Preparation method of high purity n-hexane

A kind of n-hexane and pure technology, applied in the field of preparation of high-purity n-hexane, can solve the problem of low n-hexane purity, and achieve the effects of high resource recovery and utilization rate, stable product quality and low investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a kind of preparation method of high-purity normal hexane, comprises the following steps:

[0037] a) carrying out a hydrogenation reaction of the reformed C5 oil and hydrogen under the action of a hydrogenation catalyst, and separating the C5 light component of the liquid phase product after the reaction to obtain the remaining heavy component;

[0038] b) separating the remaining heavy components obtained in step a) with isohexane to obtain heavy components after de-isohexane;

[0039] c) separating the heavy component obtained in step b) after deisohexanization with n-hexane to obtain high-purity n-hexane.

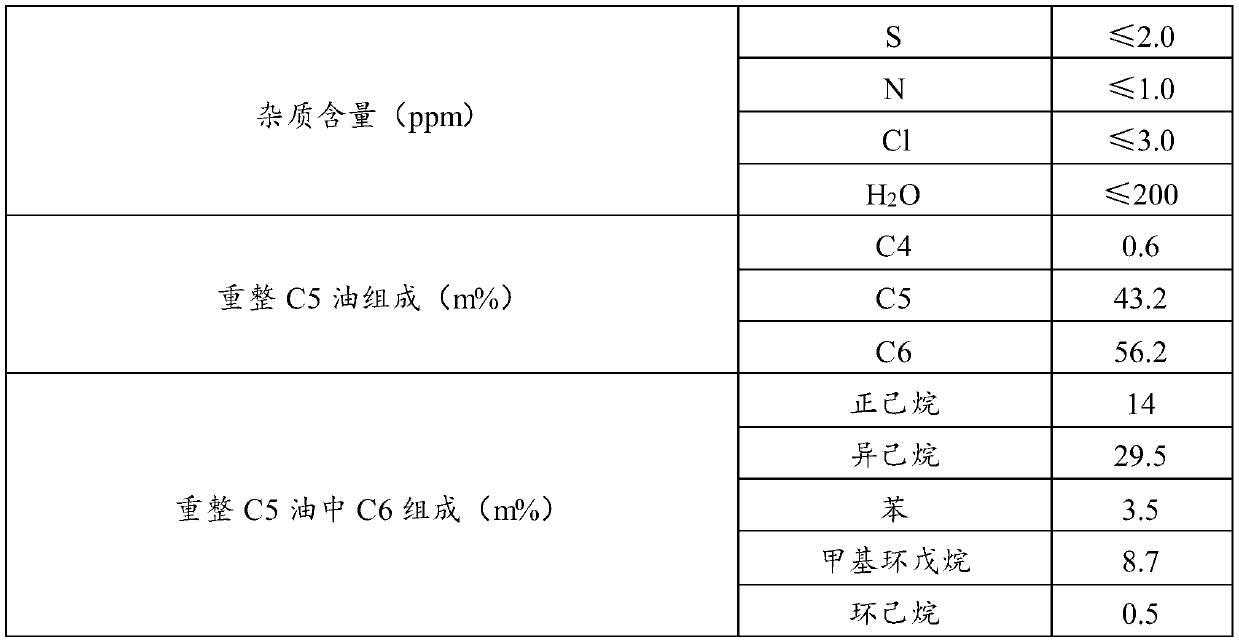

[0040] In the invention, the reformed C5 oil and hydrogen are subjected to a hydrogenation reaction under the action of a hydrogenation catalyst, and the liquid phase product after the reaction is subjected to separation of C5 light components to obtain the remaining heavy components. In the present invention, the reformed C5 oil preferabl...

