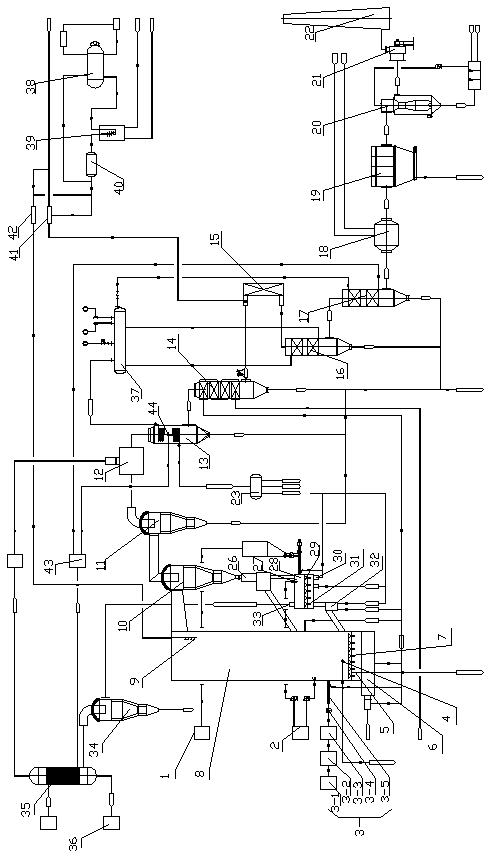

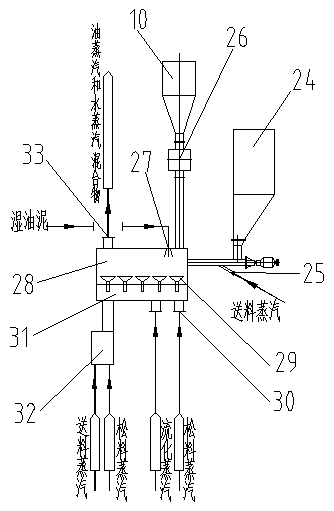

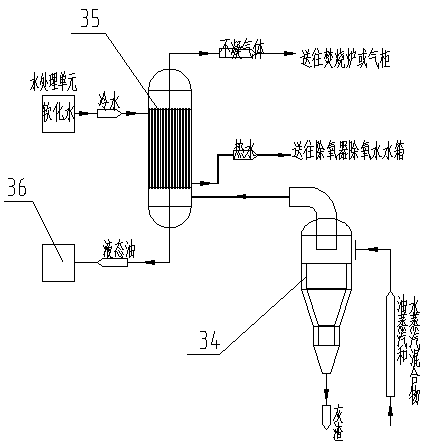

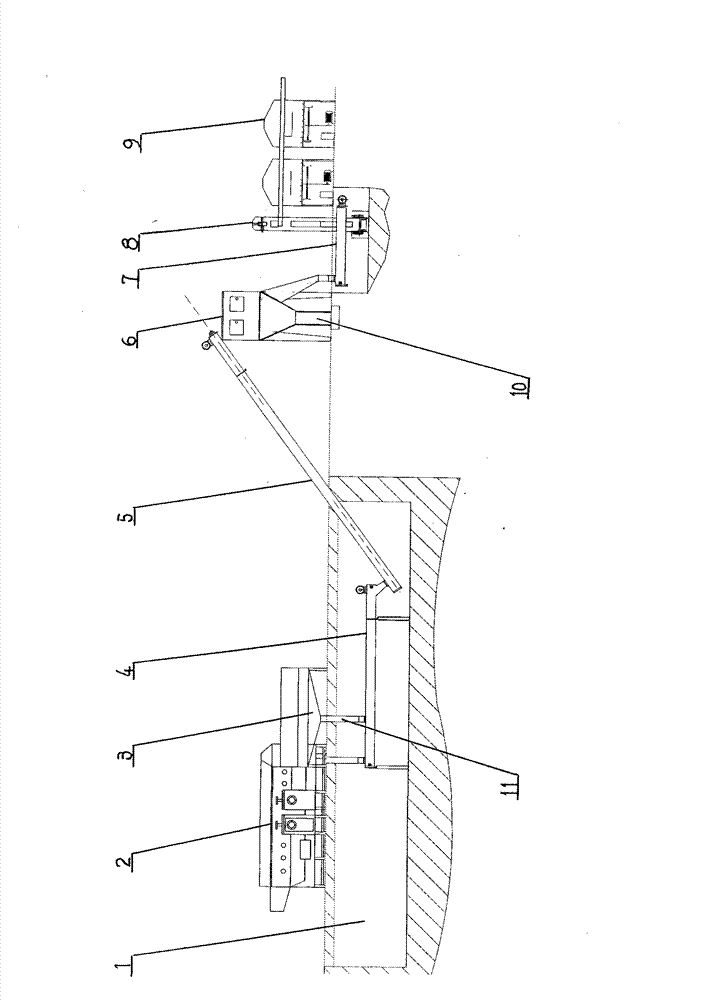

Environmentally-friendly energy-saving type recycling treatment system for oil sludge circulating fluidized bed

PendingCN109628150AHarmlessAchieve reductionEnergy inputGasification processes detailsAir preheaterCyclone

The invention discloses an environmentally- friendly energy-saving type recycling treatment system for an oil sludge circulating fluidized bed, and relates to the field of environmental protection, energy saving and waste recycling. Oil sludge is treated and then gets harmless, reduced and recycled, and liquid state fuel oil and combustible gas are recycled and merged into a user pipe network. Thesystem mainly comprises a circulating fluidized bed incinerator, two-level gas-solid cyclone separation devices, a flue gas secondary combustion room, steam superheater, an air preheater, a waste heat boiler evaporator, a waste heat boiler economizer, a glue gas mixer, a cloth bag dust collector, a deacidifying washing tower, an induced draft fan, a chimney, a gasification reactor, a gas-solid separator, a condenser and a gas holder. Gas state fuel and liquid state fuel oil with high quality are obtained through oil sludge pretreatment, combustion, gas-solid cyclone separation and condensingdehydration, meanwhile, waste heat of the system is recycled for gasification, and ash is recycled. All components of the oil sludge are separated thoroughly, the rate of resource recycling is high, equipment operates stably and reliably and occupies small land, and the process of oil sludge treatment is simple.

