Device for producing crude antimonous oxide through oxygen-enriched side-blown volatilization melting bath in smelting mode

The technology of molten pool smelting and molten pool smelting furnace is applied in the field of devices for producing crude antimony trioxide, which can solve the problems of difficult recovery and utilization of sulfur resources, low metal recovery rate and high energy consumption, so as to reduce the amount of air entering the furnace, The effect of high resource recycling rate and simple material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

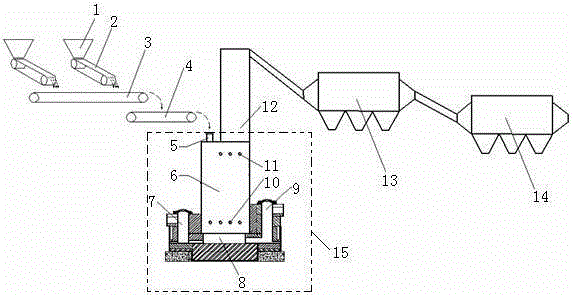

[0050] The method for using the oxygen-enriched side-blown volatilization pool smelting to produce crude antimony trioxide device in this embodiment includes the following steps:

[0051] (1) The antimony-containing materials, anthracite, iron ore, and lime are measured according to the mass ratio of 100:17:22:10 from each silo 1 through the corresponding metering belt 2, and then transported to the furnace by the transfer belt 3 The electronic belt scale 4 on the top and the electronic belt scale 4 measure the total weight of the furnace materials, and then put them into the oxygen-enriched side-blown volatilization melting pool melting furnace through the feeding port 5. The area of the oxygen-enriching side-blowing volatilization melting pool melting furnace is 2.16m 2 (1.2×1.8m), the materials entering the furnace undergo melting, dissociation, desulfurization, oxidation, volatilization and slagging reactions in the furnace. During the melting and reaction process, 75% (...

Embodiment 2

[0054] The method for using the oxygen-enriched side-blown volatilization pool smelting to produce crude antimony trioxide device in this embodiment includes the following steps:

[0055] (1) The antimony-containing materials, anthracite, iron ore, and lime are measured according to the mass ratio of 100:9:24:10 from each silo 1 through the corresponding metering belt 2, and then transported to the furnace by the transfer belt 3 The electronic belt scale 4 on the top and the electronic belt scale 4 measure the total weight of the furnace materials, and then put them into the oxygen-enriched side-blown volatilization melting pool melting furnace through the feeding port 5. The area of the oxygen-enriching side-blowing volatilization melting pool melting furnace is 2.16m 2 (1.2×1.8m), the materials entering the furnace undergo melting, dissociation, desulfurization, oxidation, volatilization and slagging reactions in the furnace. During the melting and reaction process, 65% (V...

Embodiment 3

[0058] The method for using the oxygen-enriched side-blown volatilization pool smelting to produce crude antimony trioxide device in this embodiment includes the following steps:

[0059] (1) The antimony-containing materials, anthracite, iron ore, and lime are measured according to the mass ratio of 100:11:26:10 from each silo 1 through the corresponding metering belt 2, and then transported to the furnace by the transfer belt 3 The electronic belt scale 4 on the top and the electronic belt scale 4 measure the total weight of the furnace materials, and then put them into the oxygen-enriched side-blown volatilization melting pool melting furnace through the feeding port 5. The area of the oxygen-enriching side-blowing volatilization melting pool melting furnace is 2.16m 2 (1.2×1.8m), the materials entering the furnace undergo melting, dissociation, desulfurization, oxidation, volatilization and slagging reactions in the furnace. During the melting and reaction process, 80% (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com