Embodiment 1

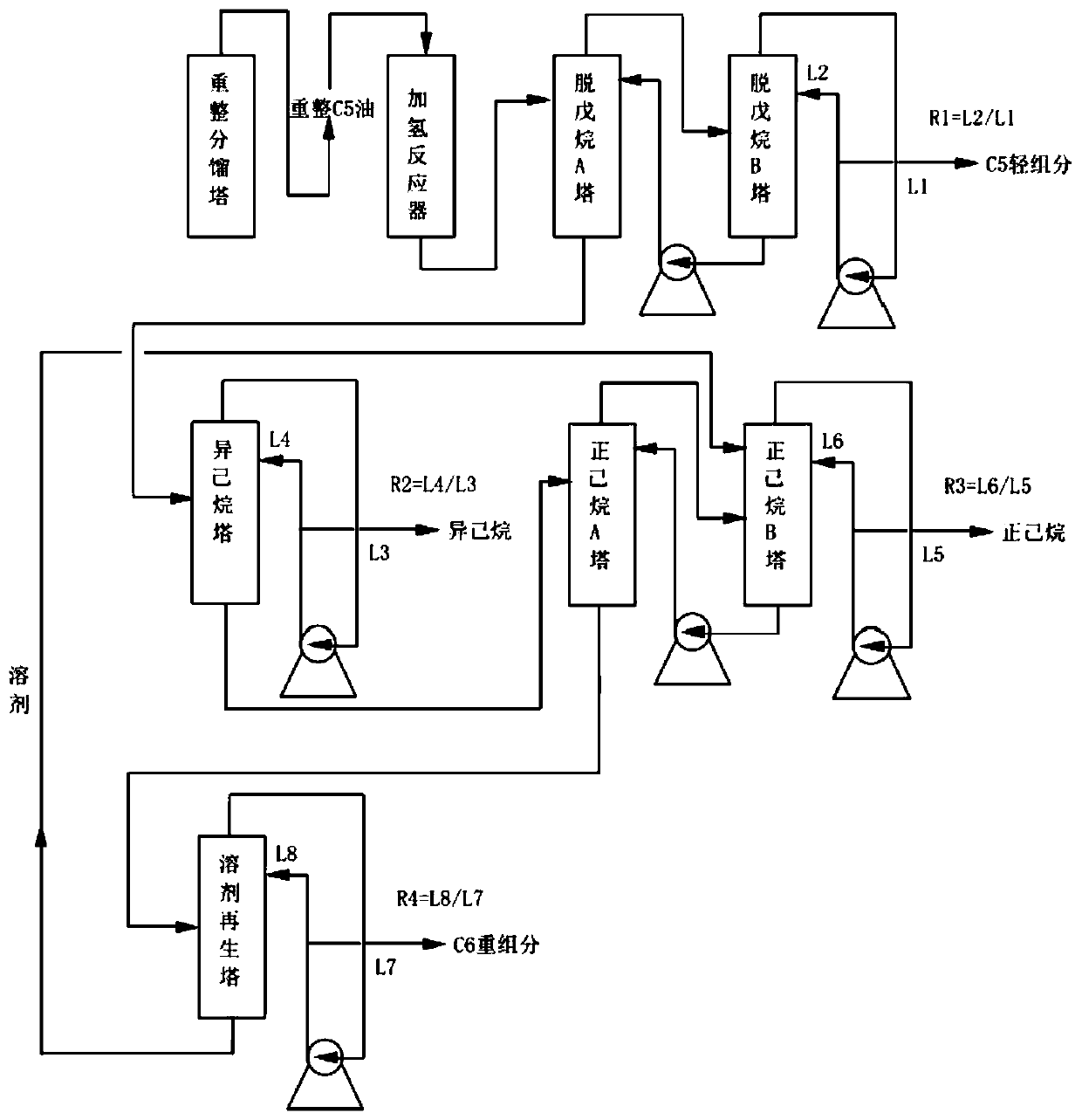

[0070] The process flow chart of the preparation method of the high-purity n-hexane provided by the embodiment of the present invention 1 can be found in figure 1 As shown, the specific steps are as follows:

[0071] (1) Pass the reformed C5 oil and hydrogen into the hydrogenation reactor according to the hydrogen-to-oil ratio of 300:1, and carry out hydrogenation under the reaction pressure of 1.8MPa, reaction temperature of 138°C and JHO-1 raffinate hydrogenation catalyst Hydrogen reaction; the liquid phase product after the reaction enters the depentanizer (due to the large number of tray layers, it is composed of the depentanizer A tower and the depentanizer B tower in series, wherein the depentanizer A tower is a stripping tower, and the depentanizer A tower is a stripping tower. The pentane B tower is a rectification tower) to separate the C5 light components:

[0072] Control the temperature at the bottom of the depentanizer A tower to be 100°C to 120°C, the pressure a...

Embodiment 2

[0081] Adopt the preparation method that embodiment 1 provides, prepare high-purity normal hexane; Difference is:

[0082] In step (3), the temperature at the bottom of the n-hexane tower A is controlled to be 160°C to 170°C, the pressure at the bottom of the tower is 110KPa to 120KPa, the temperature at the top of the n-hexane tower B is 70°C to 78°C, and the pressure at the top of the tower is 30KPa to 50KPa , reflux ratio R3=4~6;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com