Owner:大连科林能源工程技术开发有限公司

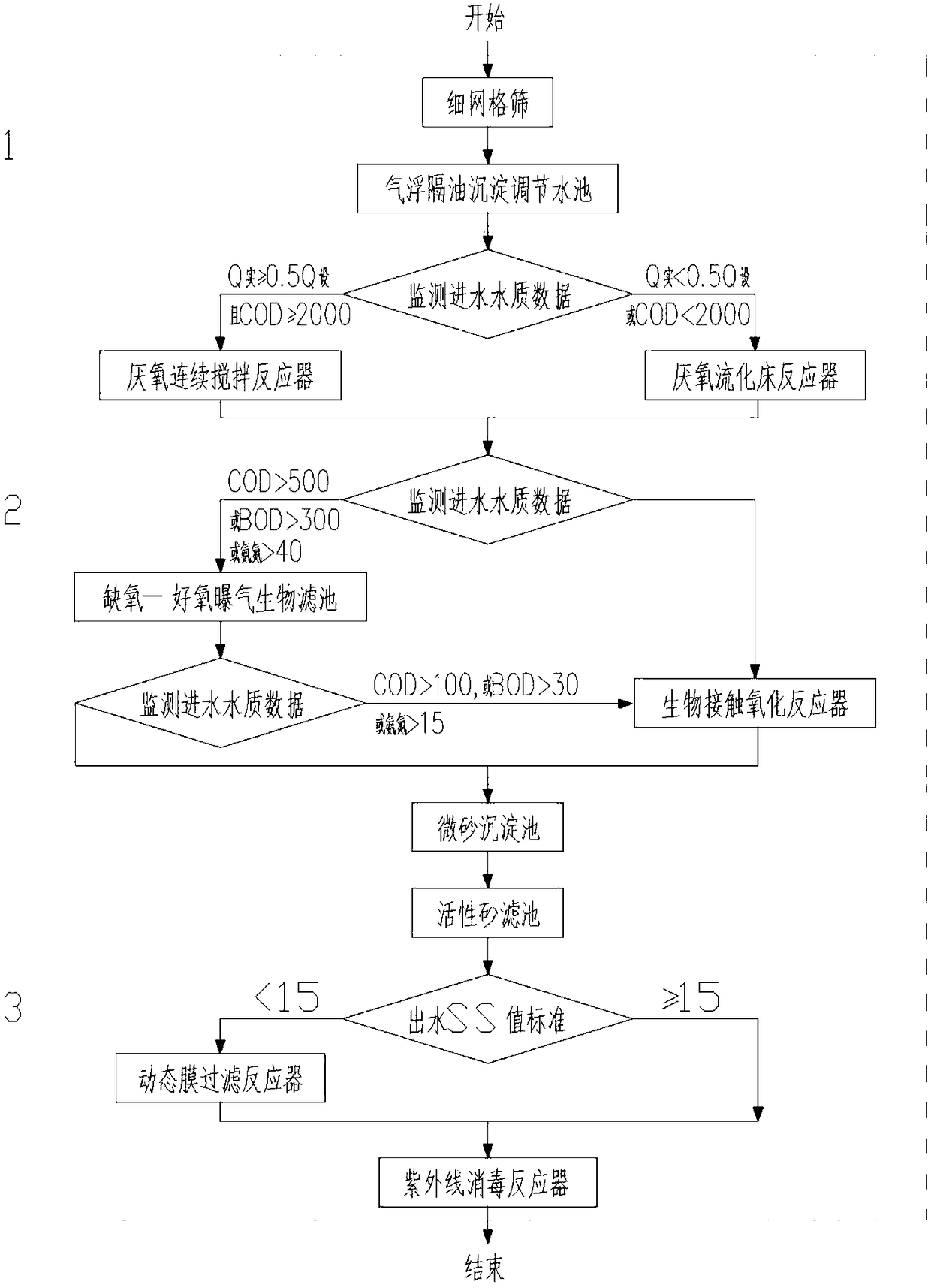

Modular integrated system and technology for treating non-fermented bean product production wastewater

ActiveCN108083579AReduce operating energy consumption and costsSmall footprintFatty/oily/floating substances removal devicesTreatment using aerobic processesOil separationHigh concentration

The invention relates to a modular integrated system and technology for treating non-fermented bean product production wastewater. The modular integrated system comprises a first-stage pretreatment module, a second-stage biochemical module and a three-stage deep treatment module, wherein the first-stage pretreatment module is provided with a fine mesh sieve and an air flotation oil separation sedimentation adjusting pool to remove suspended solids and oil slick and adjust water flow and water quality; the second-stage biochemical module is provided with an anaerobic unit and an aerobic unit toremove main pollutants in wastewater; the three-stage deep treatment module is provided with a micro sand sedimentation tank, an activated sand filter, a dynamic membrane filtration system and an ultraviolet disinfection reactor to remove SS and realize disinfection. Technology integration and parameter design are performed for high-concentration non-fermented bean product production wastewater,and different units are selected to be operated according to the inlet water quality condition. The technology has the characteristics of being flexible, efficient, convenient, intelligent and the like, and economical, effective and stable operation of wastewater treatment facilities can be guaranteed.

