Three-dimensional glazed tile made of scraping waste and manufacturing method thereof

A manufacturing method and technology of glazed tiles, applied in the field of ceramic tiles, can solve the problems of lower production efficiency, low utilization rate of waste materials, unstable brick shape, etc., achieve good leveling and ductility, and improve recycling rate , Improve the effect of spreading ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

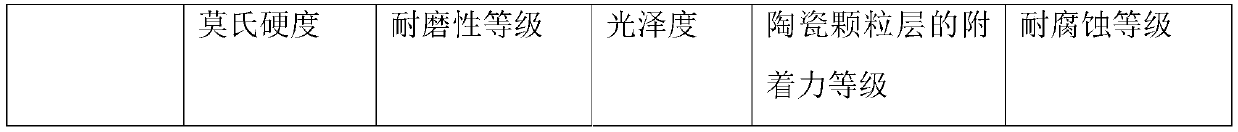

Embodiment 1

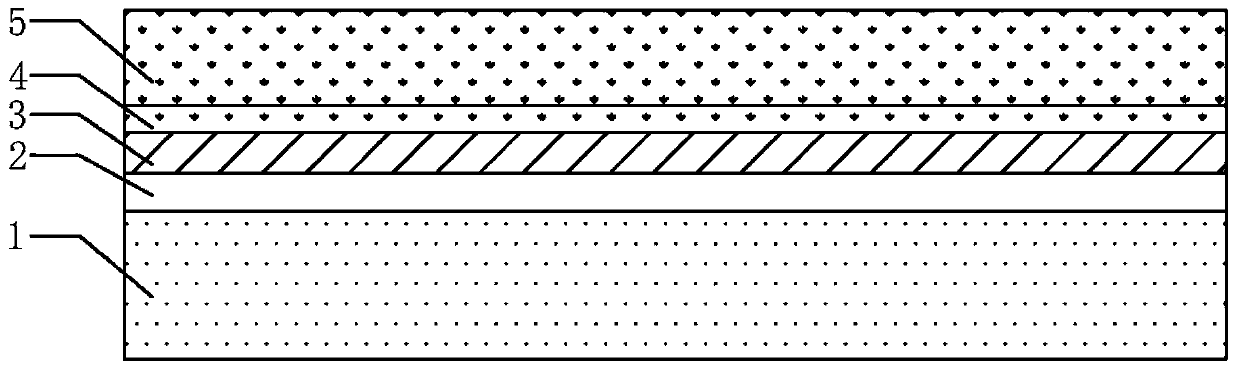

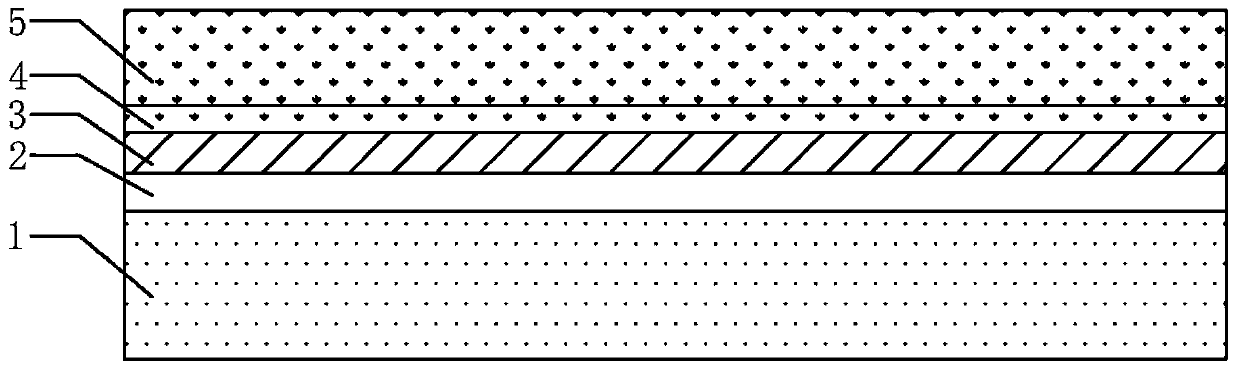

[0092] A method for manufacturing a three-dimensional glazed tile made from edge scraping waste, comprising the steps of:

[0093] A, drying the green body: the temperature of the green body is raised to 130°C for drying;

[0094] B, applying make-up soil: apply make-up soil on the body surface after step A is dried;

[0095] C, pattern decoration: carry out pattern decoration on the body surface after step B is coated with make-up soil, and then dry;

[0096] D, spraying transparent glaze slurry: spraying transparent glaze slurry on the body surface after step C drying;

[0097] E, spreading ceramic particles: spreading ceramic particles on the body surface after spraying the transparent glaze slurry in step D, and then firing to obtain a three-dimensional glazed tile;

[0098] Wherein, the raw materials for making the ceramic particles include edge scraping recycled materials.

[0099] In said step A, the drying time of green body is 30min;

[0100] In the step B, the wh...

Embodiment 2

[0126] A method for manufacturing a three-dimensional glazed tile made from edge scraping waste, comprising the steps of:

[0127] A, drying the green body: the temperature of the green body is raised to 140°C for drying;

[0128] B, applying make-up soil: apply make-up soil on the body surface after step A is dried;

[0129] C, pattern decoration: carry out pattern decoration on the body surface after step B is coated with make-up soil, and then dry;

[0130] D, spraying transparent glaze slurry: spraying transparent glaze slurry on the body surface after step C drying;

[0131] E, spreading ceramic particles: spreading ceramic particles on the body surface after spraying the transparent glaze slurry in step D, and then firing to obtain a three-dimensional glazed tile;

[0132] Wherein, the raw materials for making the ceramic particles include edge scraping recycled materials.

[0133] In said step A, the drying time of green body is 40min;

[0134] In the step B, the wh...

Embodiment 3

[0160] A method for manufacturing a three-dimensional glazed tile made from edge scraping waste, comprising the steps of:

[0161] A, drying the green body: the temperature of the green body is raised to 145°C for drying;

[0162] B, applying make-up soil: apply make-up soil on the body surface after step A is dried;

[0163] C, pattern decoration: carry out pattern decoration on the body surface after step B is coated with make-up soil, and then dry;

[0164] D, spraying transparent glaze slurry: spraying transparent glaze slurry on the body surface after step C drying;

[0165] E, spreading ceramic particles: spreading ceramic particles on the body surface after spraying the transparent glaze slurry in step D, and then firing to obtain a three-dimensional glazed tile;

[0166] Wherein, the raw materials for making the ceramic particles include edge scraping recycled materials.

[0167] In said step A, the drying time of green body is 45min;

[0168] In the step B, the wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com