Owner:植物肉(杭州)健康科技有限公司

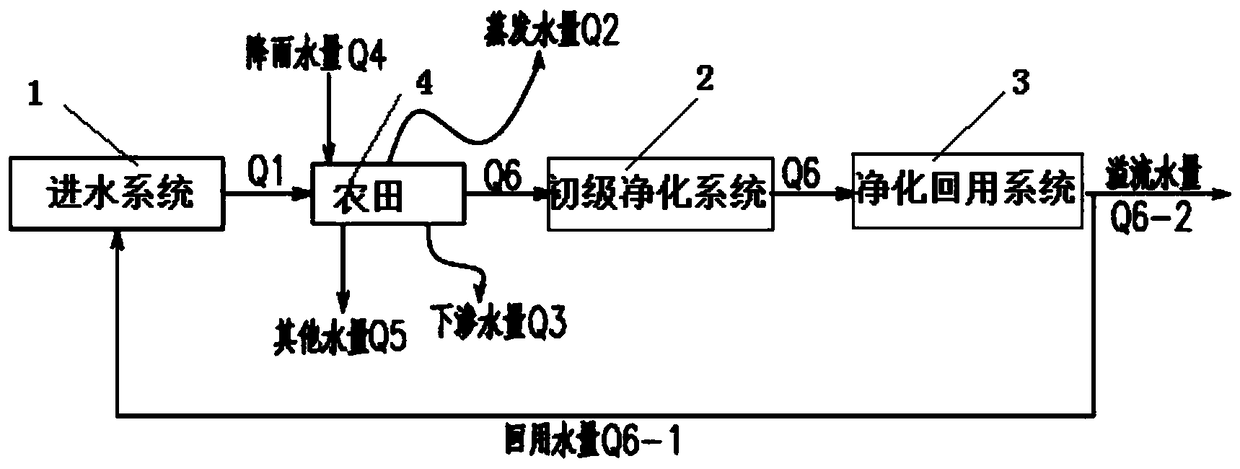

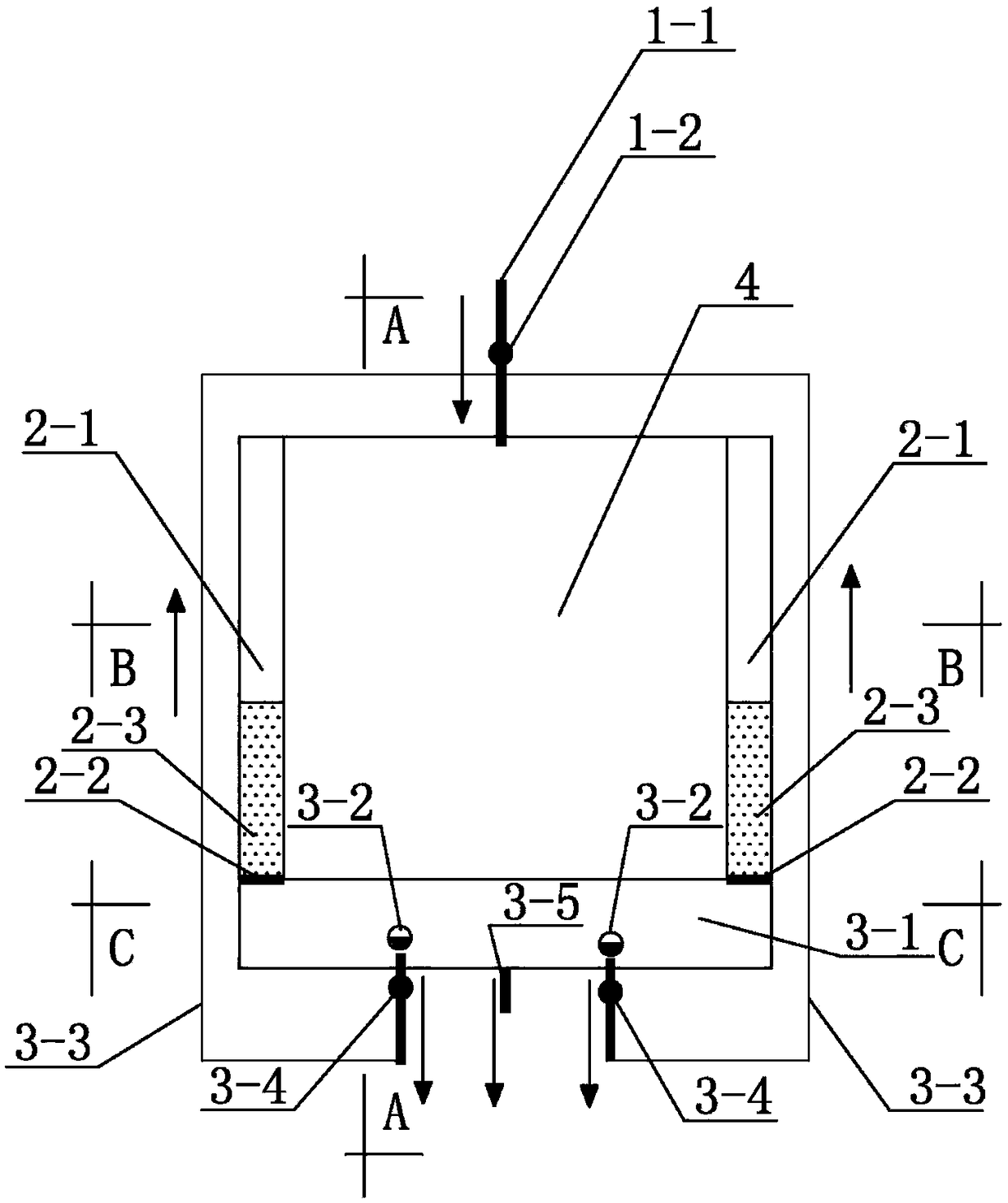

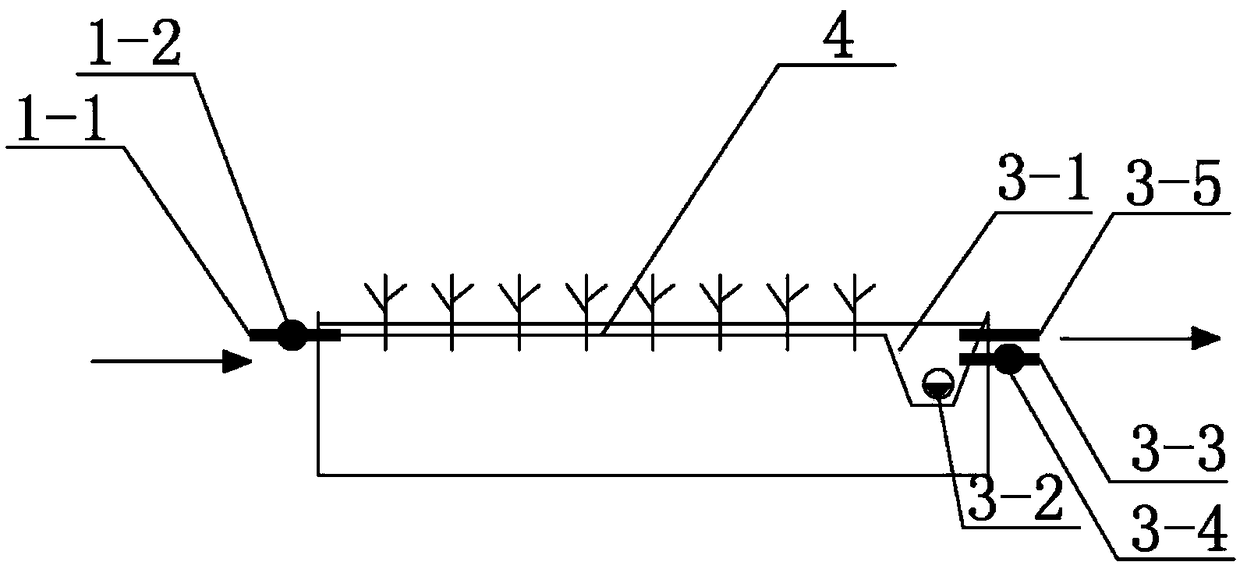

Farmland water pollution control and reuse system and operation method thereof

InactiveCN109319933AEasy to implementReduce land occupationBiological water/sewage treatmentEcological environmentWater source

The invention discloses a farmland water pollution control and reuse system and an operation method thereof. The system comprises a water inlet system, a primary purifying system, a purifying and reusing system and a farmland which are sequentially connected, wherein an output end of the purifying and reusing system is connected with an input end of the water inlet system. The water inlet system is arranged on one side of the farmland, and the purifying and reusing system and the water inlet system are oppositely arranged; the primary purifying system is arranged on the two sides of the farmland. A water resource enters the farmland through the water inlet system for crop irrigation utilization, and at a crop growth stage, chemical fertilizer and pesticide are applied; an unused agricultural non-point source flows into the primary purifying system for purification; effluent enters the purifying and reusing system, and the agricultural non-point source is further purified in a purifyingditch, and flows back to the water inlet system for repeated use. According to the farmland water pollution control and reuse system and the operation method thereof, the farmland water reuse rate ishigh, nitrogen and phosphorus non-point source loss is little, nitrogen and phosphorus in farmland water are fully used, and pollution discharge is reduced. Investment is little, and the running costis low; a technology is simple to operate, a treatment effect is good, and ecological environment benefits are good.

Owner:HOHAI UNIV

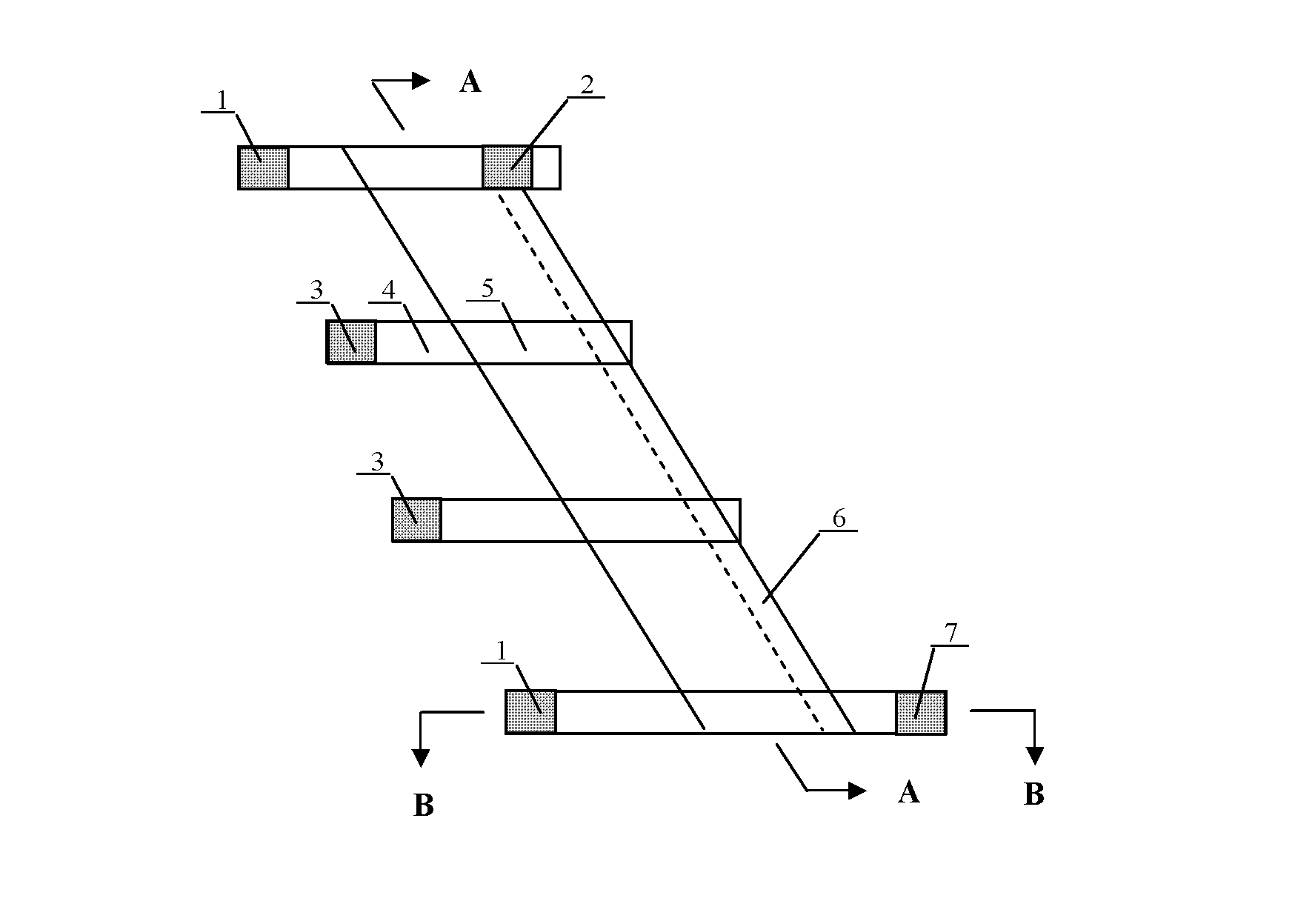

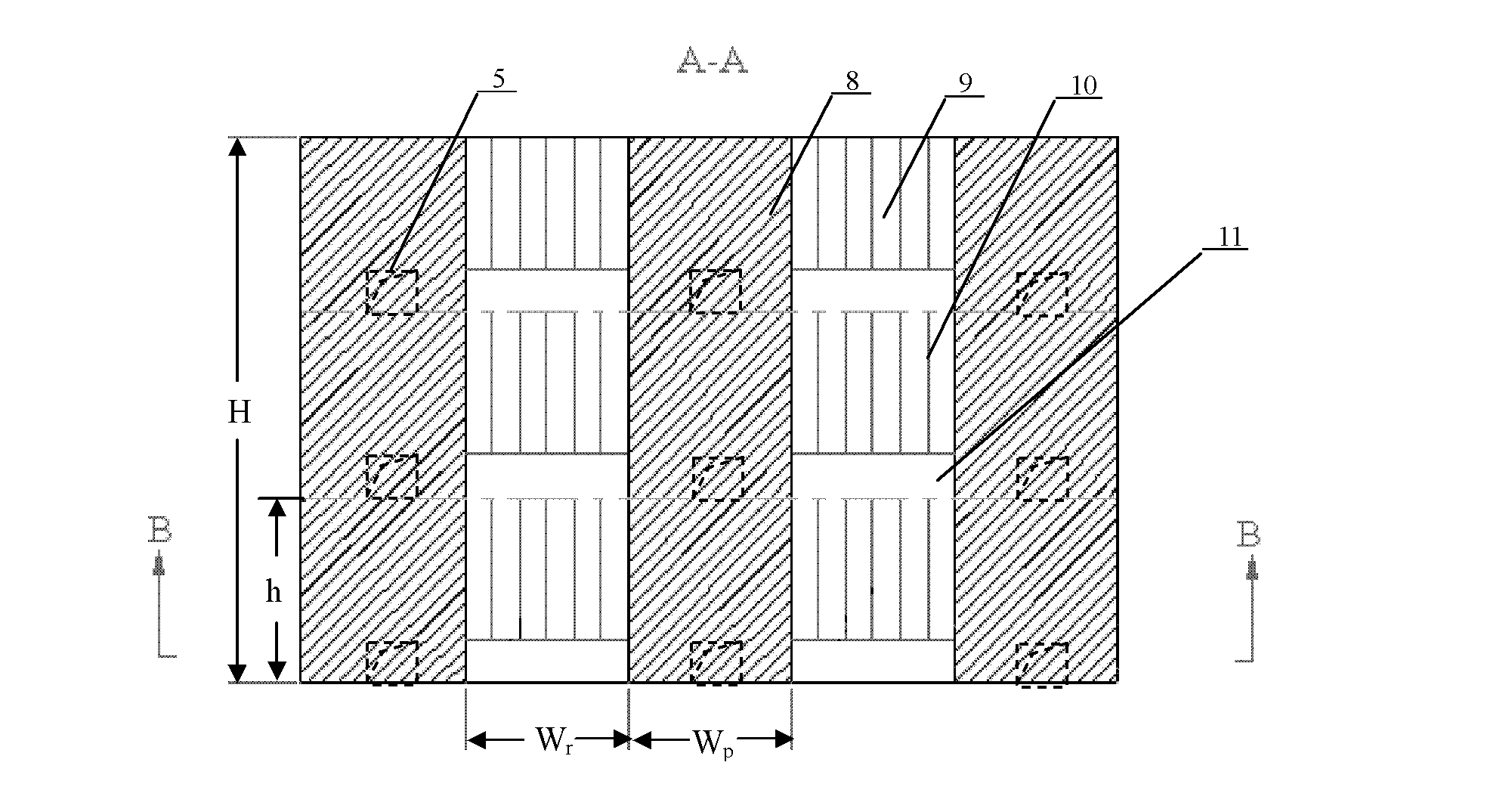

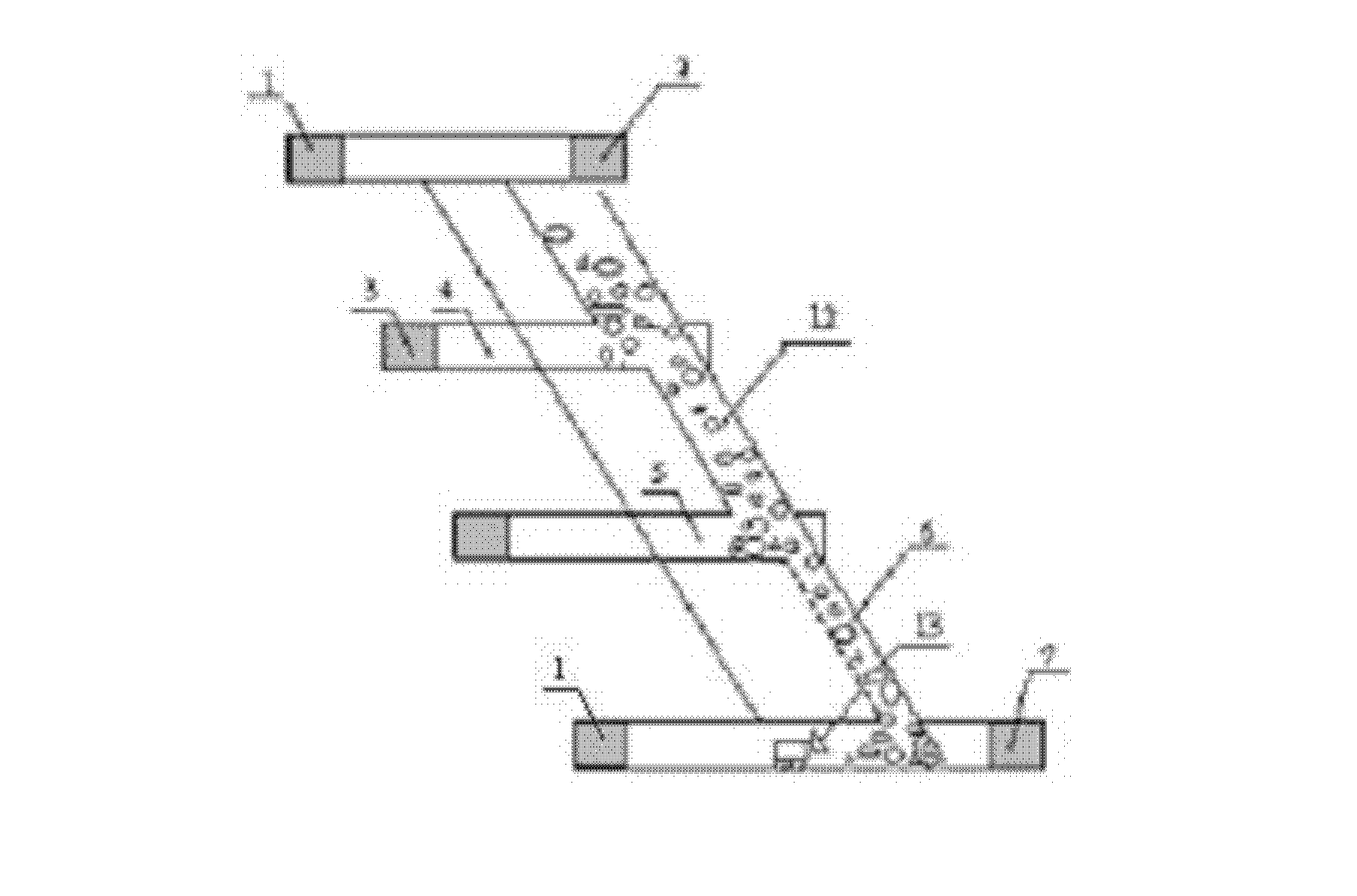

Nearly horizontal narrow vein panel mining method

InactiveCN109577984AImprove the efficiency of mining operationsHigh recycling rate of resourcesUnderground miningSurface miningVeinMineralogy

The invention belongs to the field of mining technology and particularly relates to a nearly horizontal narrow vein panel mining method. The early horizontal narrow vein panel mining method comprisespanel division, panel main haulage roadway arrangement, mining site arrangement, pillar preforming, drilling, mining and pillar recovery. By means of shallow hole ore breakdown and by combining scrapers and small carry-scrapers for ore extraction, the nearly horizontal narrow vein panel mining method can greatly improve the mining efficiency. Meanwhile, by replacing pillars with flexible box supports to recover all the pillars, the nearly horizontal narrow vein panel mining method can greatly improv the resource recycling rate. The nearly horizontal narrow vein panel mining method is applicable nearly horizontal narrow veins with a recovery thickness smaller than 0.8 m and an inclination of 0-5 degrees.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method for treating waste sludge in wiring board plant into resources

InactiveCN1669959AReduce processing costsEasy to handleSludge treatment by thermal conditioningWater/sewage treatmentSludgeEngineering

The invention provides a resources processing art for processing the waste sludge of wiring board factories, which belongs to environmental protection technical field and comprises the following steps: slurrying the sludge, heating to activate, dissolving with dilute sulphuric acid on the condition of controlling temperature and controlling PH and sufficient stirring to make the copper ion of the sludge dissolve and get into the liquid phase while the iron ion insolubilize and stay in the solid phase, then proceeding liquid-solid separation, concentration producing the liquid phase to get the crude copper sulfate and recrystallizing to get the copper sulfate, poaching the solid phase and adding hydrochloric acid or sulphuric acid to produce ferric chloride or polyferric sulfate used as a flocculant in the wiring board factory.

Owner:HUIZHOU DAYAWAN HUILU ENVIRONMENT PROTECTION SERVICE +1

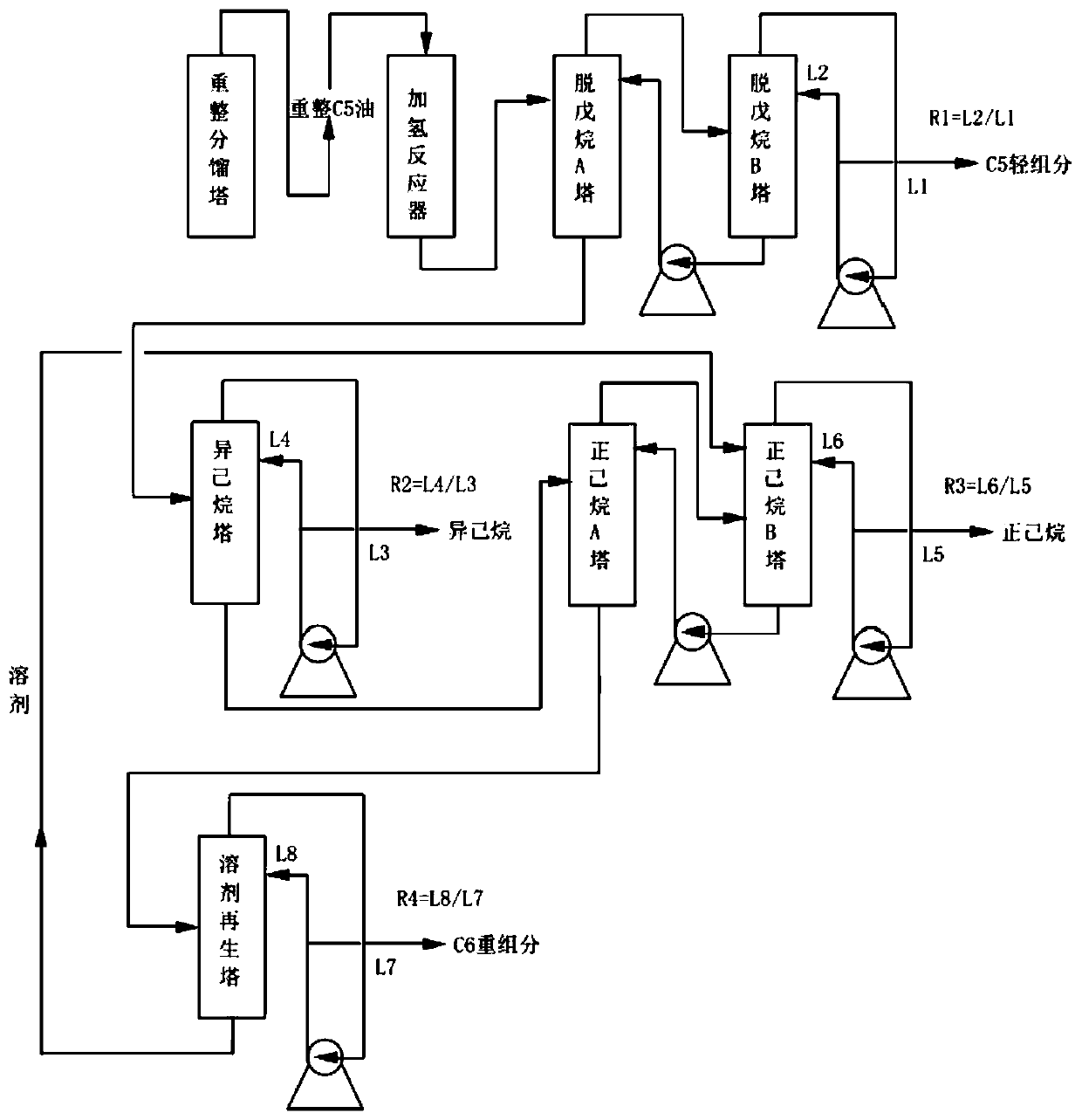

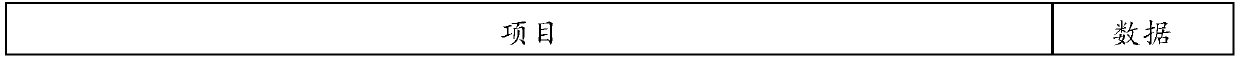

Preparation method of high purity n-hexane

ActiveCN110229042AEasy to prepareSimple processDistillation purification/separationHydrocarbonsLiquid productIsohexanes

The invention provides a preparation method of high purity n-hexane. The method includes the steps of: a) subjecting reformate C5 oil and hydrogen to hydrogenation reaction under the action of a hydrogenation catalyst, and conducting C5 light component separation on a reaction liquid product to obtain a remaining heavy component; b) subjecting the remaining heavy component to isohexane separationto obtain a isohexane removed heavy component; and c) conducting n-hexane separation on the isohexane removed heavy component obtained in step b), thus obtaining high purity n-hexane. Compared with the prior art, the preparation method provided by the invention takes reformate C5 oil as the raw material, and adopts a specific process to prepare the high purity n-hexane. The preparation method provided by the invention has the advantages of simple process, low cost, no pollution, and long-term stable operation. The prepared high purity n-hexane has purity of 99% or above, and the product quality is stable.

Owner:SHANDONG JINGBO PETROCHEM

Vacuum pyrolysis test device of wasted electronic circuit board

InactiveCN101992203BIngenious designImprove performanceSolid waste disposalPlastic recyclingAcquisition apparatusResource recovery

The invention discloses a vacuum pyrolysis test device of a wasted electronic circuit board, which comprises a pyrolysis furnace, a condenser, a vacuum gauge, a vacuum acquisition apparatus, a medium circulating box and a tail gas adsorption tower. The pyrolysis furnace is provided with a charging chamber and a heating furnace chamber, which are sealingly isolated. The top of the charging chamberis provided with an insulation cover and enclosed by resistance heating tapes. The charging chamber is communicated with the condenser through a channel. The vacuum acquisition apparatus which keeps the charging chamber, the heating furnace chamber, the condenser and the channel in a vacuum state in the prolysis process of the wasted electronic circuit board is communicated with all apparatuses or positions in the heating furnace chamber, the charging chamber, the condenser and the channel. The vacuum gauge which measures the vacuum degree of the charging chamber, the heating furnace chamber,the condenser and the channel in real time is arranged on at least one of apparatuses or positions in the heating furnace chamber. The medium circulating box is respectively connected with the vacuumacquisition apparatus and the tail gas adsorption tower through a pipeline. The test device is compact in structure, low in investment, high in comprehensive resource recovery rate, good in economic benefits and free from pollution.

Owner:GUANGDONG UNIV OF TECH

Automatic separating and recycling method of lead hanging stripes and system of the same

ActiveCN103111423ASolve the pollution of the environmentSimple structureSievingScreeningResource recoveryAutomatic testing

The invention belongs to an automatic separating and recycling method of lead hanging stripes and a system of the automatic separating and recycling method of the lead hanging stripes. The method comprises that battery electrode plates are manufactured in a batching mode, and components, usage, quantity of lead adopted in the manufacturing progress are explicitly recorded; lead hanging strip waste and lead powder which are produced in the manufacturing process of the same batch of the battery electrode plates are collected in a sealing mode; the lead hanging strip waste and the lead powder in the same batch are separated in a sealing mode; the separated lead hanging strip waste in the same batch is sent to a plate casting machine in a sealing mode, is again casted into lead plates and is reused according to components of the lead plates; the separated lead powder in the same batch is collected, purified and reused. The system mainly comprises a recycling conveyor, a lifting conveyor and a vibration separating machine. The automatic separating and recycling method of lead hanging stripes and the system of the automatic separating and recycling method of the lead hanging stripes can automatically separate and recycle the lead hanging strip waste and the lead powder and effectively solve the problem that the lead waste pollutes the environment, and have the advantages of being simple in structure, low in recycling cost, high in recycling efficiency of resources and good in energy-saving and environment-friendly effect.

Owner:江苏超威电源有限公司

Method for producing dietary fiber nutrient powder by using citrus peeling waste residue and citrus dietary fiber nutrient powder

ActiveCN102511789ALow lignin contentHigh recycling rate of resourcesDough treatmentFood preparationTrichoderma koningiiNutrient

The invention discloses a method for producing dietary fiber nutrient powder by using citrus peeling waste residue and the citrus dietary fiber nutrient powder prepared by the method. The method comprises the following steps of: mincing the citrus peeling waste residue, and regulating the water content to be 15 to 20 percent; treating for 30 to 60 minutes at the temperature of between 15 and 35 DEG C by adopting ultrasonic wave; regulating the pH value to be neutral by using NaOH and HAc; inoculating spore suspension of trichoderma koningii to the minced citrus peeling residue with regulated pH value, culturing at the temperature of between 26 and 30 DEG C, and fermenting for 2 to 3 days; performing extrusion, wherein the rotating speed of a screw of an extruder is controlled to be 90-130r / min, and the extrusion temperature is controlled to be 120-150 DEG C; and cooling and crushing the extruded granules, sieving with a sieve of 60 meshes, and thus obtaining the citrus dietary fiber nutrient powder. The invention has the advantages of simple steps, high resource recycling rate, good economic benefits, environment friendliness and capability of obtaining a product with high nutritional value.

Owner:HUNAN AGRI PRODS PROCESSING INST

Process for directly separating chalcopyrite from molybdenite through superconducting magnetic separation

InactiveCN111167599AAchieve benefitsHigh precisionHigh gradient magnetic separatorsChalcopyriteMagnetic separator

The invention discloses a process for directly separating chalcopyrite from molybdenite through superconducting magnetic separation, and aims at solving technical problems that a large number of inhibitors need to be used in existing copper-molybdenum separation of the chalcopyrite and the molybdenite, selectivity is poor, and severe pollution is easily caused to environment. A rough process of the technology comprises the steps that firstly, under a condition of low magnetic field intensity, a superconducting magnetic separator is used for carrying out superconducting low-intensity magnetic separation on mixed concentrate of the chalcopyrite and the molybdenite, and strong magnetic minerals are removed; and then under the condition of high magnetic field intensity, the superconducting magnetic separator is used for carrying out superconducting high-intensity magnetic separation, and realizing direct separation of the chalcopyrite and the molybdenite. According to the technology, a superconducting low-intensity magnetic separation-superconducting high-intensity magnetic separation combined technology is used in a breakthrough mode, separation precision and efficiency are greatly improved, and meanwhile, chemicalsdo not need to be added, a technological process is energy-saving and environmentally friendly, ecological and economic comprehensive benefits are achieved, a resourcerecycling rate is high, and separation of the chalcopyrite and the molybdenite is directly completed.

Owner:JIANGXI UNIV OF SCI & TECH

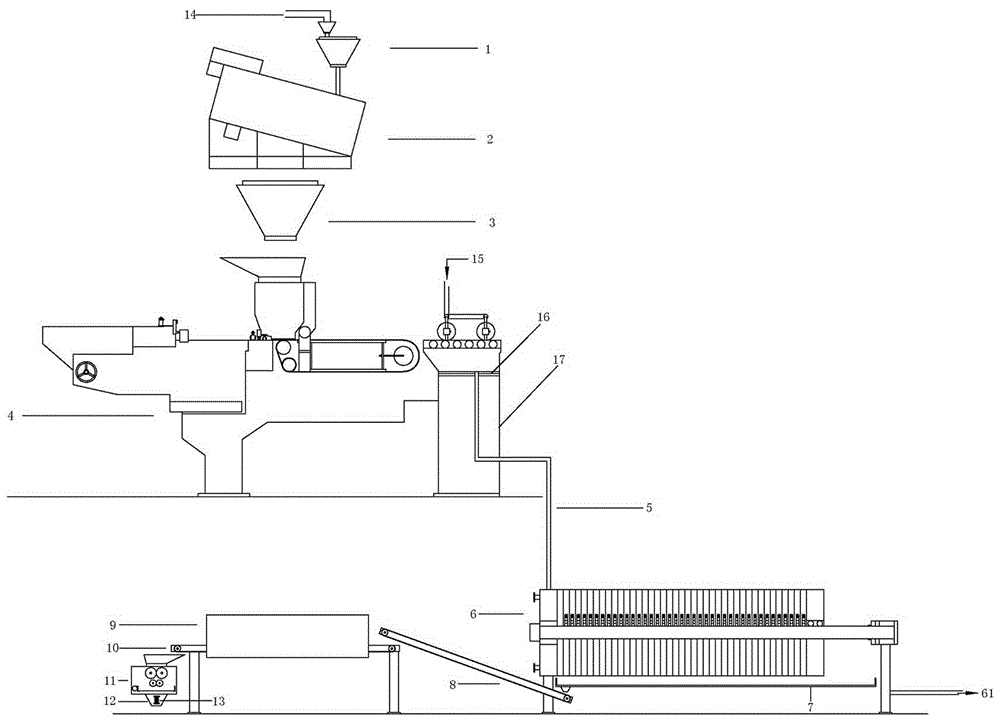

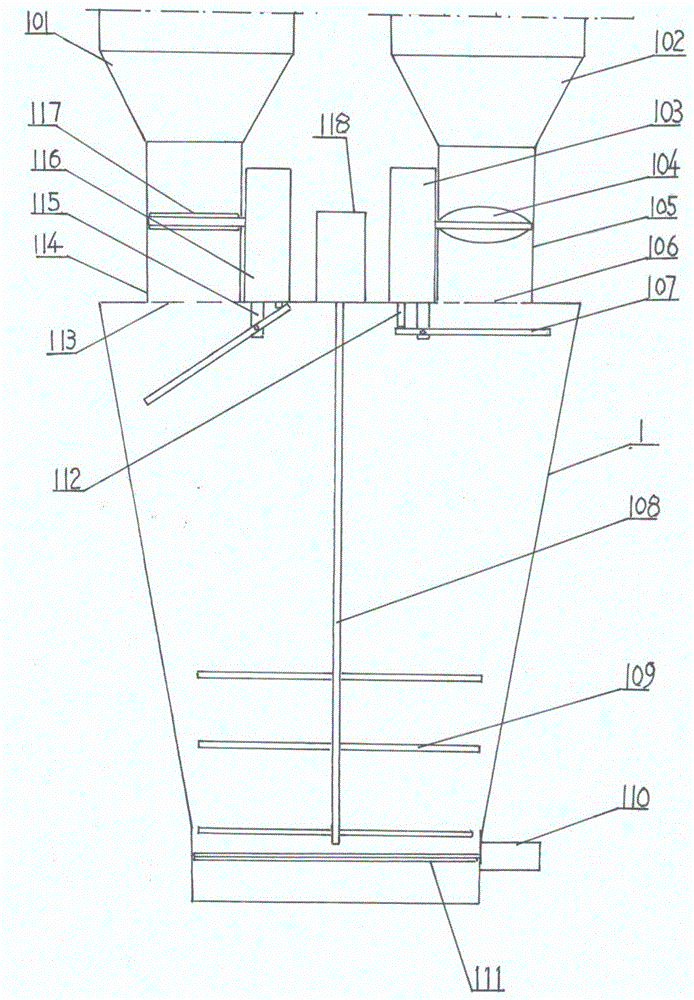

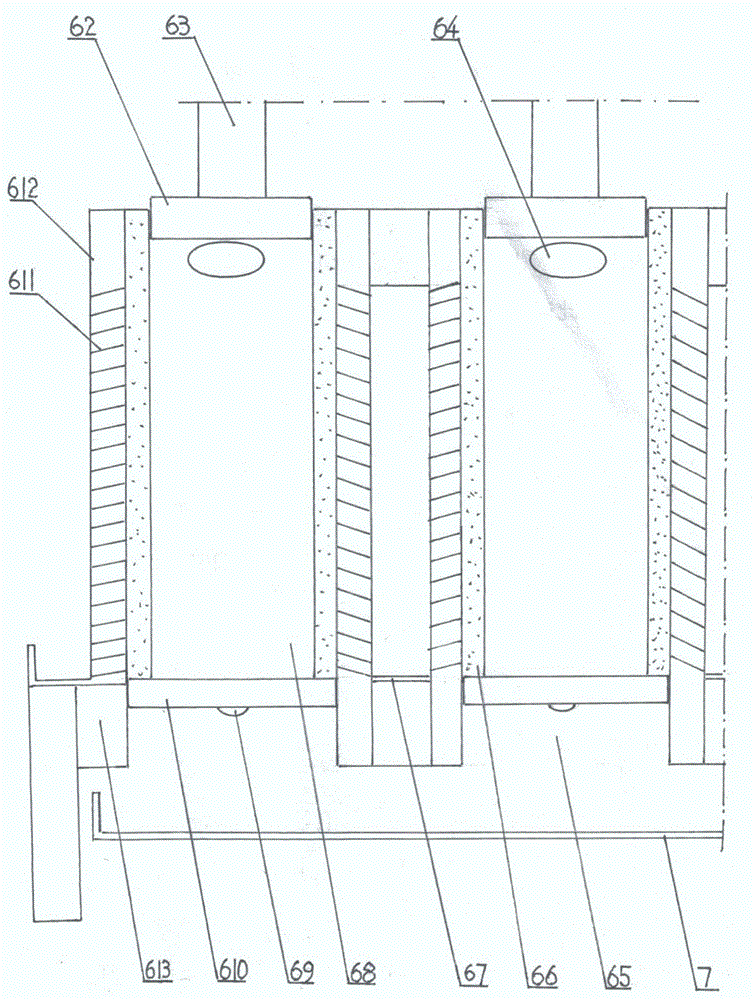

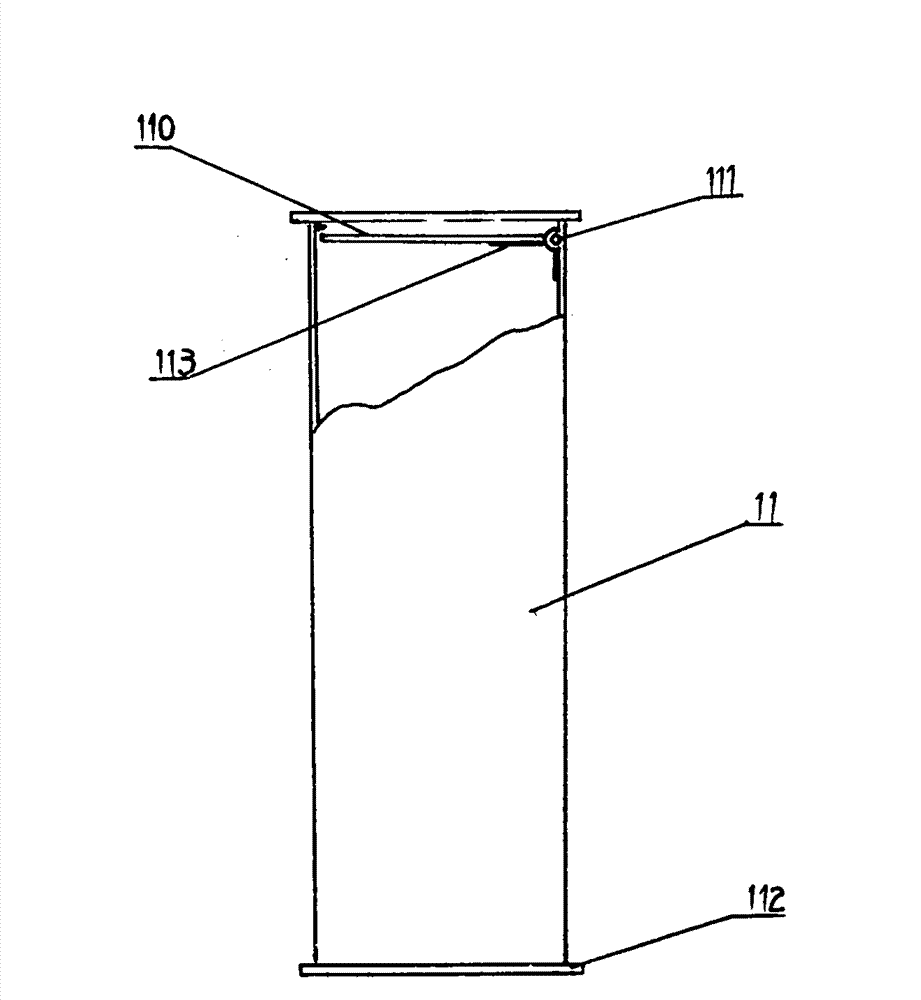

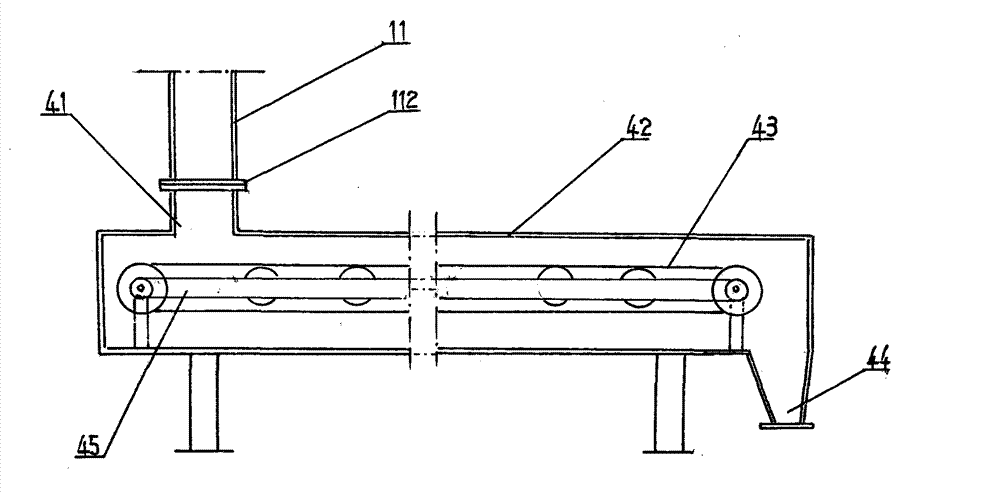

Device for producing crude antimonous oxide through oxygen-enriched side-blown volatilization melting bath in smelting mode

A device for producing crude antimonous oxide through an oxygen-enriched side-blown volatilization melting bath in a smelting mode comprises stock bins, measurement belts, a transfer belt, an electronic belt scale, an oxygen-enriched side-blown volatilization melting bath smelting furnace, a vertical uptake flue, an electric dust collector and a bag dust collector. The oxygen-enriched side-blown volatilization melting bath smelting furnace comprises a furnace body which is defined by a copper water jacket and a molten steel jacket. Oxygen-enriched air spray guns are horizontally arranged on the two sides of the copper water jacket on the lower portion of the furnace body, and the muzzles of the spray guns are flush with the inner wall of the water jacket. Secondary air nozzles are arranged on the molten steel jacket on the upper portion of the furnace body. A hearth constructed with refractory bricks is arranged under the furnace body. An antimony matte siphon chamber is arranged on the front portion of the hearth. A slag siphon chamber is arranged on the back of the hearth. A feeding inlet is formed in the top end of the furnace body. The top end of the furnace body is connected with the vertical uptake flue. A waste heat boiler is arranged in the vertical uptake flue connected with the electric dust collector. The electric dust collector is connected with the bag dust collector. The device is low in energy consumption for operation, and is clean, friendly to the environment and low in production cost when being used for producing the crude antimonous oxide.

Owner:锡矿山闪星锑业有限责任公司 +3

Process for leaching and separating metal components in heavy metal sludge by ultrasonic activation

InactiveCN100412212CNo secondary pollutionReduce processing costsProcess efficiency improvementUltrasound - actionSludge

The invention discloses an immersing and separating method of each metal component in the heavy metal sludge activated by ultrasound in the environmental protective technical domain, which comprises the following steps: adding water in the sludge to make water content at 90%; stirring 0.5-1h; pulping pumped by dense-slurry pump; stirring completely under ultrasound; adding 20-40% diluted acid; controlling different terminating point pH values to immerse acid step by step; making different metal component in the sludge into immersing liquid with different pH values; realizing separation and initial separation; purifying through normal standard method; condensing to obtain different metal salt productions.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com